An optimized structure of a small aluminum electrolytic capacitor stack machine

A technology for aluminum electrolytic capacitors and optimized structures, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as displacement of core-wrapped riveting points, impact on product quality, product failure, etc., achieve stable electrical performance parameters, and avoid riveting points of guide pins "Displacement, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

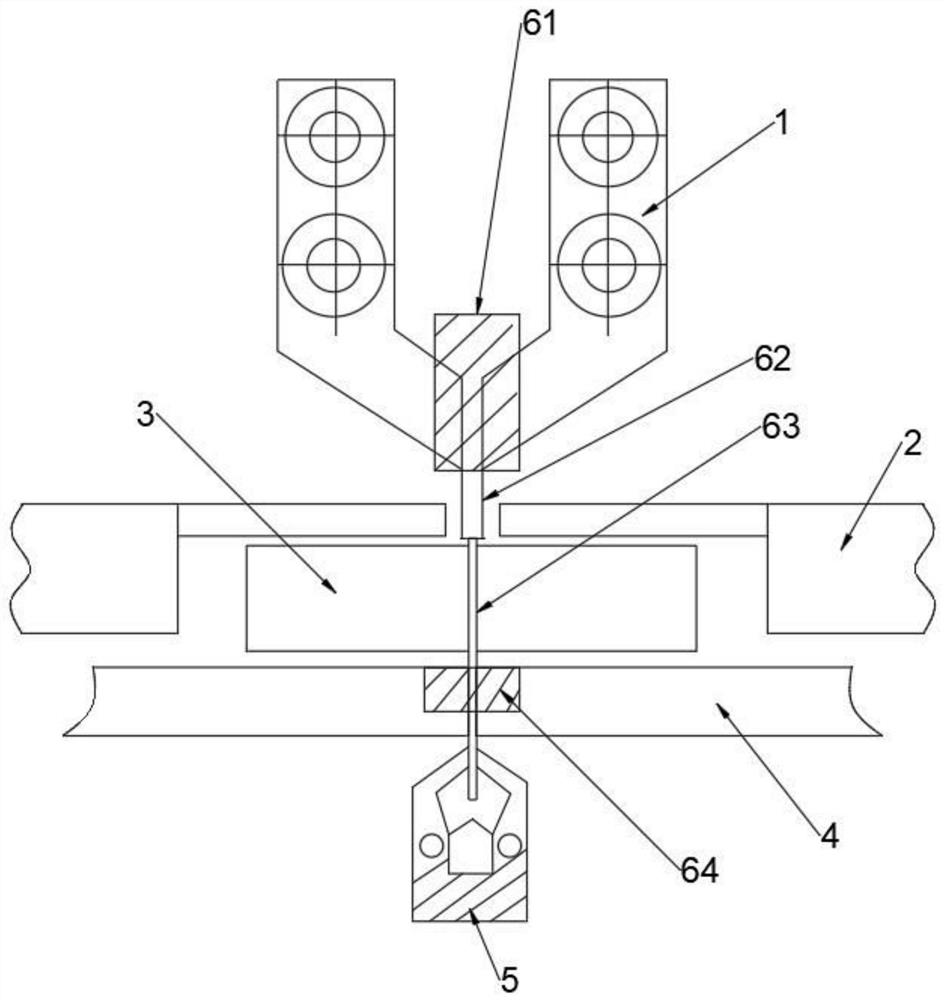

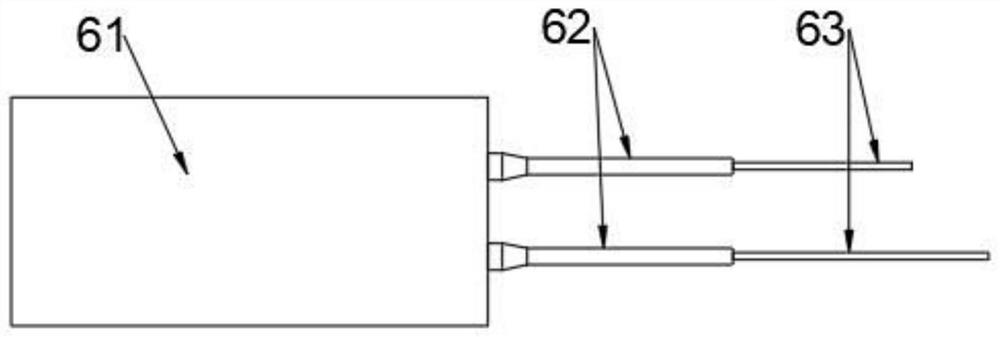

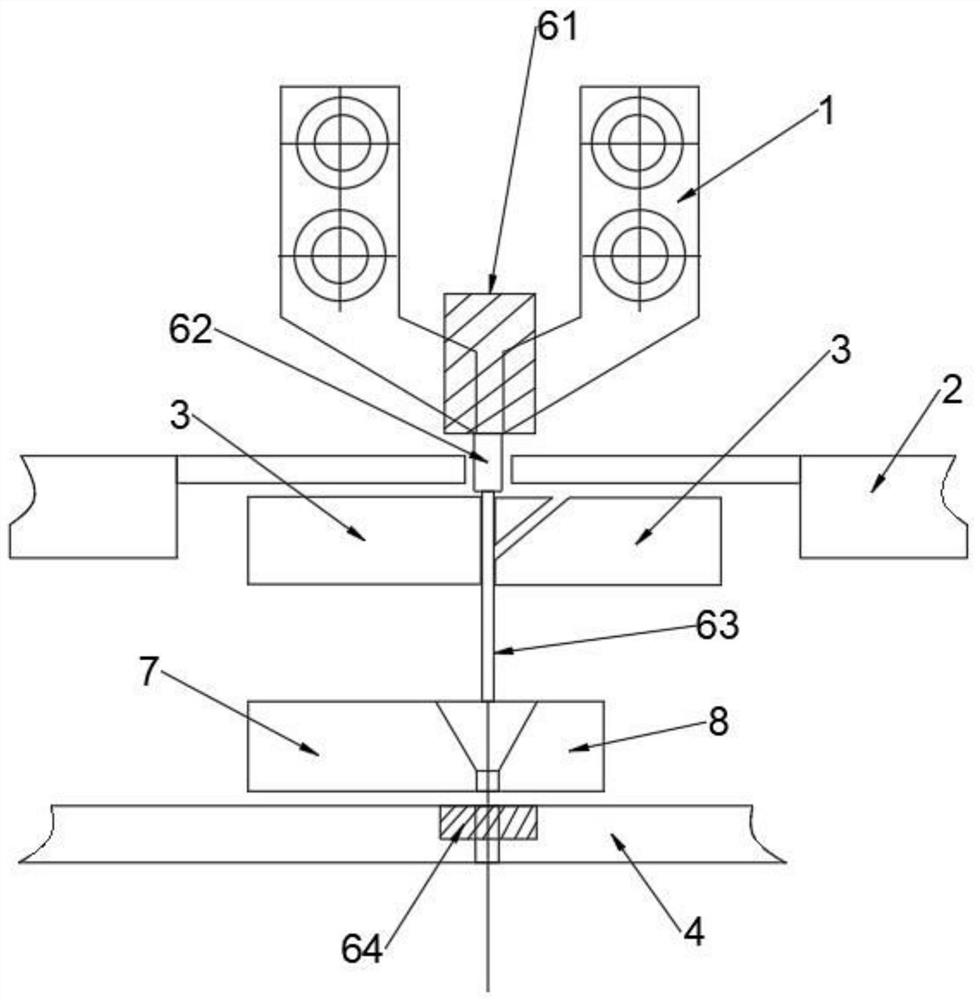

[0020] Such as figure 1 The optimized structure of a small aluminum electrolytic capacitor assembly machine is shown, including the core package clamp 1 clamping the product core package 61, the guide pin B part clamping block 2 clamping the guide pin B part 62, and the guide pin 63 The guide pin straightening clip 3 for straightening, the rubber cover station plate 4 for fixing the rubber cover 64, the secondary action cam for making the core pack 61 enter the rubber cover 64, and the pneumatic mechanical foot pulling device for clamping the end of the guide pin 63 5.

[0021] Core wrapping clamp 1, guide pin B part clamping block 2, guide pin straightening clamp 3, rubber cover station plate 4, secondary action cam and pneumatic mechanical foot pulling device 5 are arranged in sequence from top to bottom, core wrapping clamp 1 The clamping station of the guide pin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com