Preparation method of lithium iron phosphate with high compaction density and high capacity

A lithium iron phosphate and iron phosphate technology, which is applied in the field of positive electrode materials for lithium ion batteries, can solve problems such as affecting the performance of the electrical properties of materials, decline in electrical properties, and greatly improve the compaction density of lithium iron phosphate materials, so that the electrical properties are not affected. Influence, energy density increase, effect of high compaction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

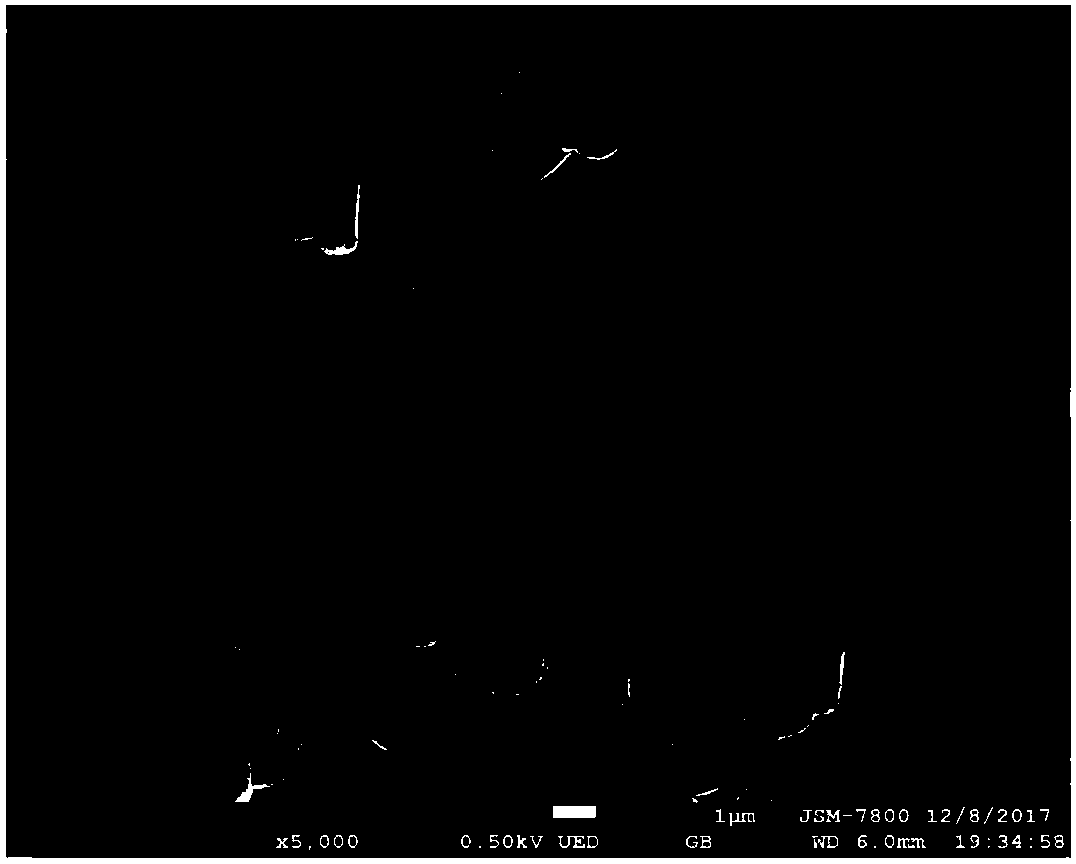

Image

Examples

Embodiment 1

[0044] Step 1: add 670kg of ferrous sulfate heptahydrate in the dissolving tank, 1.2kg of titanium sulfate and 1648.8kg of pure water, stir and dissolve completely and be mixed with iron content and be 5.8%, titanium content is 0.01% (by mass percentage) Mixed solution of ferrous sulfate. Add 277kg of ammonium dihydrogen phosphate and 1343kg of pure water in the dissolving tank, stir and dissolve completely and then prepare an ammonium dihydrogen phosphate solution with a phosphorus content of 4.6% (by mass percentage).

[0045]Step 2: Add 2320kg of the prepared ferrous sulfate mixed solution, 1620kg of ammonium dihydrogen phosphate solution, 145kg of hydrogen peroxide with a mass concentration of 30%, and 6kg of ammonia water with a mass concentration of 25% into the reaction kettle with a stirring speed of 300rpm at the same time To carry out the reaction, control the pH of the reaction slurry to 1.9, and control the reaction temperature to 50°C. After reacting for 4 hours, ...

Embodiment 2

[0050] Step 1: add 670kg of ferrous sulfate heptahydrate in the dissolving tank, 0.7kg of titanium sulfate and 2021.3kg of pure water, stir and dissolve completely and be formulated with iron content as 5.0%, titanium content as 0.005% (by mass percentage) Mixed solution of ferrous sulfate. Add 277kg ammonium dihydrogen phosphate and 1588kg pure water in the dissolving tank, stir and dissolve completely, and then prepare an ammonium dihydrogen phosphate solution with a phosphorus content of 4.0% (by mass percentage).

[0051] Step 2: Add 2692kg of the prepared ferrous sulfate mixed solution, 1865kg of ammonium dihydrogen phosphate solution, 147kg of hydrogen peroxide with a mass concentration of 30%, and 7kg of ammonia water with a mass concentration of 25% into the reaction kettle with a stirring speed of 250rpm at the same time To carry out the reaction, control the pH of the reaction slurry to 2.0, and control the reaction temperature to 60°C. After reacting for 6 hours, ad...

Embodiment 3

[0056] Step 1: add 670kg of ferrous sulfate heptahydrate in the dissolving tank, 1.4kg of magnesium sulfate and 2130.6kg of pure water, after stirring and dissolving completely, be mixed with iron content and be 4.8%, magnesium content is 0.01% (by mass percentage) Mixed solution of ferrous sulfate. Add 277kg of ammonium dihydrogen phosphate and 1686kg of pure water in the dissolving tank, stir and dissolve completely, and then prepare an ammonium dihydrogen phosphate solution with a phosphorus content of 3.8% (by mass percentage).

[0057] Step 2: 2802kg of the prepared ferrous sulfate mixed solution, 1963kg of ammonium dihydrogen phosphate solution, 140kg of hydrogen peroxide with a mass concentration of 30%, and 8kg of ammonia water with a mass concentration of 25% are simultaneously added dropwise to the reaction kettle with a stirring speed of 250rpm To carry out the reaction, control the pH of the reaction slurry to 2.2, control the reaction temperature to 40°C, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com