Benzenesulfonate amlodipine tablet and preparation method thereof

A technology of amlodipine besylate tablet and amlodipine besylate tablet, which is applied in the field of amlodipine besylate tablet and its manufacture, and can solve problems such as crystal form and preparation method limitations, and the influence of active ingredients , to reduce costs, improve content uniformity, and improve dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

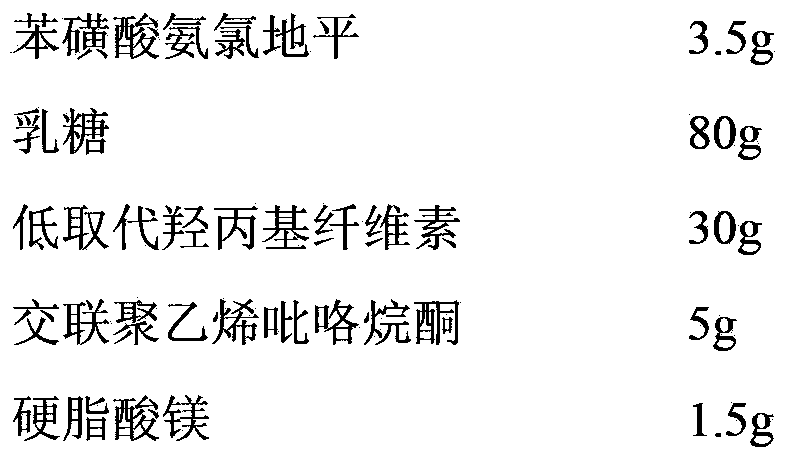

[0033] Formula: Calculated on the basis of 1000 plain tablets

[0034]

[0035] Preparation:

[0036] (1) Put the raw materials and other internally added auxiliary materials into the fluidized bed, and mix in the fluidized bed for 5 minutes to mix well.

[0037] (2) Spray 300g of starch slurry with a concentration of 1wt% into the mixed powder to make wet granules. After drying, pass through a 24-mesh sieve, add lubricant and mix evenly in a mixer. The measured moisture content reaches the standard of 1.5% to 2.5%, the particle size distribution is 30±5%, and the bulk density is 0.65±0.02g / ml;

[0038] (3) Tablet production: compress the above granules with a tablet machine.

[0039] (4) Measure the related substances contained in the prepared tablet and the dissolution rate, the results are shown in Table 1.

Embodiment 2

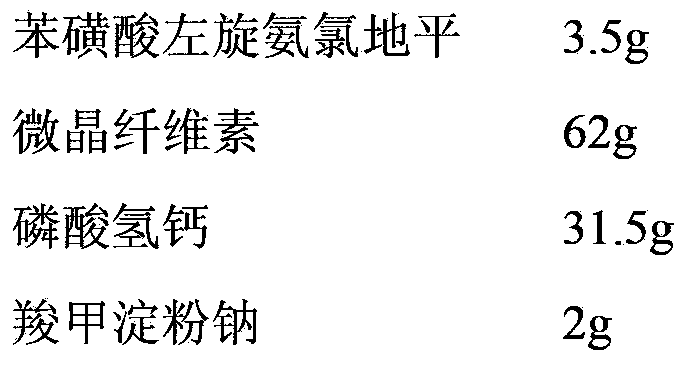

[0041] Formula: Calculated on the basis of 1000 plain tablets

[0042]

[0043]

[0044] (1) Put the raw materials and other internally added auxiliary materials into the fluidized bed, and mix in the fluidized bed for 5 minutes to mix well.

[0045] (2) Spray 300g of starch slurry with a concentration of 1wt% into the mixed powder to make wet granules. After drying, pass through a 24-mesh sieve, add lubricant and mix evenly in a mixer. The measured moisture content reaches the standard of 1.5% to 2.5%, the particle size distribution is 30±5%, and the bulk density is 0.65±0.02g / ml;

[0046] (3) Tablet production: compress the above granules with a tablet machine.

[0047] (4) Measure the related substances contained in the prepared tablet and the dissolution rate, the results are shown in Table 1.

Embodiment 3

[0049] Formula: Calculated on the basis of 1000 plain tablets

[0050]

[0051] (1) Put the raw materials and other internally added auxiliary materials into the fluidized bed, and mix in the fluidized bed for 5 minutes to mix well.

[0052] (2) Spray 100g of starch slurry with a concentration of 3wt% into the mixed powder to make wet granules. After drying, pass through a 24-mesh sieve, add lubricant and mix evenly in a mixer. The measured moisture content reaches the standard of 1.5% to 2.5%, the particle size distribution is 30±5%, and the bulk density is 0.65±0.02g / ml;

[0053] (3) Tablet production: compress the above granules with a tablet machine.

[0054] (4) Measure the related substances contained in the prepared tablet and the dissolution rate, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com