Diaphragm, preparation method thereof and lithium ion power battery comprising diaphragm

A separator and coating technology, applied in the field of lithium-ion power batteries, can solve the problems of small power cells with little effect, affecting normal use, reducing the electrical performance of the cells, and reducing the probability of thermal runaway and low cost. , the effect of enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

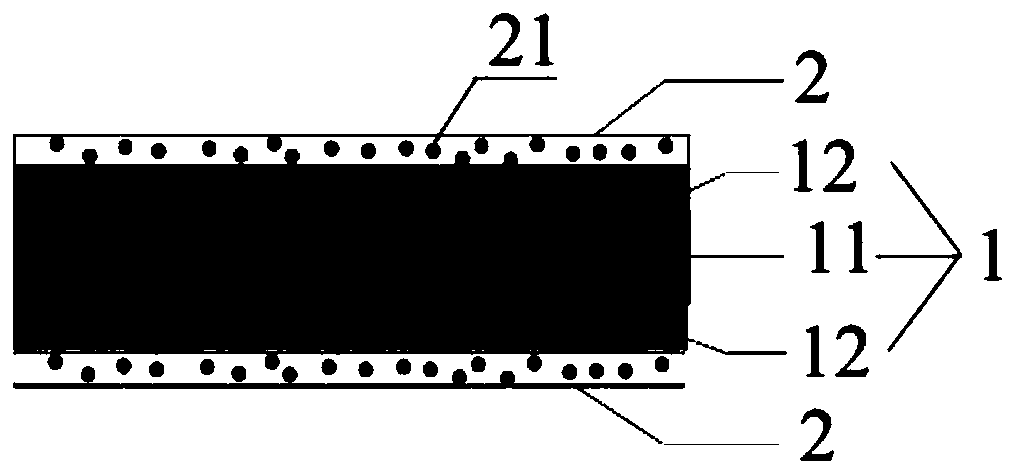

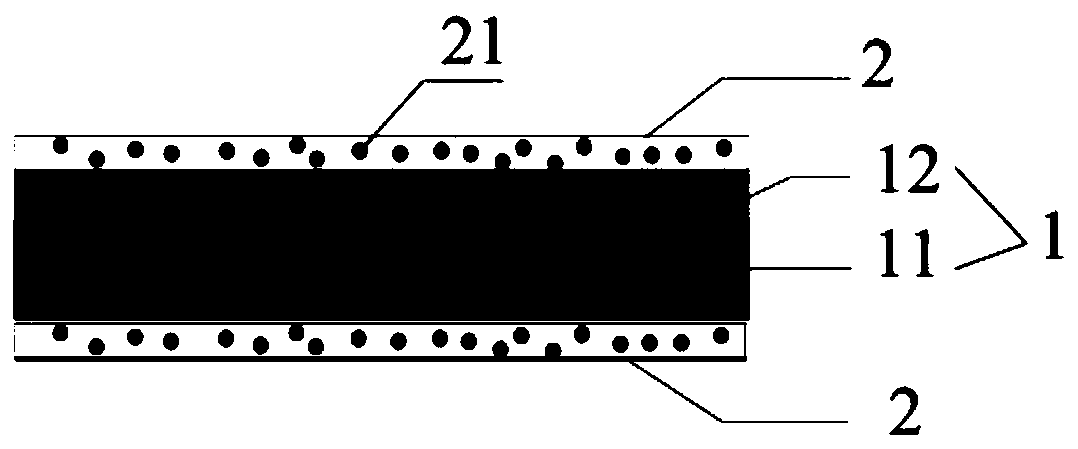

[0033] A diaphragm, comprising a diaphragm base layer 1 and a PVDF coating 2, the PVDF coating 2 is arranged on one or both sides of the diaphragm base layer 1, the PVDF coating 2 includes PVDF and nano copper powder 21, the Nano copper powder 21 is dispersed in PVDF.

[0034] Further, the particle size of the nano-copper powder 21 is 1-200nm, preferably, the particle size is 1-50nm, and the specific surface area is 10-300m 2 / g, preferably 10-70m 2 / g.

[0035] Further, the thickness of the single side coating of the PVDF coating 2 is 1-3 μm.

[0036] Further, the mass of the nano-copper powder 21 accounts for 0.09%-5% of the mass of the PVDF coating 2 . The nano-copper powder 21 dispersed in PVDF forms a heat conduction network in the PVDF coating 2, as shown figure 1 and figure 2 The diaphragm structure shown in the figure can quickly transfer heat from the inside of the cell to the surface of the cell for heat dissipation.

[0037] Further, the diaphragm base layer ...

specific Embodiment approach 2

[0046] A method for preparing the diaphragm described in Embodiment 1, comprising the following steps:

[0047] S1. Add nano-copper powder 21 to absolute ethanol, ultrasonically 10-30min, fully wet, form mixture I, add dispersant to mixture I, and continue ultrasonicating for 20-90min, disperse evenly, and form suspended and stable nano copper powder dispersion;

[0048] S2. Add the nano-copper powder dispersion into the evenly stirred and dispersed PVDF solution, and use a stirrer to stir at a speed of 200-1000r / min for 30-60min, and disperse evenly to obtain a mixture II;

[0049]S3. Coating the mixture II on one or both sides of the base layer 1 of the diaphragm, drying in vacuum, the vacuum degree is 0.01Mpa-0.04Mpa, the drying temperature is 70-90°C, the drying time is 8h-12h, and the surface coating is obtained. The diaphragm base layer 1 coated with the PVDF coating 2, ie the diaphragm.

[0050] Further, in step S1, the solid content of the nano-copper powder dispersi...

specific Embodiment approach 3

[0054] A lithium-ion power battery, comprising the separator described in Embodiment 1 or the separator prepared by the method described in Embodiment 2, and the electrode sheet of the separator and the positive electrode ternary material / lithium iron phosphate material and the negative electrode graphite material Lamination, encapsulation, liquid injection, formation, secondary sealing, sorting and other processes are carried out to produce lithium-ion power batteries with high safety.

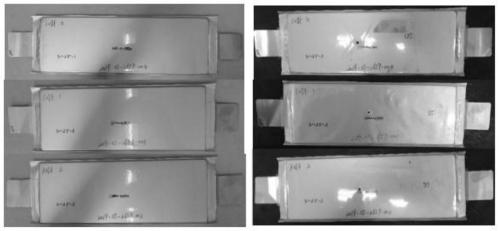

[0055] In order to verify the safety and practicability of the diaphragm, the examples all take 11A3W8-40Ah power type lithium ion power cell as the object, the positive electrode material is NCM ternary material, the negative electrode is graphite, and the electrolyte is conventional lithium ion electrolyte . The surface density of this power type cell is low, the internal resistance is small, and the heat generated instantaneously when the internal short circuit occurs during the acupunctur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com