Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Electrical properties are not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hole sealing moisture-proof anticorrosive composite coating material and its prepn process

The pore sealing moisture-proof anticorrosive composite coating material includes pore sealing material and moisture-proof anticorrosive material. The pore sealing material includes gel with high solid phase content as the basic phase and filler(s) in the amount of 10-100 % of the solid phase component. The moisture-proof anticorrosive material is sol, hydrophobic organic matter or their mixture. The pore sealing moisture-proof anticorrosive composite coating material is prepared through the four steps of preparing pore sealing material, preparing moisture-proof anticorrosive material, preparing pore sealing coating and preparing moisture-proof anticorrosive coating. The pore sealing moisture-proof anticorrosive composite coating material has excellent water permeation arresting performance, high hydrophobicity and high corrosion resistance.

Owner:WUHAN UNIV OF TECH

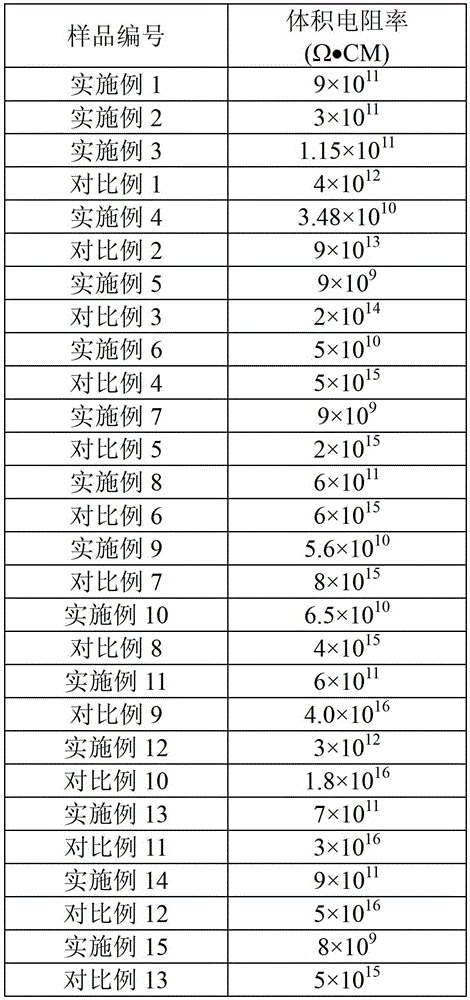

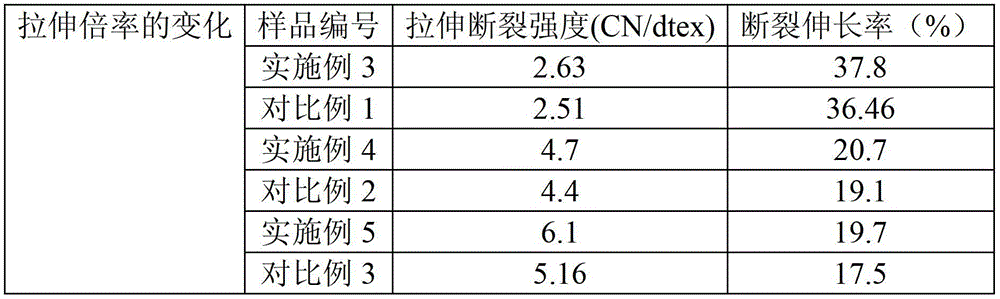

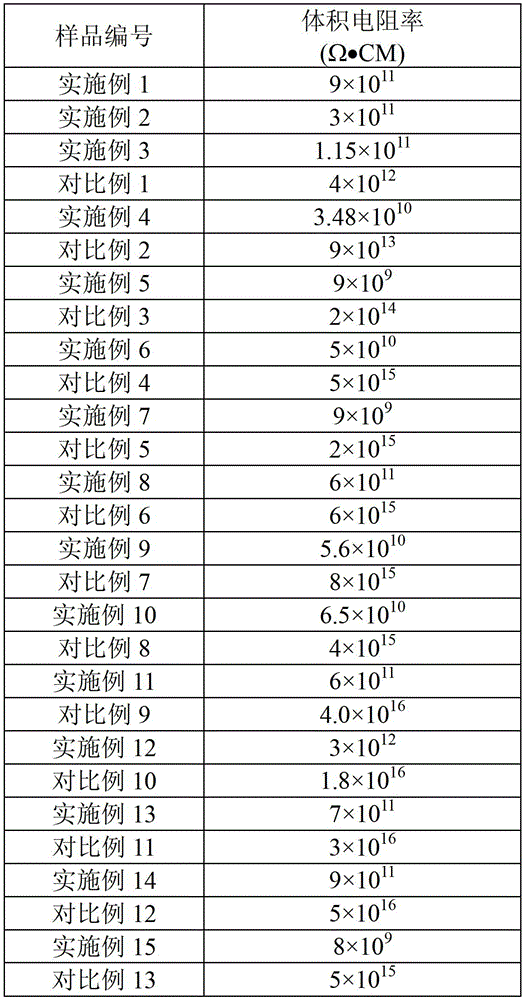

Polymer/filler/metal composite fiber and preparation method thereof

ActiveCN104099684AImprove breaking strengthElectrical properties are not affectedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

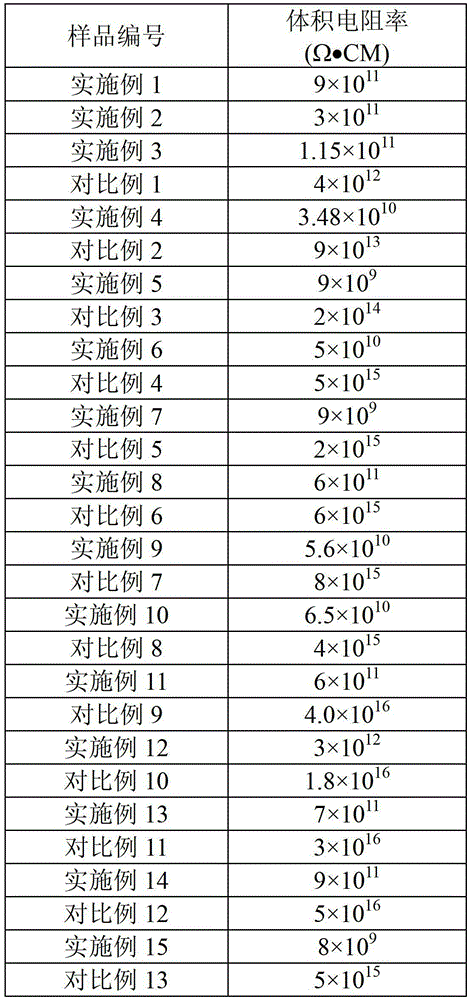

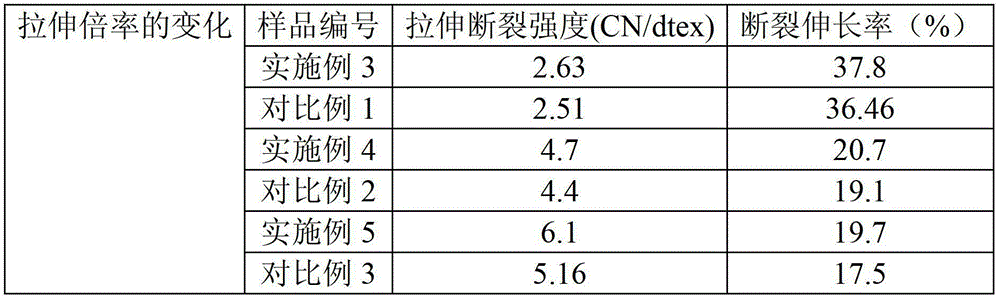

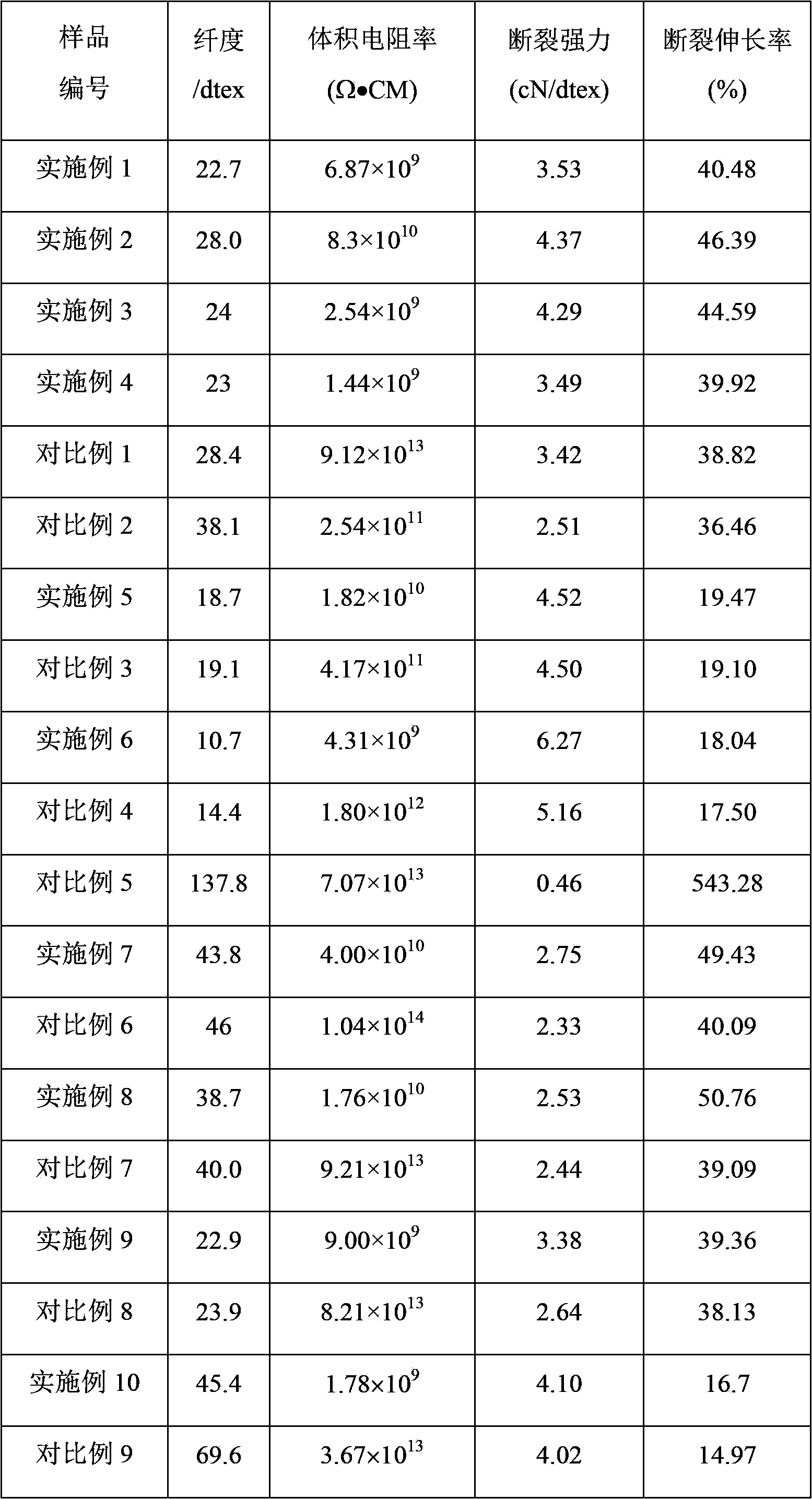

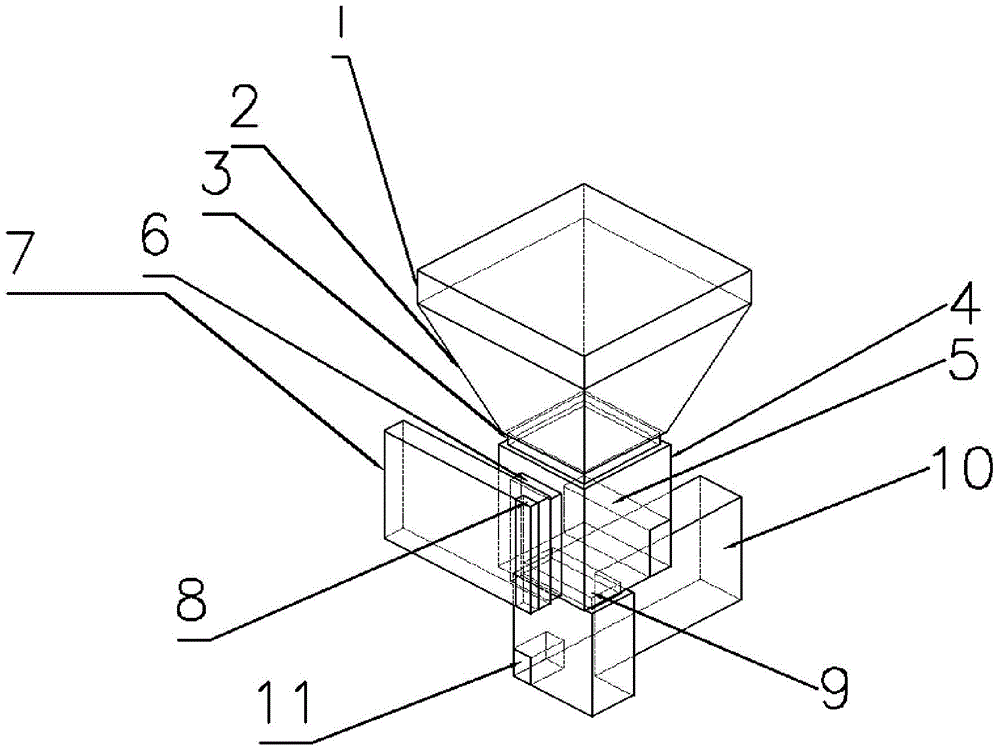

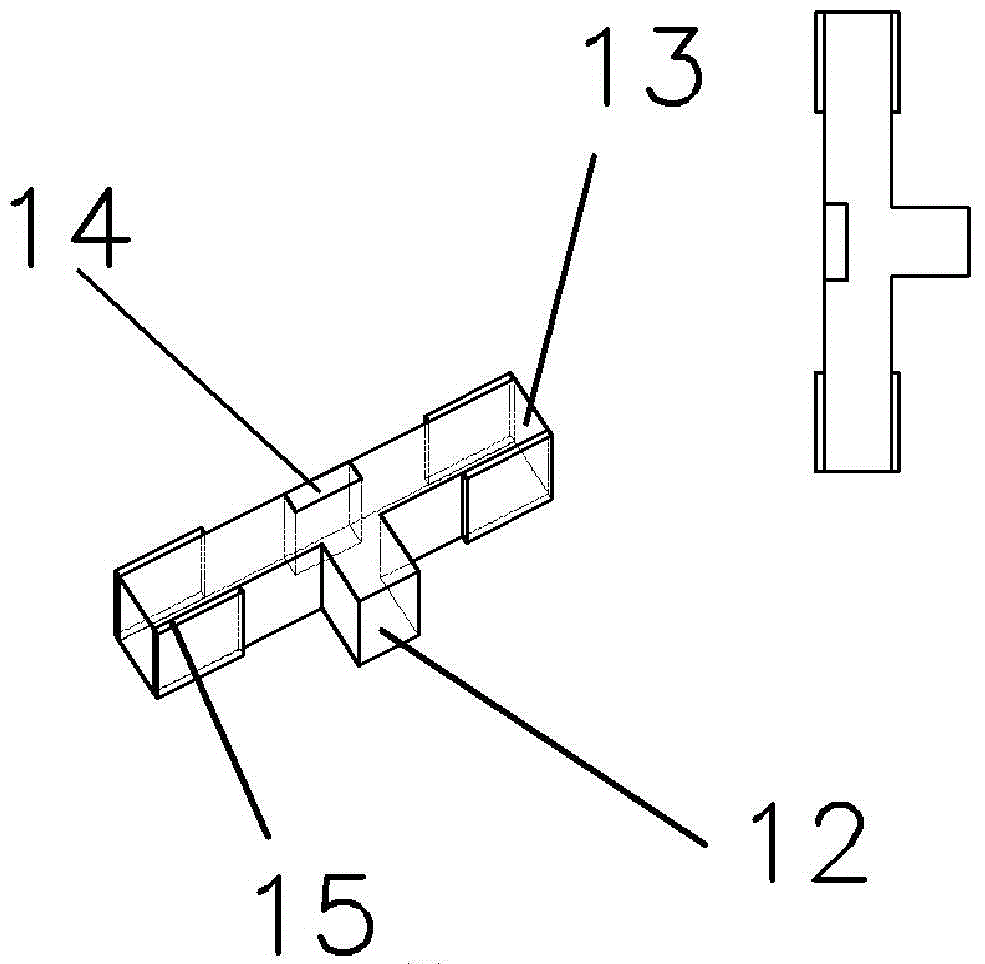

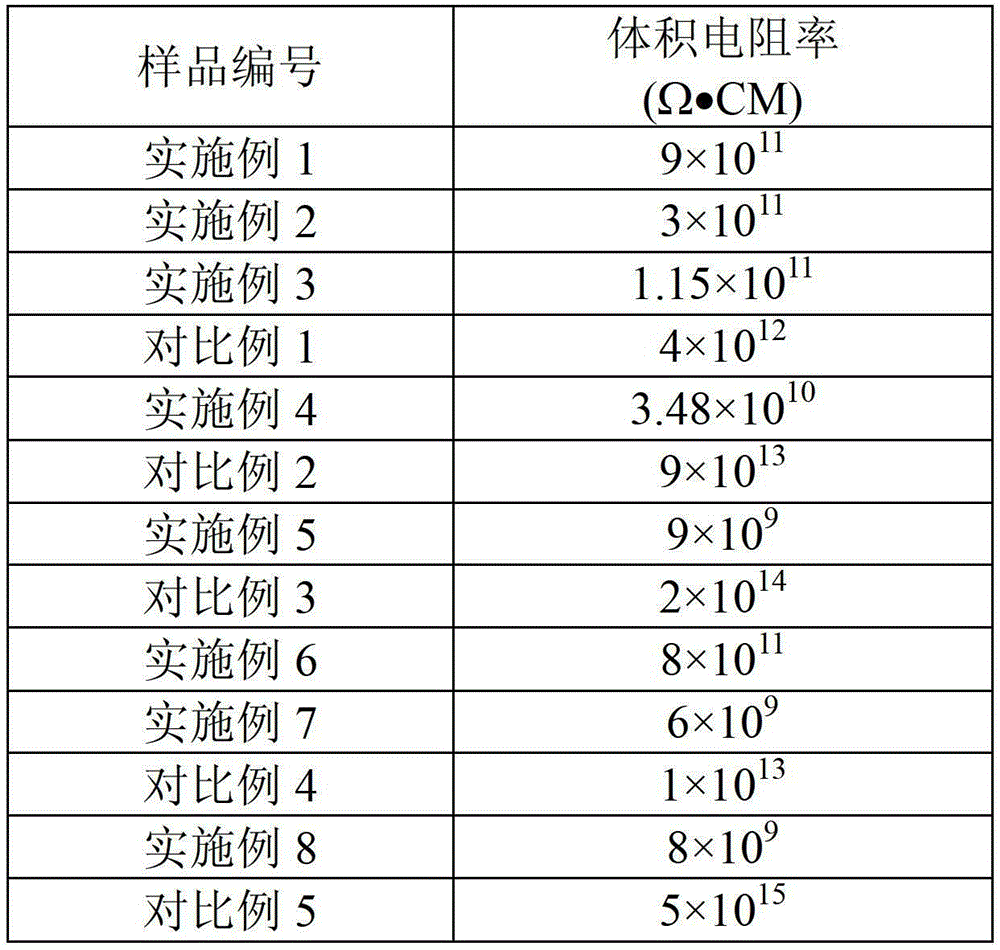

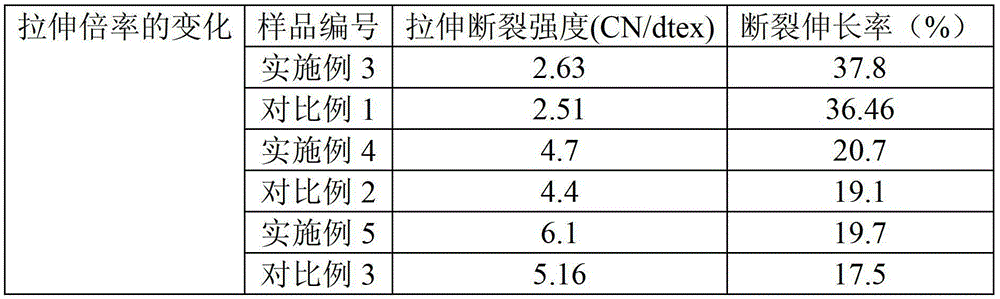

The invention relates to polymer / filler / metal composite fiber. The polymer / filler / metal composite fiber comprises polymer fiber containing metal short fiber and a filler, the metal short fiber is distributed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber, and the filler is dispersed in the polymer fiber and is distributed among the metal short fiber; the filler is not fused at a polymer processing temperature; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C and 480 DEG C and lower than the polymer processing temperature; the volume ratio of metal short fiber to polymer fiber is 0.01:100-20:100; and the weight ratio of the filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Growing method for inhibiting defect of carbon inclusion in silicon carbide single crystal

ActiveCN107385512APrevent volatilizationSuppress escapePolycrystalline material growthFrom condensed vaporsForeign matterSingle crystal

The invention belongs to the technical field of crystal growth, and particularly relates to a growing method for inhibiting a defect of a carbon inclusion in a silicon carbide single crystal. The method provided by the invention comprises growth at two stages; different pressures are controlled to inhibit volatilization and dissipation of a silicon component, so that the formation of the inclusion is reduced or even eliminated. According to the growing method provided by the invention, the inhibition of the formation of the carbon inclusion can be realized through adjusting a simple growing process without the need for adding foreign matters in a growing raw material, and the growing method is easy to implement and lower in cost.

Owner:SICC CO LTD

Photosensitive conductive silver electrode slurry and preparation method thereof

InactiveCN102969039AElectrical properties are not affectedHigh electrode precisionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodeOptoelectronics

The invention relates to photosensitive conductive silver electrode slurry and a preparation method thereof. The photosensitive conductive silver electrode slurry is characterized by being composed of the following components by mass: 5-25% of functional metal powder, 10-15% of adhesion promoter, 2-20% of photosensitive resin, 10-30% of solvent, 1-10% of curing agent, 1-5% of curing catalyst and the balance, conductive silver powder. The photosensitive conductive silver electrode slurry aims at resolving the problems in the using process of the silver electrode slurry in the background technology, is capable of conducting photocuring according to experiments, does not require sintering, enables electric performance of electronic components not to be affected, and is high in electrode accuracy and firm in connection. The preparation method of the photosensitive conductive silver electrode slurry is provided.

Owner:IRICO

Preparation method of lithium iron phosphate with high compaction density and high capacity

ActiveCN110098406AElectrical properties are not affectedImprove battery energy densityCell electrodesLithium iron phosphatePhosphoric acid

The invention provides a preparation method of lithium iron phosphate. Large single-crystal iron phosphate is prepared by the method and by using a fluxing agent, thereby being increased in compactiondensity. By doping the iron phosphate in an iron phosphate stage, a lithium iron phosphate capacity is increased. The method solves the drawbacks in a conventional method, and increases the dischargecapacity of the lithium iron phosphate while increasing its compaction density.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Polymer/conductive filler/metal composite fiber and preparation method thereof

ActiveCN104099683AImprove breaking strengthImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / conductive filler / metal composite fiber. The composite fiber comprises polymer fiber containing metal short fiber and a conductive filler, the metal short fiber is dispersed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber; the conductive filler is dispersed in the polymer fiber and distributed among the metal short fiber; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C to 480 DEG C and lower than a polymer processing temperature; the volume ratio of the metal short fiber to the polymer fiber is 0.01:100-20:100; and the weight ratio of the conductive filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

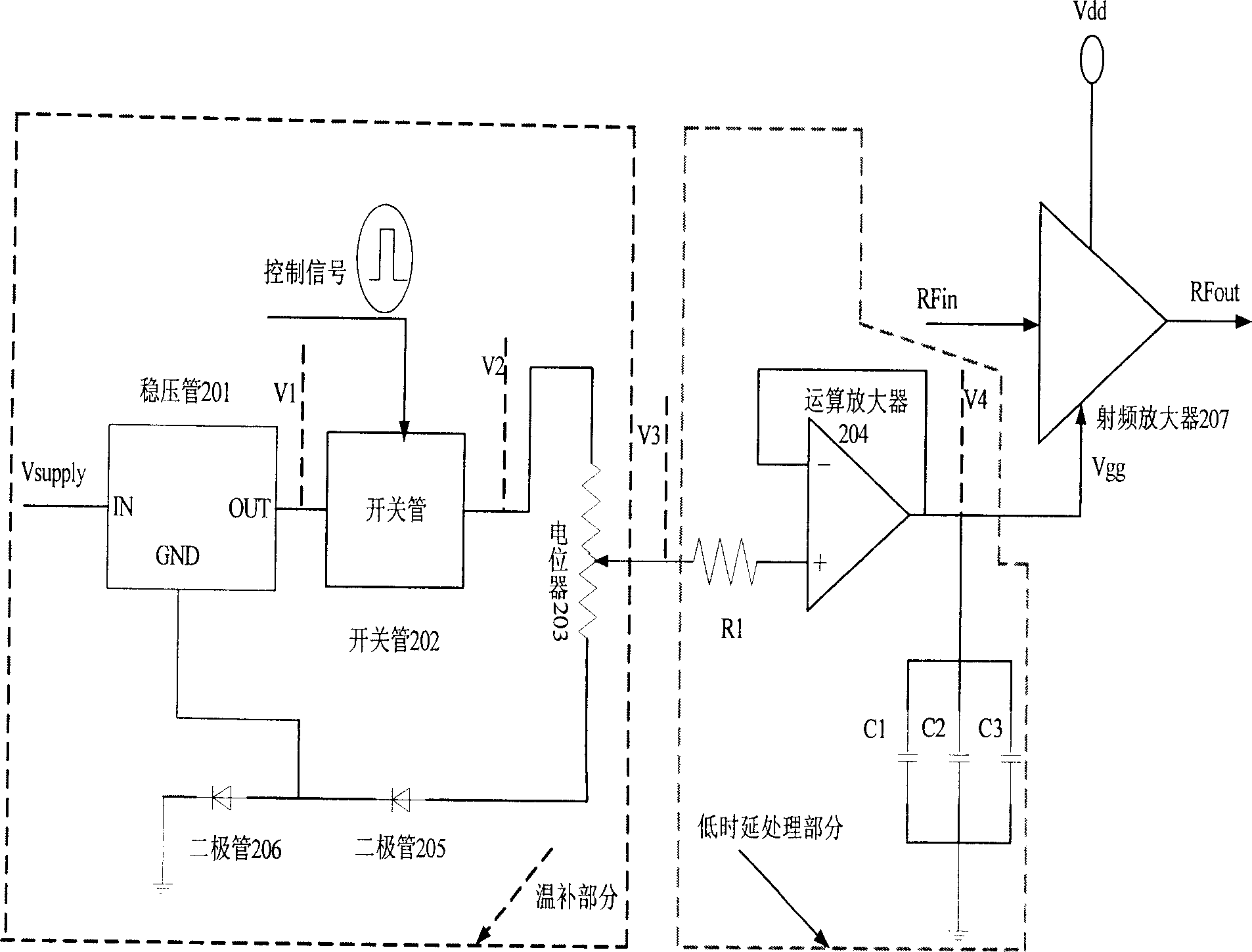

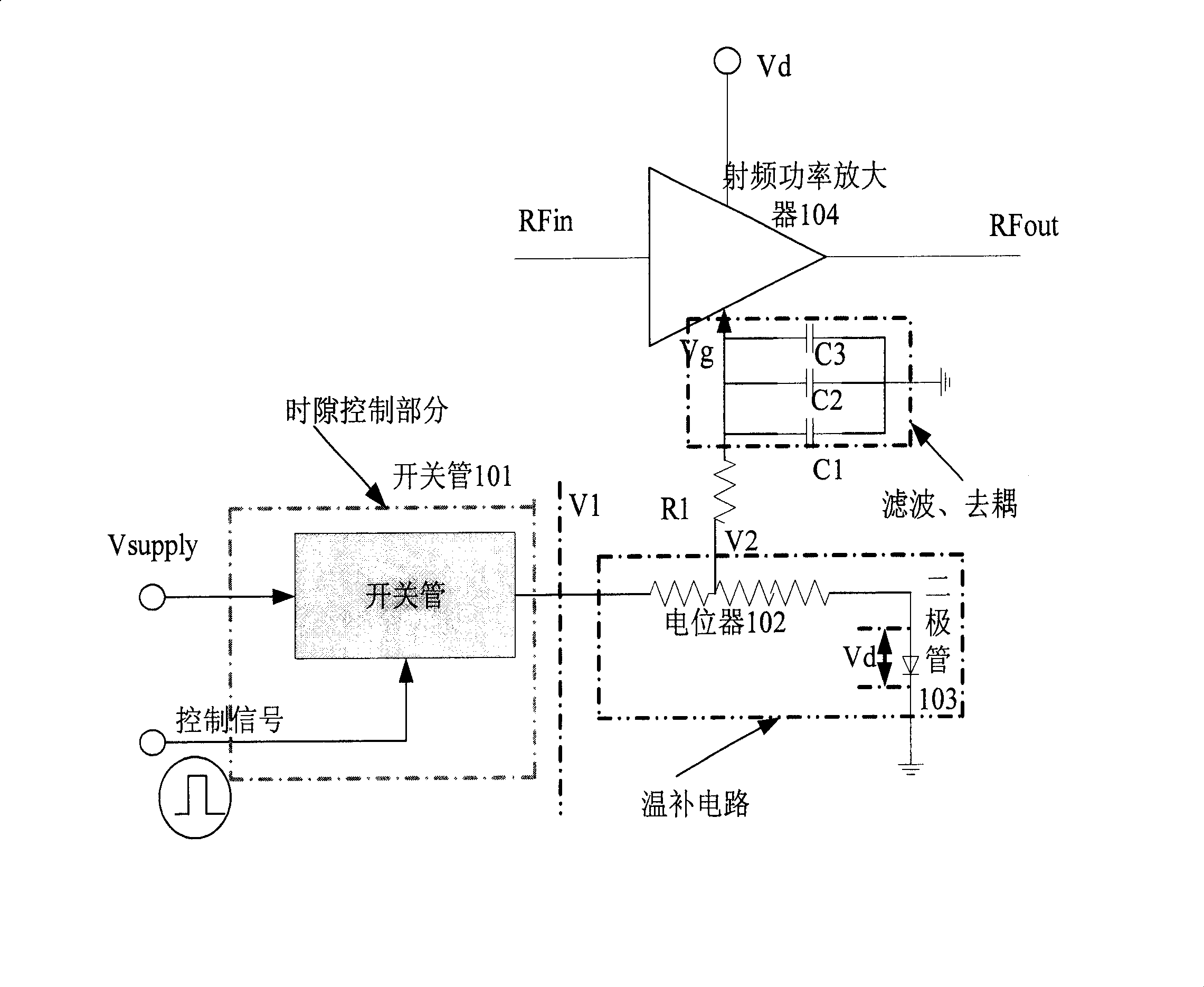

Low delay temp compensation bias circuit for TDD mode

ActiveCN1905356ASolve unsolvable problemsConstant quiescent currentAmplifier modifications to reduce temperature/voltage variationTransmissionAudio power amplifierEngineering

The invention provides a low-delay temperature compensation biasing circuit for time division duplexing mode, comprising: switch tube; potentiometer, one end connected with output end of the switch tube, voltage dividing output end passing through series-connected resistor and filter decoupling circuit and acting as output bias voltage, and another end earthed through temperature compensation diodes; the temperature compensation diodes comprise series-connected first and second diodes; the input voltage is inputted into a voltage stabilizing tube and then outputted to the switch tube, the earth end of the voltage stabilizing tube is connected in between the first and second diodes; a negative feedback amplifier is connected in series between the series-connected resistor and filter decoupling circuit. And it compensates bias voltage of the amplifier, makes the static current of the amplifier keep constant and electric performance not influenced.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

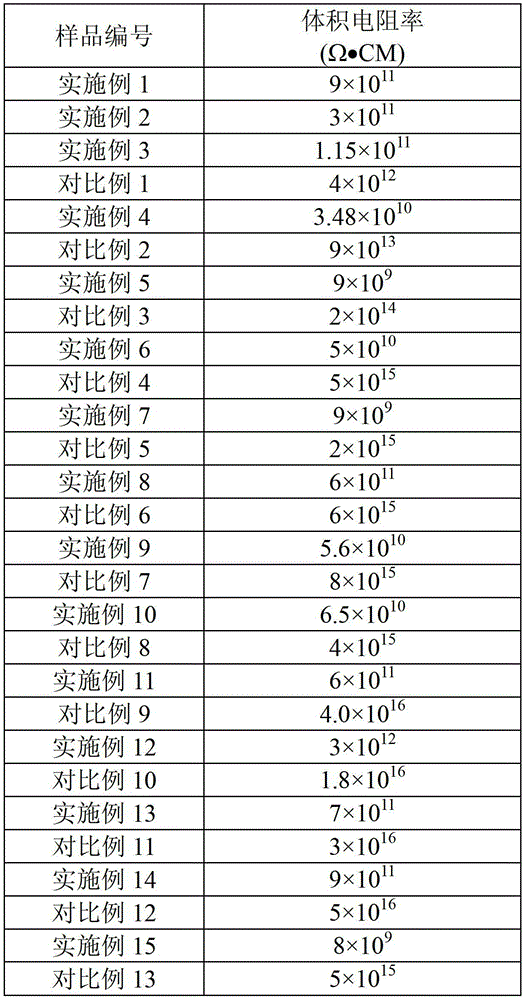

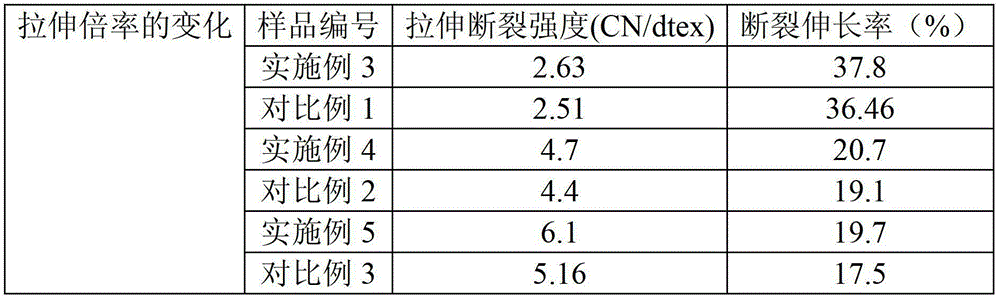

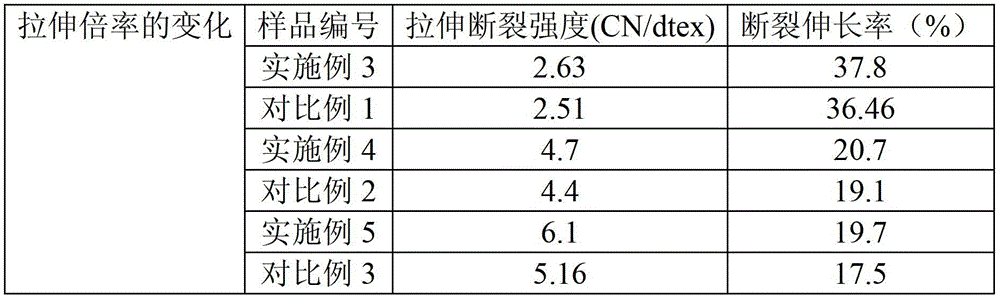

Polymer/metal composite fibers and preparation method thereof

ActiveCN103789859AImprove spin performanceLow costElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberBreaking strength

The present invention provides polymer / metal composite fibers and a preparation method thereof. The composite fibers comprise polymer fibers containing metal staple fibers, wherein the metal staple fibers are adopted as the dispersed phase and are distributed in the polymer fibers in a parallel manner along the polymer fiber axis, the polymer is a thermoplastic resin, the metal is at least one selected from a single-component metal and a metal alloy, the melting point of the metal is 20-480 DEG C and is lower than the melting point of the polymer, a volume ratio of the metal staple fibers to the polymer fibers is 0.01:100-20:100, and the volume resistivity of the composite fibers is less than or equal to 1*10<11>[omega].CM. According to the present invention, the fibers are obtained by carrying out melt blending, spinning and heating stretching on the metal and the polymer; the antistatic property, the breaking strength, and the elongation at break of the composite fibers are concurrently increased, the size is reduced, the dyeability is good, and the antistatic property is lasting; and the preparation method is simple and is easily subjected to industrialized mass production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparing method of solar cell slice with pattern

ActiveCN102255000AElectrical properties are not affectedEasy to drawFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The invention discloses a preparing method of a solar cell slice with a pattern. The reparation technique disclosed by the invention can make a random pattern locally on the surface of the solar cell slice; and the preparation technique is simple and capable of realizing industrialization rapidly if the same is combined with the current production technique tightly. A solar cell prepared by using the method is free from electrical property loss. The method can be used to draw a pattern in need randomly on the solar cell, so as to meet different demands and to enlarge the application field of the solar cells. The solar cell with the pattern prepared by using the method is simple in structure, distinctive, and suitable for being used as building materials so as to meet different building demands, and has excellent energy saving and environmental protection benefits.

Owner:山东力诺太阳能电力股份有限公司

A flat-panel antenna array in the ka frequency band

ActiveCN104201477BReduce section heightLow efficiencyWaveguide hornsAntenna arraysBroadbandWaveguide

Owner:BEIJING RES INST OF TELEMETRY +1

Polymer/carbon nanotube/metal composite fiber and preparation method thereof

ActiveCN104099682AImprove spin performanceLow costMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to polymer / carbon nanotube / metal composite fiber. The composite fiber comprises polymer fiber containing metal short fiber and carbon nanotube, the metal short fiber is dispersed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber; the carbon nanotube is dispersed in the polymer fiber and distributed among the metal short fiber; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C to 480 DEG C and lower than a polymer processing temperature; the volume ratio of the metal short fiber to the polymer fiber is 0.01:100-20:100; and the weight ratio of the carbon nanotube to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

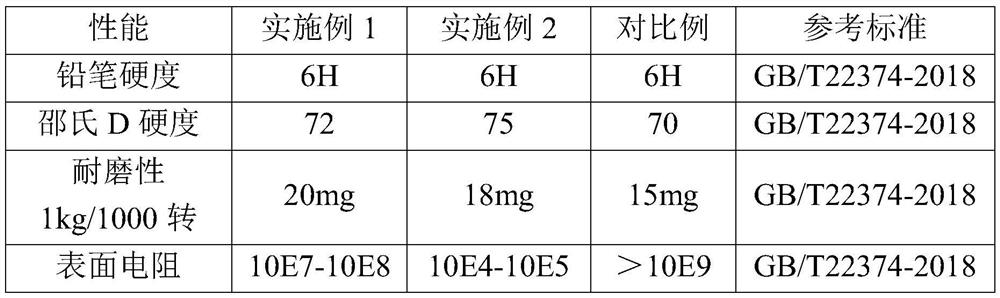

Antistatic wear-resistant floor coating and preparation method thereof

InactiveCN111808464AEasy to operateReduce dosagePolyurea/polyurethane coatingsElectrically-conductive paintsWaxPolyol

The invention discloses an antistatic wear-resistant floor coating and a preparation method thereof. The coating comprises a component A, a component B and a component C, wherein the component A comprises 30-40 parts by weight of grease polyol; 15 to 20 parts by weight of a conductive material, 20 to 25 parts by weight of a filler, 0.1 to 2 parts by weight of a dispersant, 0.1 to 1 part by weightof an antifoaming agent, 0.1 to 1 part by weight of a wetting agent, 0.1 to 1 part by weight of a leveling agent, 3 to 8 parts by weight of zeolite powder, 10 to 15 parts by weight of a pigment and 2to 5 parts by weight of polytetrafluoroethylene wax powder; the component B comprises the following components in parts by weight: 5-20 parts of grease polyol and 70-95 parts of polyisocyanate; and the component C is 100 parts by weight of quartz sand or corundum powder. The floor coating is convenient to operate and low in consumption, and can meet the requirements of production plants, assemblyworkshops and the like on anti-static performance.

Owner:MIANYANG HUILI EPOXY ENG

A kind of polymer/filler/metal composite fiber and its preparation method

ActiveCN104099684BImprove breaking strengthElectrical properties are not affectedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / filler / metal composite fiber. The polymer / filler / metal composite fiber comprises polymer fiber containing metal short fiber and a filler, the metal short fiber is distributed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber, and the filler is dispersed in the polymer fiber and is distributed among the metal short fiber; the filler is not fused at a polymer processing temperature; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C and 480 DEG C and lower than the polymer processing temperature; the volume ratio of metal short fiber to polymer fiber is 0.01:100-20:100; and the weight ratio of the filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

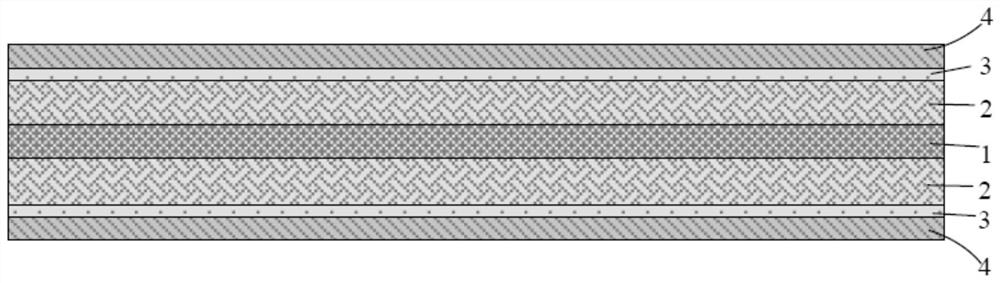

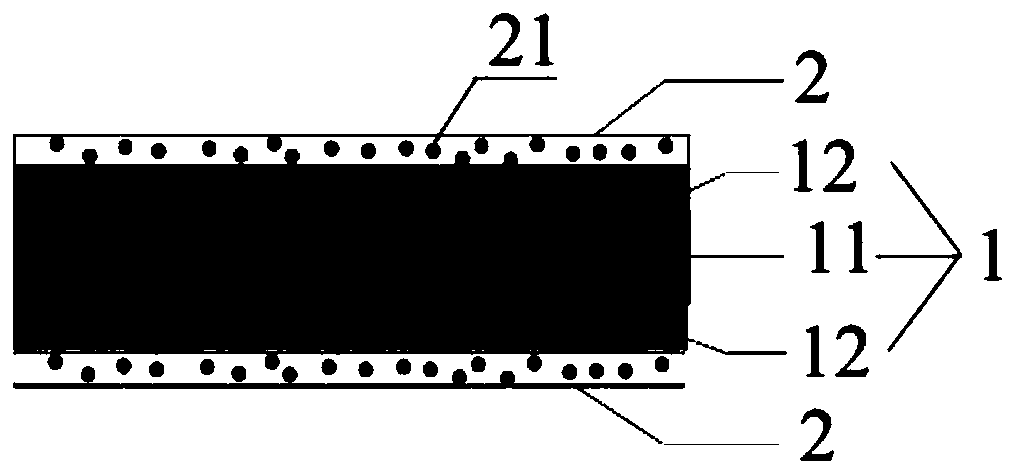

Electrode plate and lithium ion battery comprising same

ActiveCN114039027AImprove needlestick safetyPlay a role in wrappingNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceElectrical performanceLithium-ion battery

The invention provides an electrode plate and a lithium ion battery comprising the same. The electrode plate of the present invention comprises: a current collector having two opposite surfaces; an active material layer coated on at least one surface of the current collector; a first coating layer coated on the active material layer; and a second coating layer coated on the first coating layer; wherein the first coating at least comprises a first polymer and a first conductive agent; and the second coating includes at least a second polymer. According to the invention, by constructing the double-layer coating, not only can the needling safety of the battery be improved, but also the electrical performance of the battery can be ensured not to be influenced to the greatest extent.

Owner:ZHUHAI COSMX BATTERY CO LTD

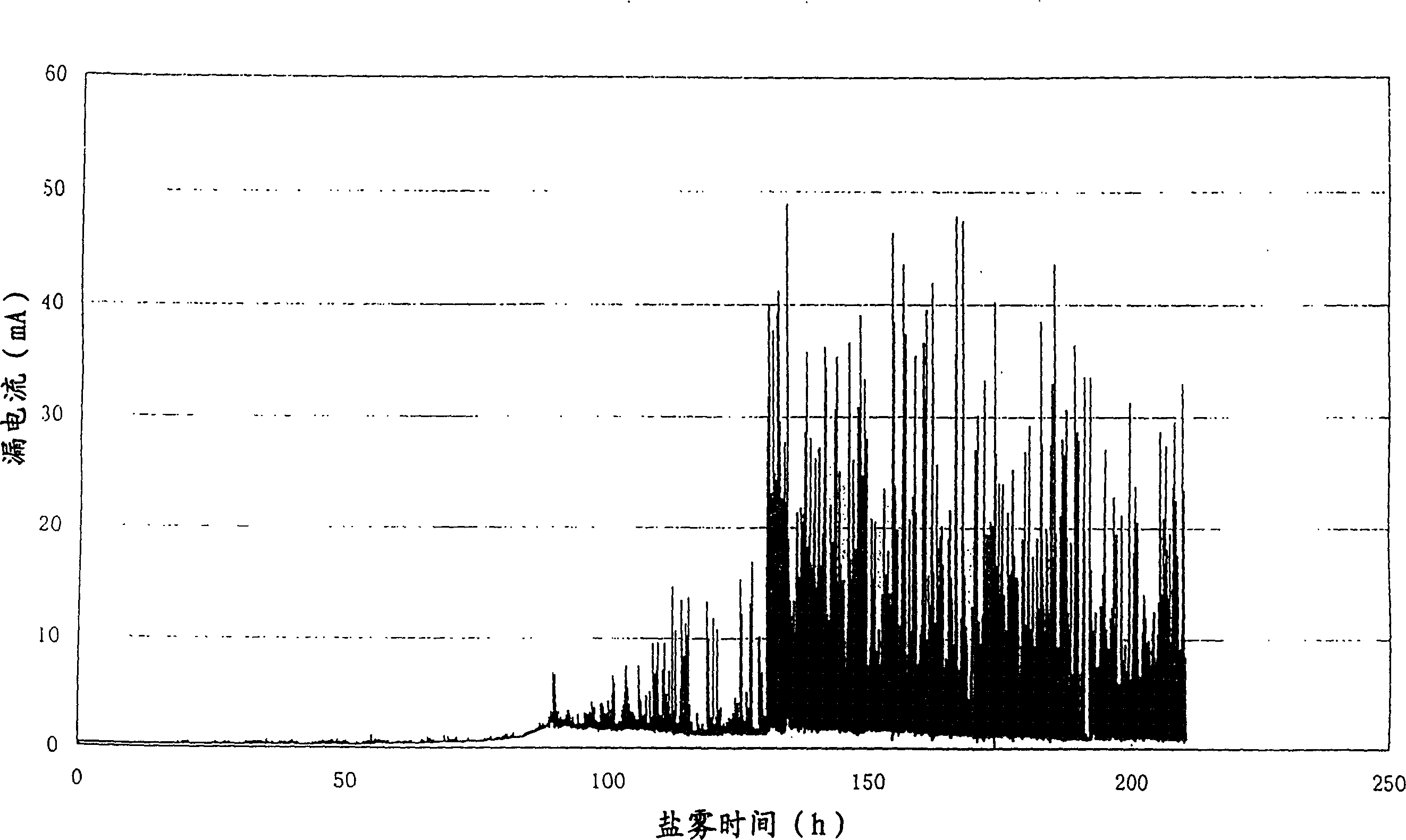

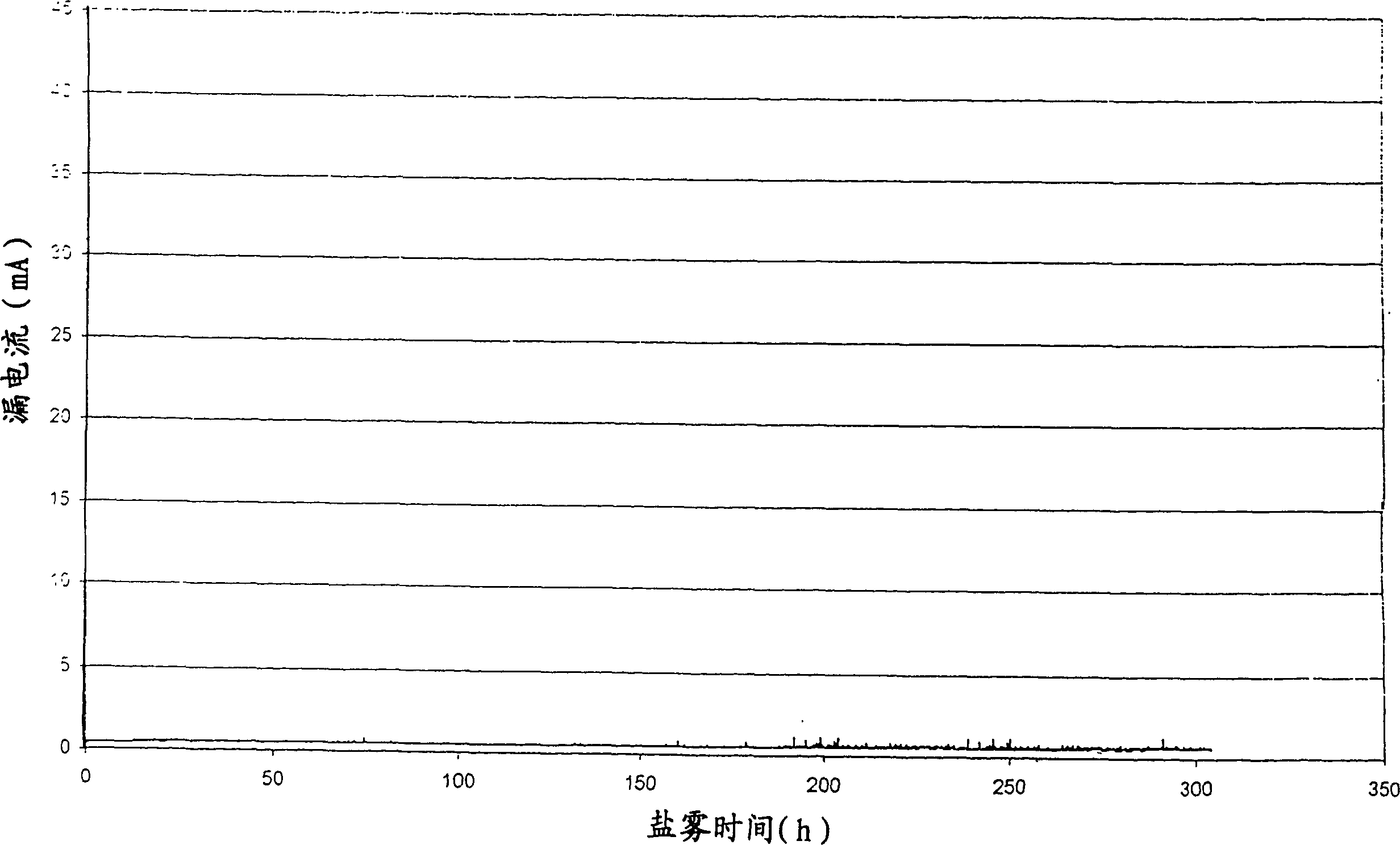

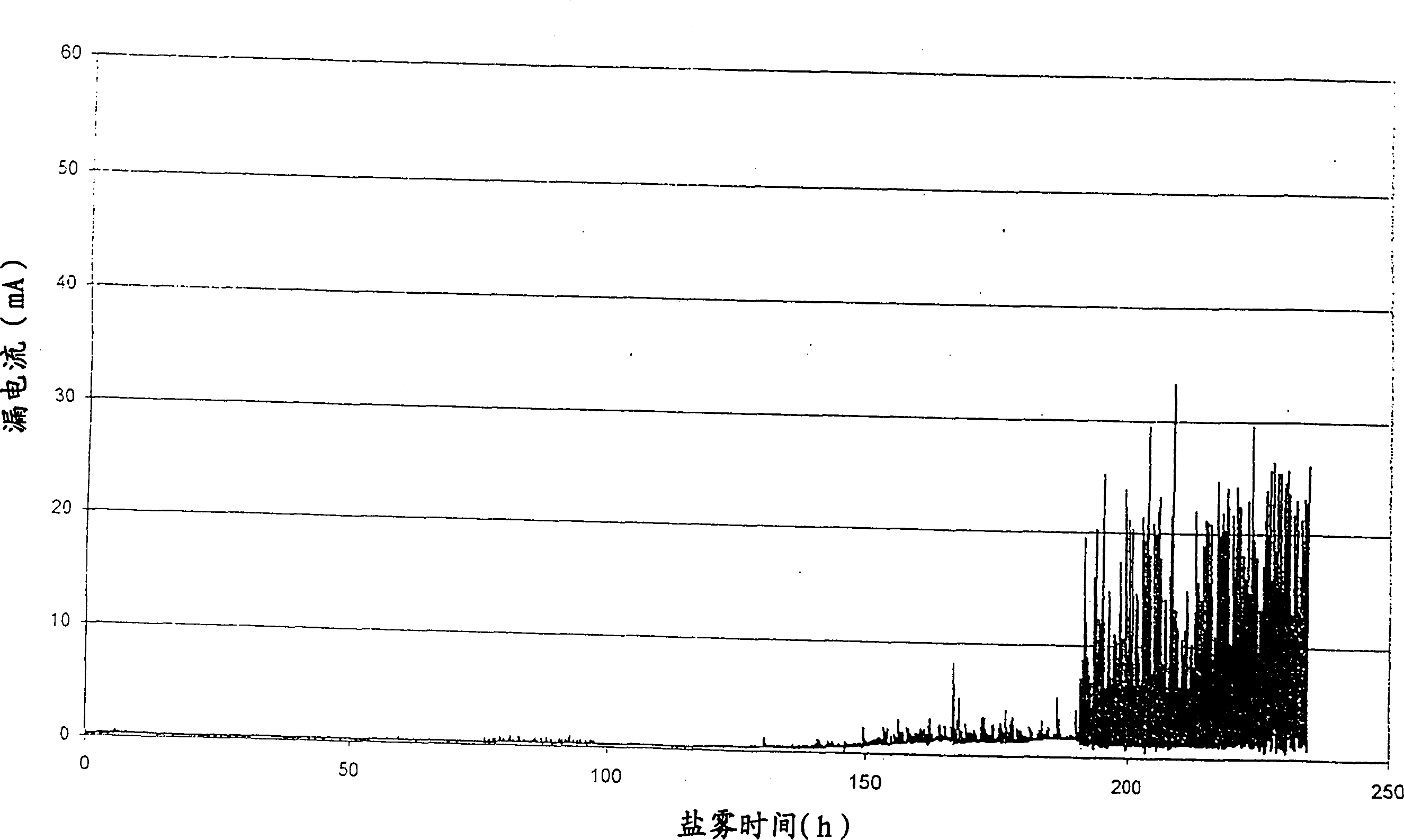

High voltage insulator coating composition and preparation and application thereof

InactiveCN1264938CLarge resistance to leakage current characteristicsElectrical properties are not affectedCoatingsHydrocarbon solventsPolydimethylsiloxane

A high-voltage insulating composite paint for the high-voltage (69 KV or more) insulator is prepared from polydimethyl siloxane, dried trihydrated alumina, dye cream, filler, organosilicon cross-linking agent, adhesion promoter, condensating catalyst and dried hydrocarbon solvent. It can suppress electric leakage and spark.

Owner:FORMOSAN RUBBER GRP

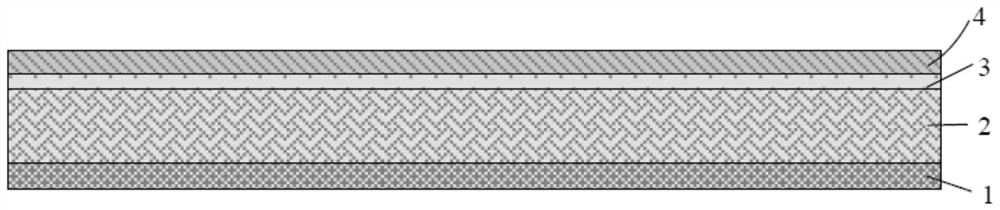

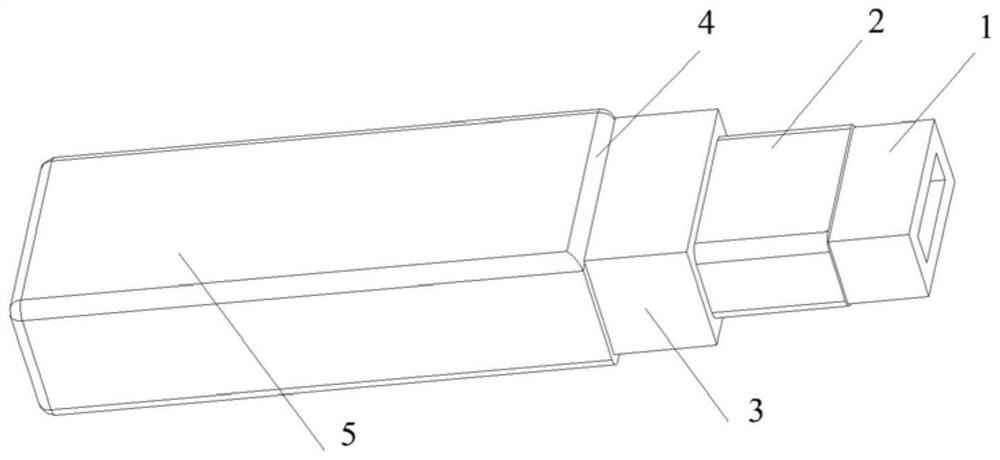

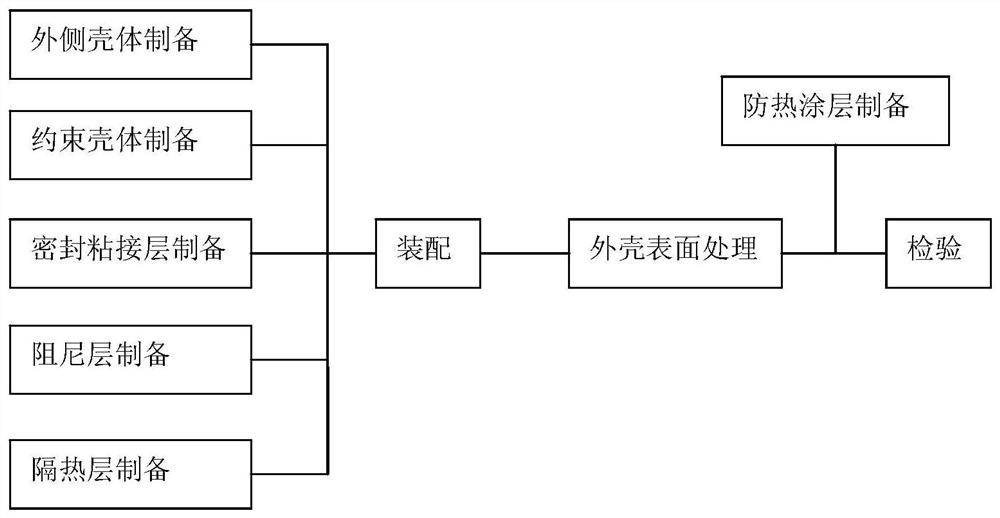

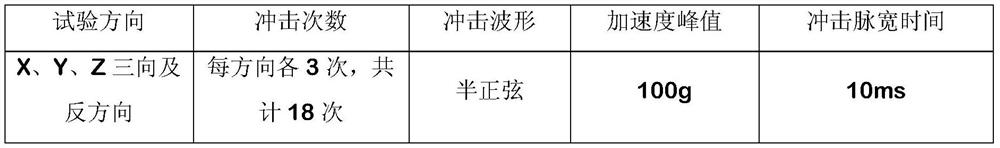

A damping heat insulation structure and its preparation method and application

ActiveCN110809378BImprove insulation performanceGood oil resistanceProtective equipmentLayered productsThermal breakHeat control

The invention relates to a damping / heat insulation structure and its preparation method and application, belonging to the technical field of protection of electronic components, in particular to a preparation method of a damping / heat insulation composite functional structure for protecting core components. The damping / insulation structure is used to protect the core components, and the structure includes a polyurethane damping layer, a restraint shell, a heat insulation layer, an outer shell and a heat shield from the inside to the outside. The preparation method includes the synthesis and potting molding of the damping layer material, the processing and molding of the heat insulation tile structure, the preparation of the constrained shell and the shell, the assembly, connection and sealing of the multilayer structure, and the preparation of the heat-resistant coating. The present invention realizes the normal operation of the core components in the environment of short-term high temperature or instantaneous severe shock and vibration through the superposition of multi-layer structures and the sealed connection between the layers. Strong vibration and shock capability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

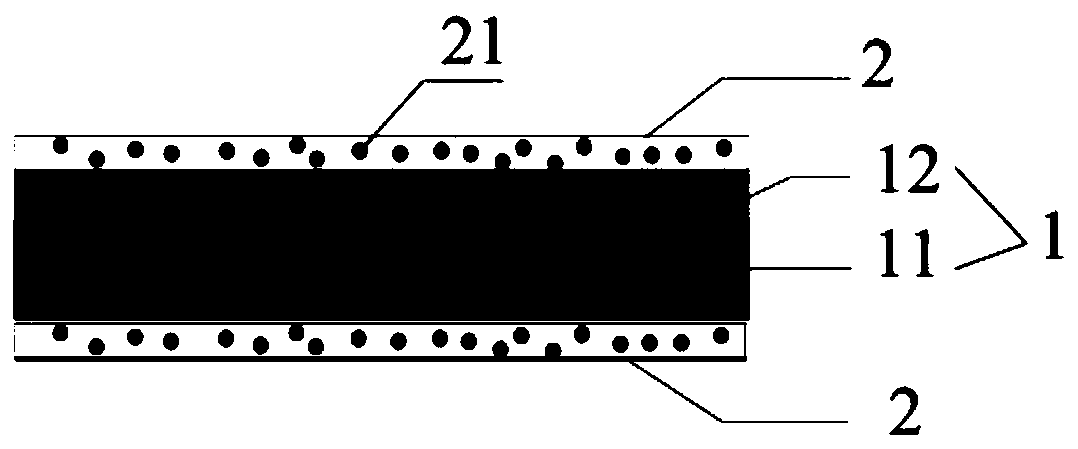

Pole piece and lithium ion battery

PendingCN114156487AImprove securityImprove the pass rate of nail penetration testElectrode carriers/collectorsSecondary cellsCarbon layerInorganic particle

The invention provides a pole piece and a lithium ion battery. The pole piece comprises a substrate, the substrate comprises a current collector and a protective layer arranged on the surface of the current collector, and an active material layer is further arranged on the protective layer; the protective layer comprises, by mass, 62%-96% of an inactive material, 0.1%-8% of a conductive agent and 3%-30% of a binder, the inactive material comprises inorganic particles and a carbon layer coating the surfaces of the inorganic particles, and the mass of the carbon layer is smaller than 10% of the mass of the inorganic particles. The pole piece provided by the invention can solve the problem that the safety and the electrical property of the lithium ion battery cannot be considered at the same time.

Owner:ZHUHAI COSMX BATTERY CO LTD

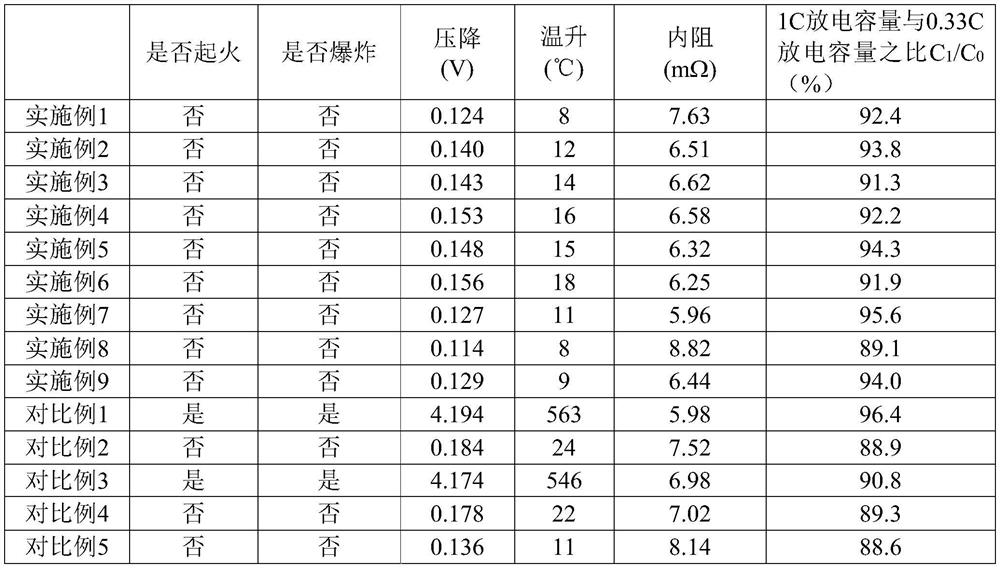

Pole piece and lithium ion battery

PendingCN114156429AImprove securityImprove the pass rate of nail penetration testSecondary cellsNon-aqueous electrolyte accumulator electrodesEngineeringPole piece

The invention provides a pole piece and a lithium ion battery. The pole piece comprises a substrate, the substrate comprises a current collector and a protective layer arranged on the surface of the current collector, and an active material layer is further arranged on the protective layer; the protective layer comprises the following components in percentage by mass: 62%-97% of a non-active material, 0.1%-8% of a conductive agent and 3%-30% of a binder, and the resistivity of the protective layer is 500-5000 omega.cm. The pole piece provided by the invention comprises the protective layer, and the mass fraction of each component in the protective layer and the resistivity of the protective layer are controlled, so that the problems of fire outbreak, aging and the like of the lithium ion battery under the conditions of mechanical abuse and the like are effectively solved, and meanwhile, the electrical property of the battery is basically not influenced; the problem that safety and electrical performance of the lithium ion battery cannot be considered at the same time is solved.

Owner:ZHUHAI COSMX BATTERY CO LTD

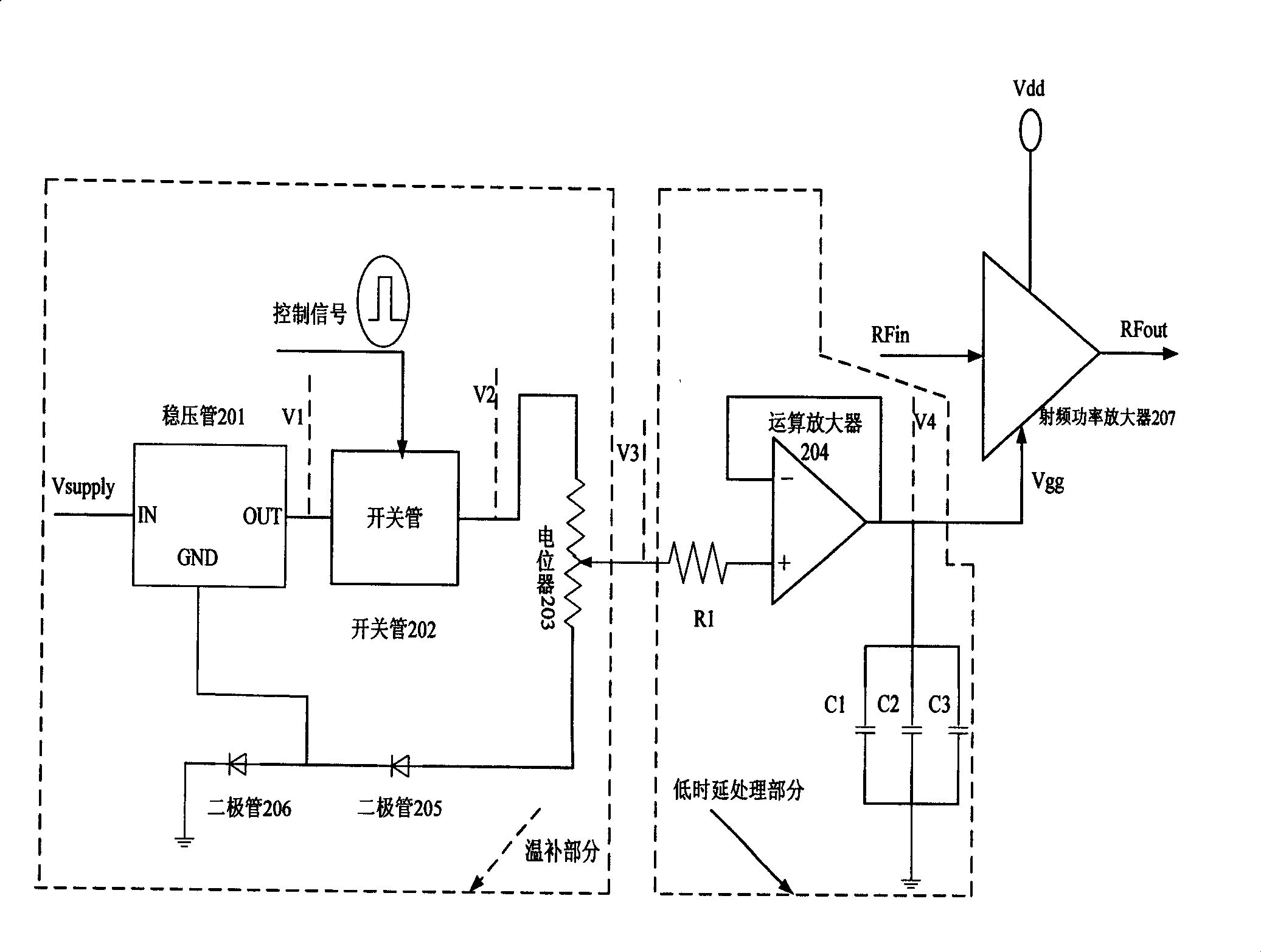

Low delay temperature compensation bias circuit for TDD mode

ActiveCN100461622CSolve unsolvable problemsConstant quiescent currentAmplifier modifications to reduce temperature/voltage variationTransmissionAudio power amplifierEngineering

The invention provides a low-delay temperature compensation biasing circuit for time division duplexing mode, comprising: switch tube; potentiometer, one end connected with output end of the switch tube, voltage dividing output end passing through series-connected resistor and filter decoupling circuit and acting as output bias voltage, and another end earthed through temperature compensation diodes; the temperature compensation diodes comprise series-connected first and second diodes; the input voltage is inputted into a voltage stabilizing tube and then outputted to the switch tube, the earth end of the voltage stabilizing tube is connected in between the first and second diodes; a negative feedback amplifier is connected in series between the series-connected resistor and filter decoupling circuit. And it compensates bias voltage of the amplifier, makes the static current of the amplifier keep constant and electric performance not influenced.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

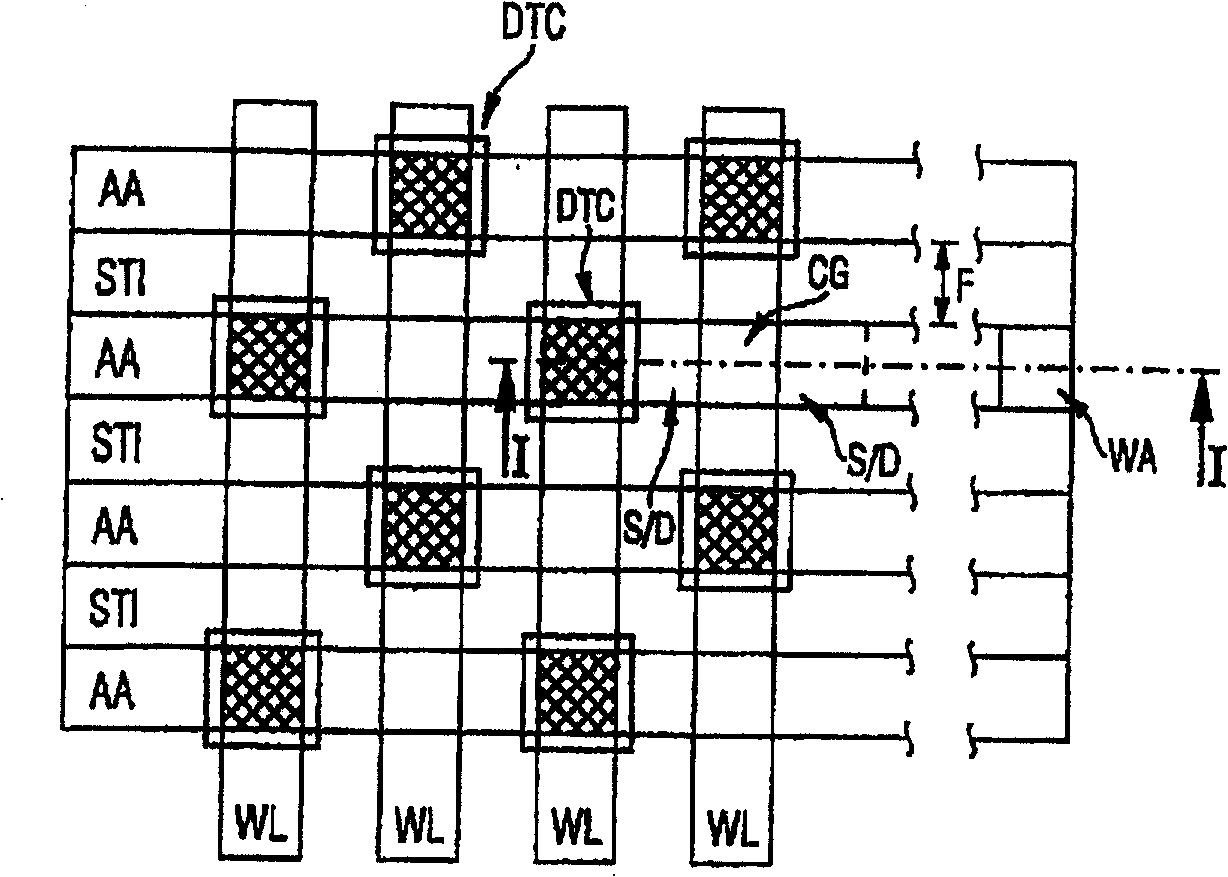

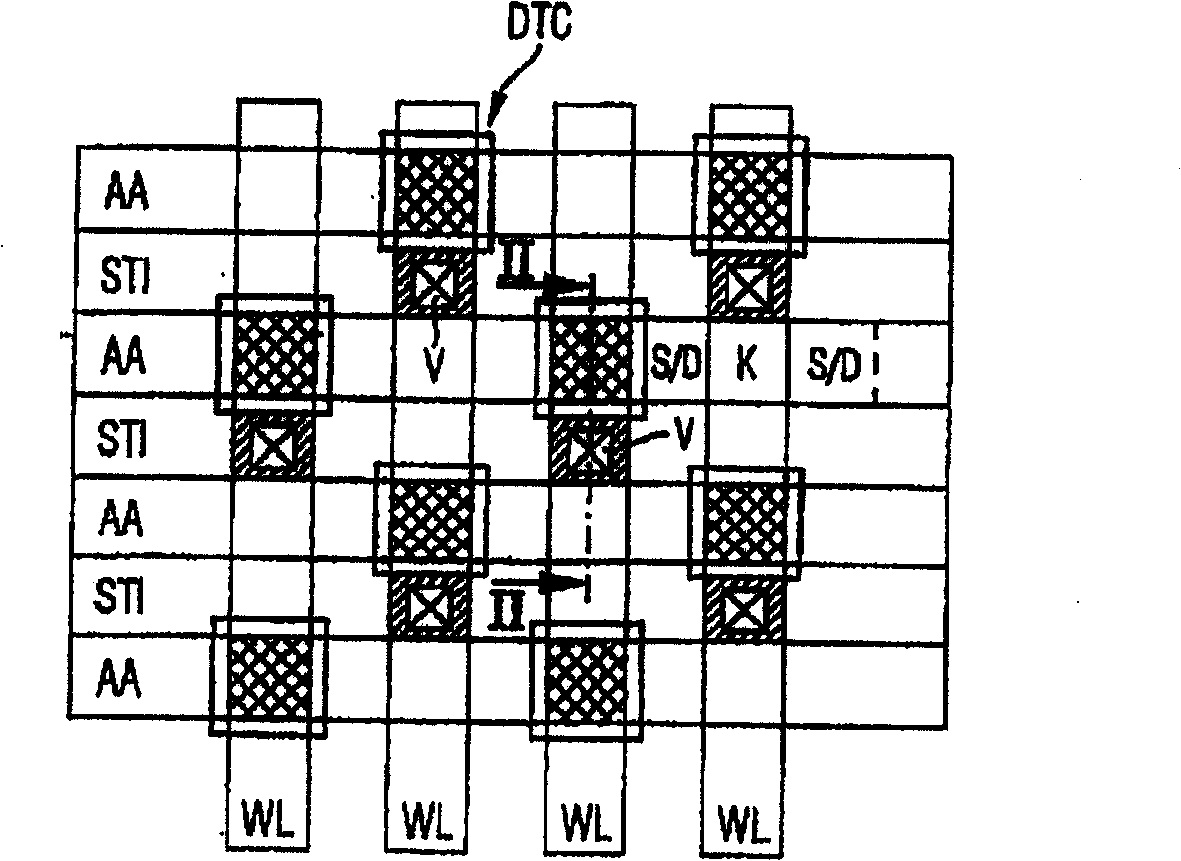

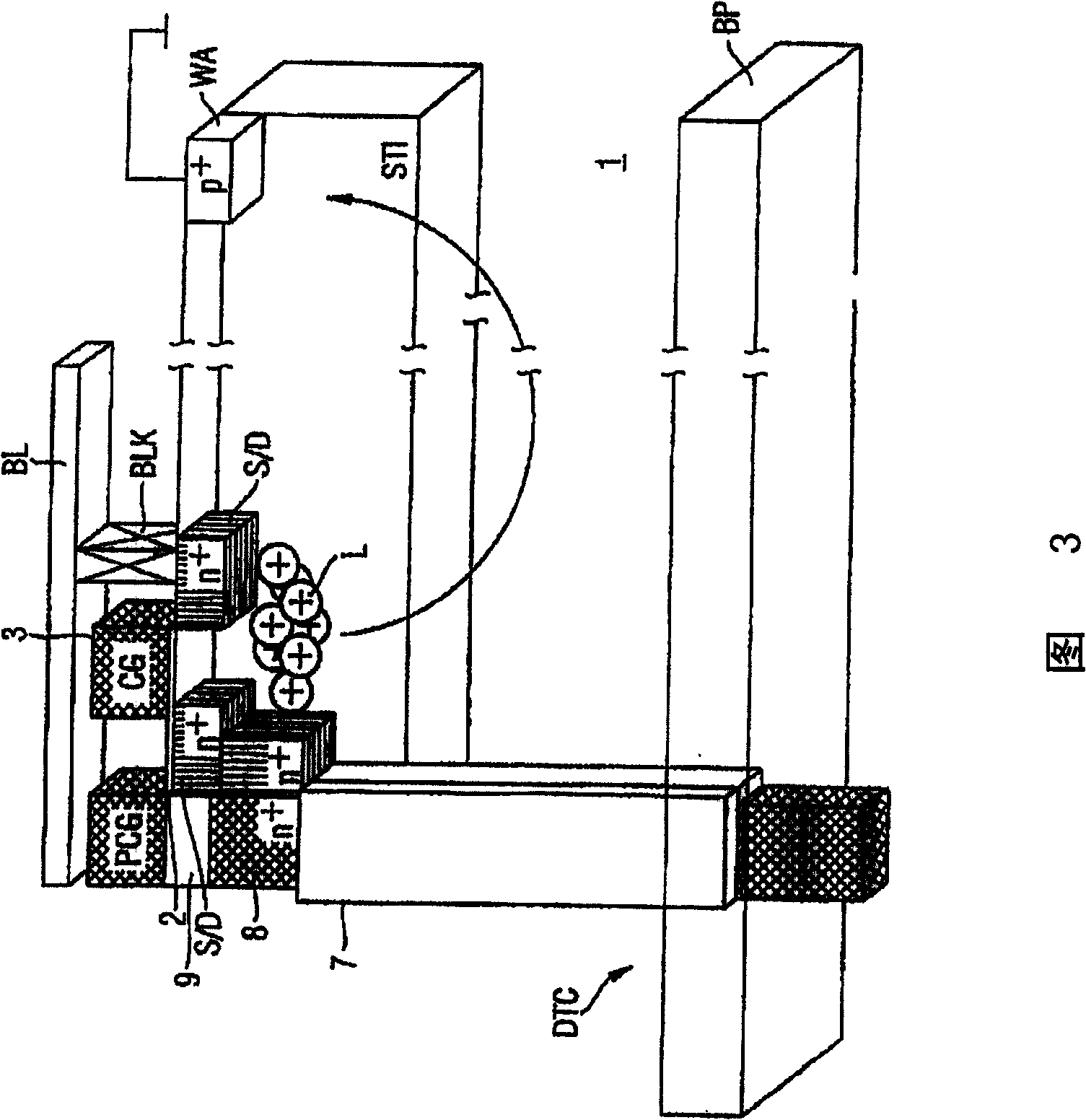

Field effect transistor structure, associated semiconductor storage cell, and corresponding production method

InactiveCN100423263CEffect AvoidanceEnhanced couplingTransistorSolid-state devicesControl layerElectrical conductor

The invention relates to a field effect transistor structure, an associated semiconductor storage cell, and a corresponding production method. A diode-doping area (4) within a semiconductor substrate (1) is embodied with a field effect transistor structure (S / D, 3, K) while an electrically conducting diode-connecting layer (5) connects a control layer (3) of the field effect transistor structure to the diode-doping area (4) so as to create a diode (D), whereby excess charge carriers (L) in the semiconductor substrate (1) can be eliminated such that an undesired body effect is prevented.

Owner:INFINEON TECH AG

A growth method for suppressing carbon inclusion defects in silicon carbide single crystals

ActiveCN107385512BPrevent volatilizationSuppress escapePolycrystalline material growthFrom condensed vaporsSingle crystalCrystal growth

The present invention relates to the technical field of crystal growing, and specifically relates to a growing method inhibiting carbon inclusion defects in silicon carbide monocrystals. The method described in the present invention divides growth into two phases, inhibiting volatilization and escape of a silicon component by means of controlling different pressures, decreasing, or even eliminating, formation of inclusions; the growing method described in the present invention does not require addition of an external substance to growing raw materials, as inhibition of carbon inclusion formation may be realized by means of only simple adjustments of growing techniques, the method being easily implemented and relatively low-cost.

Owner:SICC CO LTD

Preparing method of solar cell slice with pattern

ActiveCN102255000BElectrical properties are not affectedEasy to drawFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The invention discloses a preparing method of a solar cell slice with a pattern. The reparation technique disclosed by the invention can make a random pattern locally on the surface of the solar cell slice; and the preparation technique is simple and capable of realizing industrialization rapidly if the same is combined with the current production technique tightly. A solar cell prepared by using the method is free from electrical property loss. The method can be used to draw a pattern in need randomly on the solar cell, so as to meet different demands and to enlarge the application field of the solar cells. The solar cell with the pattern prepared by using the method is simple in structure, distinctive, and suitable for being used as building materials so as to meet different building demands, and has excellent energy saving and environmental protection benefits.

Owner:山东力诺太阳能电力股份有限公司

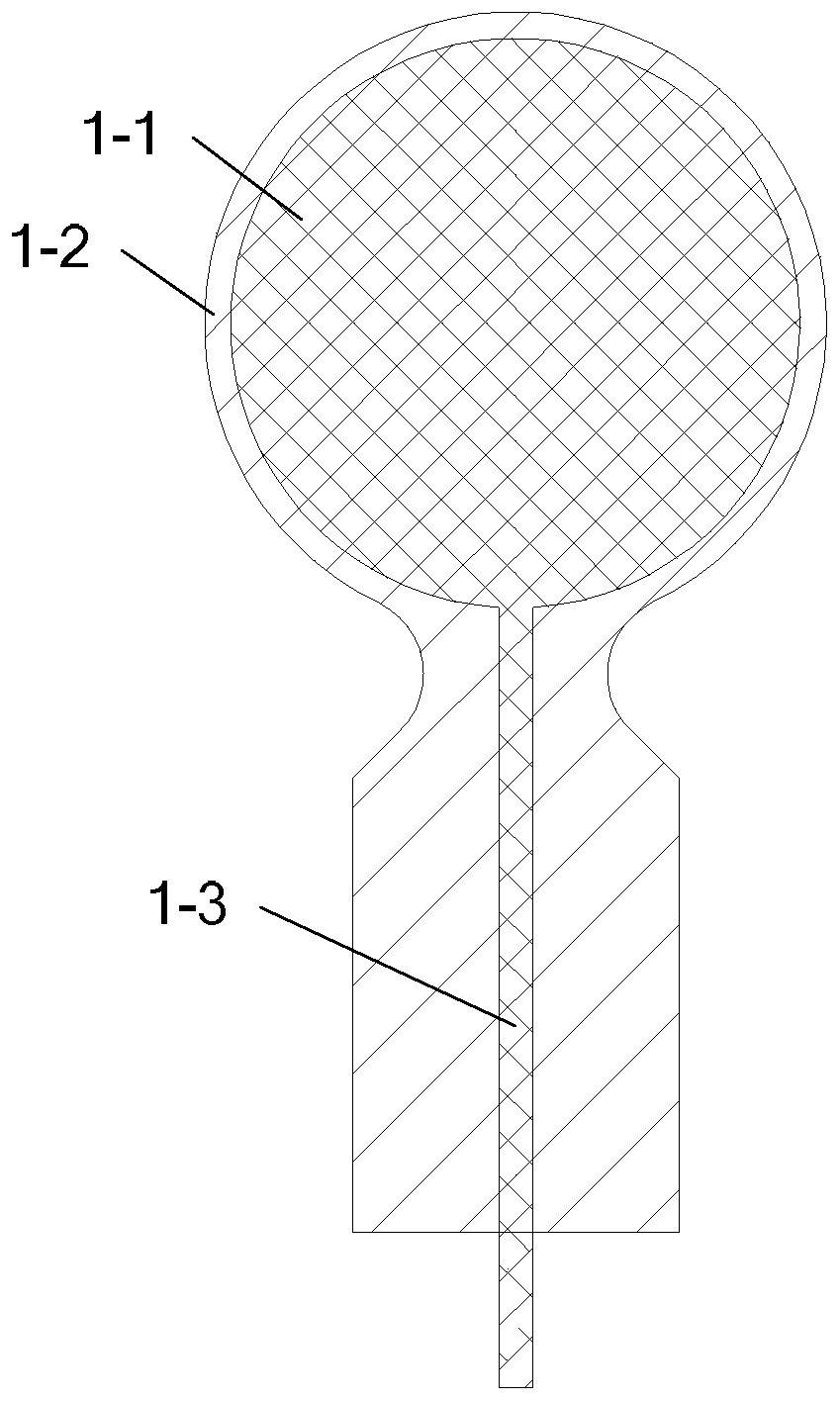

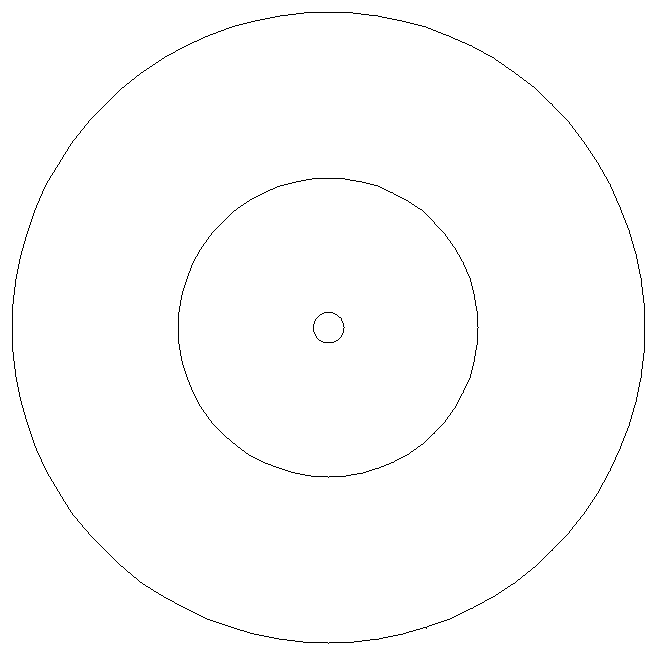

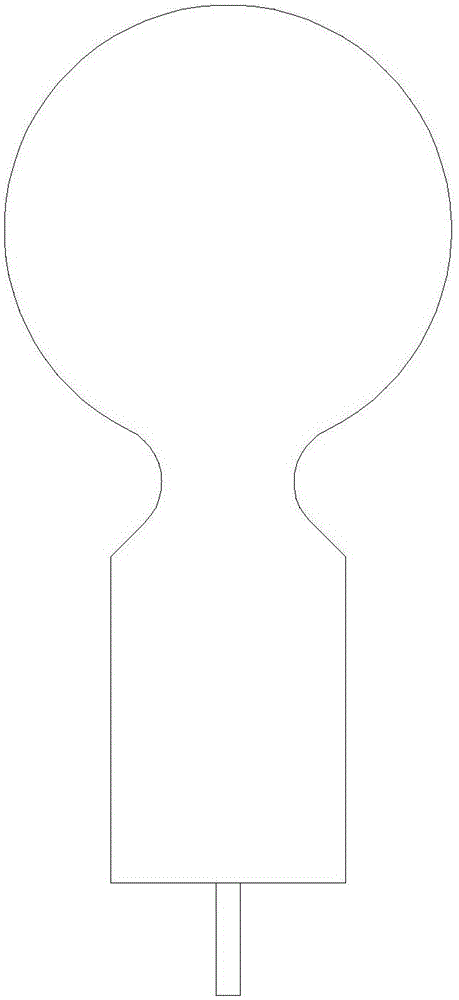

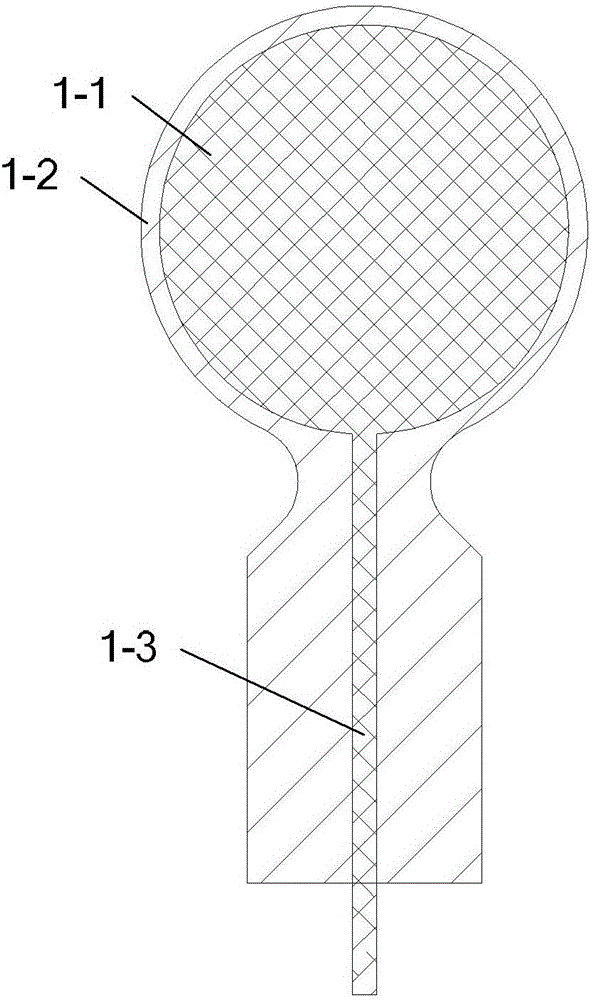

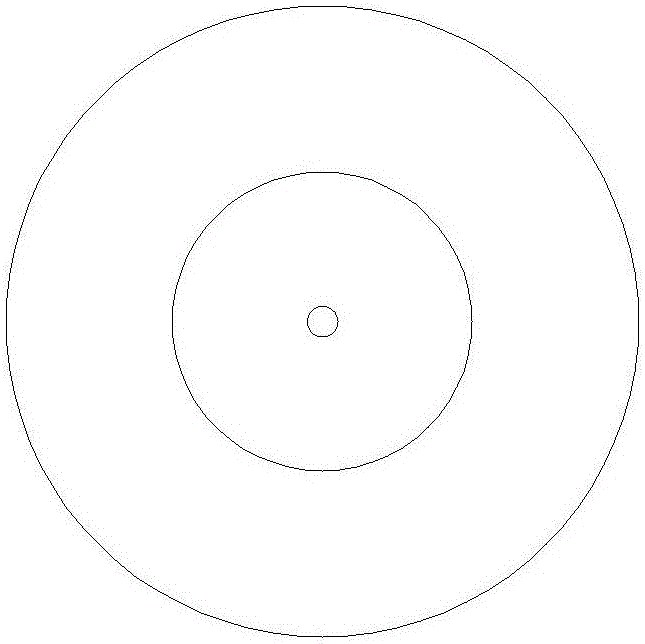

Spherical electrode and spherical capacitive hysteresis type liquid level switch containing the spherical electrode

ActiveCN106123998BImprove sensing sensitivityThe matching circuit is simpleLevel indicators by physical variable measurementEpoxyHysteresis

The invention discloses a radius tip electrode and a spherical capacitance return difference type liquid level switch with the radius tip electrode, and relates to the technical field of conductive liquid level detection. The problems that an existing liquid level switch is low in precision, high in foam floating ball water absorption rate and poor in epoxy resin insulating and pressure resistant property are solved. According to the radius tip electrode, one end of a binding post makes contact with and is connected with the outer surface of a metal spherical electrode, an insulating layer wraps the outer surfaces of the metal spherical electrode and the binding post, the insulating layer seals the metal spherical electrode and the binding post, and the other end of the binding post is located outside the insulating layer to serve as the wiring end of the radius tip electrode. According to the spherical capacitance return difference type liquid level switch, the wiring end of the radius tip electrode is connected with the measurement signal input end of a measuring circuit, and the wiring end of a liquid electrode is connected with the measurement signal input end of the measuring circuit. The radius tip electrode and the spherical capacitance return difference type liquid level switch are suitable for conductive liquid level detection.

Owner:哈尔滨西陆科技有限公司

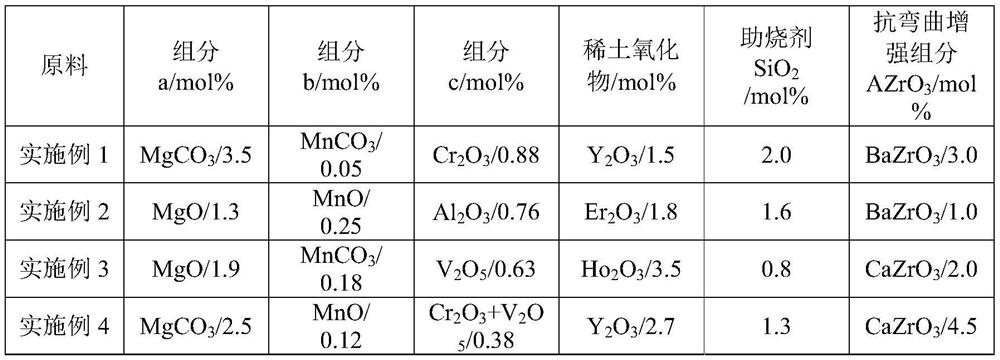

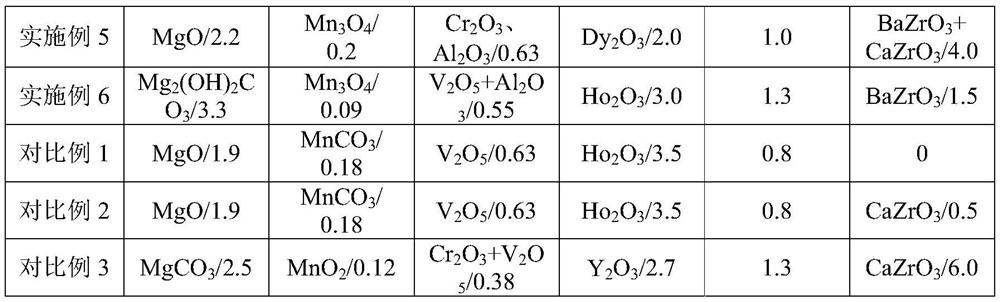

Ceramic dielectric material as well as preparation method and application thereof

ActiveCN114133238AHigh strengthImprove bending abilityFixed capacitor dielectricStacked capacitorsDielectricFlexural strength

The invention discloses a ceramic dielectric material as well as a preparation method and application thereof. The raw materials of the ceramic dielectric material comprise BaTiO3 and Zr-containing perovskite minerals. The Zr-containing calcium-titanium mineral substance is added into the ceramic dielectric material, has high toughness and high bending strength, has good lattice matching property with BaTiO3, and can be better in solid solution with BaTiO3, so that the strength and bending resistance of the MLCC can be improved, the electrical properties of the MLCC are not affected, and the MLCC can have excellent durability.

Owner:广东省先进陶瓷材料科技有限公司

A kind of aluminum-plastic film and its preparation method and drop-proof lithium battery

ActiveCN109866492BImprove thermal stabilityHigh hardnessSynthetic resin layered productsCell component detailsPhysical chemistryElectrical performance

Owner:HIGHPOWER TECH HUIZHOU

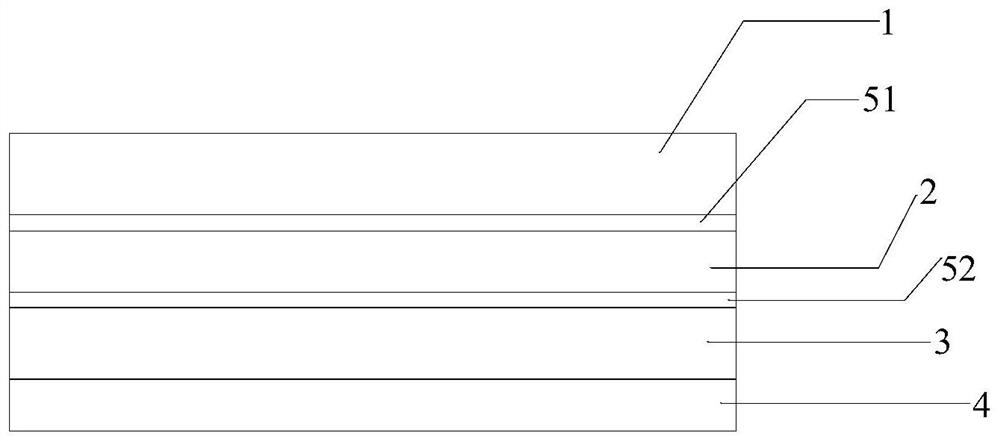

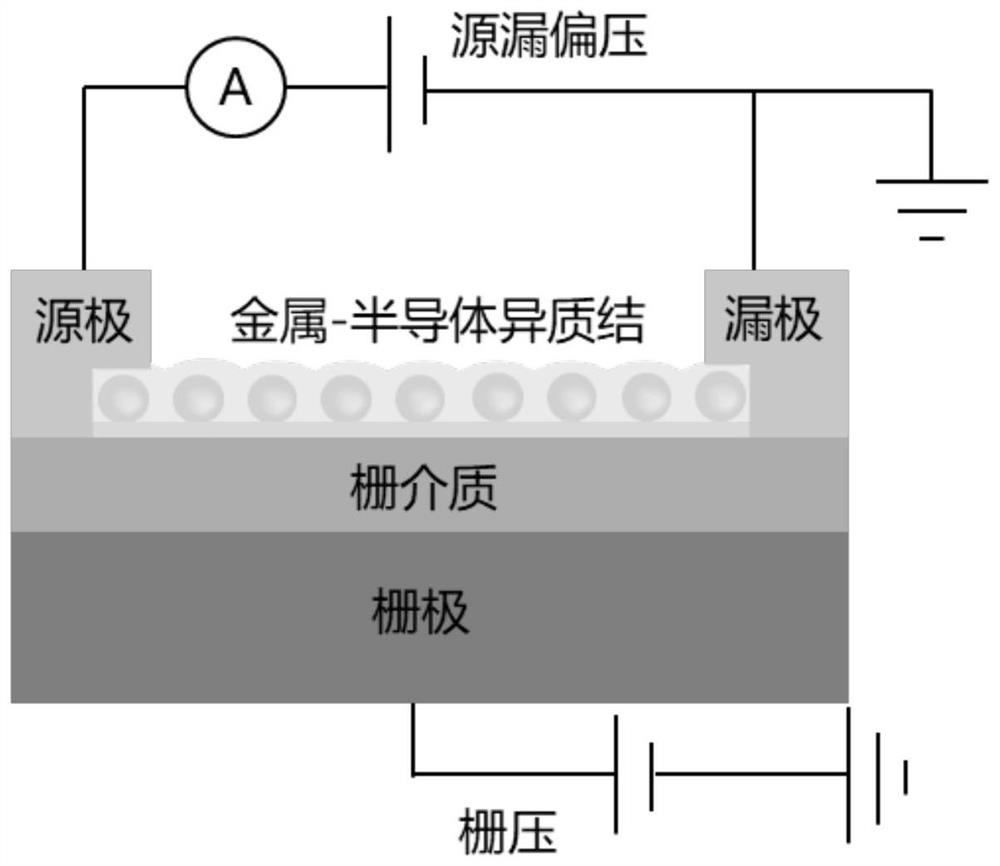

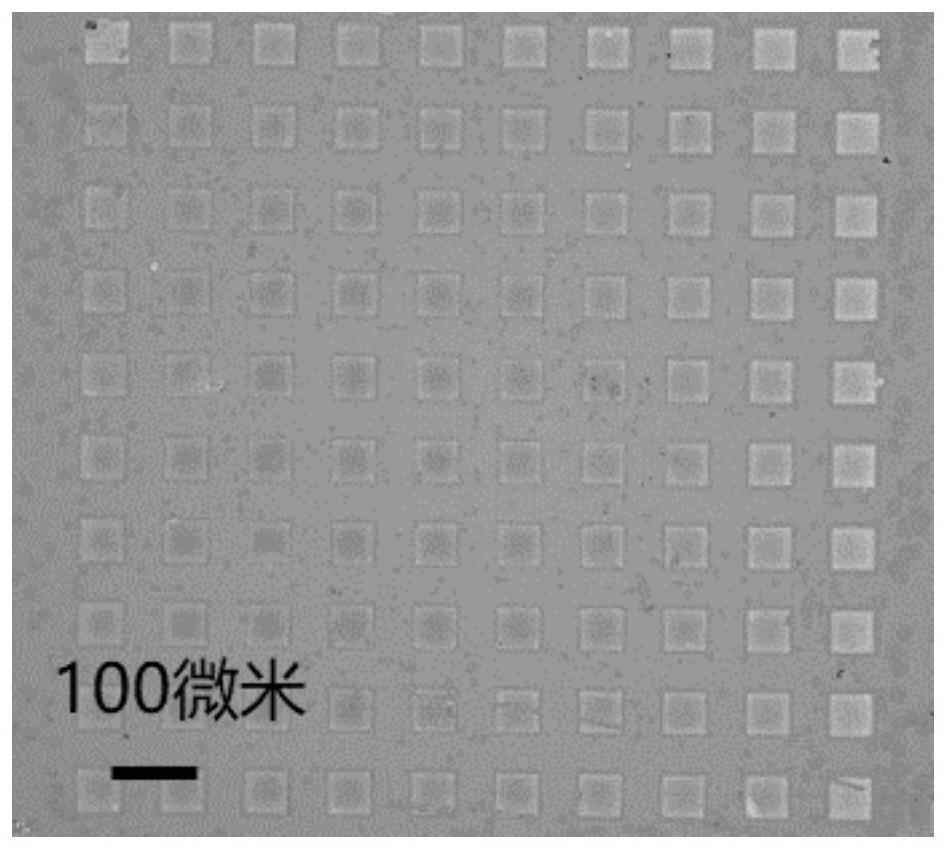

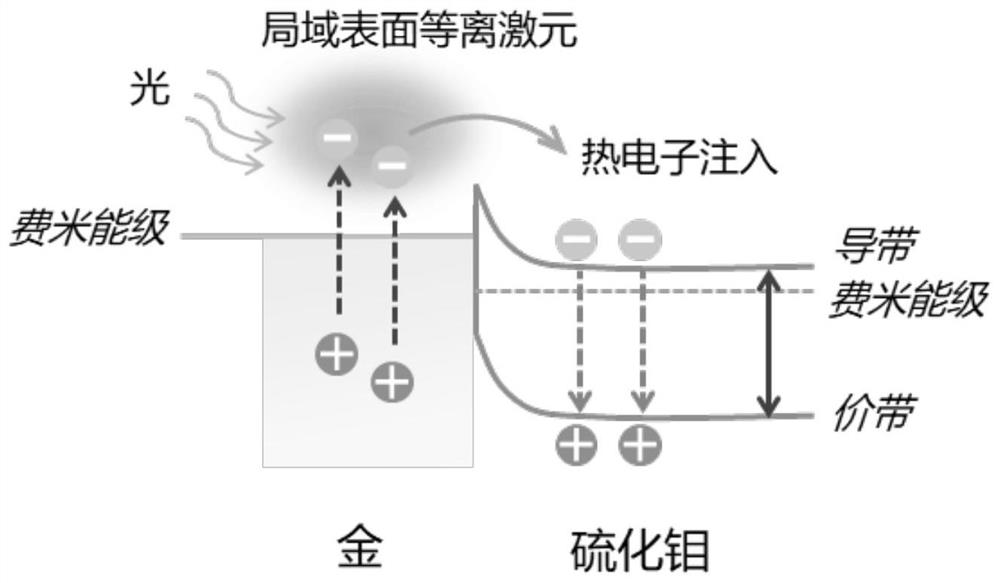

Hot carrier injection type single-pixel photoelectric detection device, preparation method and system

PendingCN114300578AAvoid adsorptionAvoid destructionFinal product manufactureNanoopticsHeterojunctionSchottky barrier

The invention discloses a hot carrier injection type single-pixel photoelectric detection device, a preparation method and a system. The method comprises the following steps: depositing metal on the surface of a substrate, and annealing to form metal nanoparticles; forming a two-dimensional semiconductor layer on the surfaces of the metal nanoparticles by adopting a chemical vapor deposition method, and forming a steep metal-semiconductor Schottky heterojunction with a clean interface; and preparing a grid electrode, a grid dielectric layer, a source electrode and a drain electrode on the semiconductor layer to obtain the hot carrier injection type single-pixel photoelectric detector. A metal-semiconductor Schottky heterojunction with a clean interface is formed, local surface plasmons of metal nanoparticles are subjected to non-radiative attenuation to generate hot carriers under illumination, and the hot carriers pass through a Schottky barrier between metal and a semiconductor to be injected into the semiconductor, so that the metal-semiconductor Schottky heterojunction with the clean interface is formed. Picosecond-level ultrafast transmission of hot carriers and ultrafast response to incident light are realized; and single-pixel photoelectric imaging with ultra-high response speed, wide spectrum and low cost can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

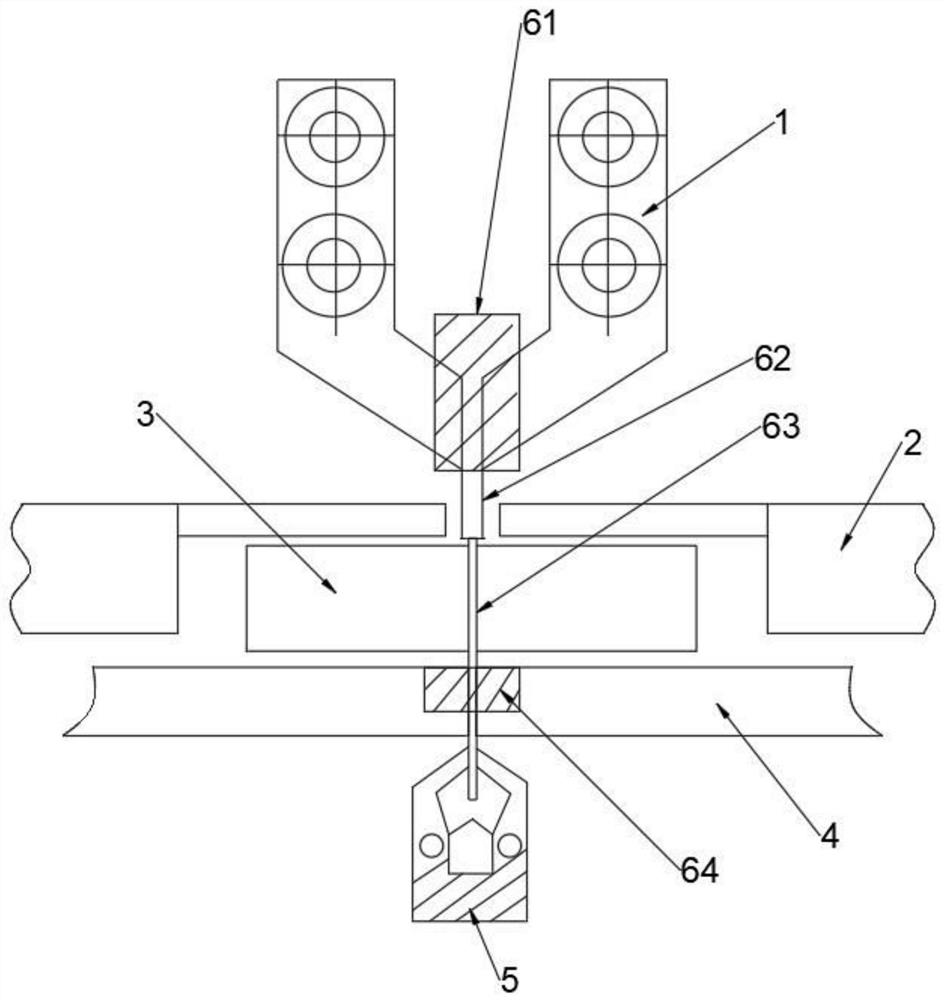

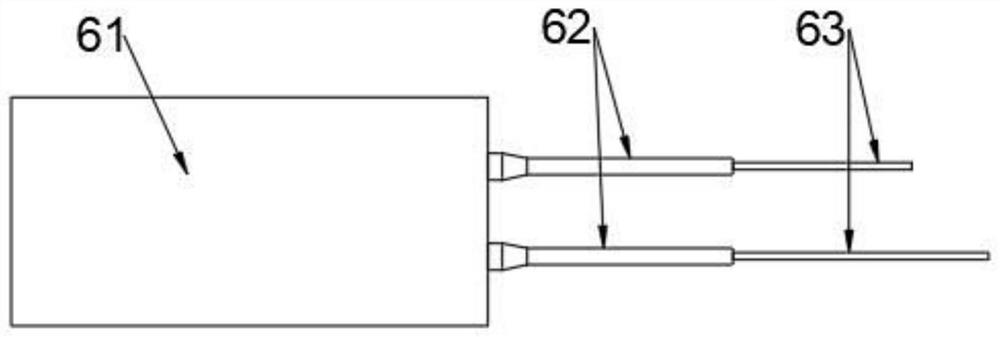

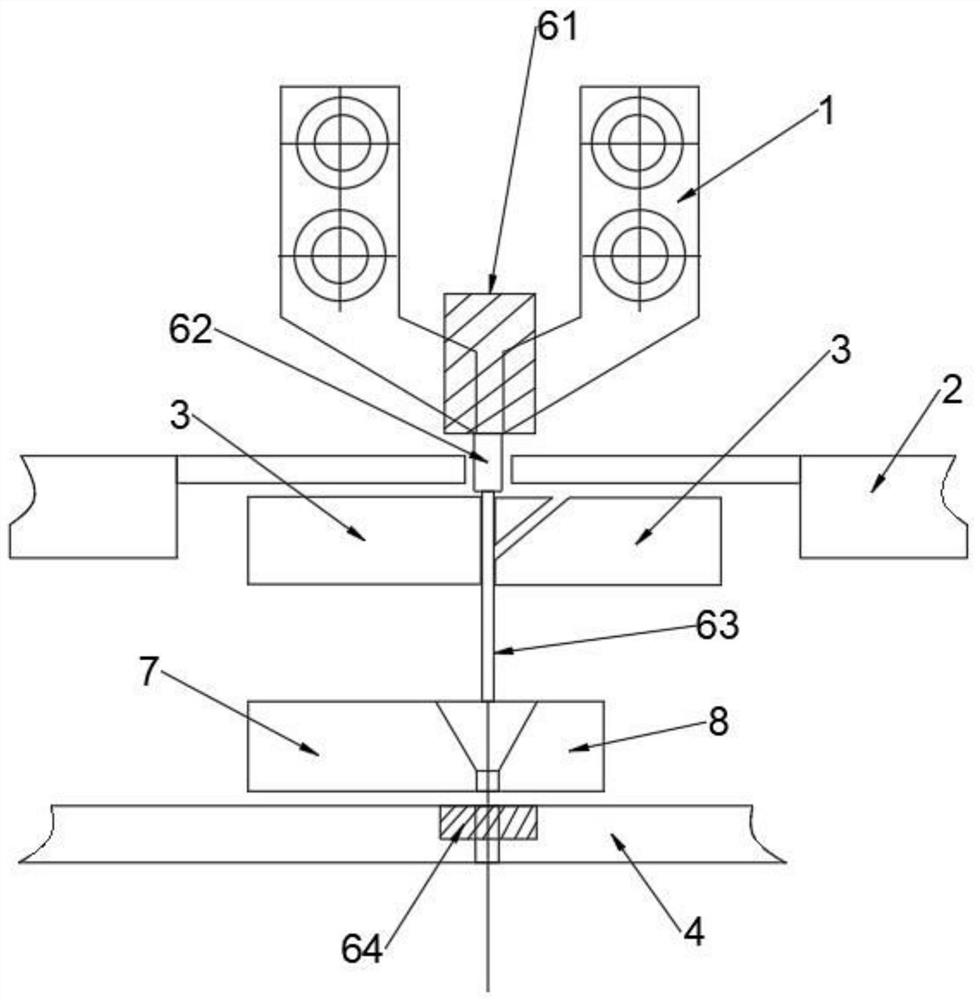

An optimized structure of a small aluminum electrolytic capacitor stack machine

ActiveCN112967893BAvoid skewAvoid strainTerminal applying apparatusCapacitanceStructural engineering

The invention discloses an optimized structure of a small aluminum electrolytic capacitor assembly machine, which relates to the technical field of aluminum electrolytic capacitor manufacturing. The invention redesigns the so-called "triple combination structure" in which the original traditional assembly core is wrapped into a rubber cover and reduces the It is a "double combination structure", by sending the core package to the end stroke of the guide pin alignment clamp, the guide pin is directly guided into the rubber cover, and it is coaxial in place in one step, avoiding the displacement of the core package riveting point; On the one hand, by setting the pneumatic mechanical foot pulling device under the rubber cover station plate, the pneumatic foot pulling device can effectively clamp the two guide pins of the core package to make it into a "vertical" state, so that the subsequent actions can be "coaxial". The guide pin enters the rubber cover under the "state", avoiding the "top-heavy" phenomenon of the core package and the guide pin, which may cause the guide pin to be skewed or strained, etc., ensuring that the electrical properties of the solid-state SMD series products are not affected, and at the same time stabilizing the capacitance of the capacitor. performance parameters, greatly improving product quality.

Owner:SHENZHEN JIANGHAO ELECTRON

A kind of polymer/conductive filler/metal composite fiber and its preparation method

ActiveCN104099683BImprove breaking strengthImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / conductive filler / metal composite fiber. The composite fiber comprises polymer fiber containing metal short fiber and a conductive filler, the metal short fiber is dispersed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber; the conductive filler is dispersed in the polymer fiber and distributed among the metal short fiber; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C to 480 DEG C and lower than a polymer processing temperature; the volume ratio of the metal short fiber to the polymer fiber is 0.01:100-20:100; and the weight ratio of the conductive filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diaphragm, preparation method thereof and lithium ion power battery comprising diaphragm

ActiveCN111599968AImprove thermal conductivityImprove needlestick safetyCell seperators/membranes/diaphragms/spacersSecondary cellsEngineeringPower battery

The invention provides a diaphragm, a preparation method thereof and a lithium ion power battery comprising the diaphragm in order to improve the needling safe passing performance of a battery cell and ensure that the electrical performance of the battery cell is not affected, and belongs to the technical field of batteries. According to the specific scheme, the diaphragm comprises a diaphragm substrate layer and a PVDF coating, wherein the PVDF coating is arranged on one side or two sides of the diaphragm substrate layer, the PVDF coating comprises PVDF and nano copper powder, and the nano copper powder is dispersed in the PVDF. According to the high-safety lithium ion power battery diaphragm provided by the invention, by adopting the ceramic diaphragm in which a trace amount of nano copper powder is mixed in the PVDF glue coating, the heat-conducting property of the diaphragm is greatly enhanced, the needling safety of the high-capacity lithium-ion power battery cell is effectively improved, particularly the safety of the power type lithium-ion power battery cell with low coating surface density is improved, and meanwhile, the electrical property of the battery cell is not influenced.

Owner:ZHUHAI COSMX POWER CO LTD

Radius tip electrode and spherical capacitance return difference type liquid level switch with radius tip electrode

ActiveCN106123998AImprove sensing sensitivityThe matching circuit is simpleLevel indicators by physical variable measurementEpoxyCapacitance

The invention discloses a radius tip electrode and a spherical capacitance return difference type liquid level switch with the radius tip electrode, and relates to the technical field of conductive liquid level detection. The problems that an existing liquid level switch is low in precision, high in foam floating ball water absorption rate and poor in epoxy resin insulating and pressure resistant property are solved. According to the radius tip electrode, one end of a binding post makes contact with and is connected with the outer surface of a metal spherical electrode, an insulating layer wraps the outer surfaces of the metal spherical electrode and the binding post, the insulating layer seals the metal spherical electrode and the binding post, and the other end of the binding post is located outside the insulating layer to serve as the wiring end of the radius tip electrode. According to the spherical capacitance return difference type liquid level switch, the wiring end of the radius tip electrode is connected with the measurement signal input end of a measuring circuit, and the wiring end of a liquid electrode is connected with the measurement signal input end of the measuring circuit. The radius tip electrode and the spherical capacitance return difference type liquid level switch are suitable for conductive liquid level detection.

Owner:哈尔滨西陆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com