A damping heat insulation structure and its preparation method and application

A damping and heat insulation layer technology, applied in applications, other household appliances, protective equipment, etc., can solve problems such as product procurement and use restrictions, protective structure volume and quality, unfavorable product assembly and use, etc. Lightweight, thermal insulation, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

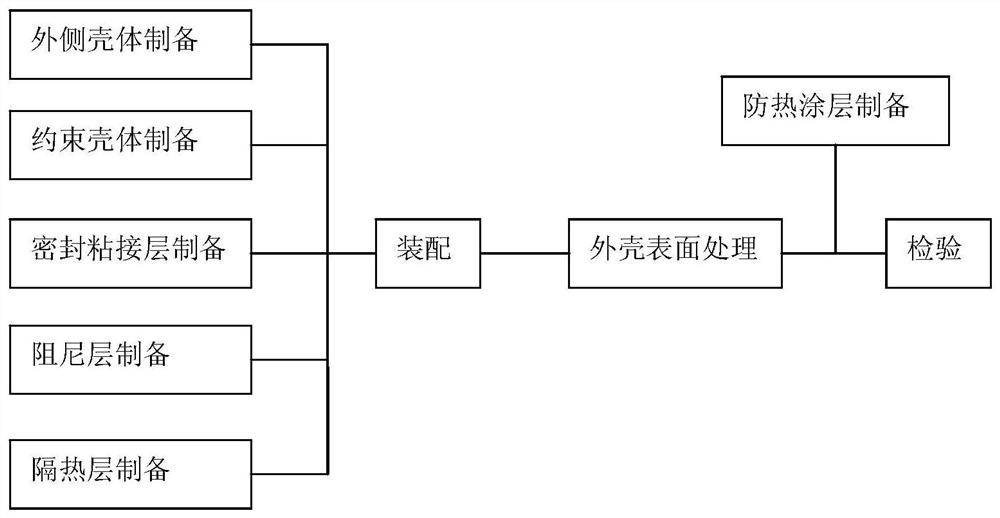

[0056] A method for preparing a damping heat insulation structure, the steps of the method comprising:

[0057] (1) Mix the raw materials of polyurethane damping layer 1 to obtain polyurethane damping material slurry;

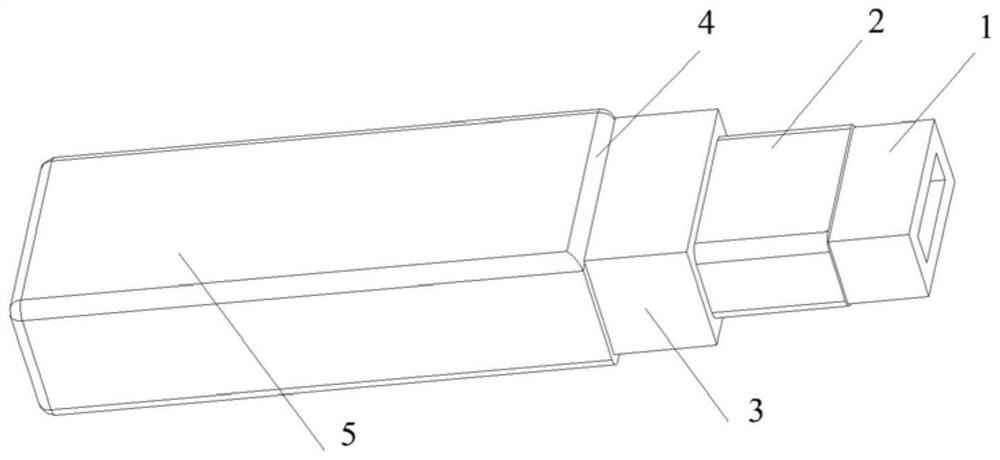

[0058] (2) Install the core components to be protected in the restraint shell 2, pour the polyurethane damping material slurry obtained in step (1) into the cavity between the core components to be protected and the restraint shell 2, and solidify ;

[0059] (3) After the curing in step (2) is completed, the outer surface of the constraining shell 2 is coated with adhesive, the inner surface of the heat insulation layer 3 is coated with adhesive, and then the constrained shell 2 coated with the adhesive on the outer surface is placed into the cavity of the thermal insulation layer 3 coated with adhesive on the inner surface, and cured at room temperature for 3 to 5 days;

[0060] (4) After the curing in step (3) is completed, apply the adhesive on the outer s...

Embodiment 1

[0071] Such as figure 2 Shown, a kind of preparation method of damping heat insulation structure, the step of this method comprises:

[0072] (1) Constraint shell 2 and shell 4 are made of high-strength alloy 0Cr17Ni4Cu4Nb, and the outer surfaces of both shells are blasted with 0.05MPa, 40-mesh sand.

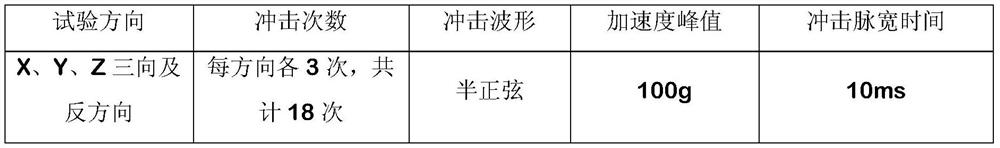

[0073] (2) The preparation method of the polyurethane damping layer 1: including the synthesis of the polyurethane material and the potting and molding of the damping layer. The synthesis of the polyurethane material includes the following components by weight: 40 parts of liquefied MDI, 60 parts of castor oil, 0.05 parts of dibutyltin dilaurate, and a chain extender polyether polyol N210 is added according to the chain extension coefficient of 0.9. The polyurethane material is synthesized by a two-step method. Use tooling to fix the data recording circuit unit in the center of the restraint shell, ensure that there is no contact point between the circuit unit and the restrai...

Embodiment 2

[0086] (1) Constraint shell 2 and shell 4 are made of high-strength alloy 30CrMnSiA, and the outer surfaces of both shells are blasted with 0.05MPa, 40-mesh sand.

[0087] (2) The preparation method of the polyurethane damping layer 1: including the synthesis of the polyurethane material and the potting and molding of the damping layer. The synthesis of the polyurethane material includes the following components by weight: 30 parts of liquefied MDI, 70 parts of castor oil, 0.1 part of dibutyltin oxide, and the chain extender polyether polyol N303 is added according to the chain extension coefficient of 0.95. The polyurethane material is synthesized by a two-step method. Use tooling to fix the data recording circuit unit in the center of the restraint shell, ensure that there is no contact point between the circuit unit and the restraint shell, inject the synthetic polyurethane slurry into the restraint shell, and stop at 1 / 2 of the bound shell. Potting, the whole is transferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com