A kind of aluminum-plastic film and its preparation method and drop-proof lithium battery

A lithium battery and aluminum-plastic film technology, applied in the field of drop-proof lithium batteries, can solve the problems of easy impact and cracking at the corners, folding of the pole piece and diaphragm of the internal battery cell, and short-circuit fire, etc., to reduce folding and avoid Effect of deformation, good cushioning and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

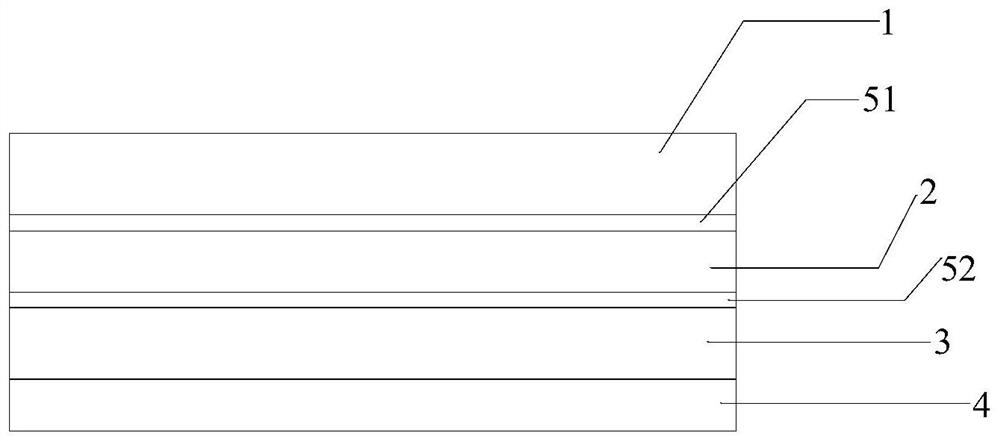

[0022] figure 1 It is a schematic diagram of an aluminum-plastic film according to an embodiment of the present invention. Such as figure 1 As shown, the aluminum-plastic film includes adjacent aluminum-plastic film substrates and polymer layers, and the aluminum-plastic film substrate includes successively adjacent external resistance layers 1, the first adhesive bonding external resistance layer 1 and aluminum intermediate layer 2 Layer 51, aluminum intermediate layer 2, second adhesive layer 52 for bonding aluminum intermediate layer 2 and inner layer 3, inner layer 3, and polymer layer 4; wherein, the outer resistance layer 1 is a PET film with a thickness of 25 μm, and the first The adhesive layer 51 and the second adhesive layer 52 are polyurethane adhesives, the aluminum intermediate layer 2 is an aluminum foil with a thickness of 40 μm, the inner layer 3 is a cast polypropylene film with a thickness of 40 μm, and the polymer layer 4 is polymethacrylate Ester film.

...

Embodiment 2

[0038] An aluminum-plastic film, the difference from Example 1 is that the material of the polymer layer is polyethyl methacrylate film.

Embodiment 3

[0040] An aluminum-plastic film, the difference from Example 1 is that the material of the polymer layer is polypropylmethacrylate film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com