Antistatic wear-resistant floor coating and preparation method thereof

A floor coating and anti-static technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow response and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

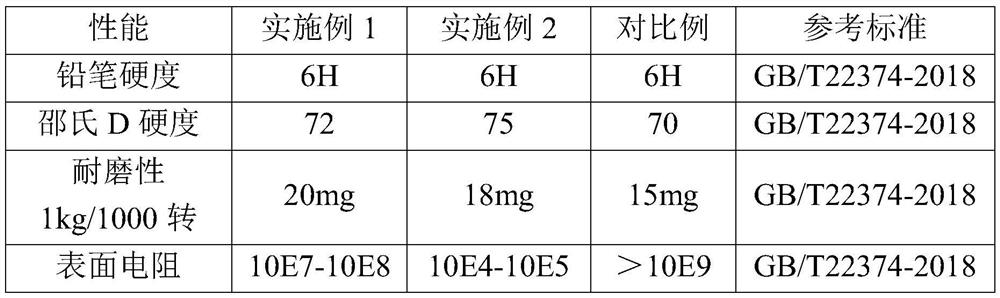

Examples

Embodiment 1

[0028] A component:

[0029] 30 parts of grease polyol, 18 parts of conductive mica powder, 25 parts of silicon micropowder, 2 parts of dispersant, 0.5 part of defoamer, 0.2 part of wetting agent, 0.3 part of leveling agent, 5 parts of zeolite powder, 15 parts of pigment, poly 4 parts of tetrafluoroethylene wax powder; among them, the oil polyol needs to be dehydrated under vacuum at high temperature, the temperature is 120°C, the vacuum degree is ≥0.1, and the dehydration is 4 hours. The conductive materials, fillers, and pigments need to be dehydrated at 130°C for 3 hours. Stir the above raw materials evenly and then seal and package to obtain component A;

[0030] Component B: 5 parts of oil polyol, 95 parts of polyisocyanate, dehydrate the oil polyol in a vacuum degree ≥ 0.1, 120°C for 5 hours, and cool it for use. Add isocyanate according to the proportion of the formula, stir and heat up, and react at 80°C for 2 hours. During the reaction, dry nitrogen is introduced. Af...

Embodiment 2

[0034] A component:

[0035] 30 parts of grease polyol, 18 parts of conductive mica powder, 1 part of single-walled carbon nanotube, 24 parts of silicon micropowder, 2 parts of dispersant, 0.5 part of defoamer, 0.2 part of wetting agent, 0.3 part of leveling agent, zeolite powder 5 parts, 15 parts of pigment, 4 parts of polytetrafluoroethylene wax powder; among them, the oil polyol needs to be dehydrated under vacuum at high temperature, the temperature is 120 ° C, the vacuum degree is ≥ 0.1, and the dehydration is 4 hours. Conductive materials, fillers, and pigments need to be dehydrated at 130 ° C. Bake at high temperature for 3 hours to dehydrate, stir the above raw materials evenly, seal and pack to obtain component A;

[0036] Component B: 5 parts of oil polyol, 95 parts of polyisocyanate, dehydrate the oil polyol in a vacuum degree ≥ 0.1, 120°C for 5 hours, and cool it for use. Add isocyanate according to the proportion of the formula, stir and heat up, and react at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com