Method for preparing electric insulation oil from gutter oil

A technology for waste oil and insulating oil, which is applied in the field of electrical insulating materials, can solve the problems of increasing process complexity, reducing ignition point, flash point, and low yield, and achieves reduction in entering the food chain, reducing acid value, and high recycling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

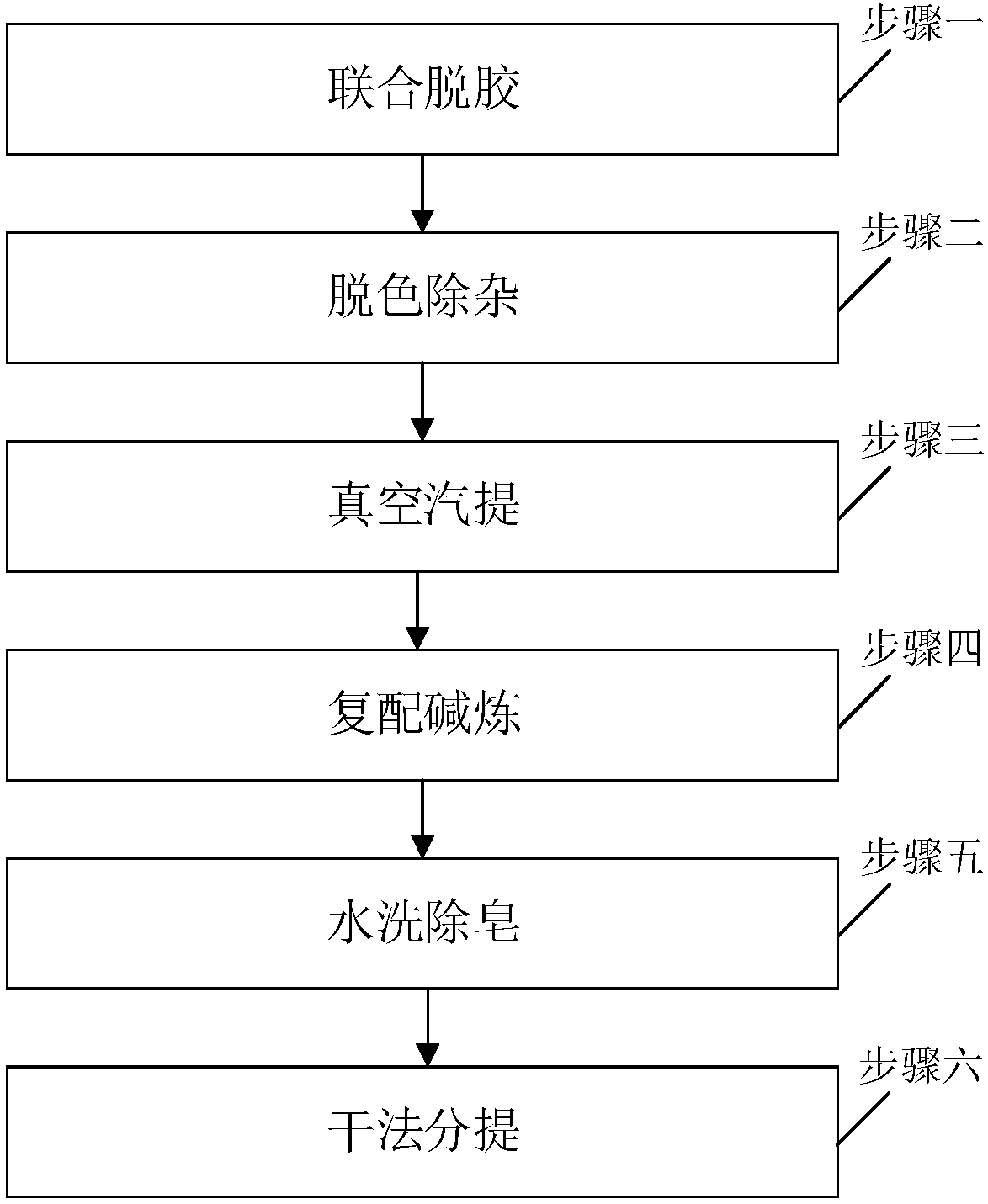

[0058] The invention provides a kind of waste oil preparation method for electric insulating oil, comprises the waste oil that is recovered through static sedimentation, floating matter skimming and rough grade filtration treatment, obtains rough grade waste oil, such as figure 1 As shown, the method also includes:

[0059] Step 1, joint degumming, including firstly preheating the crude waste oil to 65°C-75°C, adding phosphoric acid or citric acid whose mass is 0.05%-0.3% of the oil weight, stirring for 20-60 minutes and then cooling to 35 ~ 45°C; then add NaOH solution with a mass of 3% to 8% of oil weight and a concentration of 3% to 6%, stir for 20 to 60 minutes, heat to 65°C to 75°C and let it settle, release the lower layer solution, add 70 ℃~80℃, wash with soft water whose mass is 3%~8% of oil weight for 20~30min, and distill and dehydrate under reduced pressure; obtain degummed oil.

[0060] Step 2, decolorization and impurity removal, including adding activated clay o...

Embodiment 2

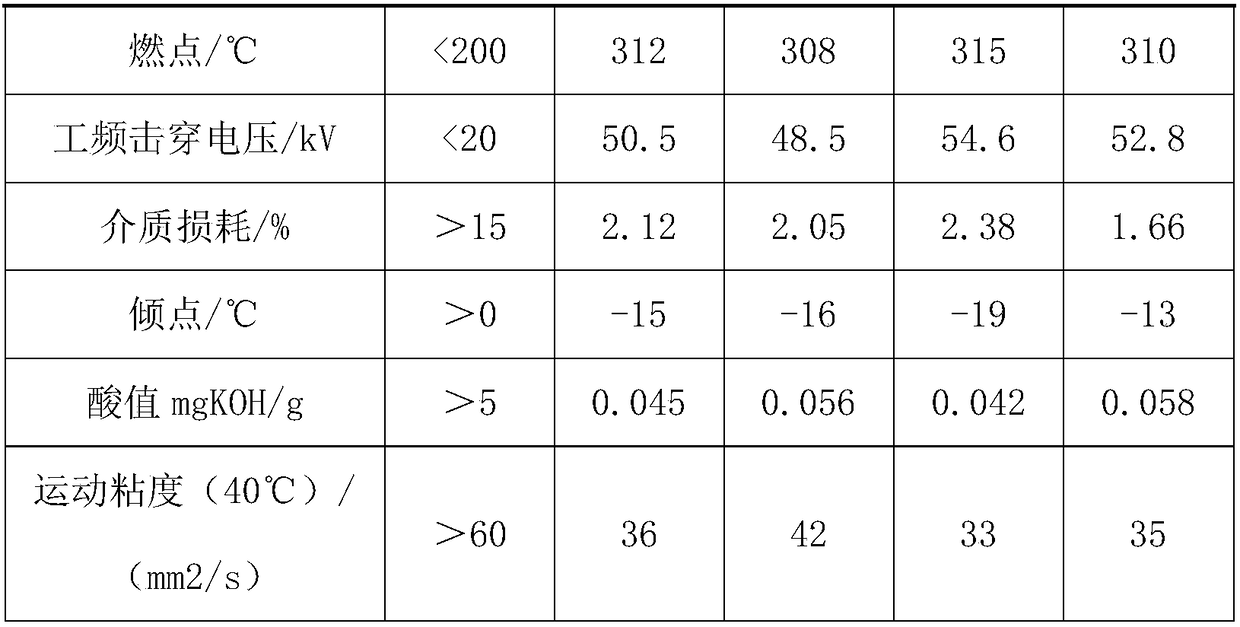

[0071] The combination of refined parameter values given in the embodiments of the present invention belongs to a mode of moderation in each embodiment of the present invention, and its parameters such as ignition point / °C, power frequency breakdown voltage / kV, dielectric loss / %, pour point / °C, acid The performance parameters of mgKOH / g and kinematic viscosity (40°C) / (mm2 / s) all belong to the middle category, and the insulating oil obtained is suitable for more conventional demand fields. Specifically, based on the implementation of the method of each step in embodiment 1, the corresponding performance in the embodiment of the present invention is as follows:

[0072] In the first step, firstly, after preheating the crude waste oil to 65°C, add phosphoric acid whose mass is 0.2% of the oil weight, stir and react for 30 minutes, and then cool to 35°C; 4% NaOH solution, stirred and reacted for 30 minutes, heated to 70°C and allowed to stand for precipitation, released the lowe...

Embodiment 3

[0079] The combination of refined parameter values given by the embodiments of the present invention belongs to a mode in which the characteristics of the embodiments of the present invention are weaker, such as ignition point / °C, power frequency breakdown voltage / kV, dielectric loss / %, pour point / °C, acid value mgKOH / g and kinematic viscosity (40 °C) / (mm2 / s), the performance is the worst in terms of ignition point and power frequency breakdown voltage, and the insulating oil obtained is suitable for controlling ignition point and industrial frequency Fields with low frequency breakdown voltage requirements. Specifically, based on the implementation of the method of each step in embodiment 1, the corresponding performance in the embodiment of the present invention is as follows:

[0080] In the first step, after preheating the crude waste oil to 75°C, add phosphoric acid with a mass of 0.1% of the oil weight and stir for 20 minutes, then cool to 40°C; 4% NaOH solution, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com