Preparation method of dentritic tetrameric cationic quaternary ammonium surface activity monomer

A technology of surface active monomer and polycation, which is applied in the preparation of quaternary ammonium salt type surface active monomer and the field of preparation of quaternary ammonium salt cationic surface active monomer, which can solve the problem that affects the final performance of the polymer and the final product cannot be purified. , low molecular weight of the polymerization reaction, etc., to achieve the effect of safe use, simple operation and easy control, and simple purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

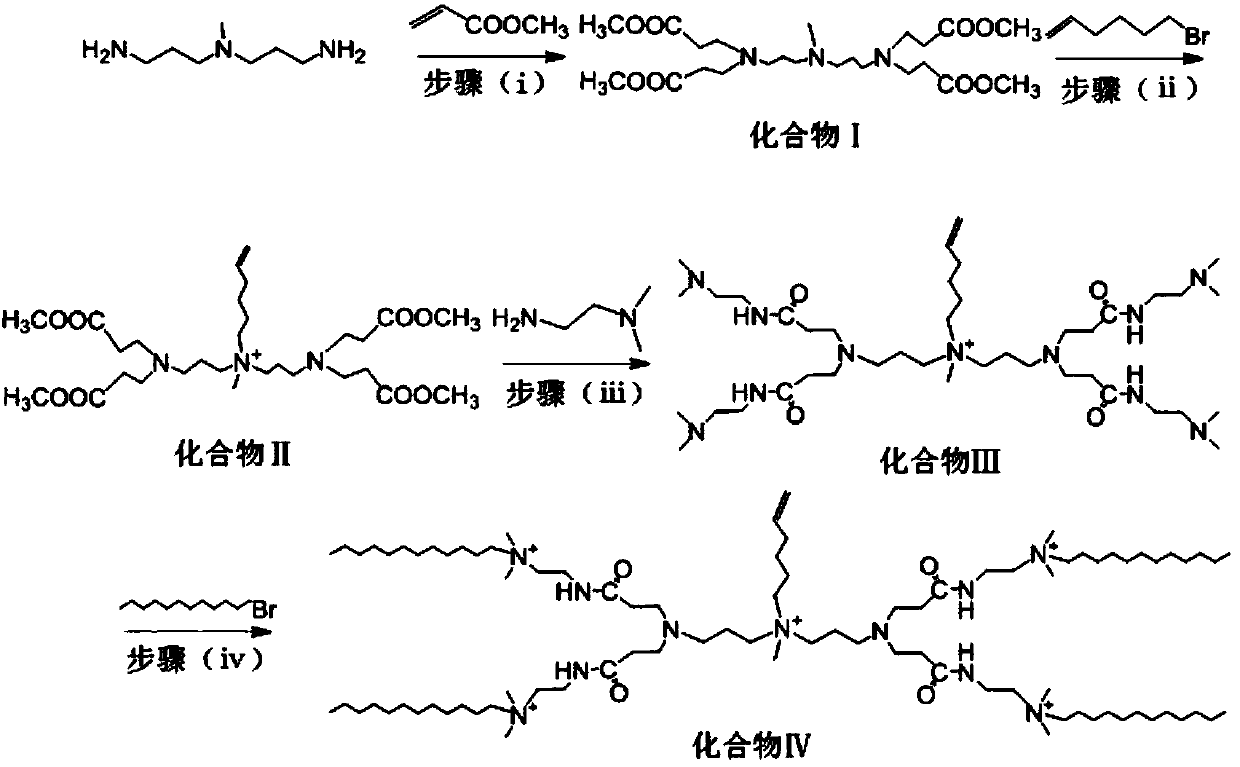

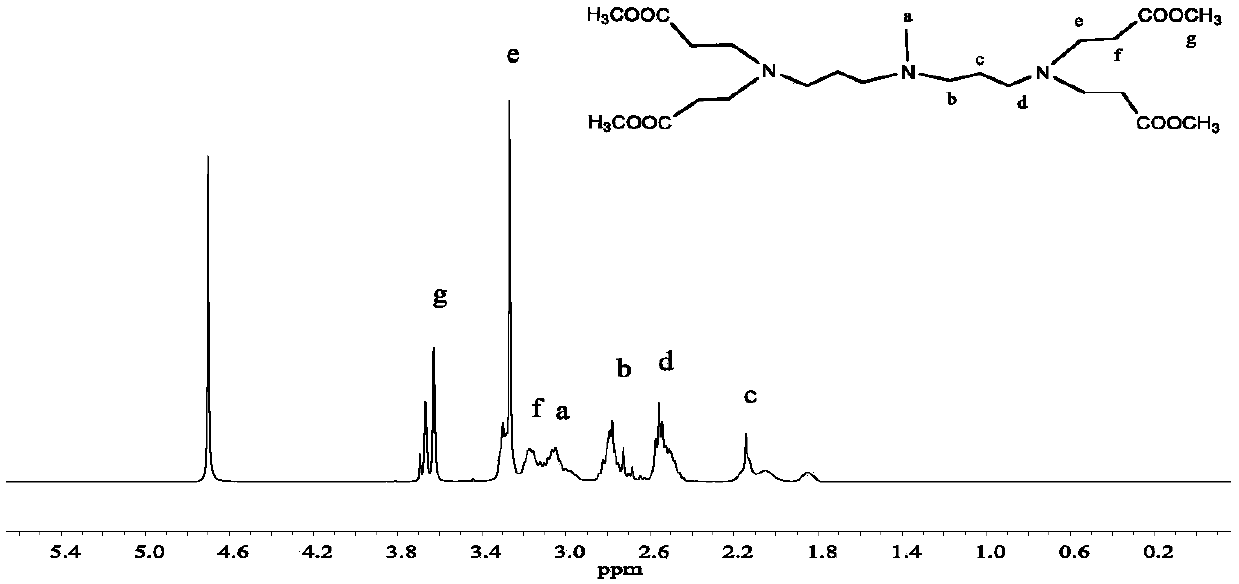

[0035] (1) Preparation of compound I

[0036] Build a reaction device, including a water bath, a three-necked flask, a spherical condenser, a drying tube, and a nitrogen supply device. First, put the built device in an ice-water bath, and pass nitrogen gas for 5 minutes, take 2.9g (20mmol) of 3,3-diamino-N-methyldipropylamine and dissolve it in 5ml of anhydrous methanol, add the spherical condensation In the three-necked flask of the tube and drying tube, pass nitrogen gas for another 20 minutes, then measure 13.76g (160mmol) methyl acrylate and add it into the three-necked flask at a rate of drop / 3s under dark conditions. After the addition, the system will naturally return to room temperature , and then set at 30°C and reacted for 24h. After the reaction was finished, methanol was removed by rotary evaporation, and methyl acrylate was removed by repeated addition of anhydrous methanol, and methyl acrylate was removed by rotary evaporation for more than 5 times, and finally ...

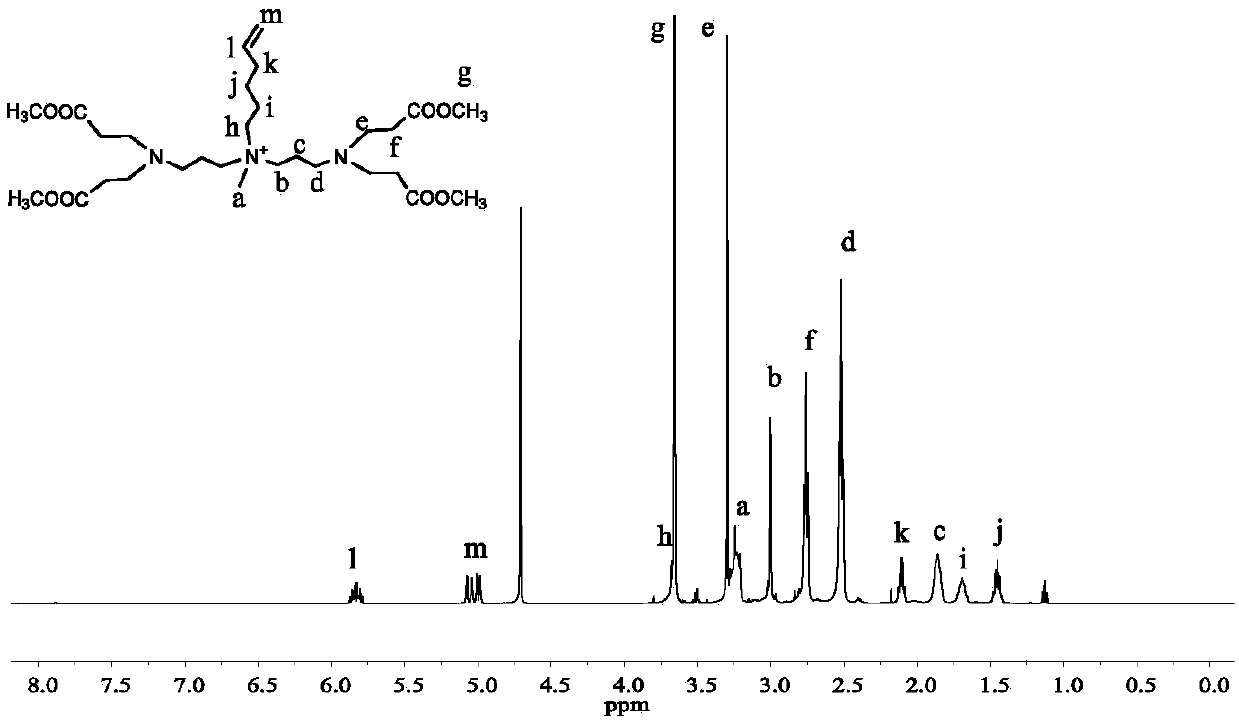

Embodiment 2

[0044] (1) Preparation of compound I

[0045] Build a reaction device, including a water bath, a three-necked flask, a spherical condenser, a drying tube, and a nitrogen supply device. First, put the built device in an ice-water bath, and pass nitrogen gas for 5 minutes, take 2.175g (15mmol) of 3,3-diamino-N-methyldipropylamine and dissolve it in 10ml of anhydrous methanol, add the spherical condensation In the three-necked flask of the tube and the drying tube, pass nitrogen gas for 20 minutes, then measure 8.6g (100mmol) methyl acrylate and add it into the three-necked flask at a rate of drop / 3s under dark conditions, and wait for the system to return to room temperature naturally after the addition , and then set at 25°C, and reacted for 30h. After the reaction was finished, methanol was removed by rotary evaporation, and methyl acrylate was removed by repeated addition of anhydrous methanol, and methyl acrylate was removed by rotary evaporation for more than 5 times, and ...

Embodiment 3

[0053] (1) Preparation of compound I

[0054] Build a reaction device, including a water bath, a three-necked flask, a spherical condenser, a drying tube, and a nitrogen supply device. First, place the built device in an ice-water bath, and pass nitrogen gas for 5 minutes, take 2.175g (15mmol) of 3,3-diamino-N-methyldipropylamine and dissolve it in 15ml of anhydrous methanol, add the top-connected spherical condensation In the three-necked flask of the tube and drying tube, pass nitrogen gas for 20 minutes, then measure 9.03g (105mmol) methyl acrylate and add it into the three-necked flask at a rate of drop / 3s under dark conditions, and wait for the system to return to room temperature naturally after the addition , and then set at 40°C, and reacted for 36h. After the reaction was finished, methanol was removed by rotary evaporation, and methyl acrylate was removed by repeated addition of anhydrous methanol, and methyl acrylate was removed by rotary evaporation for more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com