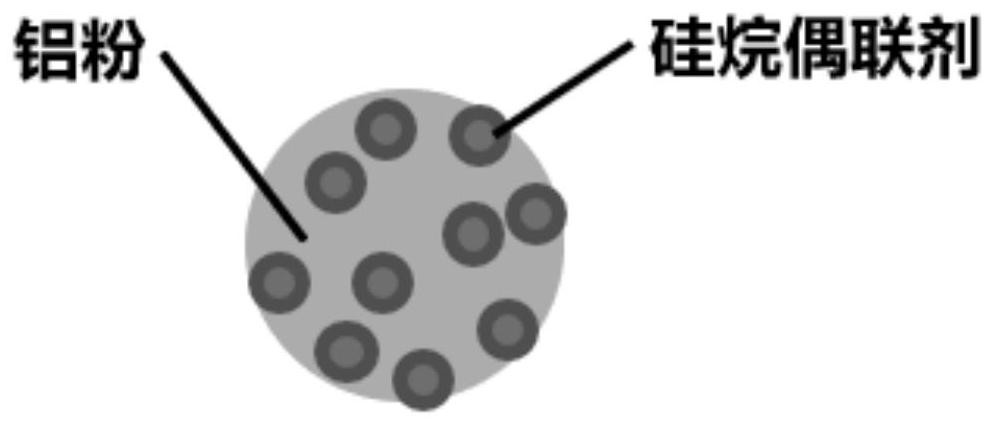

Aluminum powder surface modification method

An aluminum powder and modification technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as weak interface interaction, and achieve the effects of reduced agglomeration, high reliability and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

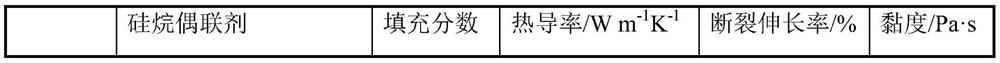

Embodiment 1

[0030] Preparation of silane coupling agent-modified aluminum powder with aluminum powder particle size of 1-2 μm: 1) Prepare a mixed solution with octyltrimethoxysilane, deionized water and absolute ethanol at a mass ratio of 1:1:3 ;

[0031] 2) Add the mixed solution in 1) into a three-necked flask, then add aluminum powder with a particle size of 1-2 μm (the mass fraction of aluminum powder in the mixed solution is 40%), condense and reflux, and continue to stir at 75 ° C for 5 The silane coupling agent-modified aluminum powder is obtained within 1 hour, and the silane coupling agent-modified aluminum powder is centrifuged, washed, and vacuum-dried for later use.

[0032] Preparation of silane coupling agent-modified aluminum powder with aluminum powder particle size of 13-15 μm: 1) Prepare a mixed solution with octyltrimethoxysilane, deionized water and absolute ethanol at a mass ratio of 1:1:3 ;

[0033] 2) Add the mixed solution in 1) into a three-necked flask, then ad...

Embodiment 2

[0038] Preparation of silane coupling agent-modified aluminum powder with a particle size of 1-2 μm: 1) Prepare a mixed solution of decyltrimethoxysilane, deionized water and absolute ethanol at a mass ratio of 1:1:3 ;

[0039] 2) Add the mixed solution in 1) into a three-necked flask, then add aluminum powder with a particle size of 1-2 μm (the mass fraction of aluminum powder in the mixed solution is 40%), condense and reflux, and continue to stir at 75 ° C for 5 The silane coupling agent-modified aluminum powder is obtained within 1 hour, and the silane coupling agent-modified aluminum powder is centrifuged, washed, and vacuum-dried for later use.

[0040] Preparation of silane coupling agent-modified aluminum powder with an aluminum powder particle size of 13-15 μm: 1) Prepare a mixed solution of decyltrimethoxysilane, deionized water and absolute ethanol at a mass ratio of 1:1:3 ;

[0041] 2) Add the mixed solution in 1) into a three-necked flask, then add aluminum powd...

Embodiment 3

[0046] Preparation of silane coupling agent-modified aluminum powder with aluminum powder particle size of 1-2 μm: 1) Prepare dodecyltrimethoxysilane, deionized water and absolute ethanol in a mass ratio of 1:1:3 mixture;

[0047] 2) Add the mixed solution in 1) into a three-necked flask, then add aluminum powder with a particle size of 1-2 μm (the mass fraction of aluminum powder in the mixed solution is 40%), condense and reflux, and continue to stir at 75 ° C for 5 The silane coupling agent-modified aluminum powder is obtained within 1 hour, and the silane coupling agent-modified aluminum powder is centrifuged, washed, and vacuum-dried for later use.

[0048] Preparation of silane coupling agent-modified aluminum powder with aluminum powder particle size of 13-15 μm: 1) Dodecyltrimethoxysilane, deionized water and absolute ethanol are prepared in a mass ratio of 1:1:3 mixture;

[0049] 2) Add the mixed solution in 1) into a three-necked flask, then add aluminum powder wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com