Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

376results about How to "Easy to use in production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

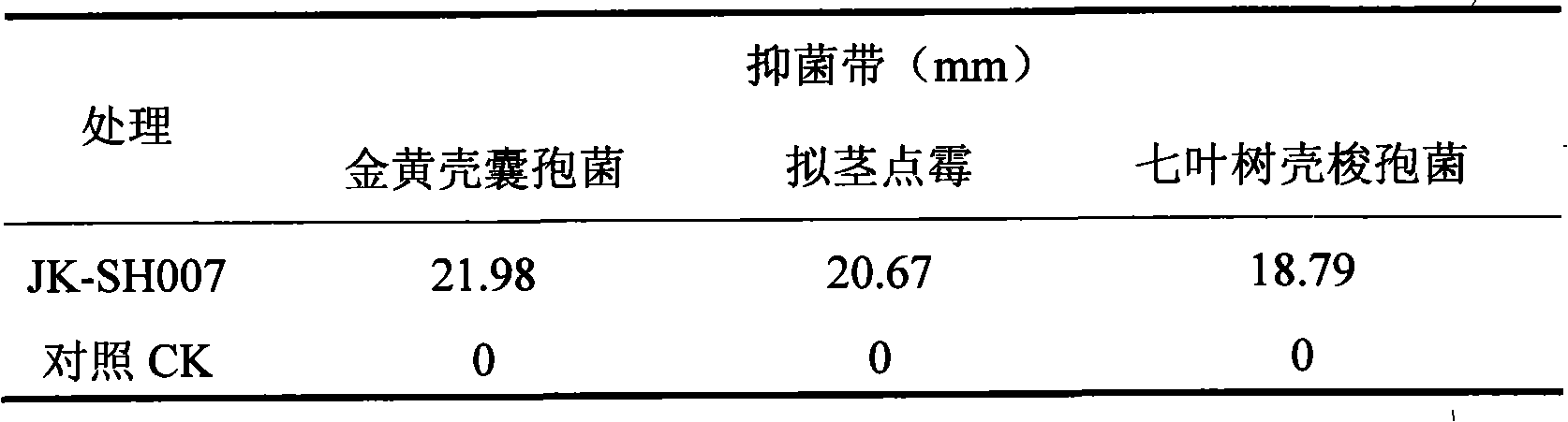

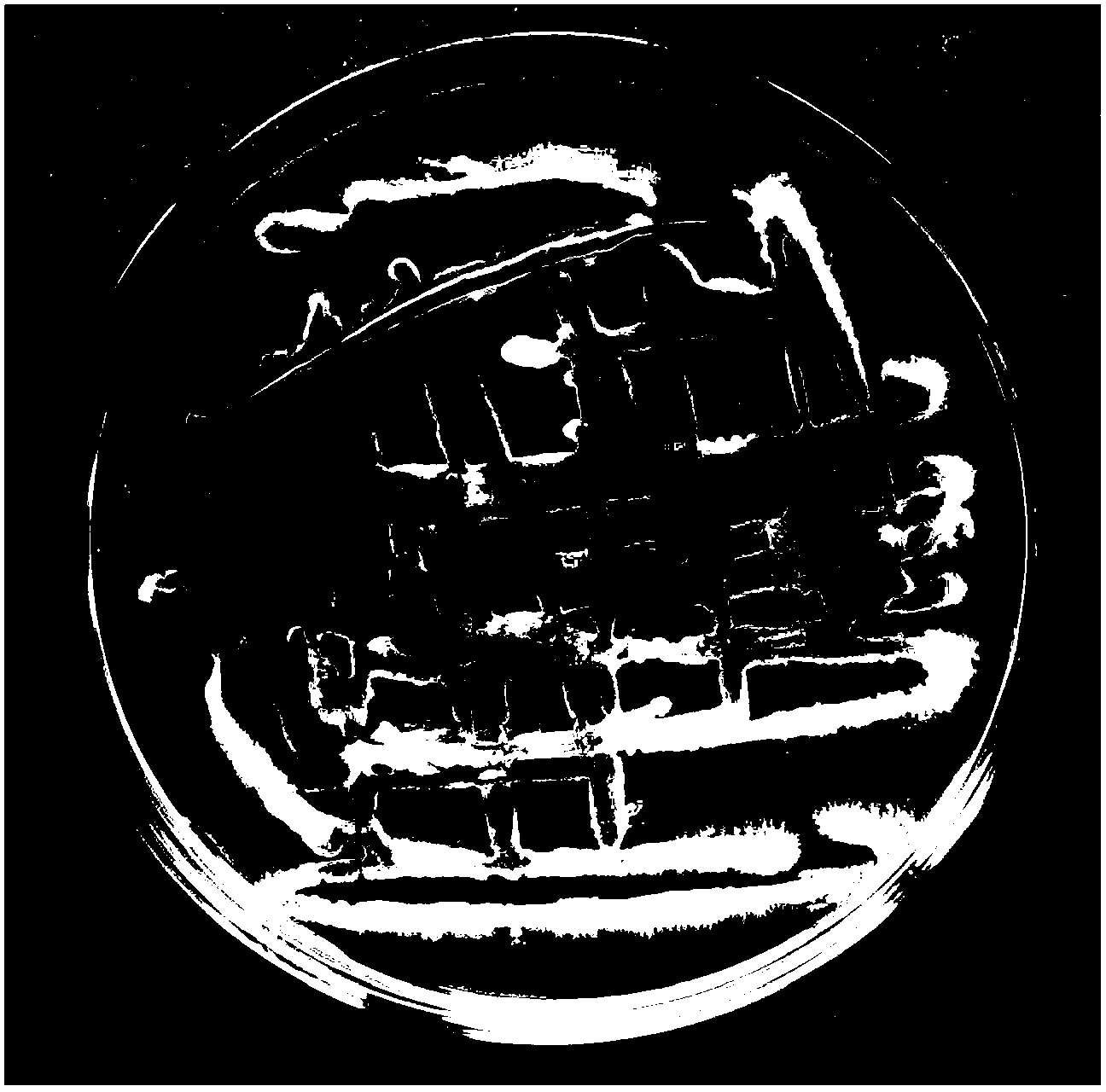

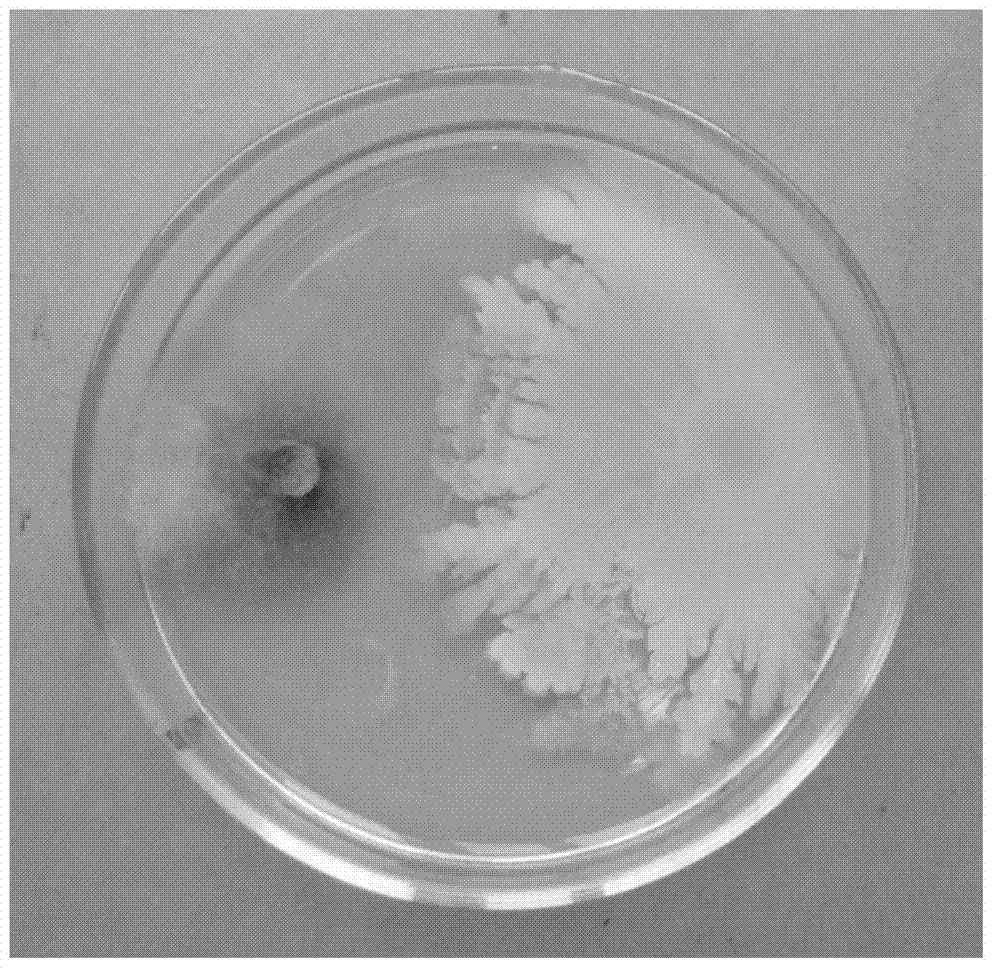

Burkholderia pyrrocinia and application thereof in control of dothiorella gregaria

ActiveCN101555458ARapid identificationAccurate identificationBiocidePlant growth regulatorsFungal endophyteMicrobiology

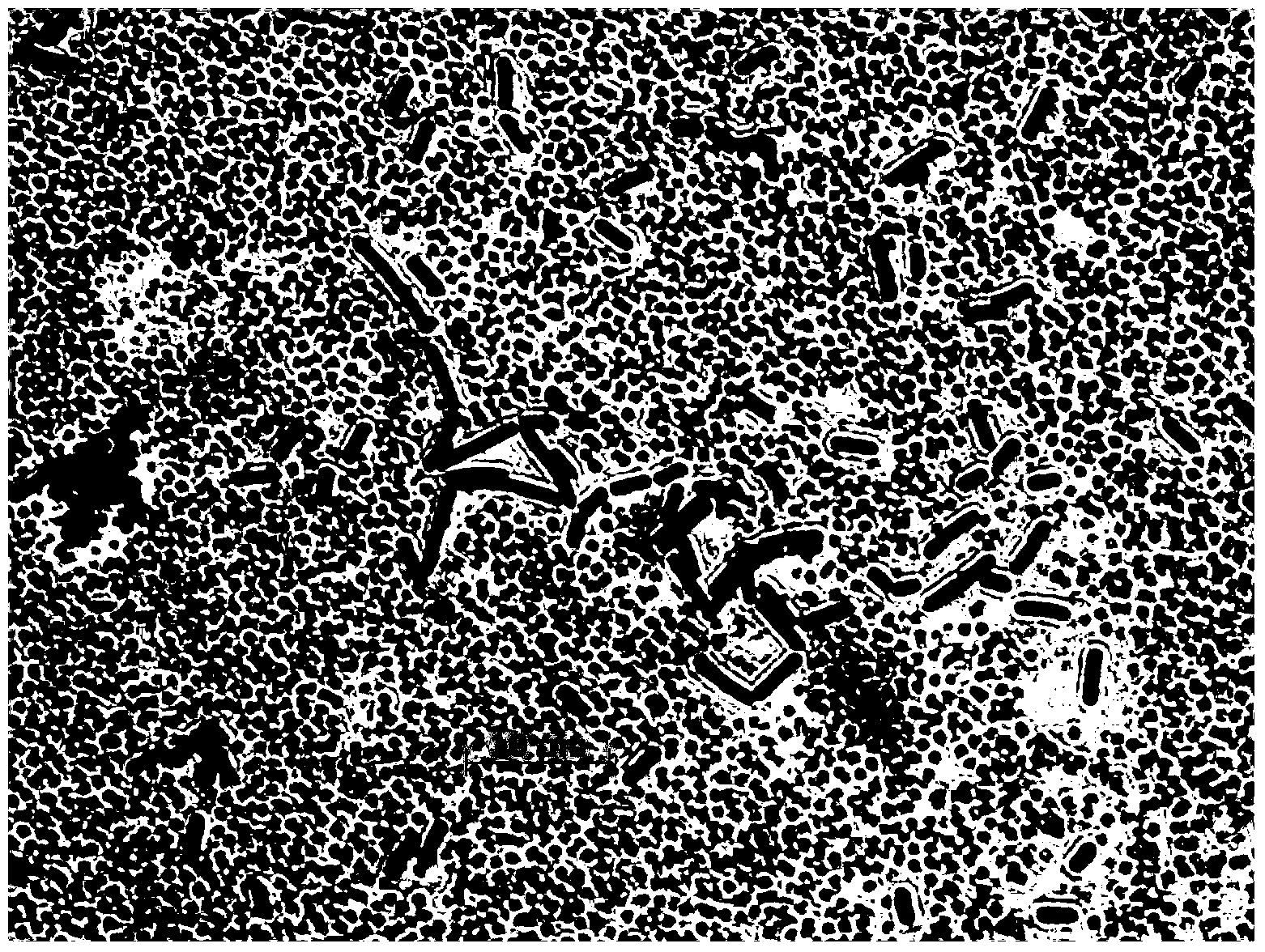

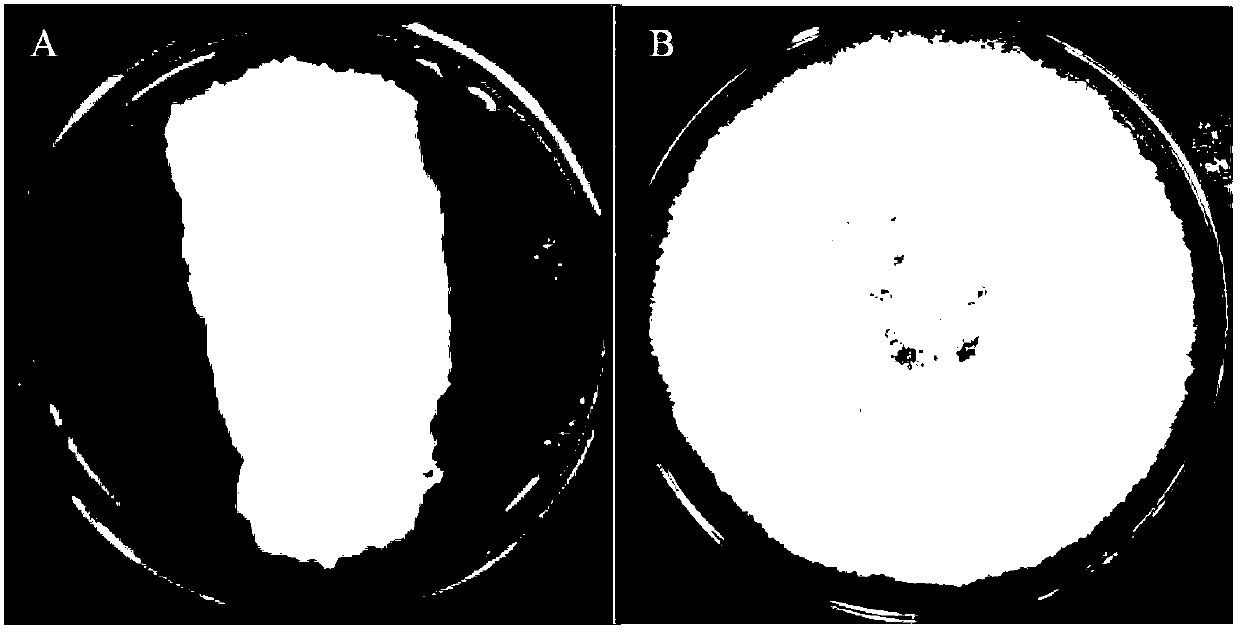

The invention discloses a burkholderia pyrrocinia JK-SH007 which is classified and named as burkholderia pyrrocinia and preserved in China center for type culture collection (CCTCC) with the preservation number of M 209028 and the preservation date of February 18th, 2009. The invention also discloses the application of the burkholderia pyrrocinia in controlling dothiorella gregaria and promoting poplar to grow. The invention further provides a bactericide for controlling dothiorella gregaria, which is obtained by inoculating the JK-SH007 in a culture medium to be fermented and cultured. The JK-SH007 is plant endophyte which has strong inhibiting effect for botryosphaeria dothidea of the poplar and antagonism for various pathogenic fungis, and has the advantages of simple culture condition, easy storage and commercial process as well as good developing and applying prospect.

Owner:NANJING FORESTRY UNIV

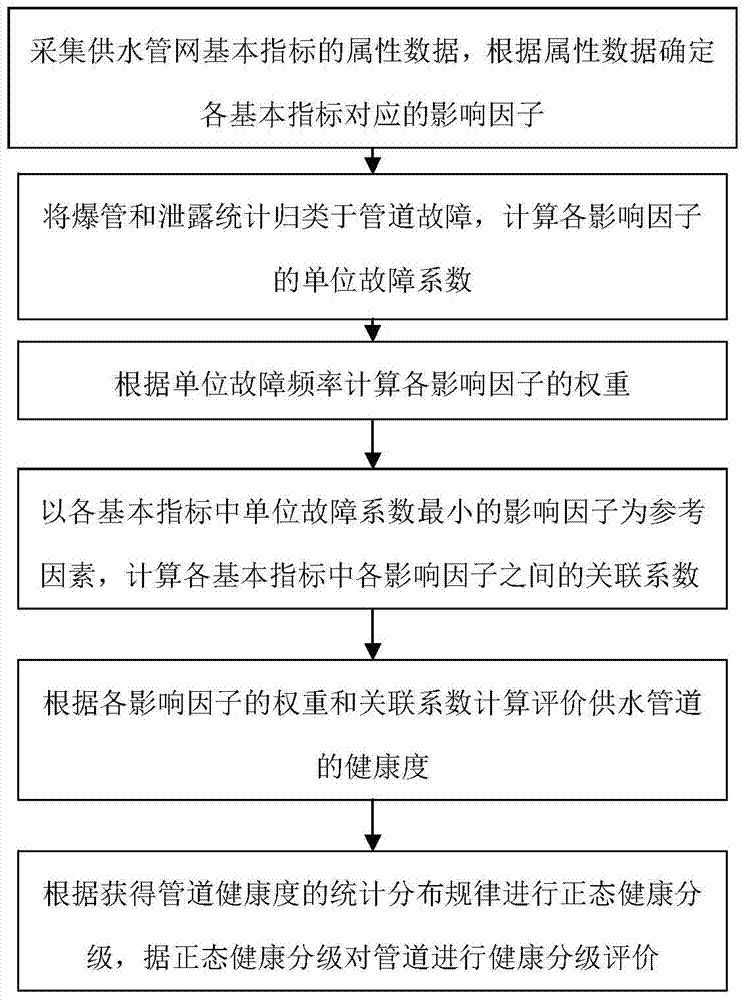

Method for evaluating health of water supply pipelines

InactiveCN103578045AEvaluation results are intuitiveEasy to use in productionData processing applicationsCorrelation coefficientEngineering

The invention relates to the field of water supply pipelines, in particular to a method for evaluating the health of water supply pipelines. The method particularly includes the steps that data of primary attributes of basic indexes of a water supply pipe network are acquired, and impact factors corresponding to the basic indexes are determined according to the data of the attributes; pipe explosion and leakage are ranked to pipeline failures in a statistical mode, and unit failure coefficients of the impact factors are calculated; weights of the impact factors are calculated according to unit failure frequency; the impact factor with the minimum unit failure coefficient in the basic indexes is used as a reference factor, and the correlation coefficients between the impact factors in the basic indexes are calculated; the health degrees of the water supply pipelines are calculated and evaluated according to the weights of the impact factors and the correlation coefficients; health classification is conducted according to the evaluated health degrees of the water supply pipelines, and the health states of the pipelines to be evaluated are evaluated according to the health classification. The evaluation result is visual, universality is good, and production and application are easy to conduct.

Owner:GUANGDONG UNIV OF TECH

Pipeline water quality risk evaluation method based on water supply network dynamic model

InactiveCN106600094AGuaranteed accuracySolve the evaluation problem of water quality riskGeneral water supply conservationResourcesWater supply networkEngineering

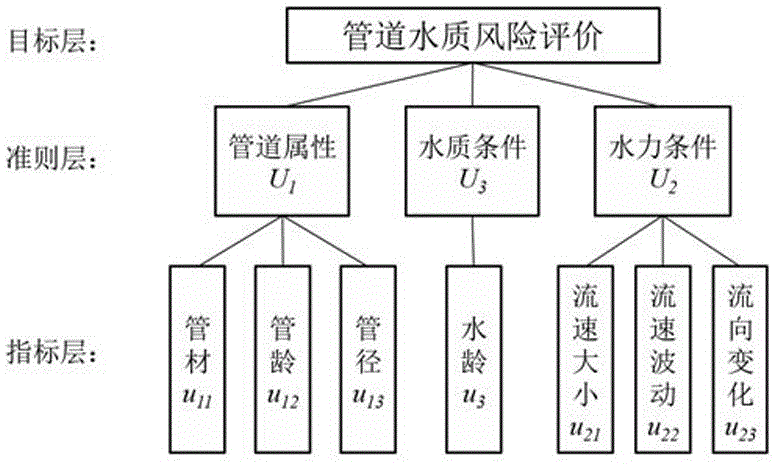

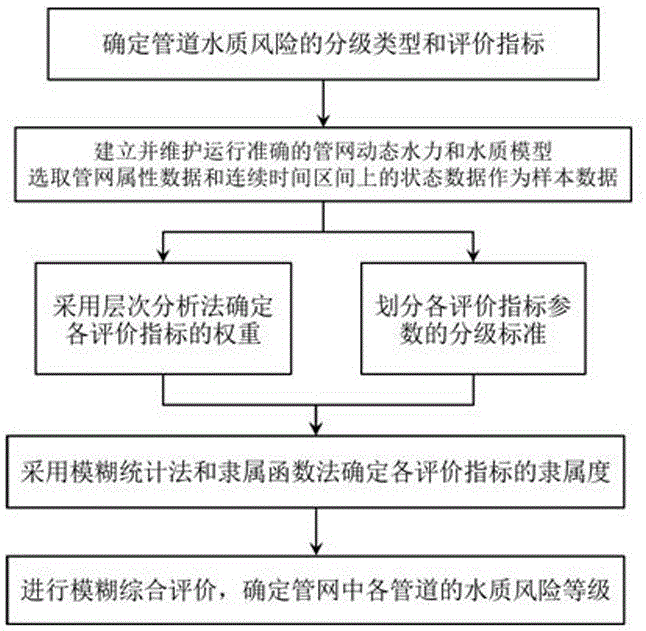

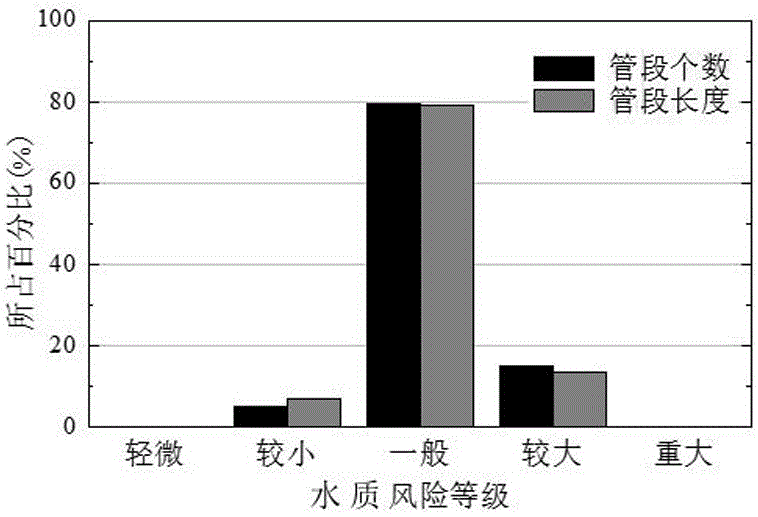

The present invention discloses a pipeline water quality risk evaluation method based on a water supply network dynamic model. Establishing a water supply network dynamic waterpower and water quality model and performing accurate checking of the water supply network dynamic waterpower and water quality model through determination of the classification type and the evaluation indexes of the pipeline water quality risk; determining the weight of each evaluation index through adoption of the analytic hierarchy process; and dividing the grading standard of each evaluation index parameters based on the state data samples of the pipe network dynamic model, determining the degree of membership of each evaluation index, performing the fuzzy comprehensive evaluation, and determining the grade of the water quality risk of each pipeline in the pipe network. Though the steps mentioned above, all the pipelines of the whole water supply network are subjected to water quality risk evaluation, and the comparison and the ordering are performed according to the evaluation result to determine risk degree ordering of water quality changing and provide decision support for the management and maintenance of the pipe network; and moreover, the pipeline water quality risk evaluation method based on the water supply network dynamic model overcomes the defects that other evaluation methods are simple in index and do not take incomprehensive consideration, and the evaluation result is more reliable to ensure the accuracy and the life cycle of the evaluation.

Owner:GUANGZHOU JINGWEI INTELLIGENT TECH

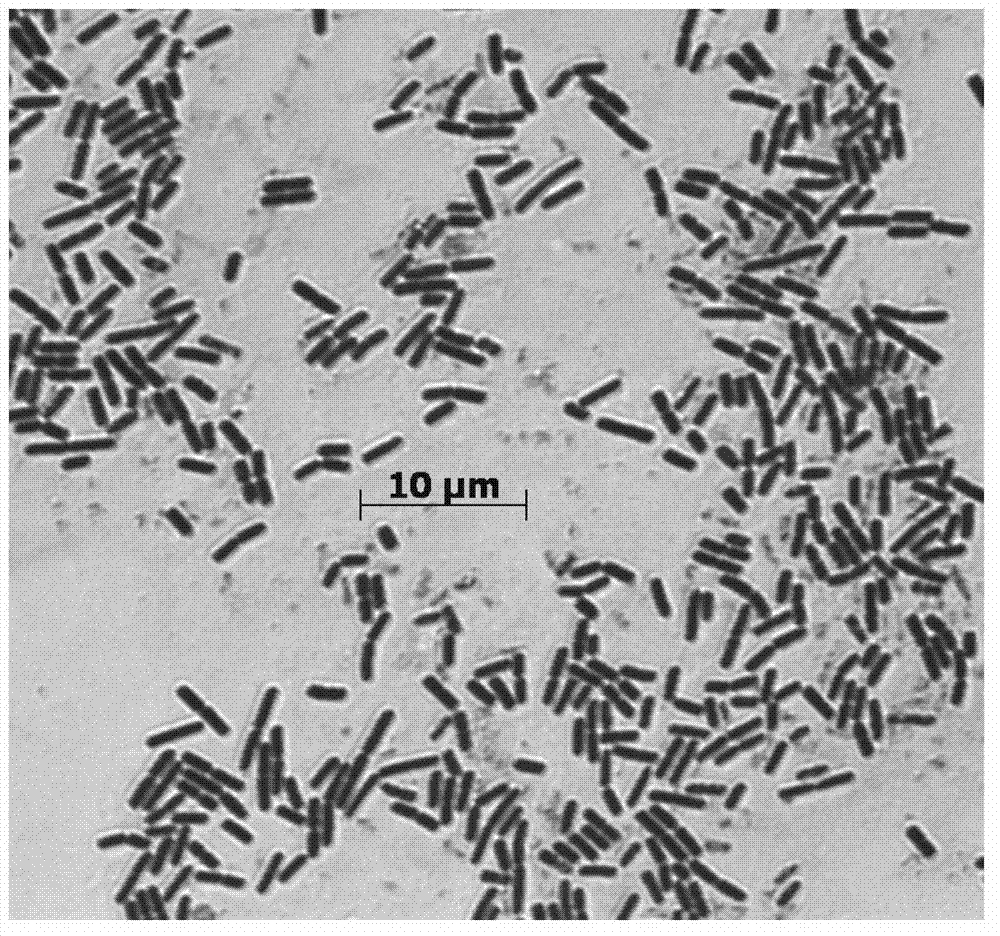

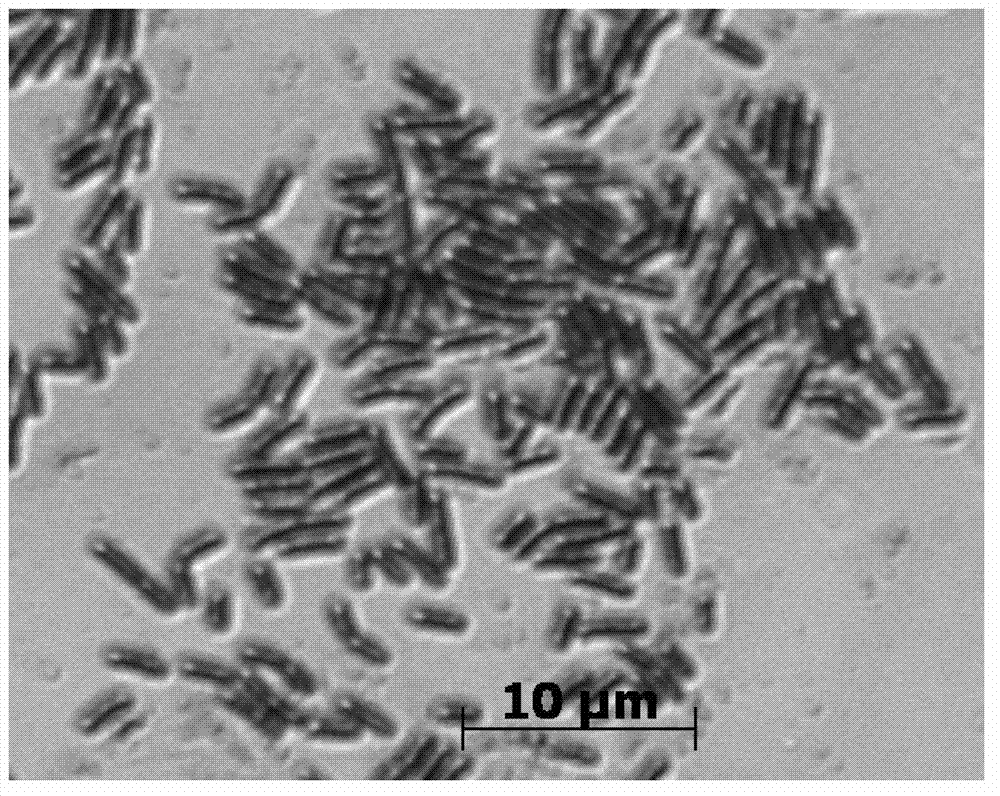

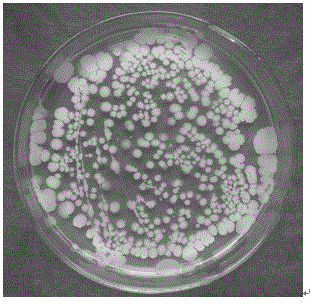

Bacillus pumilus and application in preventing and treating dothiorella gregaria

ActiveCN101643711ASimple cultivation conditionsEasy to storeBiocidePlant growth regulatorsBacillus pumilusFungal endophyte

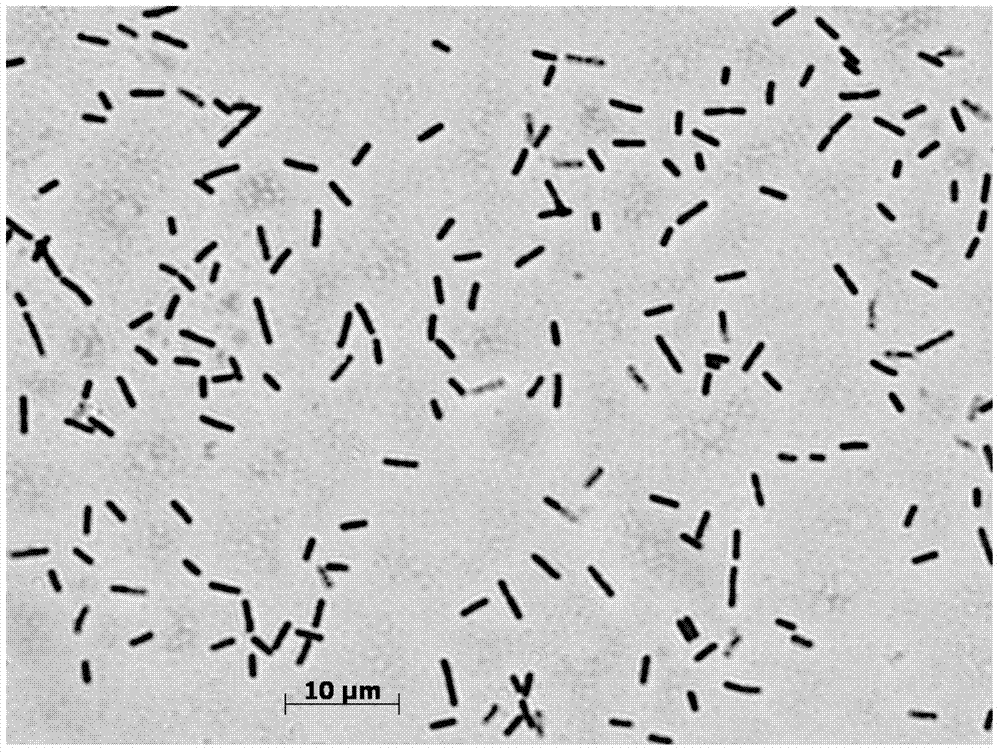

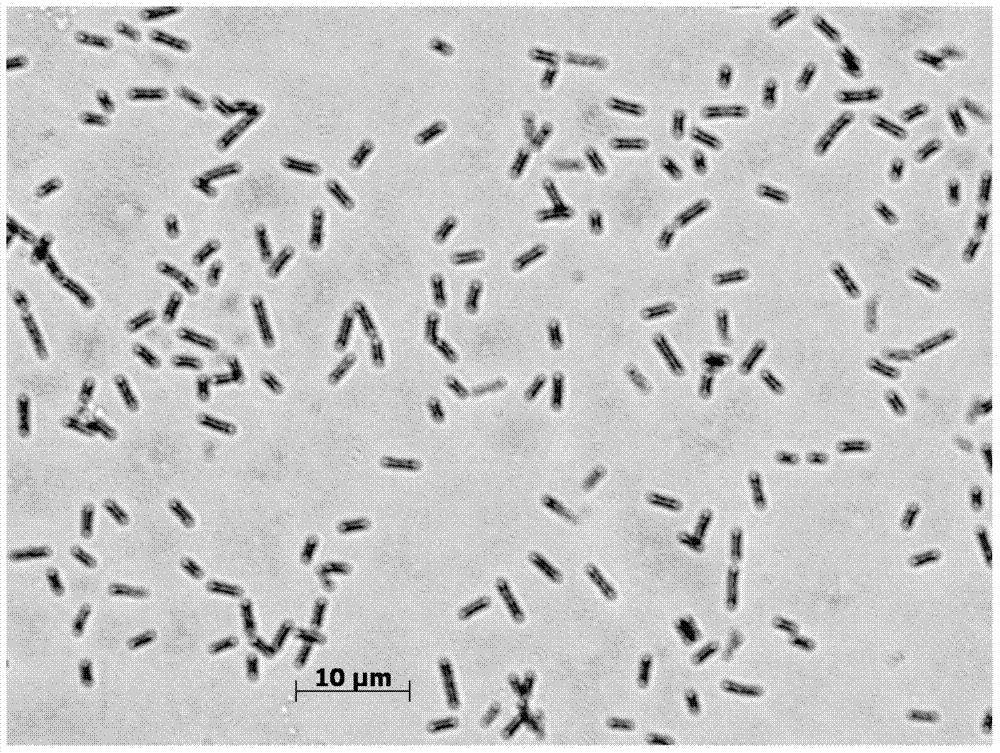

The invention discloses a bacillus pumilus JK-SX001 which is classified and named bacillus pumilus and collected in a China center for type culture collection (CCTCC) and has the collection number ofM 209026 on February 18th, 2009. The invention also discloses applications of the bacillus pumilus in preventing and treating dothiorella gregaria and promoting the growth of a poplar. The invention also provides a bactericide for preventing and treating the dothiorella gregaria, which is obtained by vaccinating the JK-SX001 in a culture medium to ferment and culture. The JK-SX001 is a plant endophyte, has obvious inhibiting effect on dothiorella gregaria, simple culture condition, easy storage and favorable development and application prospect and is easy for industrialized production.

Owner:NANJING FORESTRY UNIV

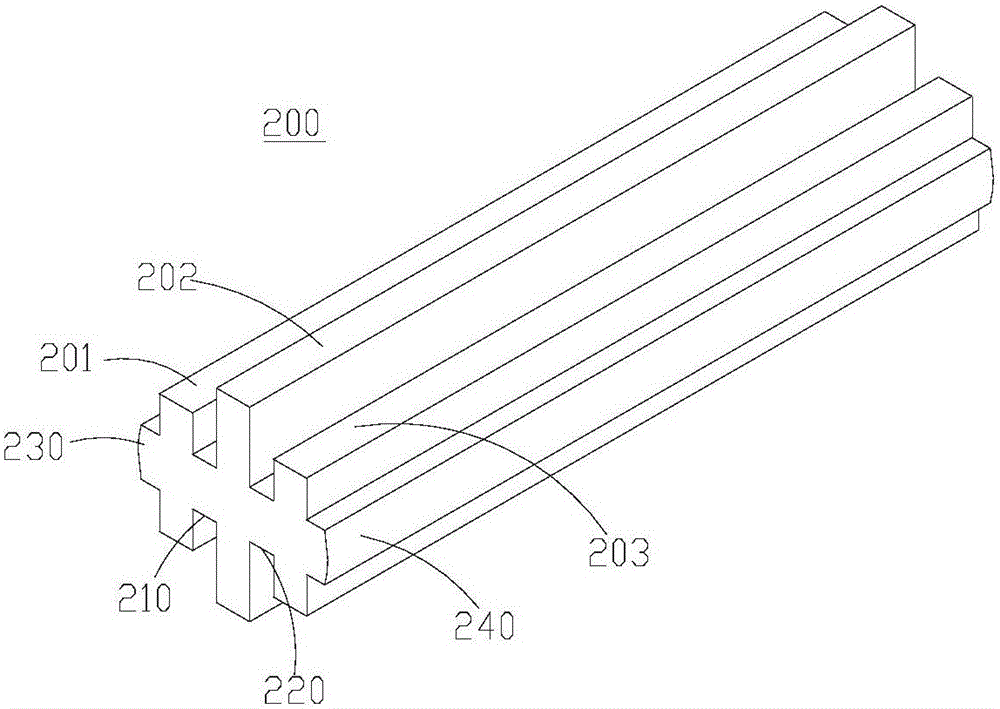

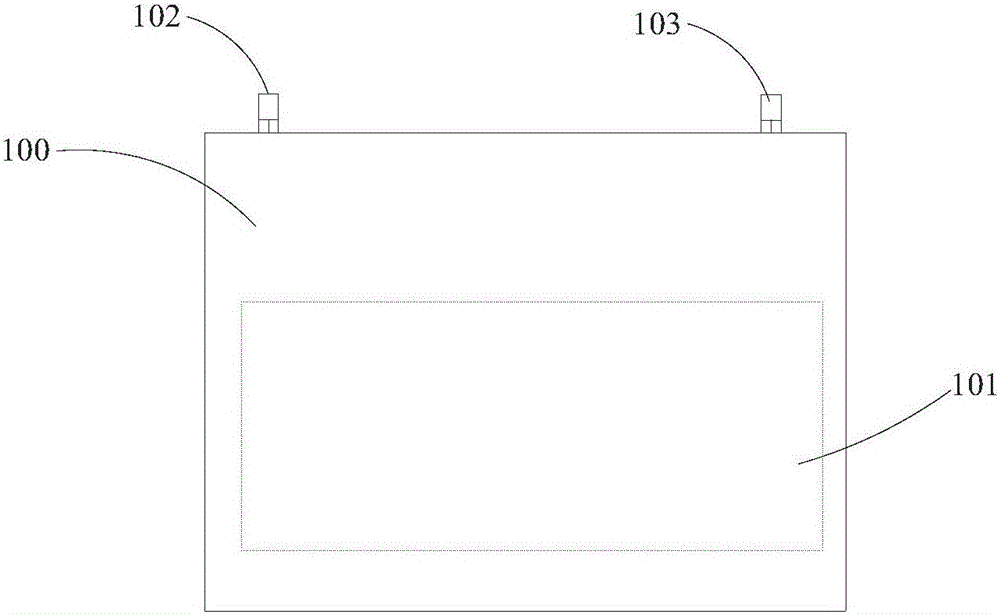

Thermal management device and power source device

InactiveCN105789733ATo achieve the purpose of heat dissipationReduce thermal resistanceSecondary cellsLiquid storage tankEngineering

The invention provides a thermal management device and a power source device, and relates to the technical field of battery thermal management. The thermal management device specifically comprises a liquid cooling plate and at least one heat conduction fin, wherein a liquid storage tank is arranged inside the liquid cooling plate, a liquid inlet and a liquid outlet are formed in the outside wall of the liquid cooling plate, the liquid inlet and the liquid outlet are communicated with the liquid storage tank, the liquid cooling plate is arranged on one side of a battery module, one end of each heat conduction fin is connected with the liquid cooling plate, and the other end of each heat conduction fin extends into the battery module and is placed in a gap between adjacent single batteries. Compared with the traditional heating and radiating device, the thermal management device greatly reduces thermal resistance between the liquid cooling plate and the battery module, and thermal conductivity is significantly increased.

Owner:HUATING HEFEI POWER TECH

Metal mining area contaminated soil remediation agent capable of improving plant growth

InactiveCN106811204AEasy to use in productionReduce manufacturing costOrganic fertilisersSoil conditioning compositionsIonContaminated soils

The invention discloses a metal mining area contaminated soil remediation agent capable of improving plant growth. The remediation agent is prepared from the following six ingredients of mineral humic acid, attapulgite, coal ash, polyglutamic acid, ground phosphate rock and microorganism organic fertilizer. When the remediation agent is utilized to process contaminated soil, the remediation agent and the mining area contaminated soil are fully mixed according to the weight ratio of (1 to 2) : 1000, then appropriate water is added to wet, and plants are cultivated after the remediation agent and the mining area contaminated soil are fully mixed. The soil remediation agent can fix heavy metal ions in soil through heavy metal adsorption property of the mining humic acid, the attapulgite and the coal ash and a chelating effect of the polyglutamic acid and can prevent the heavy metal ions from migrating through leaching and runoff. On one hand, the humic acid, the ground phosphate rock and the microorganism organic fertilizer are utilized to regulate absorption of plants to soil heavy metal to improve moisture and fertilizer retention property of soil. According to the metal mining area contaminated soil remediation agent disclosed by the invention, a lot of mineral materials are chosen and matched, so that product cost is low; the metal mining area contaminated soil remediation agent can improve survival, growth and development of mining area plants in a dry condition and especially is suitable for quick greening and restoring engineering of high-concentration heavy metal polluted soil with an obvious toxic effect on plants.

Owner:北京威业源生物科技有限公司

Bacillus amyloliquefaciens subsp. plantarum and application thereof

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Method for constructing fixed-point integrated exogenous DNA transgenic pigs

ActiveCN108285906AEasy to use in productionEasy to breedVector-based foreign material introductionAnimal husbandryExogenous DNAHigh activity

The invention discloses a method for constructing fixed-point integrated exogenous DNA transgenic pigs. The method comprises the following steps: S1, performing safety target screening and target binding gRNA cleavage efficiency verification; S2, constructing a homologous arm donor plasmid and obtaining a fixed-point integrated transgenic cell line; S3, constructing the fixed-point integrated exogenous DNA transgenic pigs. The method disclosed by the invention has the benefits that a gRNA target sequence is introduced in the donor plasmid, the donor plasmid is linearized while a Cas9 nucleasecleavage target gene is induced by utilizing intracellular transcription gRNA, the test steps are significantly simplified, the labor is saved, and the co-transfection efficiency is favorably improved; carriers used for the fixed-point integration are less, a homologous arm is moderate in size, and the transgenic cell line is more favorably obtained; an efficient site-directed integration technology, a high-activity site-specific transgenic cell culture technology and a somatic cell cloning technology are combined, so that the efficient preparation of fixed-point integrated transgenic animalsis facilitated, and the breeding speed of new transgenic animal varieties is accelerated.

Owner:WENS FOOD GRP CO LTD +1

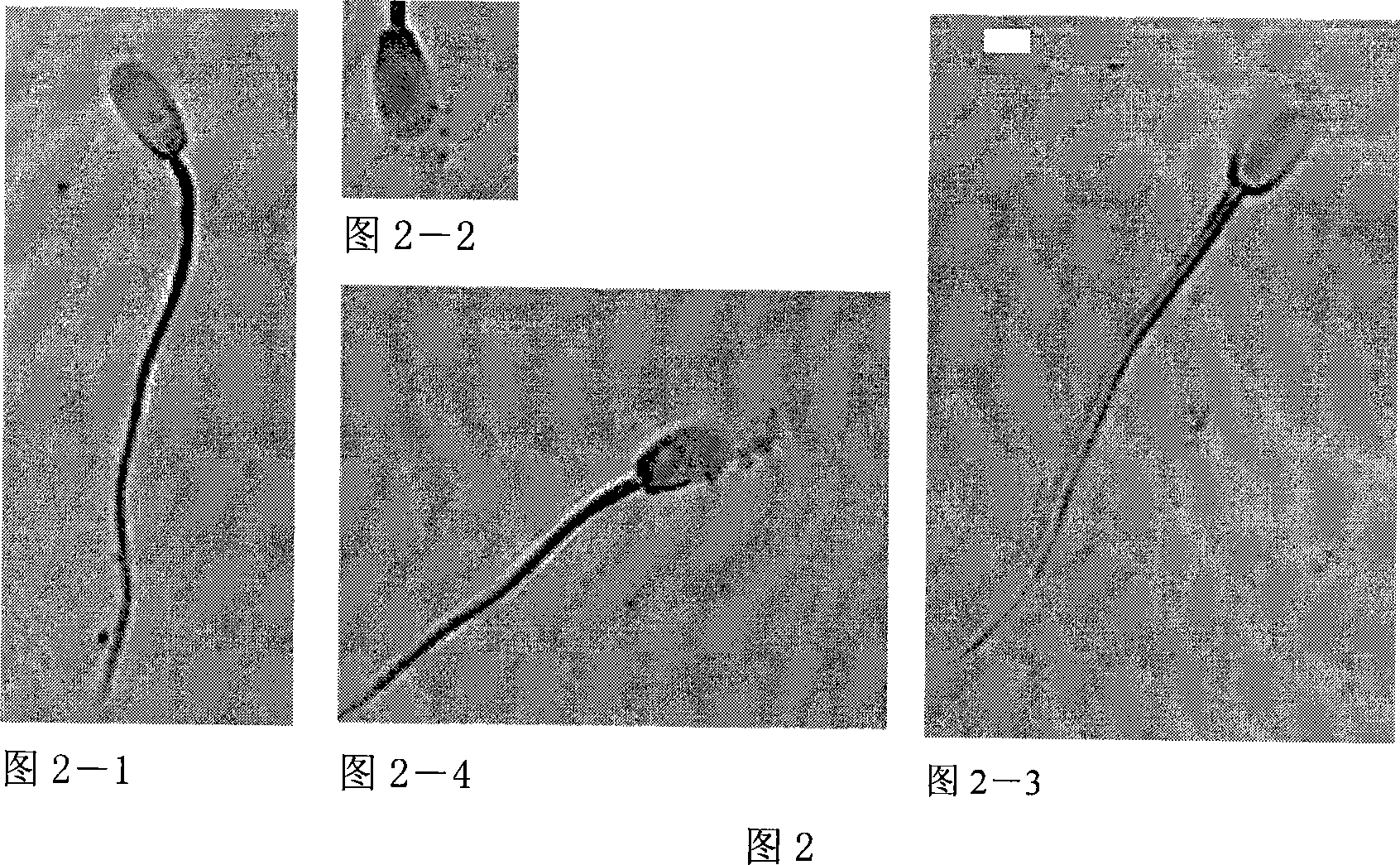

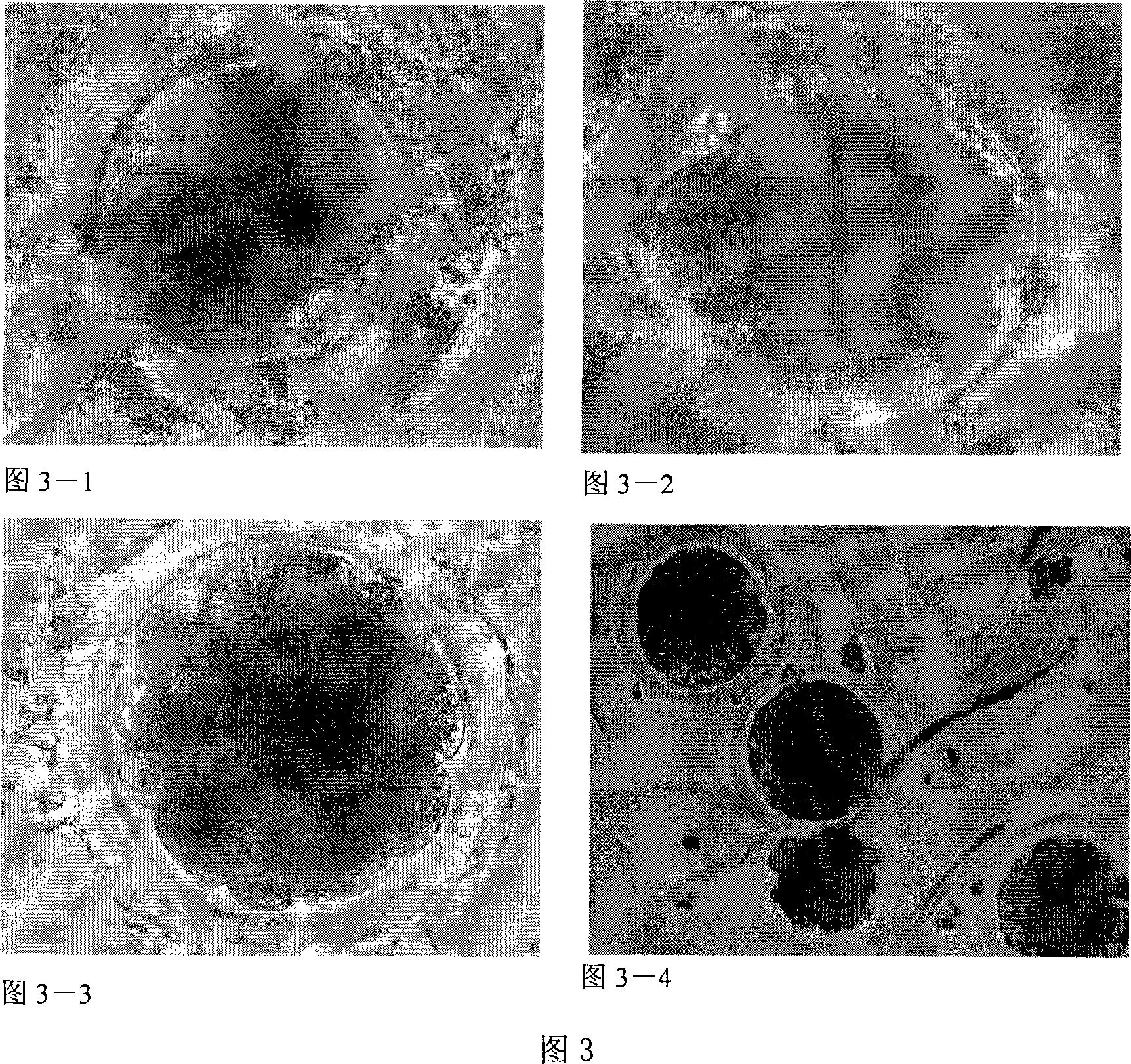

Tubule high-density type method for freezing pig jism and the products thereof

InactiveCN101062058AIncrease vitalityGood repeatabilityDead animal preservationMammal material medical ingredientsHigh densityFistula

The invention discloses a high density freezing maintain pig seminal fluid method with fistula and product in animal propagation technical domain, which comprises the following steps: collecting fresh seminal fluid; detecting; pre-treating the seminal fluid; defreezing; proceeding assessment procedure of defreeze seminal fluid; diluting with freezing diluting liquid; storing with high density super low temperature with 0. 25mL fistula; stabilizing the defreezing sperm above 0. 5 and average active at 0. 58; reaching the highest at 0. 68; proceeding pig external fertilization with the sperm; getting 54. 3% cleavage ratio and 48. 5% morula developing ratio; meeting one sperm dosage with sperm quantity of one 0. 25mL fistula. This invention possesses larger using latent force and market developing prospect.

Owner:NANJING AGRICULTURAL UNIVERSITY

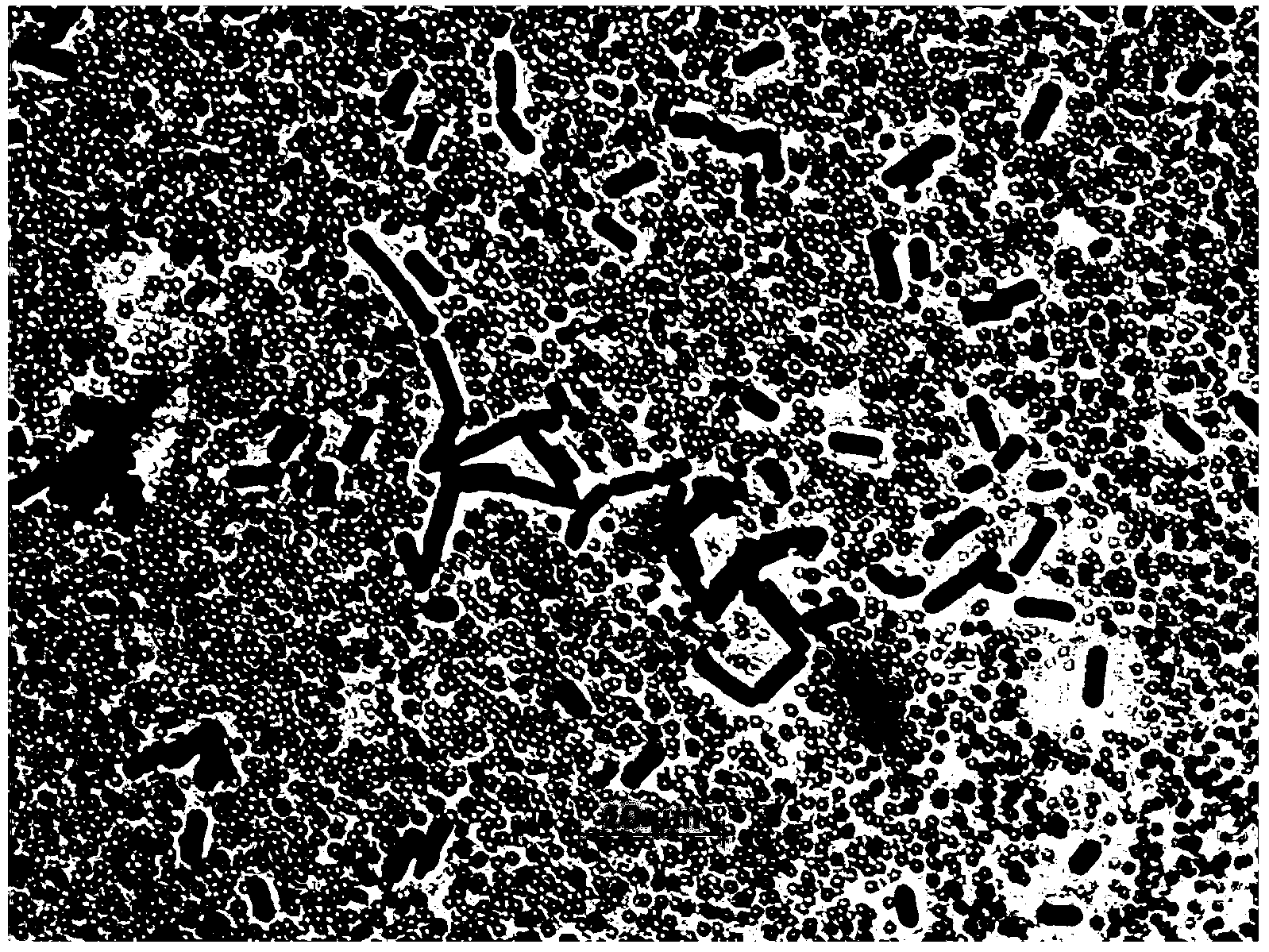

Bacillus amyloliquefaciens and its application

The invention discloses a bacillus amyloliquefaciens. Its classification name is (Bacillus amyloliquefaciens)B293. The bacillus amyloliquefaciens is preserved at the common microorganisms center of the CCCCM. Its collection number is CGMCC No.6081 and its collection date is April, 28th, 2012. The bacillus amyloliquefaciens is mainly used for biological control of strawberry botrytis. The bacillus amyloliquefaciens B293 has an effect of inhibiting a plurality of pathogenic fungi on strawberries and poplars. The antagonistic bacterium has a good effect of preventing and treating other plant diseases, is rapid to reproduce, can be artificially cultured, is easy to operate and convenient for production and application, has strong resistance ability, and especially is of great significance for preventing and treating strawberry botrytis caused by fungi. The antagonistic bacterium requires a simple culture condition, is easy to preserve, is easy for industrial production, and has a good development and application prospect.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

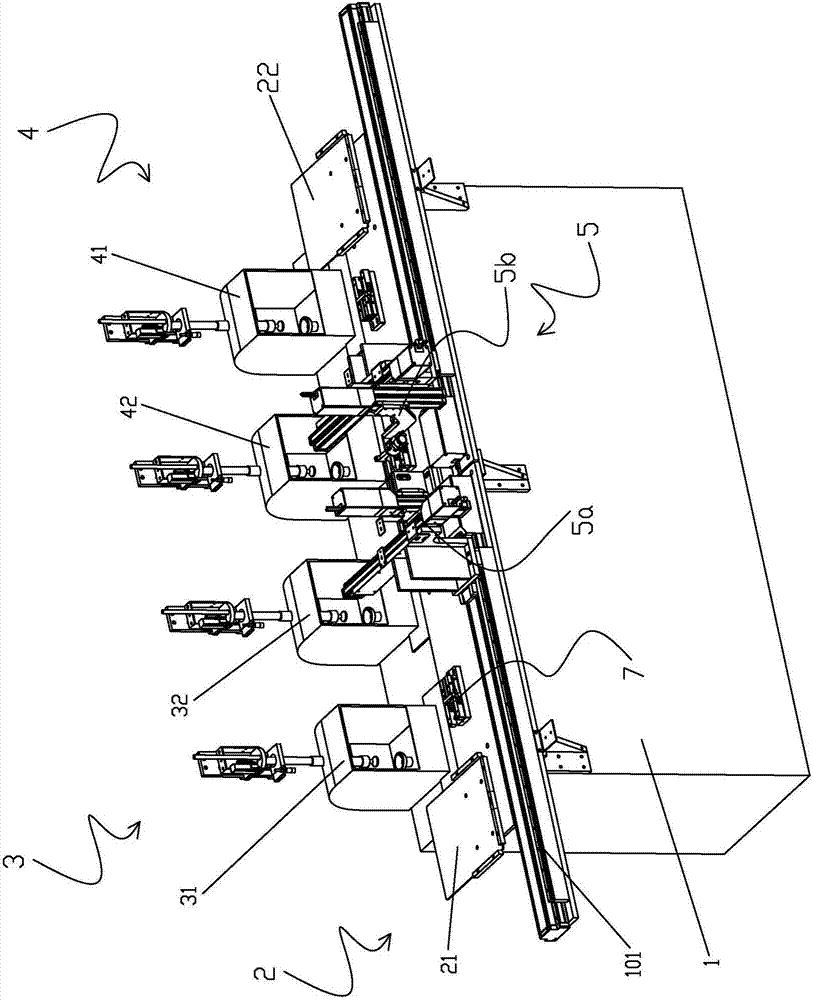

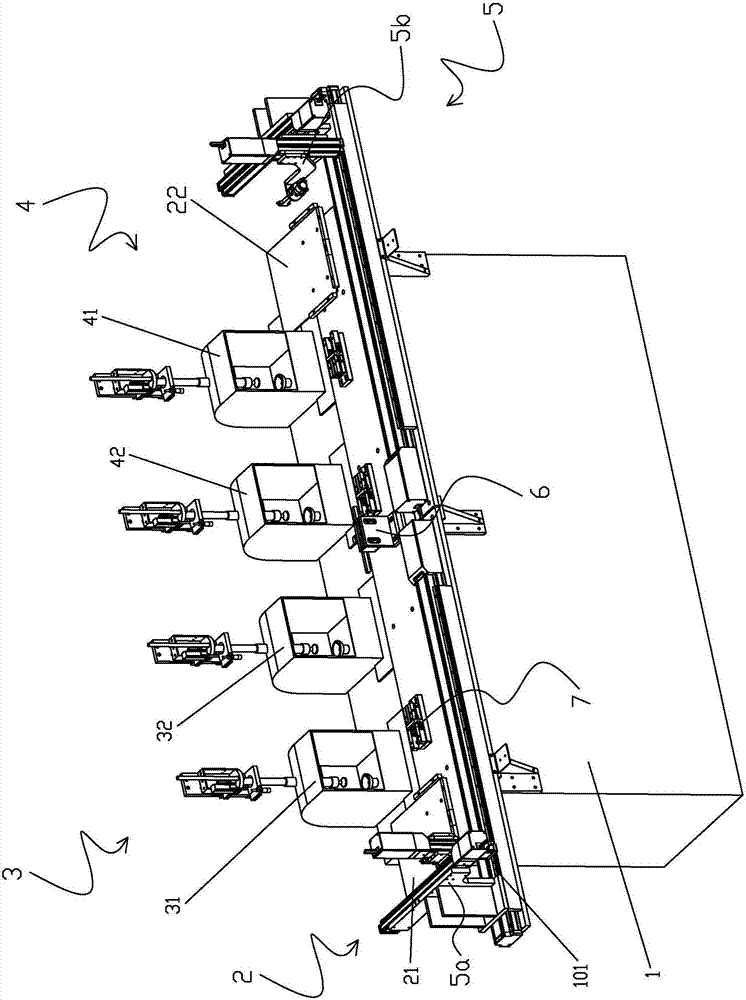

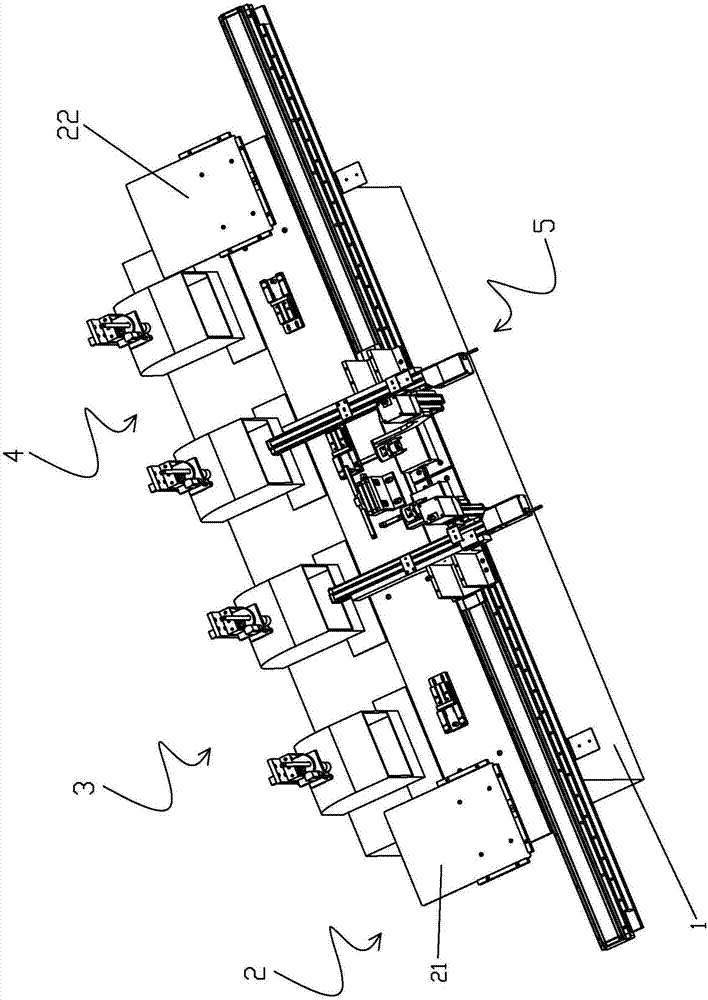

Classification full-automatic pick-and-place grinding device for optical lenses

PendingCN107486772AReliable and durable structureImprove stabilityOptical surface grinding machinesOptic lensManipulator

The invention discloses a classification full-automatic pick-and-place grinding device for optical lenses. The classification full-automatic pick-and-place grinding device for the optical lenses comprises a machine table, a primary grinding unit, a secondary grinding unit and a pick-and-place conveying manipulator, wherein the machine table comprises a lens placement station used for placing to-be-ground optical lenses; the primary grinding unit is arranged on the machine table and used for performing rough grinding or / and fine grinding on the front sides or the reverse sides of the optical lenses; the secondary grinding unit is arranged on the machine table and used for performing rough grinding or / and fine grinding on the front sides or the reverse sides of the optical lenses; and the pick-and-place conveying manipulator is used for picking up the optical lenses from the lens placement station and conveying the optical lenses onto the primary grinding unit or the secondary grinding unit for grinding or simultaneously conveying the optical lenses onto the primary grinding unit and the secondary grinding unit for grinding. According to the technical scheme, the classification full-automatic pick-and-place grinding device for the optical lenses has the characteristics that the technical problems that rough grinding, fine grinding and front-reverse grinding of the optical lenses cannot be performed on the same equipment, the automation degree is low, and the production efficiency is low in the optical lens grinding field are solved.

Owner:中山市光维智能科技有限公司

Eiderdown silk down-proof composite processing technology

InactiveCN101081690AReduce manufacturing costEasy to use in productionApparelUpholstery fillingPolyesterTextile fiber

The present invention is composite down feather wadding producing process. The down feather wadding consists of one bulking down feather wadding of mixture, adhesive and environment friendly permeating film. The bulking down feather wadding is made of mixture comprising down feather fiber, 3D crisp hollow polyester staple fiber, low smelting point fiber and textile fiber; the adhesive is made of polymer resin of acryl monomer; and the environment friendly permeating film is made of polyester and carbamate. Polyester, carbamate and the adhesive are mixed, heated to 23-27 deg.c, and pressurized to combine with bulking down feather wadding. The present invention has the features of no bubbling, less generation of static electricity, no down leakage, etc.

Owner:廖祺光 +1

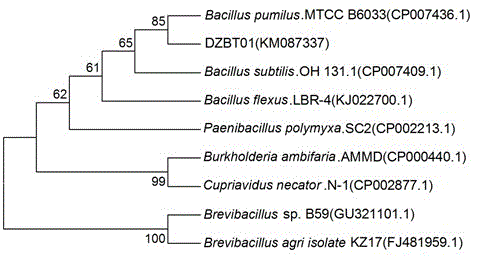

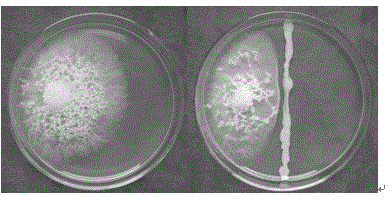

Eucommia ulmoides endogenous bacillus pumilus and application thereof

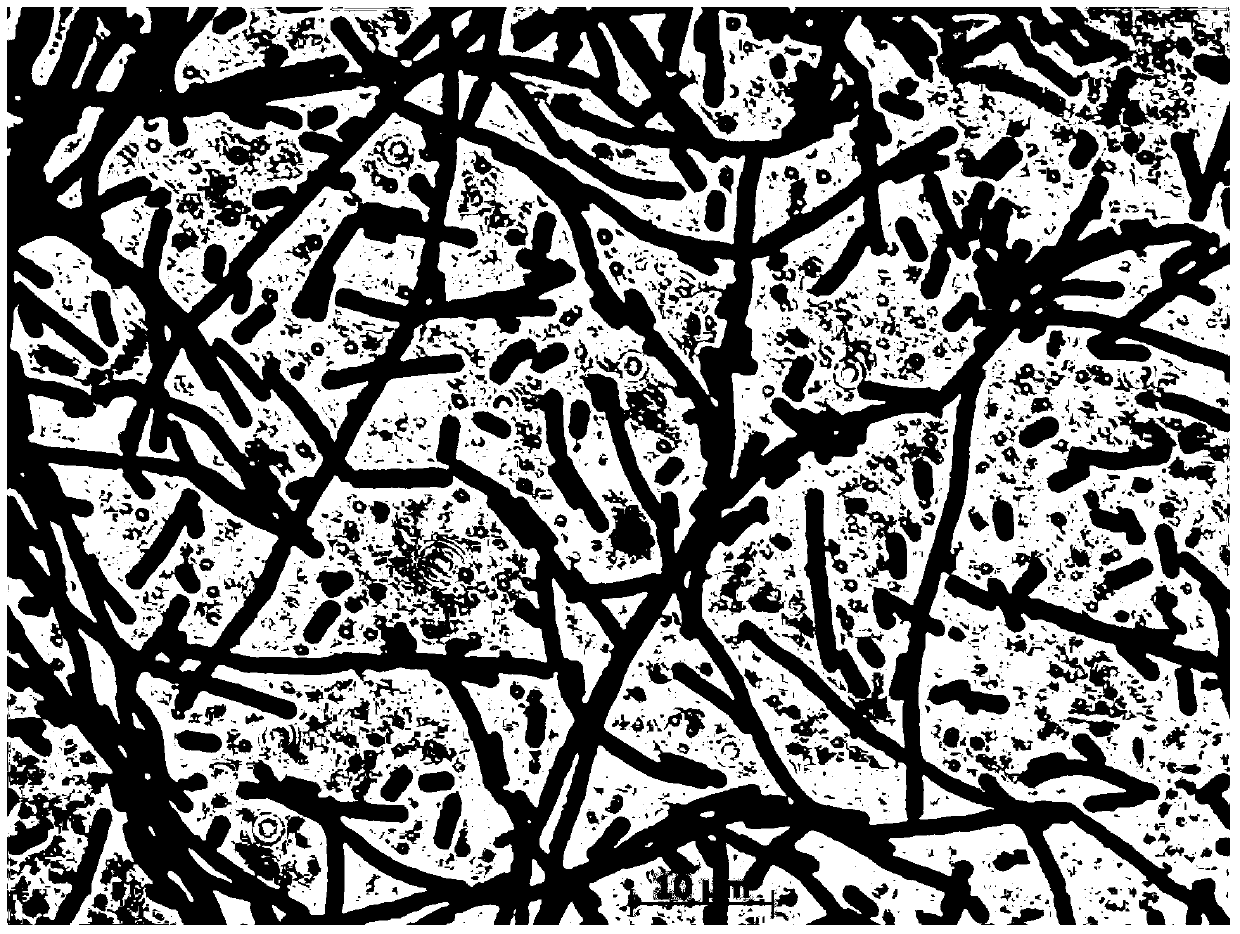

ActiveCN104789509AGrowth inhibitionGood inhibitory effectPlant growth regulatorsBiocideBacteroidesTriticeae

The invention relates to the technical field of microbes. The eucommia ulmoides endogenous bacteria are separated from eucommia ulmoides living plants by adopting an endogenous bacteria microbe separation technology. Through identification by microbial taxonomy, strain is named Bacillus pumilus DZBT01 and is collected in China General Microbiological Culture Collection Center, the collection number is January 30, 2015, and the collection register number is CGMCC NO.10470. The strain disclosed by the invention has the characteristics that the strain can achieve an obvious effect of inhibiting plant pathogenic fungi. The invention discloses an application of the Bacillus pumilus DZBT01 in control of wheat sharp eyespot and an application of Bacillus pumilus in promotion of wheat growth. The Bacillus pumilus DZBT01 disclosed by the invention refers to eucommia ulmoides plant endogenous bacteria, is simple in culture conditions and easy to preserve and refers to an agriculturally important microbial resource.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for accelerating aging of white spirit

InactiveCN110317705AEasy to use in productionShorten aging timeAlcoholic beverage preparationAccelerated agingOxygen

The invention belongs to the field of liquor making methods and particularly relates to a method for accelerating aging of white spirit. The method comprises the steps of inoculating new liquor into an outdoor storage vessel, inoculating old liquor, putting an adsorption column into the vessel, introducing oxygen into the vessel, introducing white spirit which has been aged for a certain period oftime into an indoor storage vessel from the outdoor storage vessel, and controlling the indoor temperature. Compared with a traditional natural aging technology, the method has the advantages that the a natural aging effect costing 9-10 years can be achieved in one year after aging acceleration of the new liquor; the strange smell and foreign flavor of the white spirit which is subjected to agingacceleration are obviously removed, the mouthfeel is mellow, sweet and soft, the aftertaste is long, and the fragrance of the aged liquor is obvious.

Owner:SHANDONG BANDAOJING

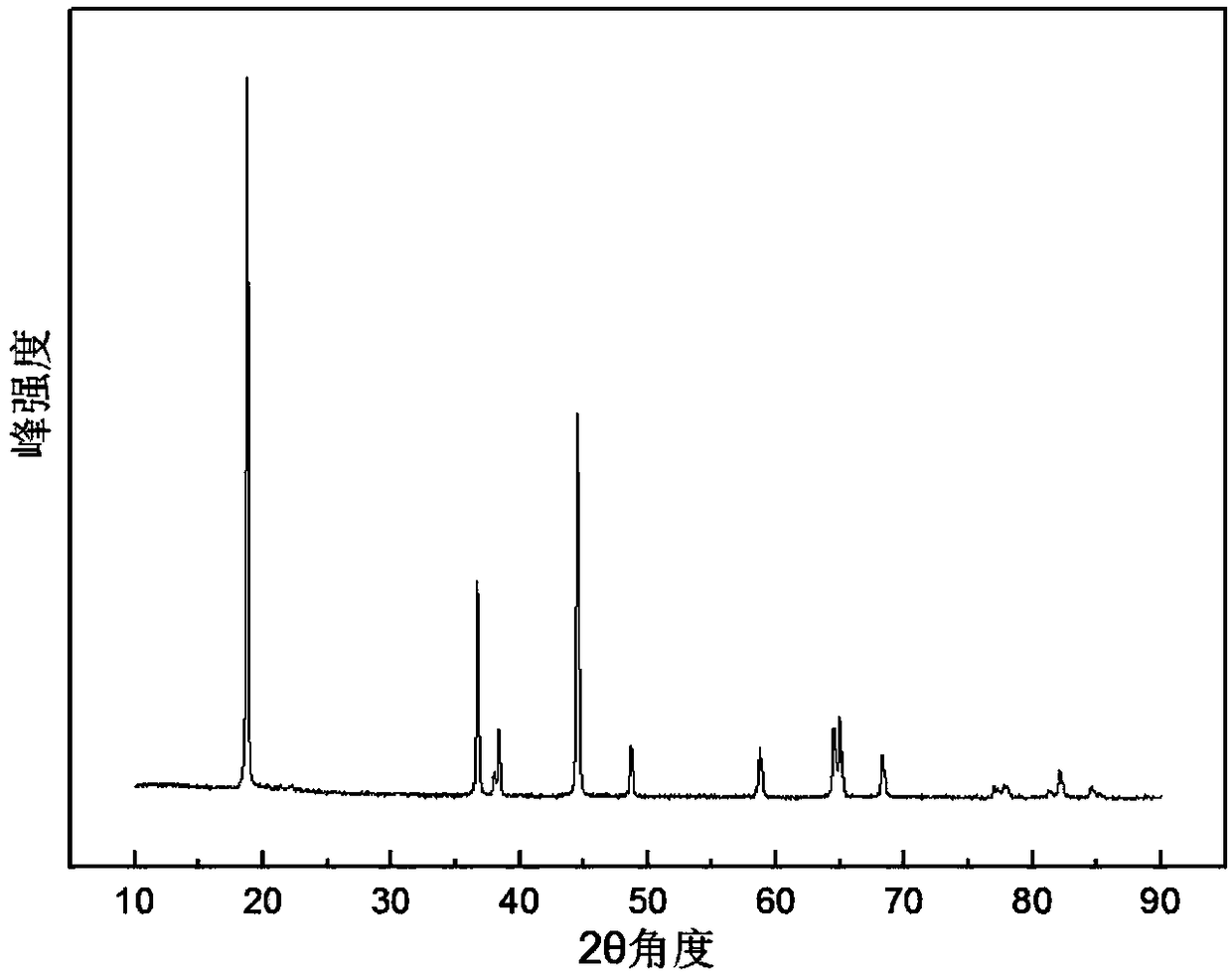

Lithium-ion battery cathode material with super-lattice ordered structure and synthesizing method thereof

ActiveCN108483516AEasy to operateFacilitate large-scale production and applicationCell electrodesSecondary cellsSolid phasesLithium electrode

The invention belongs to the technical field of lithium-ion battery materials and manufacturing processes thereof, and particularly discloses a lithium-ion battery cathode material with a super-lattice ordered structure and a synthesizing method thereof. The lithium-ion battery layered cathode material with the super-lattice ordered structure disclosed by the invention has a unique super-lattice ordered structure on the basis of keeping a hexagonal layered R-3m spatial group structure of a common layered cathode material. The lithium-ion battery cathode material disclosed by the invention is synthesized through a specially made double-kettle interconnected co-precipitation reaction kettle, and is synthesized through the following specific steps: firstly, preparing a solution; secondly, preparing a precursor; thirdly, embedding lithium into a high-temperature solid phase. The cathode material prepared by the synthesizing method is applied to a lithium-ion battery.

Owner:HARBIN INST OF TECH

Bacillus subtilis and application thereof

The invention discloses bacillus subtilis. The bacillus subtilis with the preservation number of CGMCC No.7542 is preserved in the China General Microbiological Culture Collection Center on April 28, 2013. The invention further provides an application of the bacillus subtilis in strawberry root rot. The bacillus subtilis B85 has a very good inhibition effect on strawberry root rot, grey mould fruit rot of strawberry, strawberry anthracnose and other pathogenic fungi, and also has a very good preventing and controlling effect on other plant diseases. The bacillus subtilis has a high proliferation speed, can be artificially cultured, is easy to operate, facilitates production and application, has the advantages of strong stress resistance and the like, especially has an important meaning to prevention and control of fungi caused strawberry root rot, is simple in culture condition and easy to preserve, is convenient for industrial production, and has excellent development and application prospects.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Method for cultivating Taxus media bag seedlings by edible fungus waste

InactiveCN103931393AConvenient sourceLow costClimate change adaptationAfforestationRoot systemTaxus × media

The invention relates to a method for cultivating Taxus media bag seedlings by edible fungus waste. The method comprises the five steps of light matrix preparation, cutting slip processing, rooting processing, cutting method implementation and final-period management. According to the method, light matrixes are used for cultivating the Taxus media bag seedlings, due to the fact that the light matrixes are high in water absorption property, good in permeability and fast in seedling growing, roots are grown in 40-50 days at a normal temperature, the roots are robust, young sprouts can be grown out in 80-90 days, and the rooting rate reaches 90%. Due to the fact that the light matrixes have good physical characteristics, the light matrixes are more suitable for growing and developing of plant roots, and the light matrixes of the plants which do not root or do not survive can further be recycled and reused. The light matrixes are light in weight so as to be convenient to transport and be prone to forestation. Accordingly, the method for cultivating the Taxus media bag seedlings by the edible fungus waste improves the seedling survival rate, facilitates industrial cultivation of the Taxus media bag seedlings, and lowers seedling cultivation and transportation cost.

Owner:桂林市林业科学研究所

Bacillus amyloliquefaciens subsp.plantarum B232 and application thereof

The invention discloses bacillus amyloliquefaciens subsp.plantarum which is classified and named as bacillus amyloliquefaciens subsp.plantarum B232 and preserved in the China General Microbiological Culture Collection Center (CGMCC) of the China Committee for Culture Collection of Microorganisms (CCCCM) on June 9th, 2014, and has the preservation number of CGMCCNo.9279. The bacillus amyloliquefaciens subsp.plantarum B232 is mainly used for carrying out biological prevention and treatment on Dothichiza populea Sacc.et Briard, and has good functions of inhibiting Dothichiza populea Sacc.et Briard germs, dendrobium officinale botrytis and other various pathogenic fungi. The bacillus amyloliquefaciens subsp.plantarum B232 taken as an antagonistic bacterium also has good effects of preventing and treating other plant diseases. The bacillus amyloliquefaciens subsp.plantarum B232 has the advantages of being rapid in propagation speed, easy to operate, convenient in production application, strong in stress resistance and the like, and can be artificially cultured. The bacillus amyloliquefaciens subsp.plantarum B232 requires a simple culture condition and is easy to store and favorable for industrial production. Thus, the bacillus amyloliquefaciens subsp.plantarum B232 has a good development and application prospect.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Anti-rutting modifier as well as preparation method and application thereof

The embodiment of the invention discloses an anti-rutting modifier which is prepared from the following components in parts by weight: 40-80 parts of recycled polyolefin, 10-30 parts of tire rubber powder, 20-50 parts of a toughening modifier, 0-5 parts of inorganic packing, 0.5-2 parts of a coupling agent and 0.1-1 part of an antioxidant. The embodiment of the invention further provides a preparation method and application of the anti-rutting modifier in asphalt. The anti-rutting modifier disclosed by the embodiment of the invention is relatively high in strength and toughness, and after the anti-rutting modifier is mixed with asphalt, the strength of an asphalt mixed material can be improved, the toughness of the asphalt mixed material can be also greatly improved, and the high-temperature anti-rutting property, the low-temperature cracking resistance and the fatigue resistance of the asphalt mixed material can be improved.

Owner:ROADMAINT CO LTD

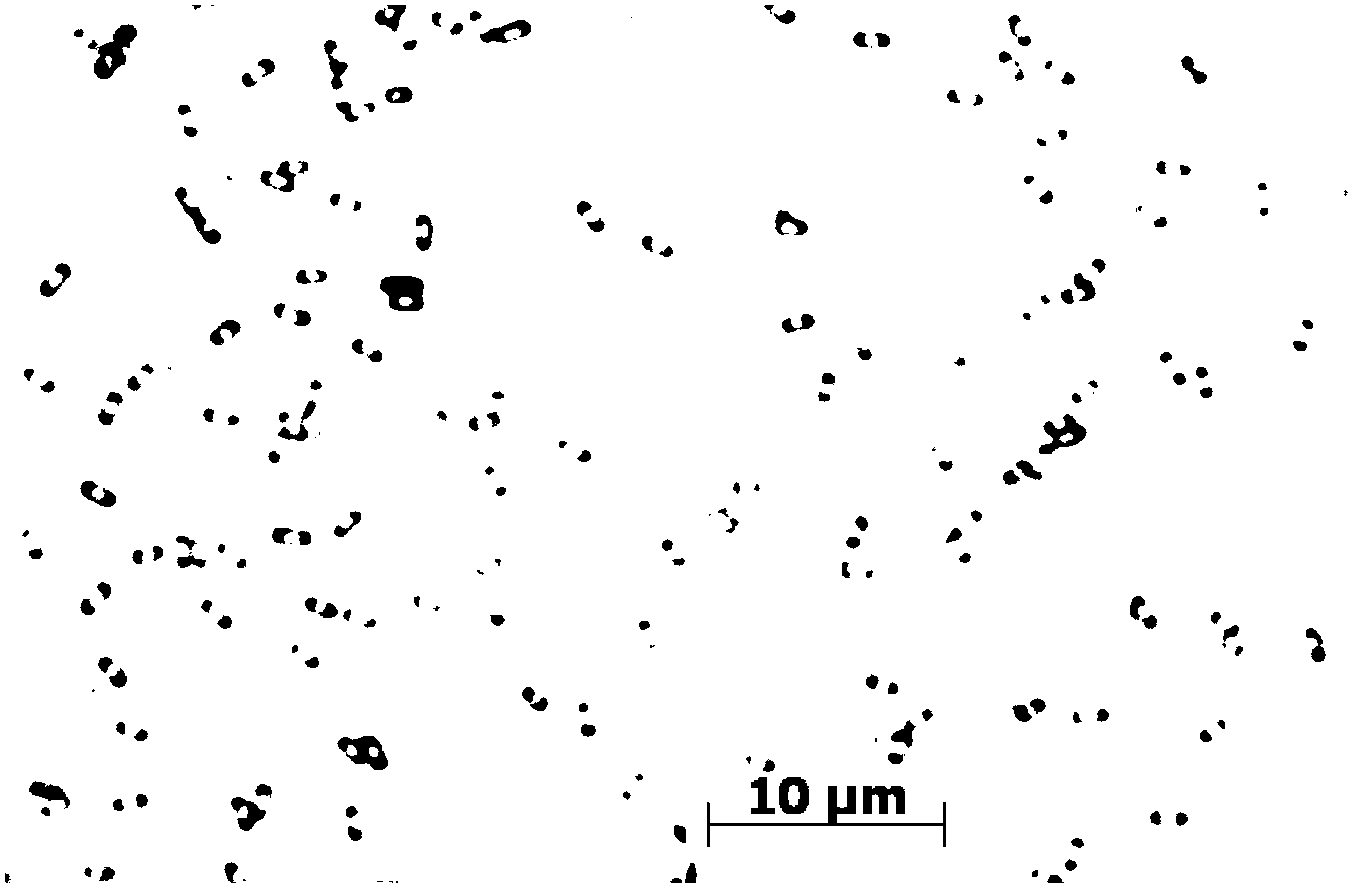

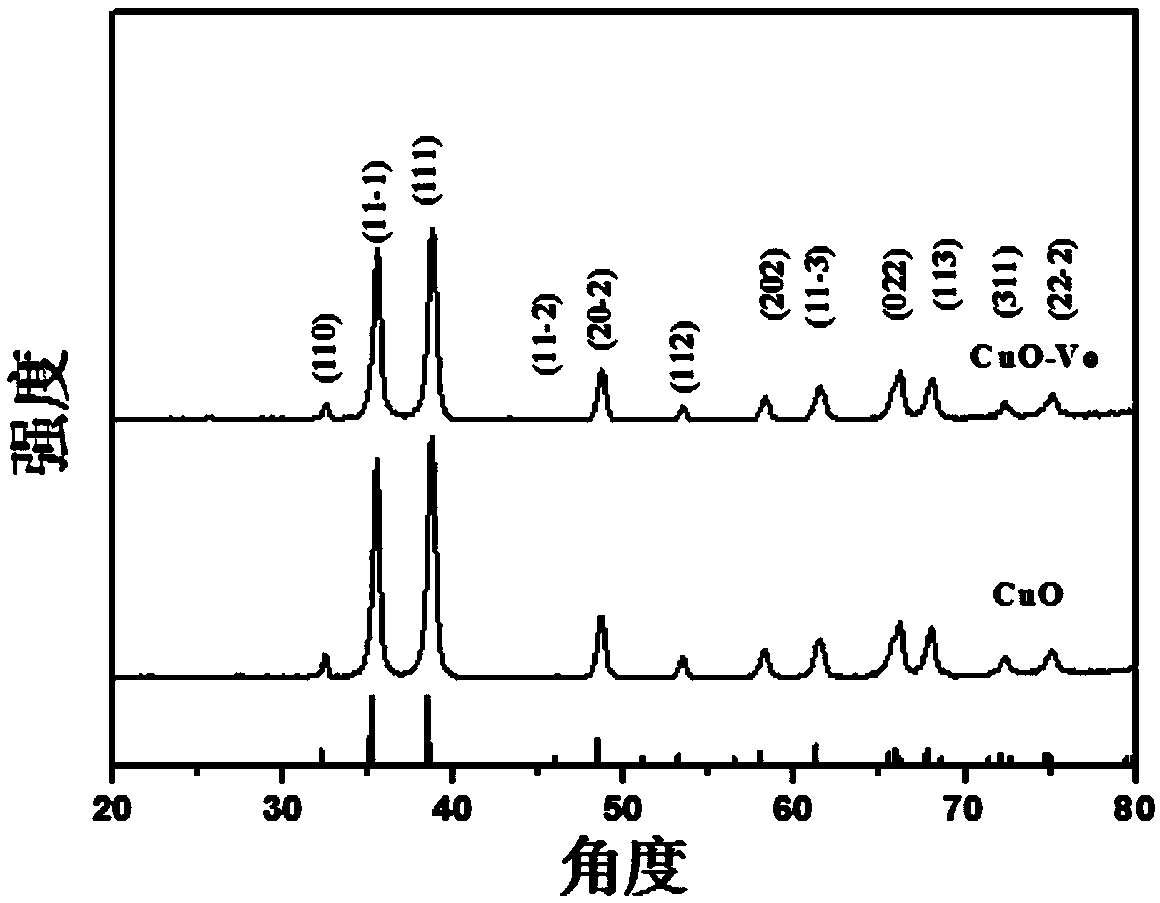

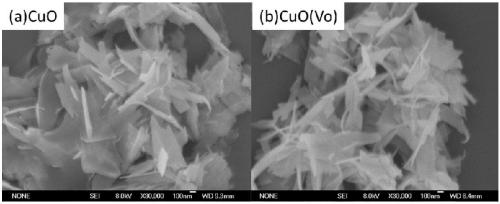

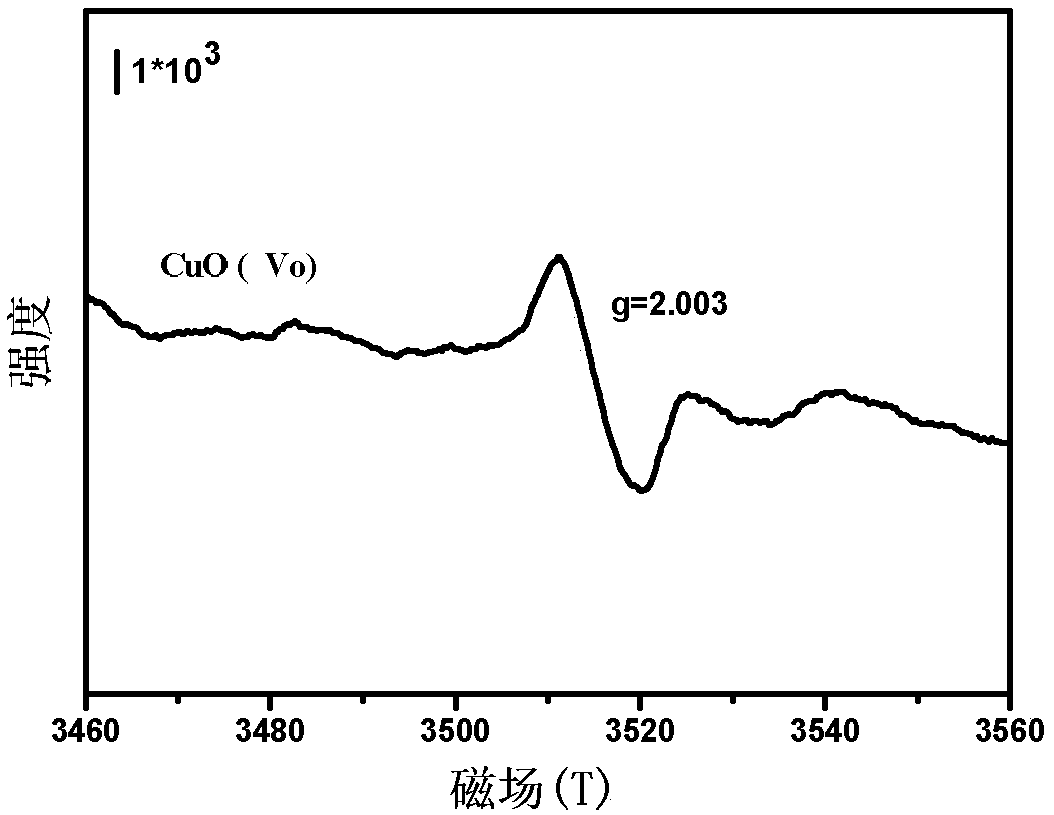

Method for producing oxygen vacancy-containing CuO nanosheets

PendingCN111377475AHigh activityLow costCopper oxides/halidesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOxygen vacancy

The invention discloses a method for producing oxygen vacancy-containing CuO nanosheets. The method comprises the following steps: preparing CuO nanosheets and treating the CuO nanosheets with sodiumborohydride. According to the preparation method, the CuO catalyst containing the oxygen vacancy is prepared by adopting a chemical preparation method at a low temperature, so the cost is relatively low, the synthesis method equipment and process are simple, the operation is simple and convenient, a large amount of catalysts can be synthesized, and the practical production and application are facilitated. For the CuO catalyst containing the oxygen vacancy, through the existence of the oxygen vacancy, the activity of the catalyst is improved, and particularly in a propylene catalytic activity test, T50 is reduced by about 70 DEG C.

Owner:HUAZHONG NORMAL UNIV

Bacillus subtilis and application thereof in preventing and treating plant leaf spot diseases

The invention discloses bacillus subtilis which is classified and designated as bacillus subtilis JSNL1205 and preserved in the China General Microbiological Culture Collection center, the preservation number is CGMCC No.6303, and the preservation date is June, 28th, 2012. The invention also discloses application of the bacillus subtilis in preventing and treating plant leaf spot diseases such asdendrobium candidum. The bacillus subtilis JSNL1205 has a suppression effect on various pathogenic fungi on the dendrobium candidum, can be artificially cultured and has the advantages of high propagation speed, convenience for large-scale production and good development and application prospects.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Bacillus subtilis B51 and application of bacillus subtilis B51

The invention discloses bacillus subtilis B51. The preservation serial number of the bacillus subtilis B51 is CGMCCNo.7541; the preservation date of the bacillus subtilis B51 is April 28, 2013; the bacillus subtilis B51 is named as Bacillus subtilis and has been preserved in the general microbiology culture preservation management center of China. The bacillus subtilis B51 plays a good role in inhibitingvarious pathogenic funguses such as the dendrobium officinale ceitocybe bescens, the wheat scab and the grey mould fruit rot of strawberries, and antagonistic bacteria play a good role in preventing and treating other plant diseases; the bacillus subtilis B51 has the advantages of being high in breeding speed, easy to operate, convenient to produce and apply, high in resilience capacity, capable of being artificially cultivated and the like; in particular, the bacillus subtilis B51 is of important significance in preventing and treating the dendrobium officinale ceitocybe bescens caused by the funguses; culture conditions are simple, preservation is easily carried out, industrial production is easily achieved, and the bacillus subtilis B51 has good development and application prospects.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

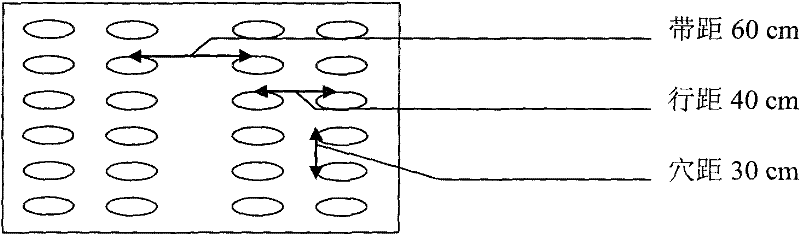

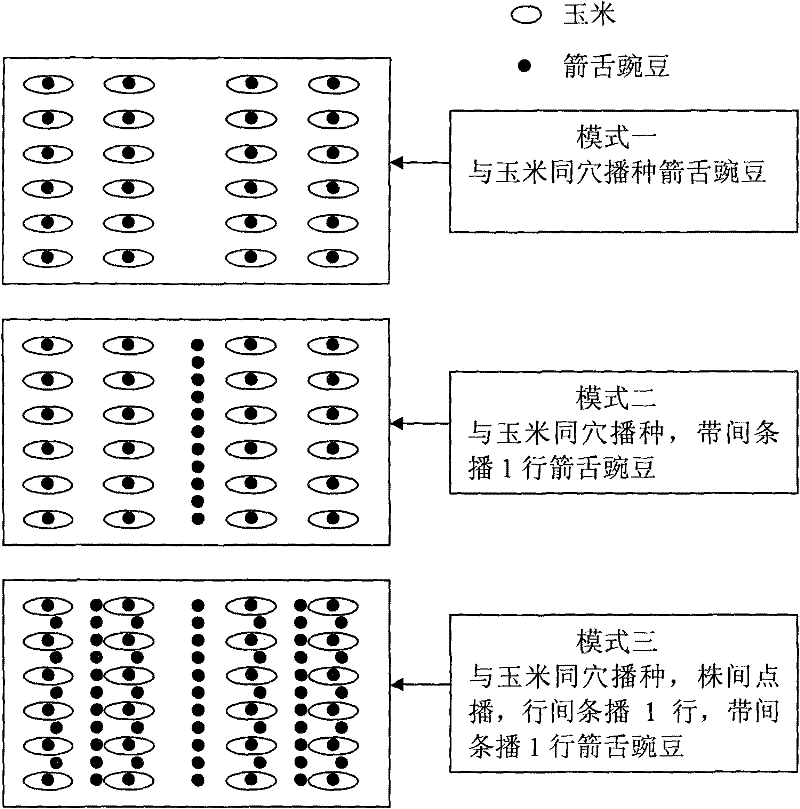

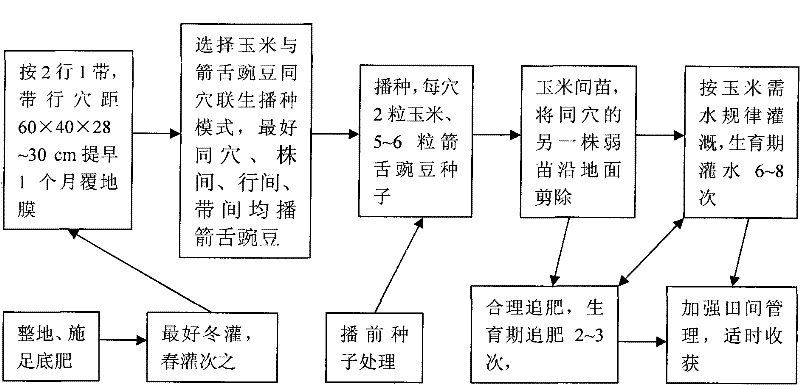

Combined cultivation method of sand corn and associated plant

The invention belongs to a combined cultivation method of sand corn and an associated plant. The associated plant has strong and early nitrogen fixation selecting capability and does not compete with the corn for fertilized annual herb of Vicia sativa L.; the corn is planted in a two-row stripped mode; the hill spacing of strip rows is the product of strip spacing 60, row spacing 40 and plant spacing 28-30cm; the planting density is from 4500 plants / mu to 4700 plants / mu; and an intercropping mode taking combined cultivation with the corn as a core is adopted. A test proves that the corn yield and the water utilization rate are directly proportional to the biomass of the Vicia sativa L. in the combined cultivation of the corn and the Vicia sativa L. Under the condition that the fertilization quantity and the irrigation quantity of a corn field are not increased, the early biological coverage on the field is obviously increased; the ineffective evaporation of soil is further converted into the effective transpiration of the plant; the biological nitrogen fixation is increased; the solar biological converting capability is enhanced; and the purpose of increasing the corn yield and the water utilization rate is achieved.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

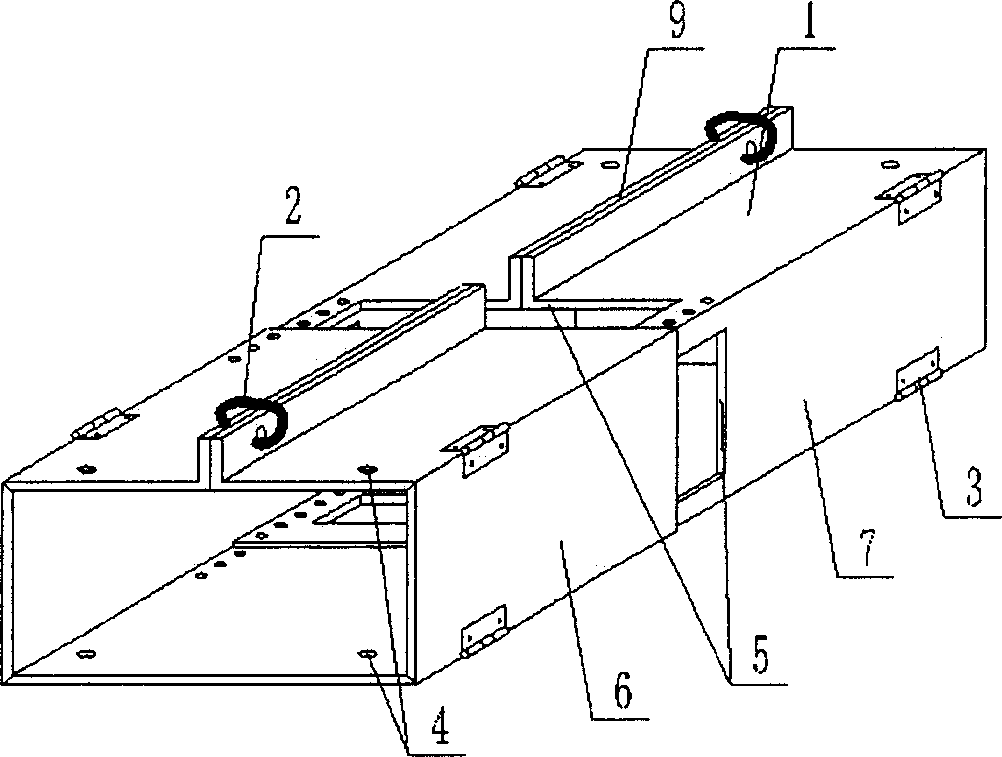

Forming die for component in polyhedron

InactiveCN1727148AEasy to splitEasy to assembleMould separation apparatusMouldsBiomedical engineeringFastener

Owner:湖南邱则有专利战略策划有限公司

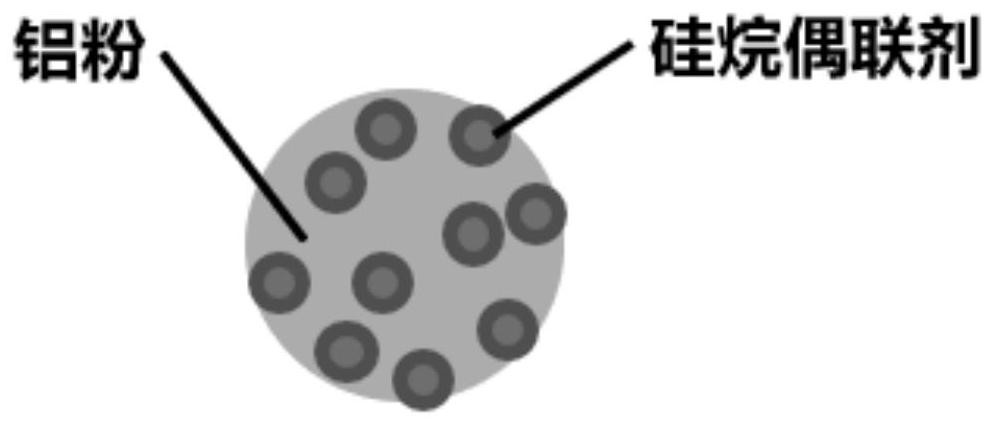

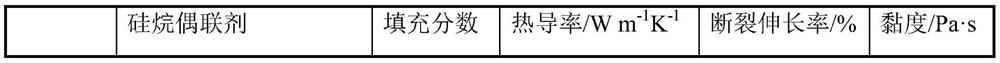

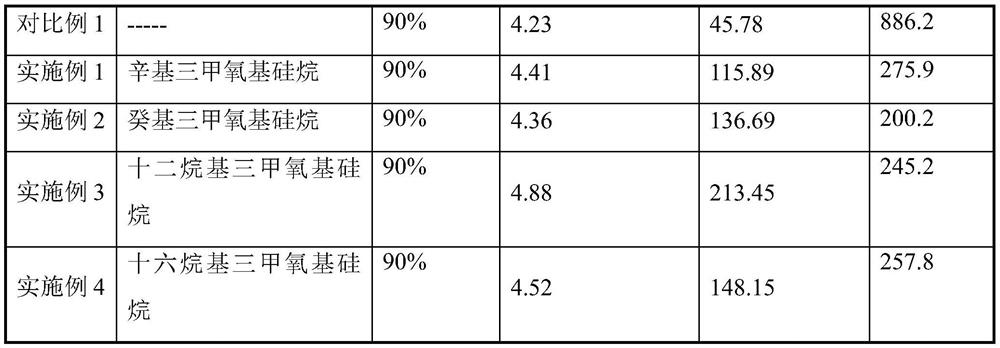

Aluminum powder surface modification method

InactiveCN112705702AReduce polarityReduce reunionTransportation and packagingMetal-working apparatusChemical treatmentAlcohol

The invention discloses an aluminum powder surface modification method. The aluminum powder surface modification method comprises the following steps of preparing a silane coupling agent, deionized water and absolute ethyl alcohol into a mixed solution according to a certain proportion; and adding the mixed solution into a reaction container, then adding aluminum powder, condensing and refluxing, and continuously stirring at 70-80 DEG C for 4-5 hours to obtain silane coupling agent modified aluminum powder. According to the aluminum powder surface modification method, the aluminum powder surface treatment method is a chemical treatment method, the silane coupling agent is grafted to a aluminum powder surface in a chemical bond mode, the polarity of the aluminum powder surface is remarkably reduced, agglomeration of the aluminum powder surface in a polymer substrate is effectively reduced, dispersity is better, and the contact area between the aluminum powder surface and the polymer substrate becomes larger; when modified aluminum powder is used in heat-conducting gel, the interfacial strength between the modified aluminum powder and the polymer substrate is higher; compared with unmodified aluminum powder, the modified aluminum powder has better compatibility with a polymer, so that the heat-conducting gel prepared from the modified aluminum powder has better mechanical properties under the same filler fraction.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

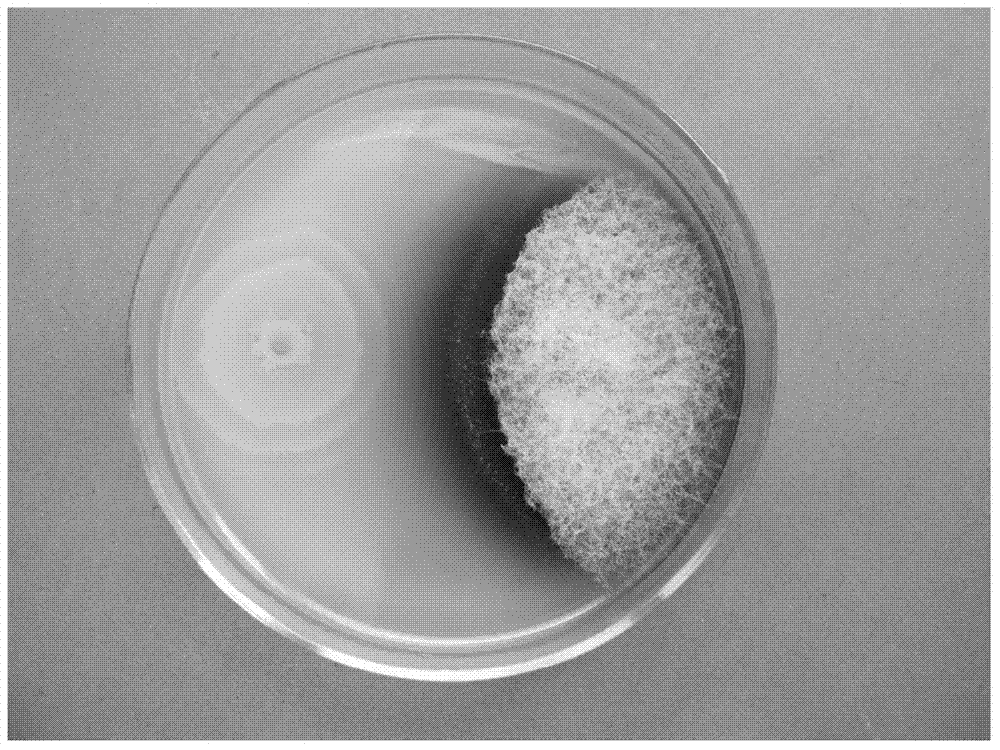

Trichoderma harzianum JSNL1404 and application thereof

The invention discloses trichoderma harzianum JSNL1404. The type of the trichoderma harzianum JSNL1404 is named as trichoderma harzianum. The trichoderma harzianum JSNL1404 is preserved in the general microbiological center of China General Microbiological Culture Collection Center on June 9th, 2014, and the preservation number is CGMCC No.9281. The invention further discloses the application of the trichoderma harzianum JSNL1404. The trichoderma harzianum JSNL1404 is mainly used for preventing and controlling dendrobium officinale southern blight germs, has the restraining function on multiple kinds of phytopathogen and plays an important role in antagonistic fungi plant disease biological control. The trichoderma harzianum JSNL1404 has the advantages that the number of types is large, the amount of the trichoderma harzianum is large, multiple action modes on pathogenic bacteriae are provided, the breeding speed is high, artificial culturing can be achieved, operation is easy, production and application are convenient, and the adversity resistance is high. Especially, the trichoderma harzianum JSNL1404 has a good preventing and controlling effect on southern blight caused by fungus.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

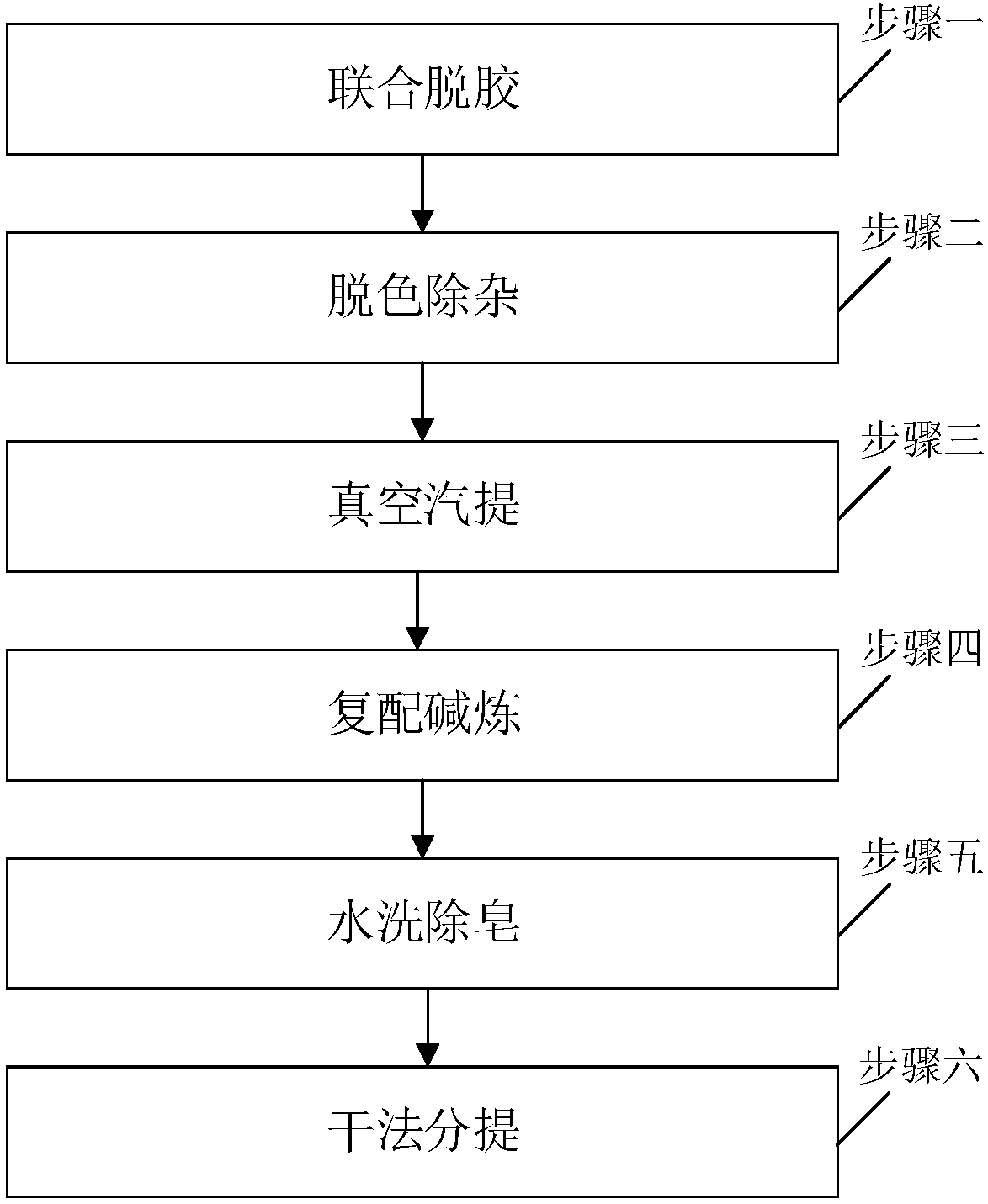

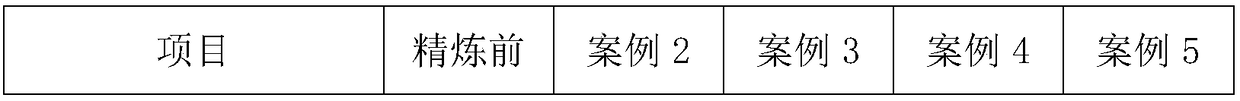

Method for preparing electric insulation oil from gutter oil

InactiveCN108359532ALow acid valueLowering the freezing pointFatty oils/acids recovery from wasteFatty substance recoveryOil processingGutter oil

The invention relates to the technical field of recycling of renewable resources, oil processing and electric insulation materials and provides a method for preparing electric insulation oil from gutter oil. The method comprises steps as follows: S1, combined degumming; S2, decoloration and impurity removal; S3, vacuum steam stripping; S4, compounding and alkali refining; S5, water washing and soap removal; S6, dry fractionation. According to the combined degumming technology, hydratable phospholipids and non-hydratable phospholipids can be effectively removed simultaneously, the degumming efficiency is high, the settling effect is good, and the refining effect of the following process is facilitated; through cooperation of vacuum steam stripping with compounding and alkali refining, the acid value of oil can be substantially reduced; through dry fractionation, the condensation point of oil can be further reduced according to specific demands.

Owner:武汉泽电新材料有限公司

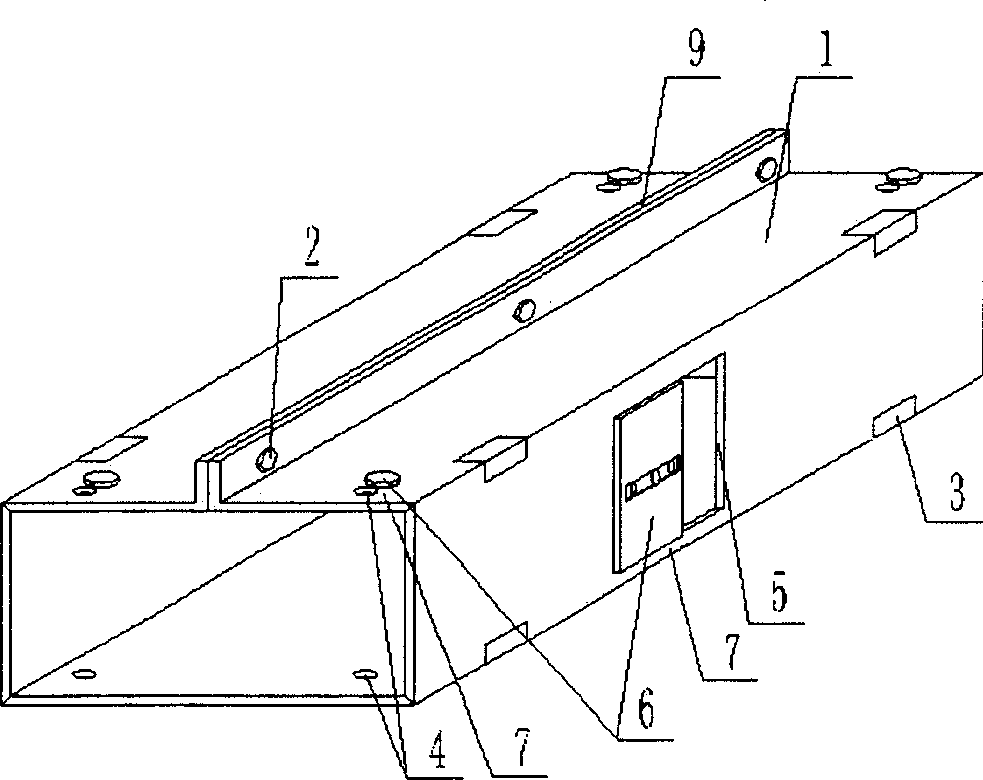

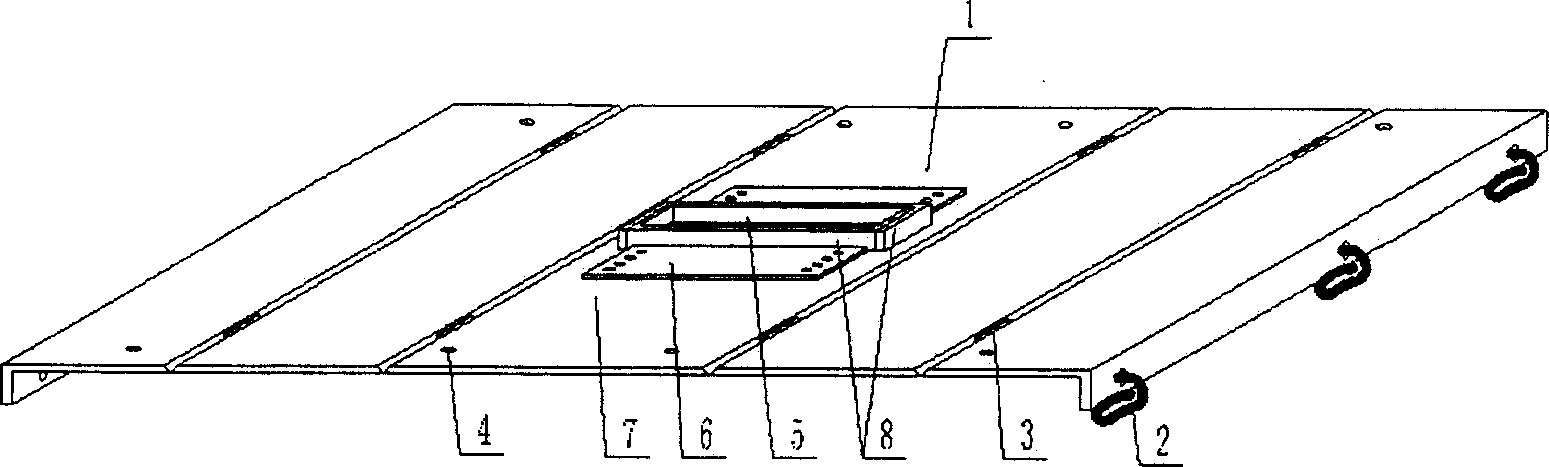

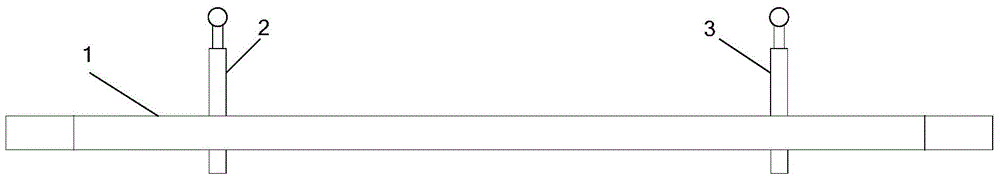

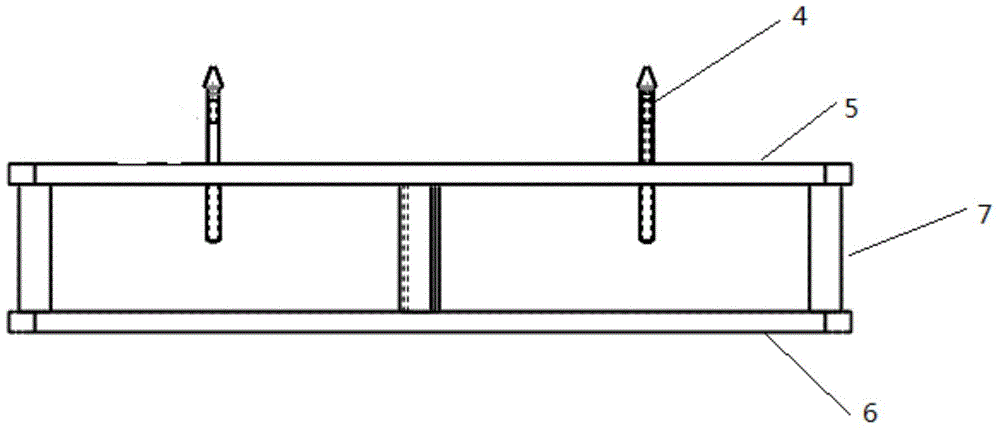

Test device for measuring plates for distributors of photovoltaic header boxes

ActiveCN104793125AReduce stepsImprove test efficiencyElectronic circuit testingTest proceduresTest fixture

The invention relates to a test device for measuring plates for distributors of photovoltaic header boxes. The test device comprises a base, an input test probe and an output test probe. The input test probe and the output test probe are vertically fixed onto the base, the upper end of the input test probe is fittingly spliced with a bottom interface of an input terminal of a to-be-tested measuring plate, the upper end of the output test probe is fittingly spliced with a bottom interface of an output terminal of the to-be-tested measuring plate, and the lower end of the input test probe and the lower end of the output test probe are connected with measuring wires. According to the scheme, the test device has the advantages that the test probes are fixed onto the base and are connected with the test wires, the measuring plate can be spliced onto the test probes when about to be tested and can be tested after being powered on, accordingly, the test efficiency can be improved, the test device is simple in structure and easy to produce and apply; owing to the design of the double-layer base, the test wires can be arranged in gaps on the upper and lower surfaces of the base, the wire contact possibility can be reduced for operators, and the safety of test procedures can be improved.

Owner:XUJI GRP +2

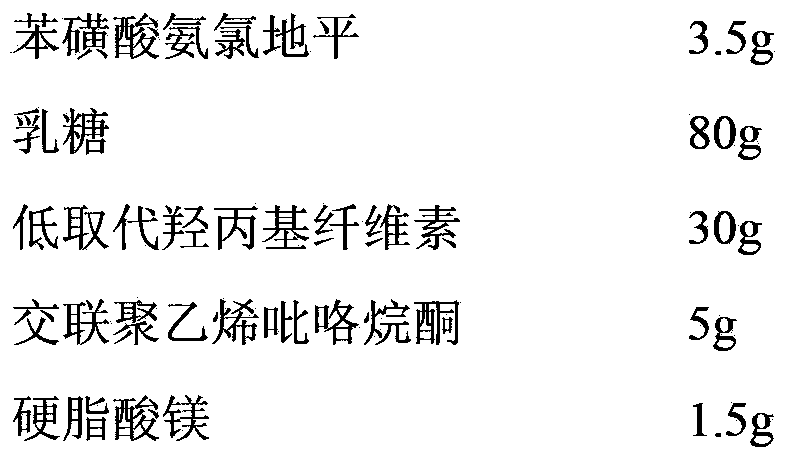

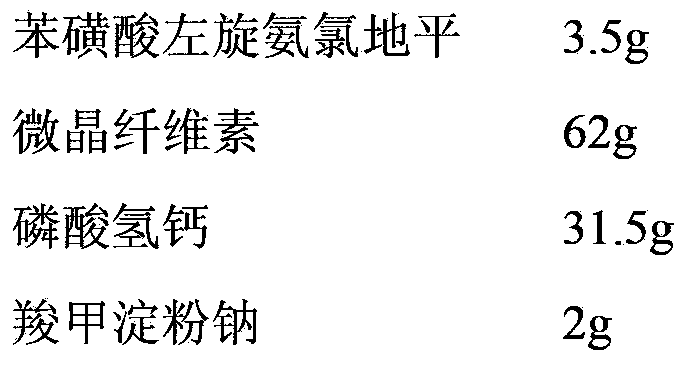

Benzenesulfonate amlodipine tablet and preparation method thereof

InactiveCN103356497AEasy to use in productionLow costOrganic active ingredientsPill deliveryUrologySodium carboxymethyl starch

The invention provides a benzenesulfonate amlodipine tablet. The benzenesulfonate amlodipine tablet is prepared by using benzenesulfonate amlodipine as an active component; adding starch slurry having a concentration of 0.8wt%-3.5wt%; using microcrystalline cellulose and calcium hydrophosphate dosages of which are in conventional dosage ranges, as fillers; using magnesium stearate as a lubricant; and using sodium carboxymethyl starch as a disintegrating agent. According to the benzenesulfonate amlodipine tablet, by addition of the starch slurry having a concentration far lower than the conventional concentrations, an increase of the dissolution rate of the benzenesulfonate amlodipine is achieved. In addition, the benzenesulfonate amlodipine tablet is adapted to conventional production technologies and equipment at present which are used for similar tablets-producing without needs of configuring extra equipment or changing production processes, and has high universality.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Fipronil self-nanoemulsion solution, and preparation method and application thereof

InactiveCN108926532ASolve the problem of instability and prone to demulsificationEvenly distributedOrganic active ingredientsAntiparasitic agentsFipronilSolvent

The invention discloses a fipronil self-nanoemulsion solution, and a preparation method and an application thereof. The fipronil self-nanoemulsion solution is mainly prepared from, by weight, 1-20 parts of fipronil, 20-50 parts of an oily solvent, 40-80 parts of an emulsifier and 10-40 parts of a co-emulsifier. The oil-in-water fipronil nanoemulsion has the advantages of uniformity in distribution, good transparence and stability, low surface tension, good fluidity, convenience in use, narrow particle size distribution, small particle size, increase of the absorption rate of the effective component, and good in vitro permeability. The preparation method has the advantages of simplicity, convenience, and easiness in production and application; and the emulsion can be directly used in in-vitro parasite expelling of pets as a spray or a drop, and can be diluted with water to form the oil-in-water nanoemulsion having a small particle size, a good stability and a high pet skin permeabilityin order to expel in vitro parasites from the pets, and the above preparation is clinically used for treating the parasites of the pets.

Owner:南京威特动物药品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com