High voltage insulator coating composition and preparation and application thereof

An insulator and high-voltage technology, applied in the direction of coating, etc., can solve the problems of high leakage and poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

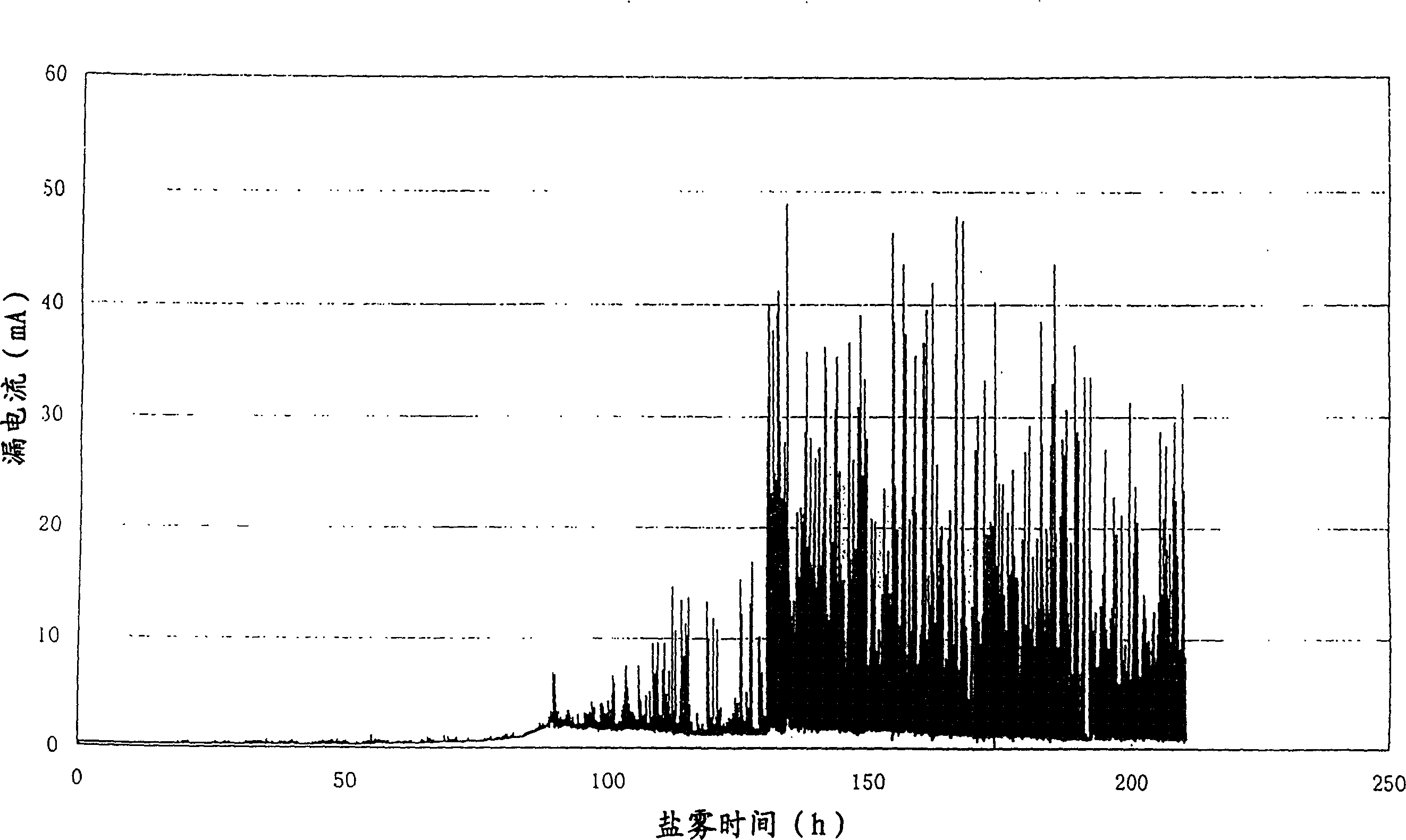

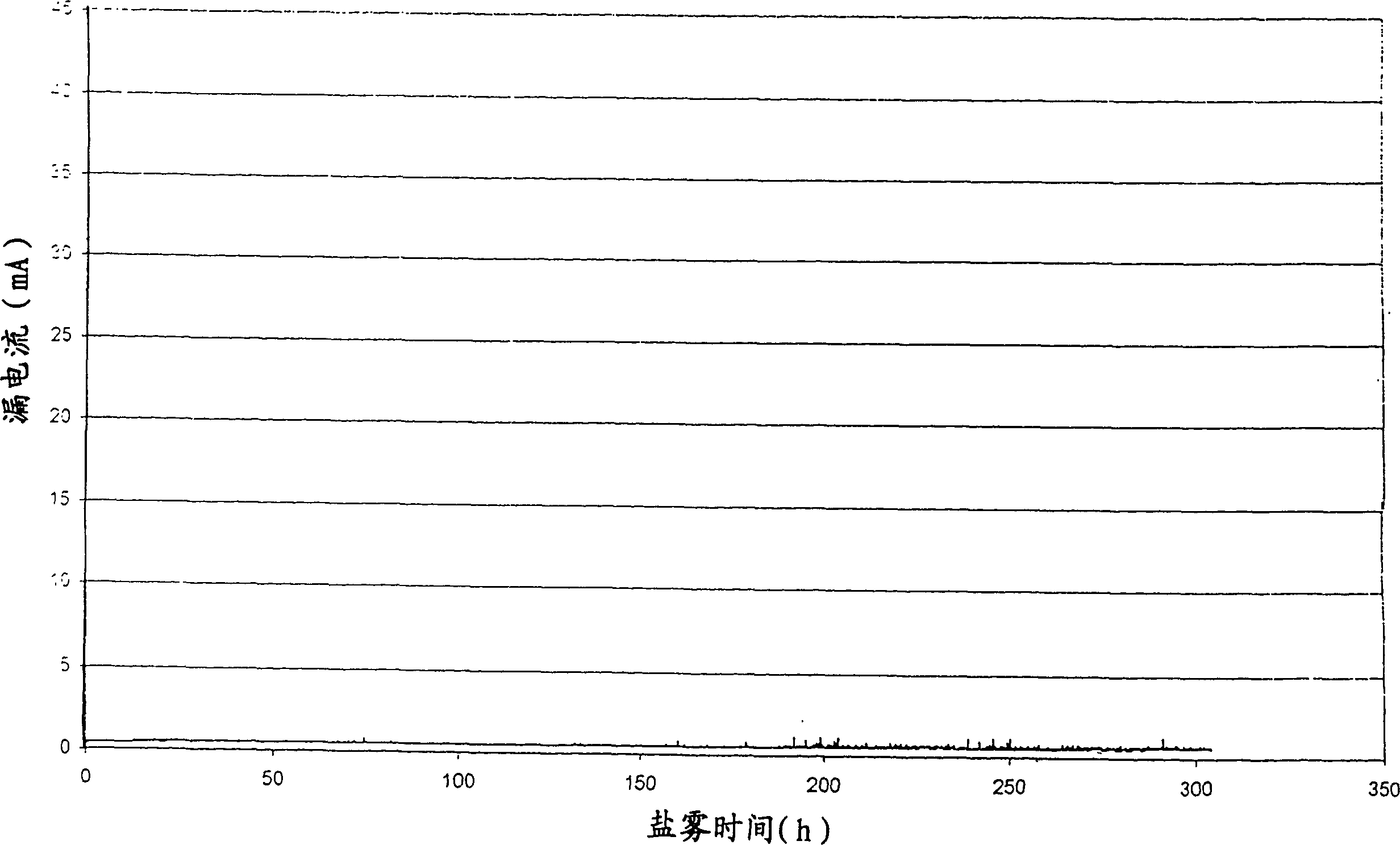

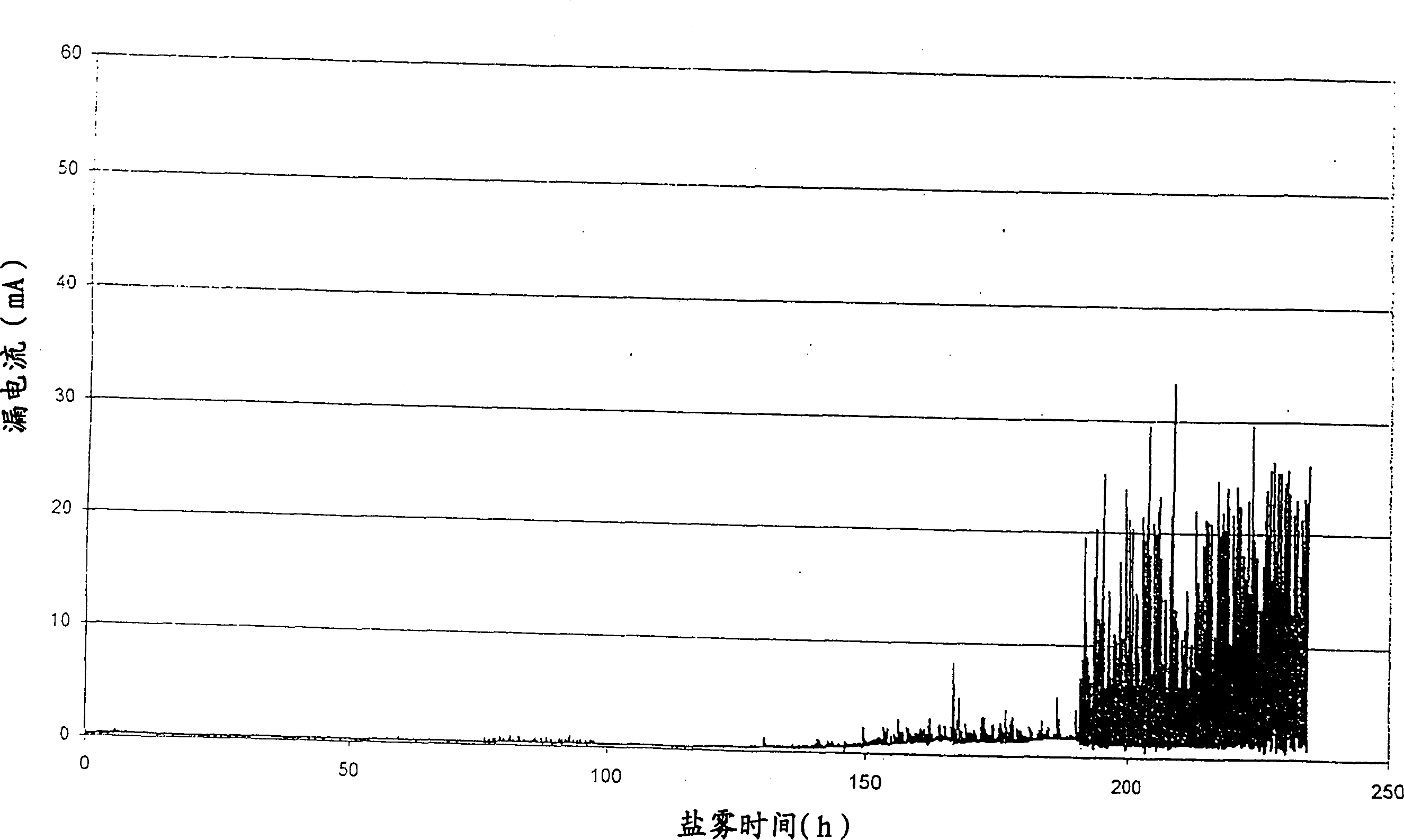

[0029] See Figure 4- Image 6 As shown, first, the relationship between the particle size of the experimental filler and the leakage current. Suspend the ceramic insulator in the salt spray test chamber and apply 10KV (400V / cm) energy. The salt spray comes from vaporized salt water, and its conductivity is 250μS / cm. The leakage current is monitored by the data collection system.

[0030] refer to Figure 5 As shown, it is a diagram of the variation of the ceramic surface leakage and the particle size of the three-water bauxite filler. The insulator is suspended on the surface of the ceramic insulator coating by passing through the above-mentioned 400V / cm under the filler with different average sizes varying from 1-13μm. The relationship between the time required for leakage current to occur and the average particle size of the bauxite trihydrate filler;

[0031] The particle size of SU-101 is 4.5μm, and its leakage time will occur within 100 hours;

[0032] The particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com