Ceramic dielectric material as well as preparation method and application thereof

A ceramic dielectric, ceramic capacitor technology, applied in the direction of fixed capacitor dielectric, fixed capacitor components, fixed capacitors, etc., can solve the problems of MLCC products such as electrical performance decline, poor bending resistance, cracking failure, etc., to achieve excellent durability, The effect of improving bending resistance and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with specific examples. The raw materials used in the following examples, unless otherwise specified, can be obtained from conventional commercial channels; the processes used, unless otherwise specified, are conventional processes in the art.

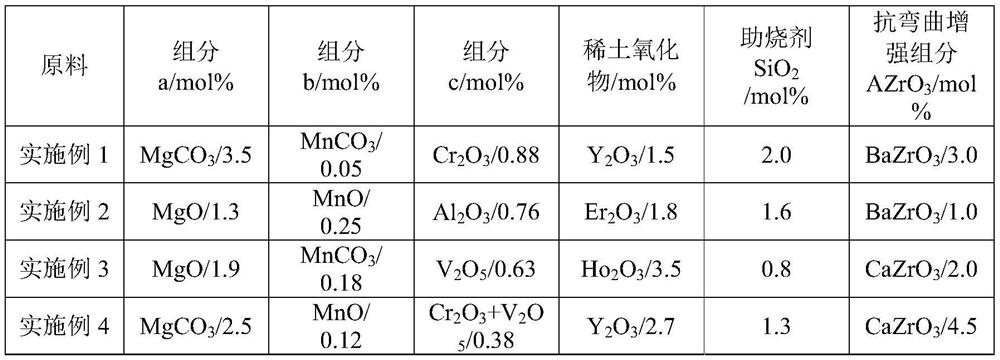

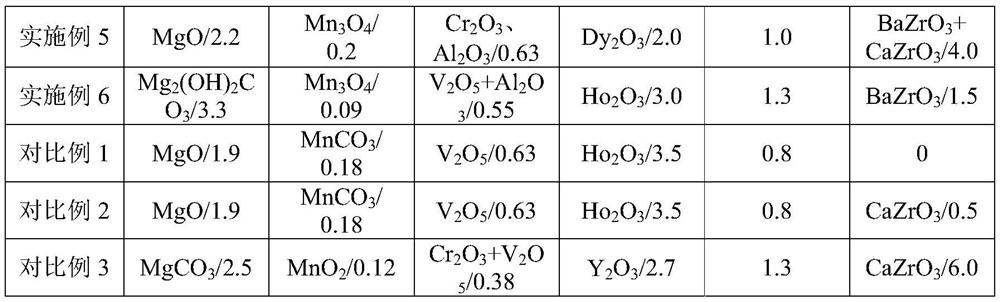

[0044] A ceramic dielectric material whose main component is BaTiO 3 , according to BaTiO 3 The molar percentage of is 100% meter, also contains other raw materials of proportioning as described in table 1 below:

[0045] Table 1. Raw materials and mole percentages of ceramic dielectric materials

[0046]

[0047]

[0048] In addition, the raw materials of the ceramic dielectric materials of each embodiment and comparative example also include BaTiO 3 0.5% by mass of dispersant polyester amide salt, accounting for BaTiO 3 7.0% by mass of binder PVB, accounting for BaTiO 3 3% plasticizer polyethylene glycol by mass and accou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com