Hot carrier injection type single-pixel photoelectric detection device, preparation method and system

A photodetector and hot carrier technology, applied in the field of photodetection, can solve the problem of unsatisfactory photoelectric response speed of photodetector devices, and achieve the effects of avoiding the adsorption of impurities at the interface, avoiding damage, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

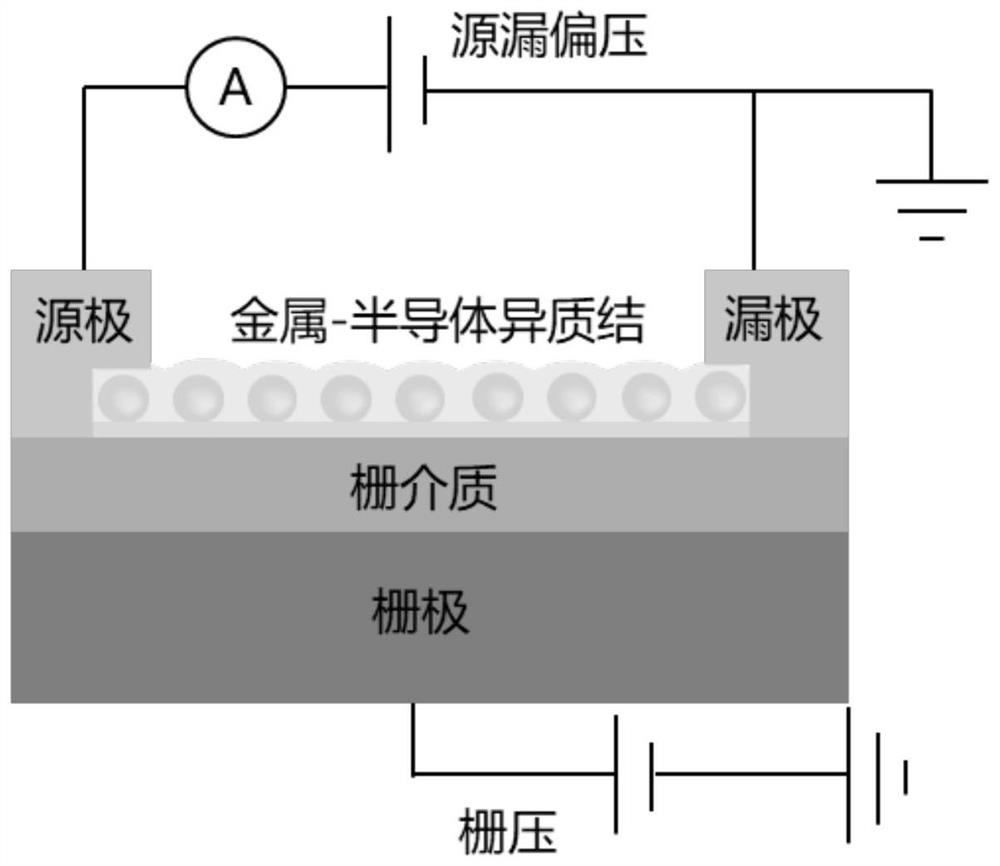

[0036] Cr / Au / Au-MoS 2 / Au / Cr lateral devices, see figure 1 .

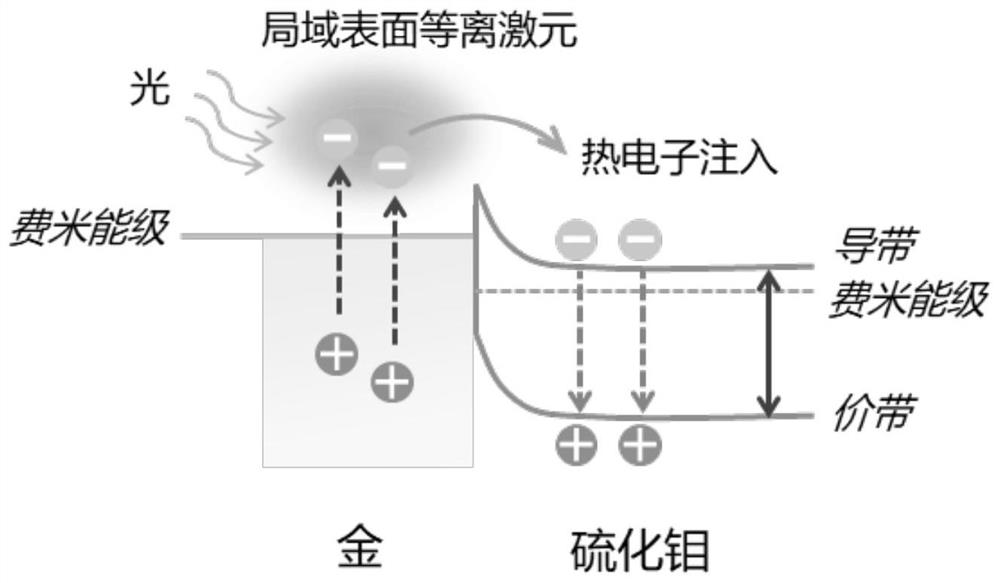

[0037] (1) First in the clean Si / SiO 2 3nm Au is deposited on the surface of the substrate, and the rapid heating and cooling annealing process is realized by a moving slide tube furnace, and Si / SiO with 3nm Au is deposited 2The substrate is annealed at 550° C. for 7 minutes to form uniformly distributed nanoparticles with a particle size of 20-40 nm.

[0038] (2) Subsequent preparation of Au-MoS on the surface of Au nanoparticles by chemical vapor deposition 2 Heterojunction, choose sulfur powder and molybdenum oxide as the reaction source, set the temperature in the central temperature zone of the single temperature zone tube furnace used for the reaction to 625-750°C, and the reaction time is 3-10min. After natural cooling, uniform and continuous patterns can be obtained. oxidized heterojunction samples.

[0039] (3) Si with a thickness of 2mm is used as the gate electrode, and SiO with a thickness of 300nm...

Embodiment 2

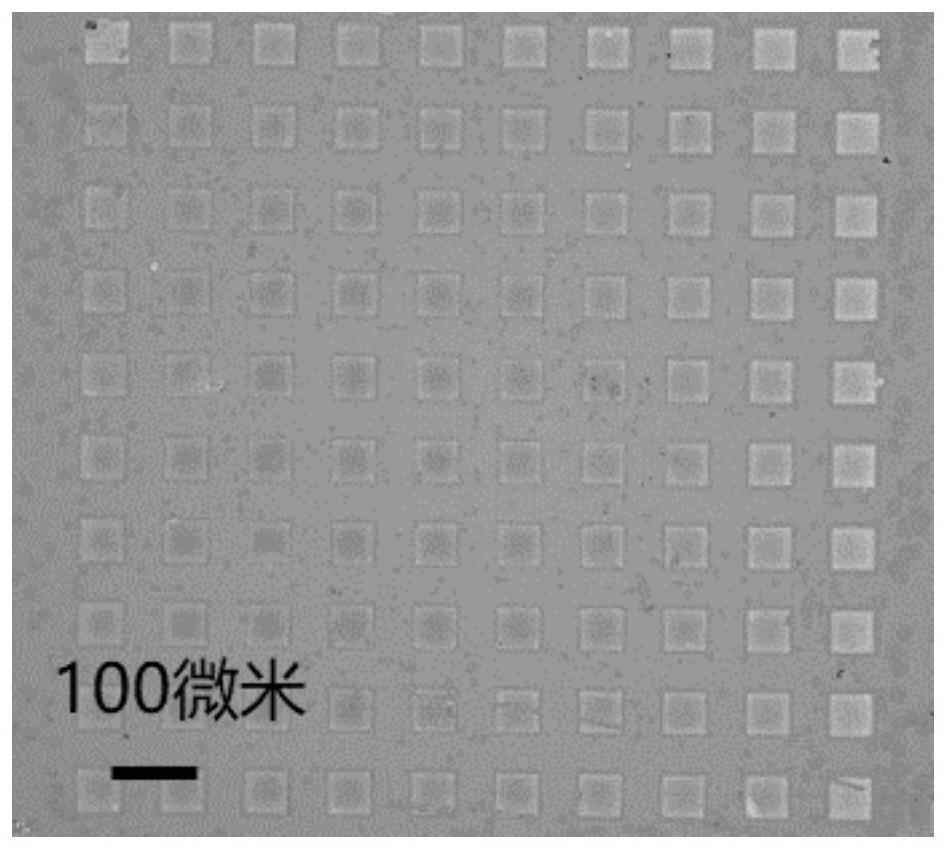

[0046] Cr / Au / Ag-WSe 2 / Au / Cr lateral devices: first on clean Si / SiO 2 5nm Ag is deposited on the surface of the substrate, and annealed at 350°C for 7min to form evenly distributed nanoparticles with a particle size of 20-40nm. Subsequently, Ag-WSe was prepared on the surface of Ag nanoparticles by chemical vapor deposition. 2 For heterojunction, tin powder and tungsten oxide are selected as the reaction source. With 2mm thick Si as the gate electrode, 300nm thick SiO 2 As the gate dielectric, expose the electrode area on the surface of the sample and deposit Cr / Au electrodes as source and drain electrodes to form a lateral device. A bias voltage of 0-10V is applied to the source and drain electrodes, and a rapid photoelectric response is obtained when light is applied with a wavelength range of 365-800nm, and the channel performance can be adjusted by applying a voltage of 0-60V to the gate. The device is placed in a single-pixel imaging system, and a light source with a ...

Embodiment 3

[0048] Cr / Au / Au-CsPbBr 3 / Au / Cr Lateral Devices: Preparation of Au-CsPbBr 3 heterojunction, first in clean Si / SiO 2 3nm Au is deposited on the surface of the substrate, and the rapid heating and cooling annealing process is realized by a moving slide tube furnace, and Si / SiO with 3nm Au is deposited 2 The substrate is annealed at 550° C. for 7 minutes to form uniformly distributed nanoparticles with a particle size of 20-40 nm. Preparation of Au-CsPbBr by Chemical Vapor Deposition 3 Sample, with Si as the gate electrode, SiO 2 As the gate dielectric, Cr / Au electrodes are deposited on the surface of the sample as source and drain electrodes to form a lateral device. A fast photoelectric response is obtained when the source and drain electrodes are applied with proper bias voltage and light, and the channel performance can be adjusted by applying a voltage on the gate. The device is placed in a single-pixel imaging system, and a light source with a certain wavelength is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com