Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Does not affect basic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

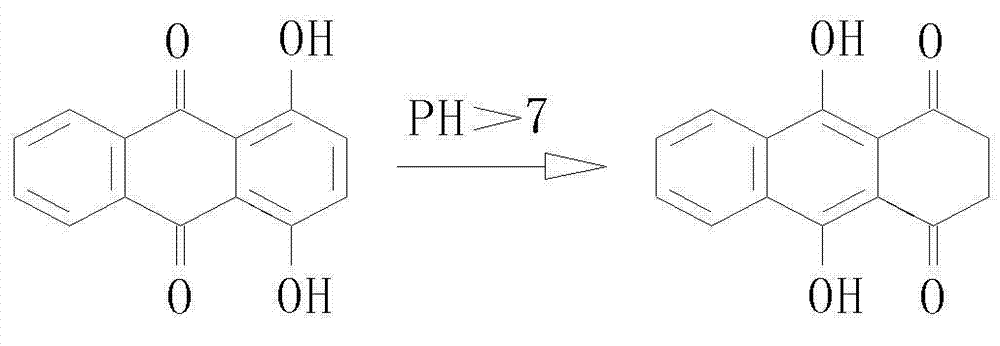

Preparation method of colorful polyurethane emulsion

InactiveCN102924682ASolid content distribution is wide and adjustableImprove performanceOrganic compound preparationCarbonyl compound preparationPrepolymerIsocyanate

The invention provides a preparation method of colorful polyurethane emulsion, comprising the following steps of: (1) reacting isocyanate, polyether polyol and polyester polyol to obtain a prepolymer; (2) carrying out chain extension reaction on the prepolymer prepared by the step (1), a colorful micromolecule chain extender, a common micromolecule chain extender and a hydrophilic chain extender; and (3) neutralizing by a salt-forming agent, emulsifying in a dispersing way by adding water, and removing an organic solvent by means of reduced pressure distillation to obtain the colorful hydrophilic polyurethane emulsion. According to the preparation method, the colorful micromolecule chain extender participates in the chain extension reaction, so that the prepared colorful polyurethane emulsion is better in whole performance, wide and adjustable in solid content distribution, and less in residuals of harmful substances in the colorful polyurethane emulsion. The red, yellow and blue three-color polyurethane emulsion can be synthesized by the micromolecule chain extenders with different colors, and the required polyurethane emulsion with the other colors can be obtained due to simple blending.

Owner:JIAXING HEXIN CHEM IND

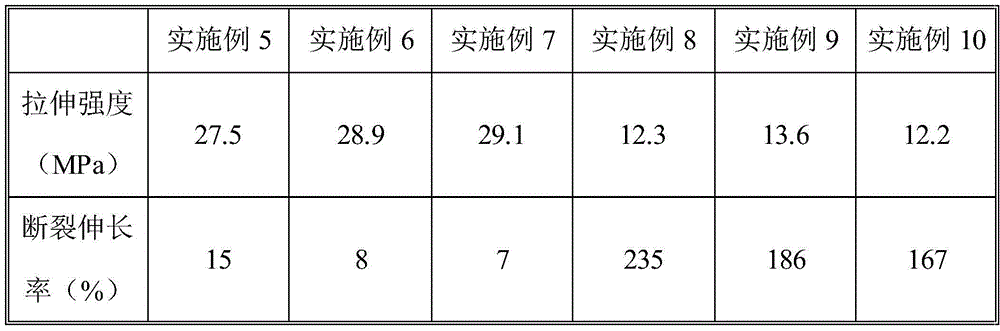

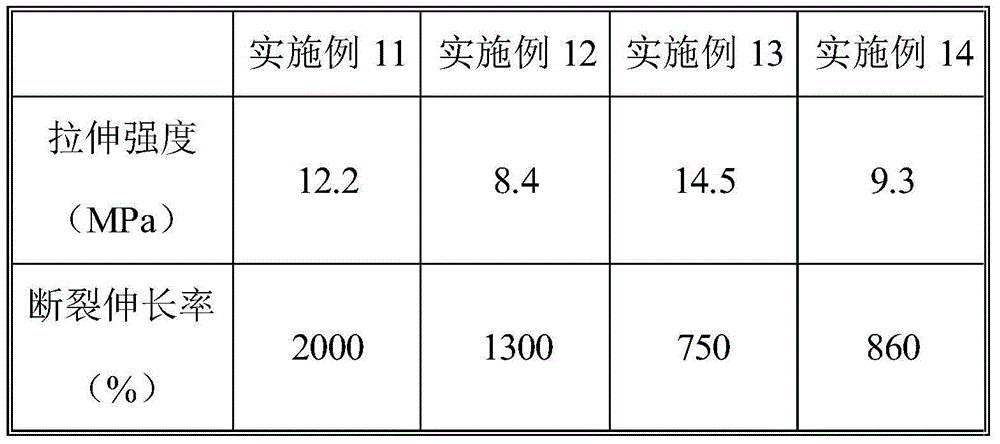

Starch based thermoplastic material and preparation method thereof

The invention discloses a starch based thermoplastic material and a preparation method thereof. The thermoplastic material is prepared from polymerization of components comprising, by weight, 100 parts of modified starch, 100-300 parts of monomers, 0.5-10 parts of initiators and 200-1000 parts of water. The modified starch is prepared from components comprising, by weight, 100 parts of natural starch, 0-200 parts of solvent, 10-50 parts of catalysts and 1-50 parts of modifiers. The preparation method includes that that the starch based thermoplastic material is prepared from the components according to the stated amounts after polymerization reaction. Plasticizing processing of starch can be realized without adding of plasticizers and blending with other materials, production efficiency is high, the thermoplastic material is low in cost, simple in process, controllable in performance, and applicable to preparation of thermoplastic materials with various performance requirements.

Owner:JIANGNAN UNIV

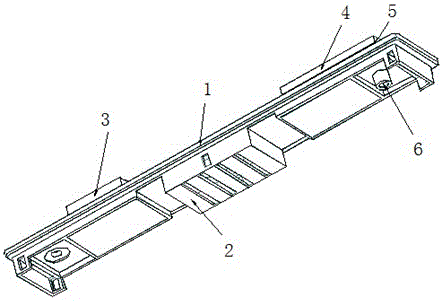

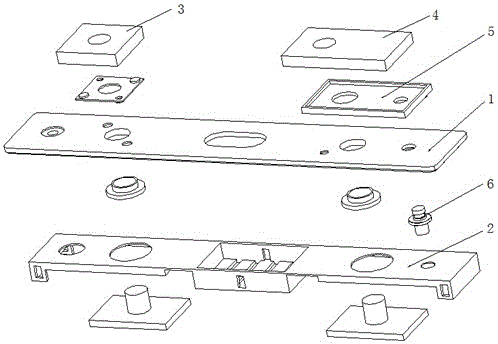

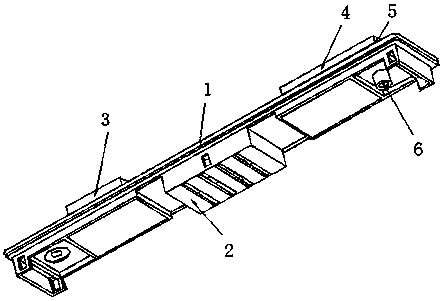

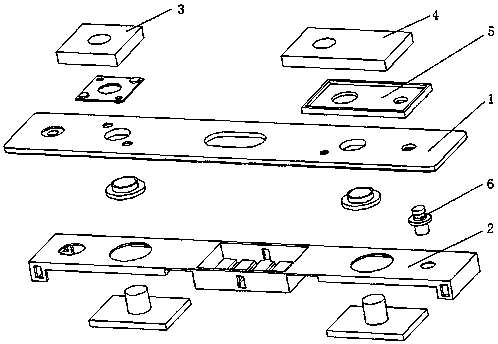

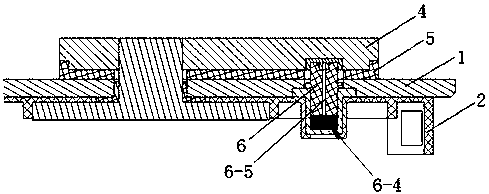

Radiating structure for display module of refrigerator

InactiveCN102564054ADoes not affect basic performanceImprove cooling effectDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:CHANGHONG MEILING CO LTD

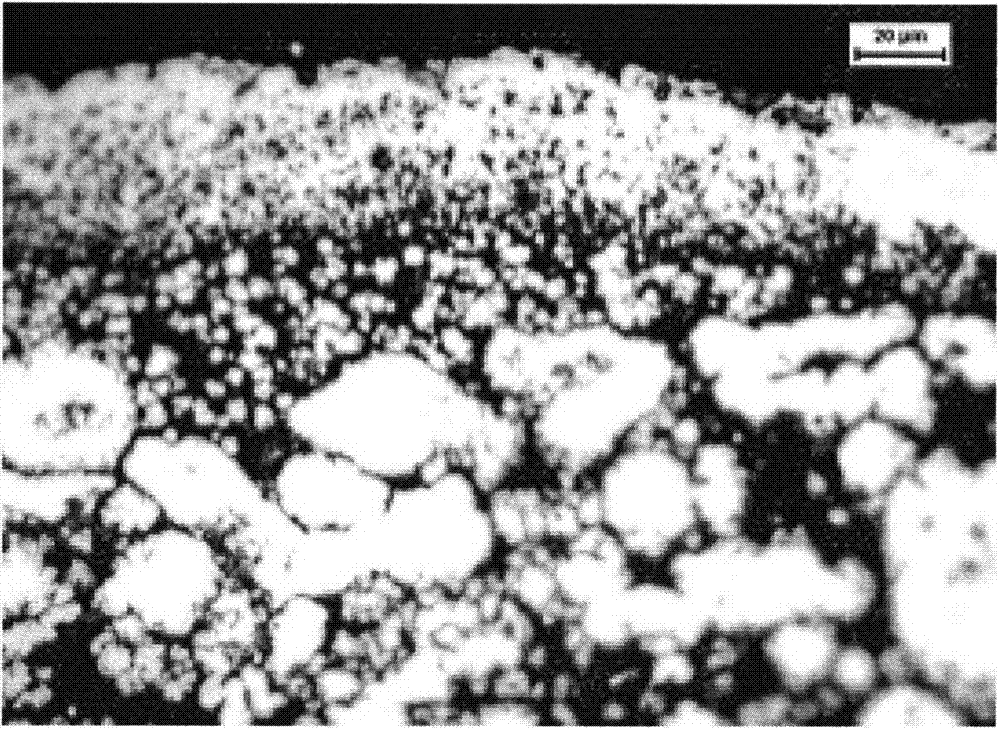

Preparation method of porous stainless steel film

ActiveCN103691329AImprove other performanceSolve the problem of easy peelingSemi-permeable membranesCompression moldingPore diameter

The invention discloses a preparation method of a porous stainless steel film. The preparation method comprises the following steps: firstly, carrying out compression molding on large-grain-size stainless steel powder coated with a low-melting-point metal layer on the surface through a powder compressing machine; secondly, preparing a stainless steel powder film layer on a molded blank body; and finally, sintering to obtain the highly-asymmetrical porous stainless steel film. According to the preparation method provided by the invention, the stainless steel powder surface of the base body for preparation is coated with the low-melting-point metal layer so as to reduce the sintering temperature of stainless steel powder of the base body. Therefore, the base body and the film layer are sintered together; the asymmetrical degree of the prepared porous stainless steel film material is high; the pore diameter distribution of the film layer is narrow; the film layer and the base body are firmly combined; the low-melting-point metal on the surface of the base body powder and the base body powder are alloyed by high temperature sintering; meanwhile, the mechanical intensity of the film material is ensured, and the other metal properties of the porous stainless steel film are improved.

Owner:NANJING UNIV OF TECH

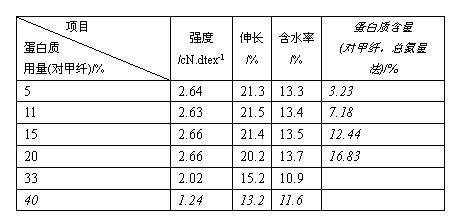

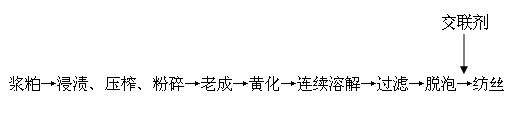

Modification method of regenerated cellulose fibre

InactiveCN102080270AReduce water swellingImproved boiling water shrinkageArtificial filaments from viscoseViscose fiberChemistry

The invention provides a modification method of a regenerated cellulose fibre, comprising: pulping, dipping, squeezing, crushing, maturation, etiolation, continuous dissolving, filtering, deaeration and spinning, wherein functional additives are added in a continuous dissolving step or before a spinning step; and the functional additives are added with cross-linking agents which take 1 to 3 percent of a gross weight of the functional additives. The invention can increase fixation rates of additives and reduce water swelling properties of the regenerated fibres, therefore having a great significance for viscose glue continuous spinning products, specifically, a shrinkage in boiling water of continuous spinning rayon products can be improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

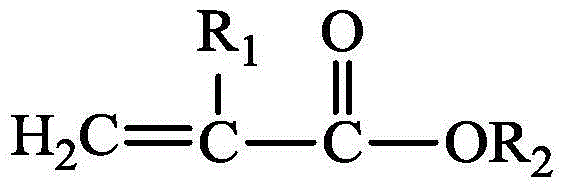

Modified starch-based toughened thermoplastic composite material and preparation method thereof

The invention discloses a modified starch-based toughened thermoplastic composite material and a preparation method thereof. The toughened thermoplastic composite material comprises 1-60 parts by weight of a starch-based graft copolymer and thermoplastic resin; the thermoplastic resin is at least one of polylactic acid, polyhydroxyalkanoate, polyformaldehyde, polyvinyl chloride, polymethyl methacrylate, polystyrene, polycarbonate, polyamide, polyester, polyphenyl ether, polyurethane and polypropylene; and the starch-based graft copolymer is formed by modifying natural starch, grafting an alkene monomer with the modified natural starch and polymerizing the grafted monomer. The preparation method is characterized in that all above components undergo melt blending according to corresponding use amounts in order to prepare the modified starch-based toughened thermoplastic composite material. Brittle plastic is toughened with the graft modified starch to realize the emulsifying process without an emulsifier and also realize the plasticizing processing of the thermoplastic composite material without adding a plasticizer, and the preparation method has the advantages of high production efficiency, low cost, simple technology and performance control.

Owner:JIANGNAN UNIV

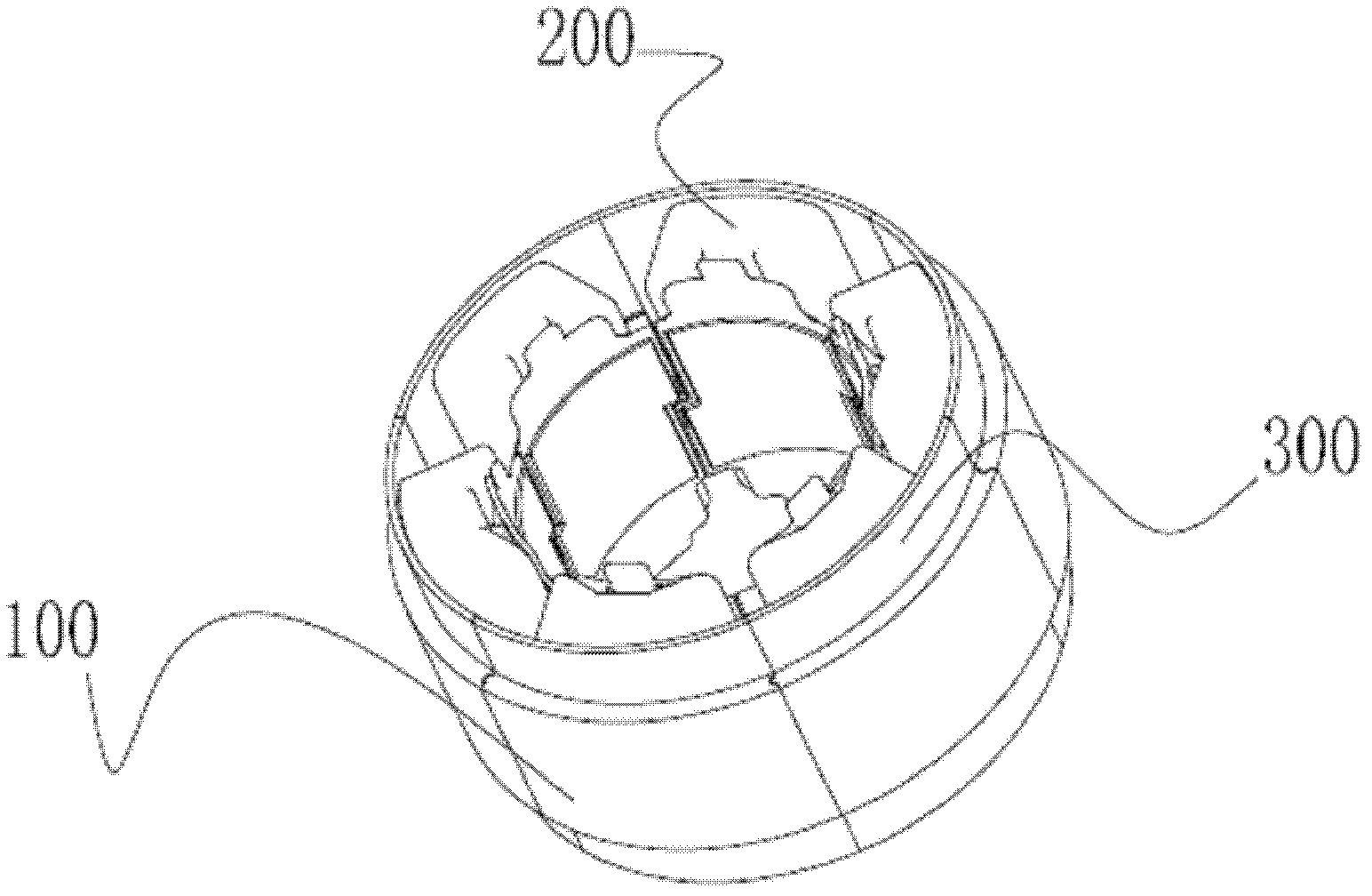

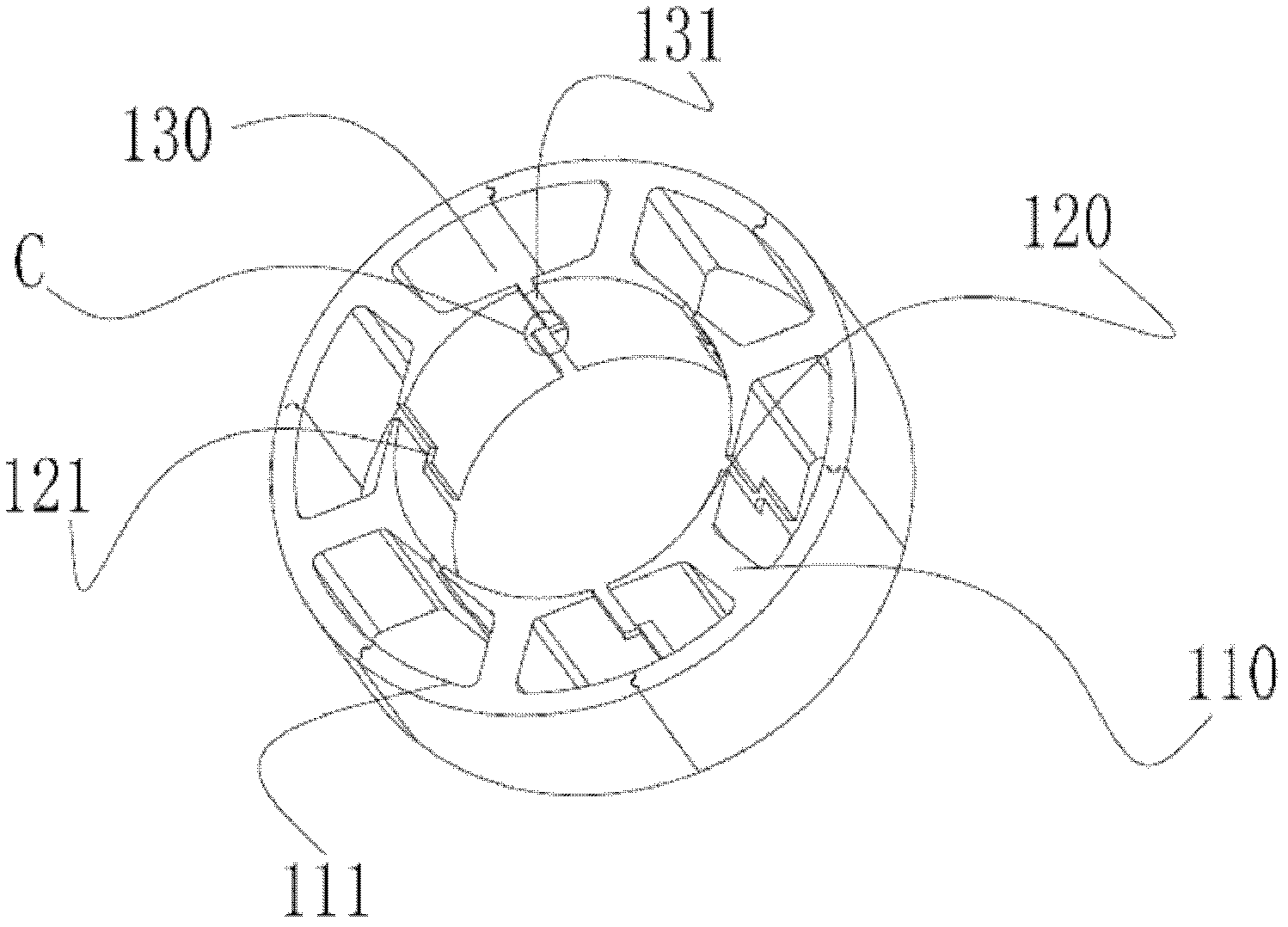

Low-cogging-torque motor stator and assembling method thereof

InactiveCN102545416ADoes not affect basic performanceEliminate torqueMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunchingStator coil

The invention relates to a low-cogging-torque motor stator. The low-cogging-torque motor stator comprises a stator iron core and stator coils, wherein a plurality of stator teeth are distributed at intervals and extended integrally from the inner circumference of the stator iron core; pole shoes are arranged at the tail ends of the stator teeth; a stator groove is formed between the adjacent stator teeth; the stator coils are placed in the stator grooves; one or more than one steps are arranged on two sides of each pole shoe; and the steps are correspondingly matched with the steps on the adjacent pole shoe to form a bend notch. The invention also relates to an assembling method for the low-cogging-torque motor stator. The assembling method comprises the following steps of: laminating stator punching sheets with different pole shoe widths into the stator iron core; correspondingly matching the steps with the steps on the adjacent pole shoe to form the bend notch; and placing the stator coils in the stator grooves so as to finish assembly of the stator. The invention meets the basic performance of a motor and greatly reduces cogging torque.

Owner:CHANGZHOU XINYA ELECTROMOTOR

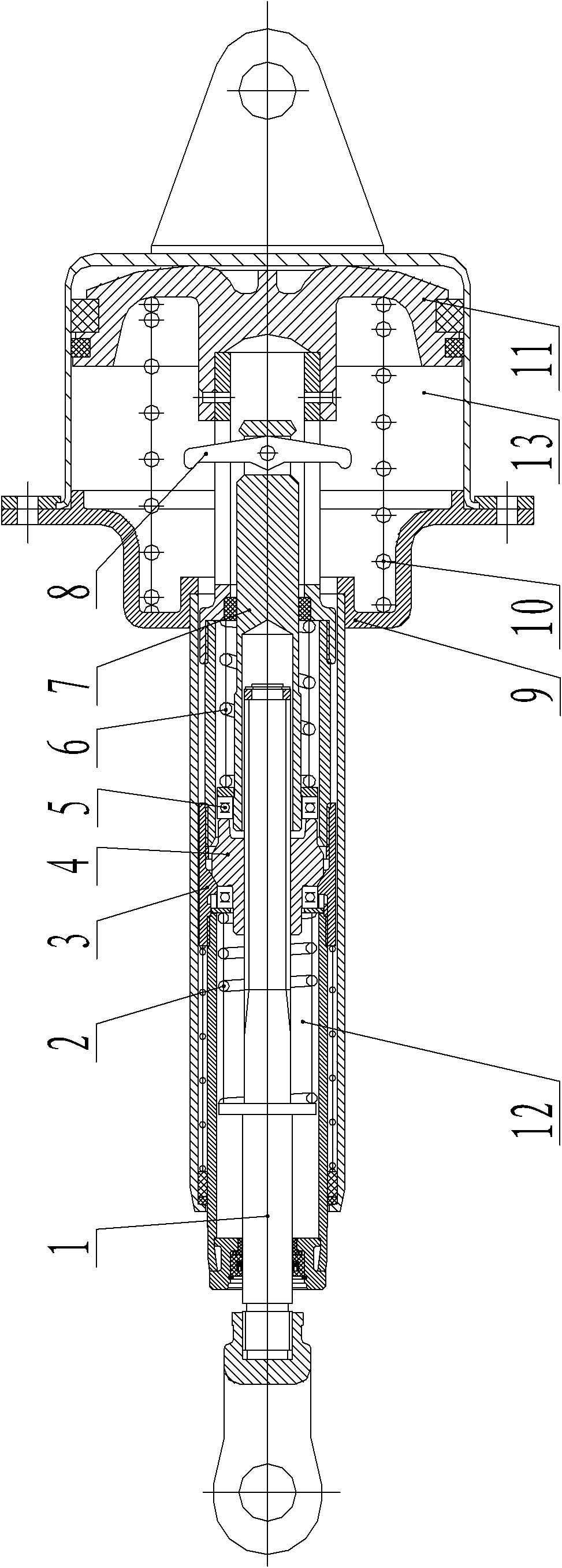

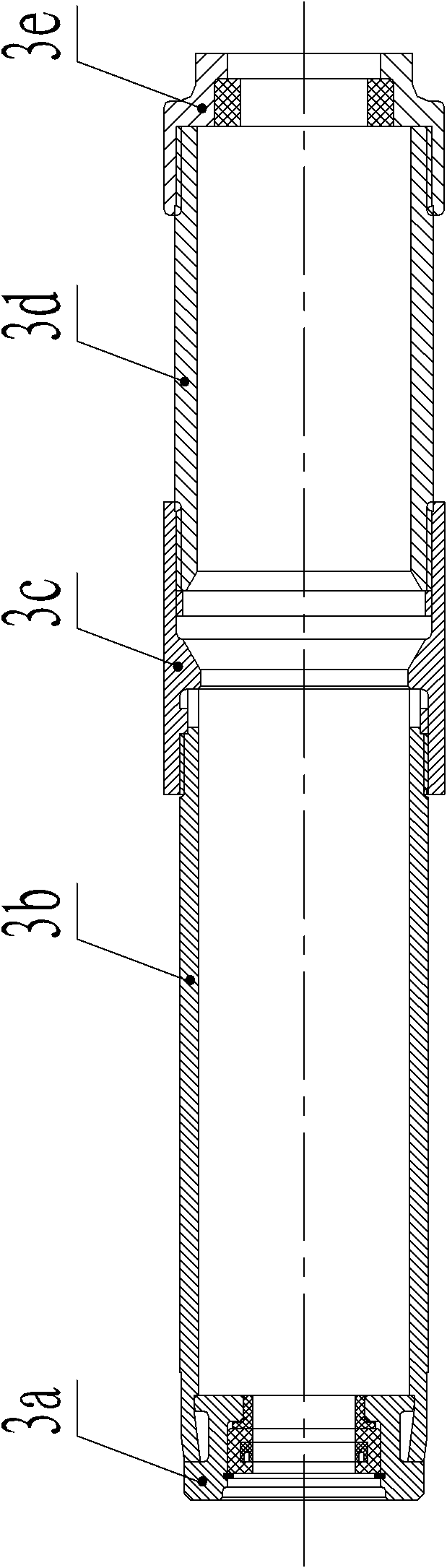

Automatically adjustable stroke type brake cylinder of railway vehicle

ActiveCN102352902AMeet the needs of stable work scheduleImprove securityBrake actuating mechanismsSlack adjustersEngineeringBrake shoe

The invention discloses an automatically adjustable stroke type brake cylinder of a railway vehicle, which mainly comprises a brake cylinder body and a brake shoe gap adjusting mechanism. The brake cylinder body comprises a cylinder body, a piston, a release spring and a pushing sleeve connected with the piston; the top end of the cylinder body is provided with an outer sleeve; and the top of thepushing sleeve is provided with a guide groove and can be pushed into the outer sleeve. The brake shoe gap adjusting mechanism comprises a screw rod, a first spring, a combined sleeve, an adjusting nut, a second spring, a pull rod and a control lever, wherein the combined sleeve can be installed in the outer sleeve in an axial moving way; the combined sleeve supports against the pushing sleeve under the action of an offsetting spring, the pull rod is connected with the control lever, the control lever is embedded in the guide groove of the pushing sleeve, and a boss at the end part of the control lever can be matched with a boss in an inner cavity of the cylinder body in a supporting way. The automatically adjustable stroke type brake cylinder of the railway vehicle is simple and compact in structure, reliable in operation performance and high in transmission efficiency and can meet the requirement for stable working strokes of brake cylinders of most of railway vehicles and improve the safety in operation of the railway vehicle.

Owner:CRRC ZHUZHOU ROLLING CO LTD

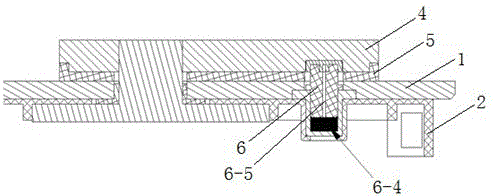

Superfine needle-shaped wollastonite powder-containing liquid rubber spray coating

InactiveCN102329562ADoes not affect basic performanceUniform particle size distributionUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a superfine needle-shaped wollastonite powder-containing liquid rubber spray coating and relates to the technical field of spray coatings. The superfine needle-shaped wollastonite powder-containing liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 10 to 65 percent of superfine needle-shaped wollastonite powder and 0.1 to 10 percent of silane coupling agent; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The superfine needle-shaped wollastonite powder is added into the spray coating, and the coating has high fireproof performance.

Owner:大连美宸特环保节能产品有限公司

Method for connecting AlN (aluminum nitride) ceramics and SiC/Al composite material respectively plated with thin-film metal layer on surface

InactiveCN102009240ADoes not affect basic performanceWelding/cutting media/materialsSoldering mediaSolderingFluoride

The invention provides a method for connecting AlN (aluminum nitride) ceramics and a SiC / Al composite material respectively plated with a thin-film metal layer on the surface, which belongs to the field of electrical packaging materials and technology. The method is characterized in that the surfaces of the adopted AlN ceramics and SiC / Al composite material are respectively plated with a thin-film metal layer, and the metal layer is made of nickel with a thickness of 1 to 10 mu m; and the adopted solder is a 40Al-40.7Ag-19.3Cu eutectic solder which is required to be used with fluoride soldering flux; the method comprises the following steps: firstly, cleaning the AlN ceramics, the SiC / Al composite material and the solder by using a physical or chemical method; putting the solder between the welding surfaces of the AlN ceramic and the SiC / Al composite material, then adding appropriate fluoride soldering flux; and finally, carrying out heat preservation on the obtained product for 3 to 30 minutes in a protective atmosphere at the temperature of 560 to 600 DEG C. The method provided by the invention has the advantages: at the brazing temperature, the basic properties of base metals are not affected; the solder does not intrude into the base metals so as to affect the properties of the base metals and welded joints; and the welded joints are good in property, the shearing strength of the welded joint reach 110MPa, and the air tightness of the welded joint is 1.0*10-11 Pa m<3> / s.

Owner:UNIV OF SCI & TECH BEIJING

Self-lubricating silicone rubber and preparation method thereof

InactiveCN107815124AImprove physical performanceDoes not affect basic performanceOther chemical processesPolymer scienceSilica gel

The invention provides a self-lubricating silicone rubber which is characterized by being prepared from all the following ingredients in parts by weight: 100 parts of methyl vinyl silicone rubber, 20to 50 parts of fumed silica, 1 to 5 parts of hydroxyl silicone oil, 0.1 to 1 part of fluorine mold release agent, 10 to 20 parts of methyl phenyl silicone oil and 2 to 10 parts of magnesium oxide. According to the self-lubricating silicone rubber and a preparation method thereof, raw rubber matching is improved to improve physical performance of the silicone rubber, non-reactive silicone oil is added to reduce surface friction after silica gel vulcanization, the defined amount of MgO is added to improve reverse resistance of silica gel products, and the special fluorine mold release agent ingredient is added to improve demoulding performance and roller banding performance; thus, basic performance of the silicone rubber is not affected, surface friction of the silica gel is reduced, productabrasion is reduced, a dynamic sealing effect of the silica gel is achieved, and service life of products is prolonged.

Owner:东莞新东方科技有限公司

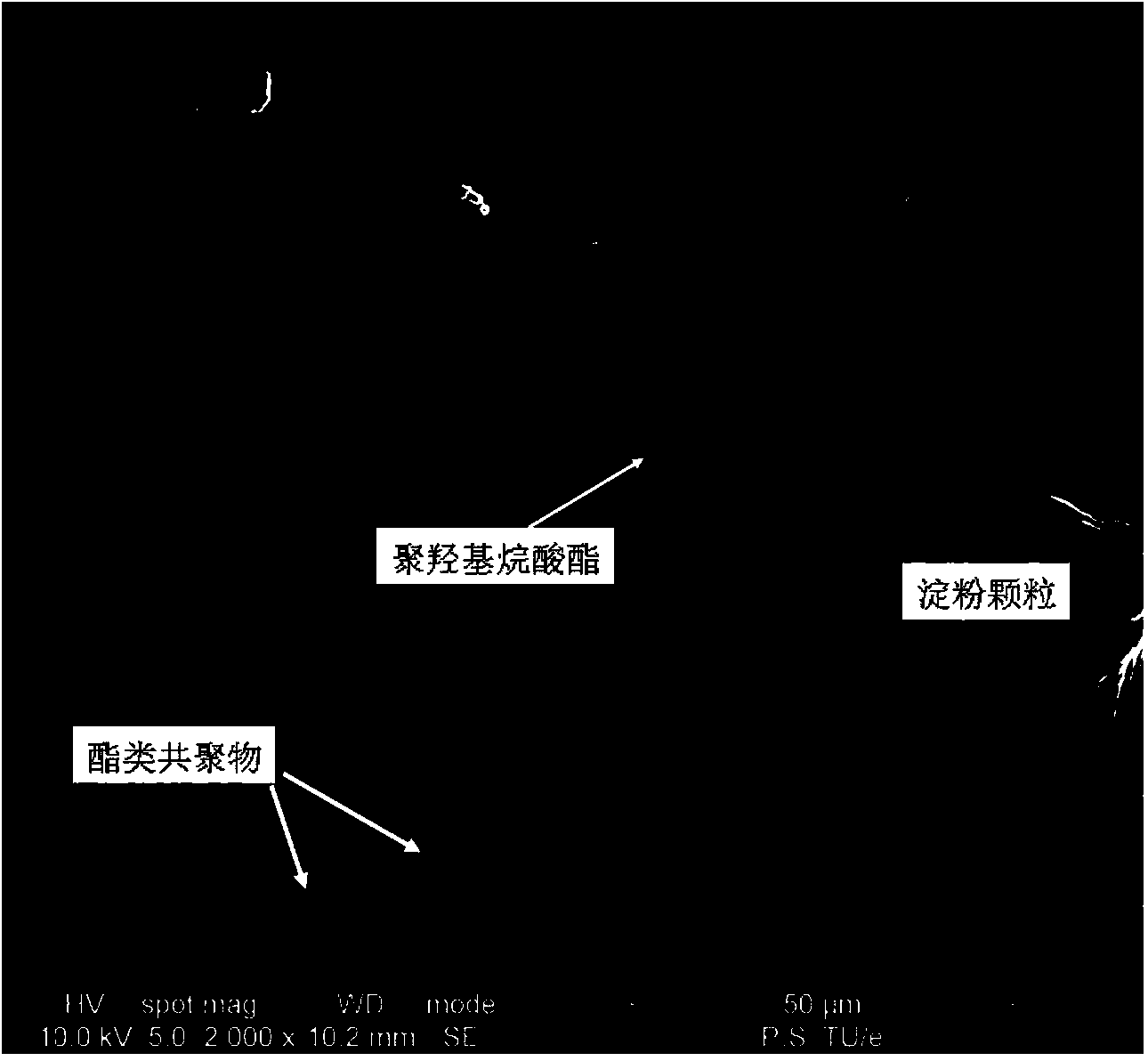

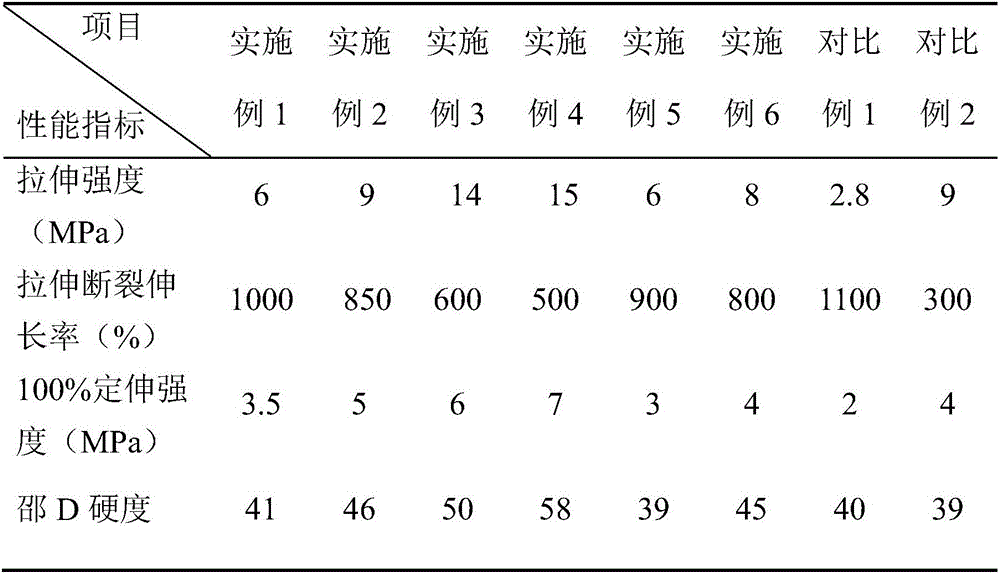

Polyhydroxyalkanoate composite material and preparation method thereof

The invention discloses a polyhydroxyalkanoate composite material and a preparation method thereof. The polyhydroxyalkanoate composite material is composed of the following raw materials in parts by weight: 90-120 parts of polyhydroxyalkanoate, 10-80 parts of starch, 1-25 parts of alcohol plasticizer, 20-100 parts of ester copolymer, 0.1-5 parts of anhydride and 0.01-2 parts of radical initiator. The polyhydroxyalkanoate composite material obtained by the preparation method provided by the invention is capable of remarkably improving the elasticity and strength of the PHA composite material and thinning the phase morphology of the PHA composite material. The composite material has the advantages of small starch particle size, good material elasticity, low cost biodegradability and the like; and the preparation method of the composite material is simple and easy to realize industrialization.

Owner:上海英华辰睿新材料有限公司

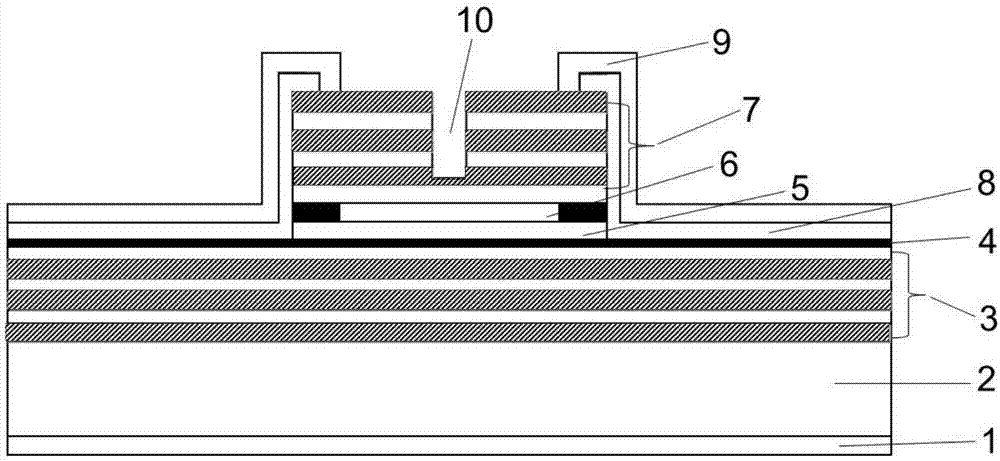

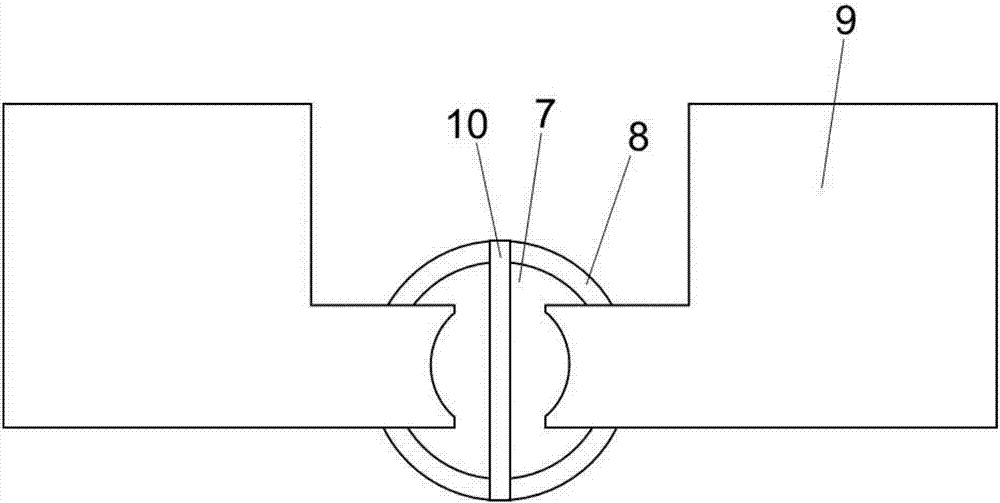

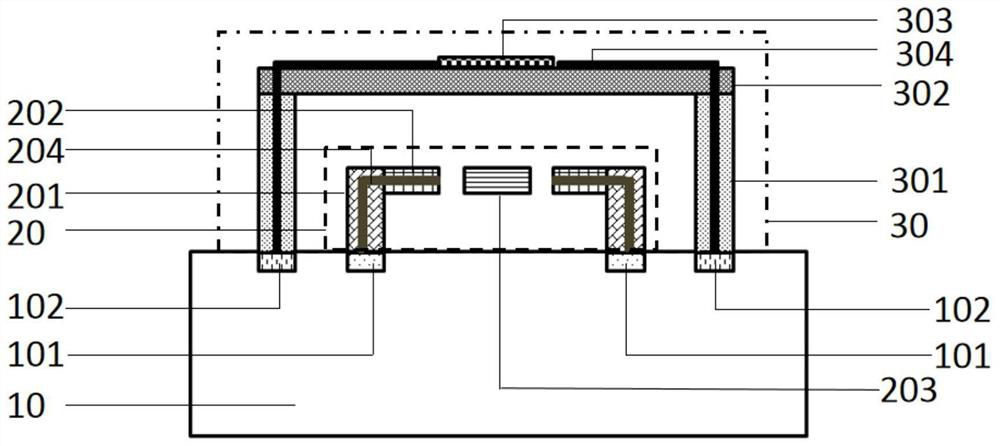

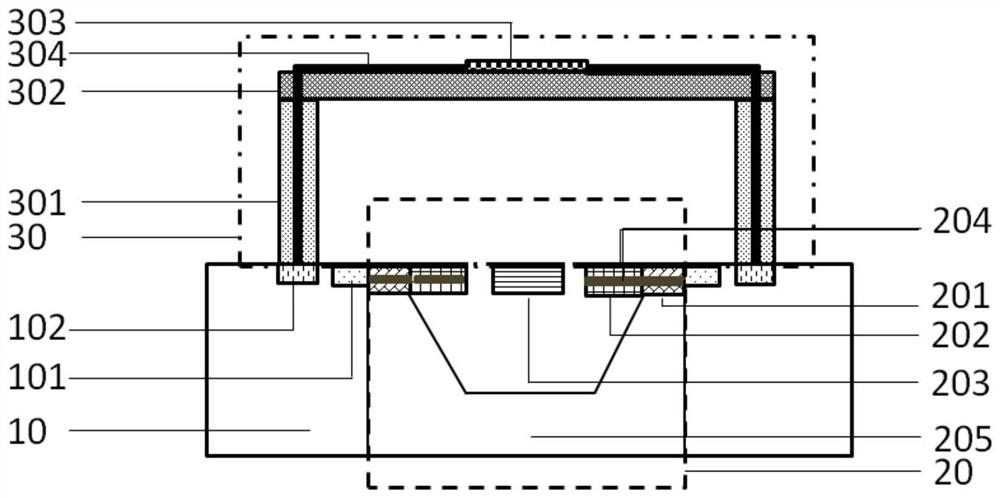

Vertical cavity surface laser emitter and manufacturing method thereof

ActiveCN106887788AAchieve independent controlNo growth processLaser detailsSemiconductor lasersMode controlMultiplexer

The invention discloses a vertical cavity surface laser emitter which comprises an active layer, a function assisting layer and a P-type DBR (Distributed Bragg Reflector) layer which are arranged in an overlapped manner, wherein the function assisting layer and the P-type DBR layer form a table surface structure; channels are formed inside the P-type DBR layer; the table surface structure is divided into a plurality of secondary table surface structures by the channels; P-surface electrodes in one-to-one correspondence to the secondary table surface structures are arranged at upper ends of the secondary table surface structures. Therefore, multiple waveguides can be formed by using the channels, carrier distribution and the waveguides can be associated, and furthermore the purposes that single mode output is independently controlled by a single electrode and a small deal of mode output is under hybrid control of multiple electrodes can be achieved. The invention further discloses a manufacturing method of the vertical cavity surface laser emitter. The table surface structure can be directly etched to form the channels, so that a novel mode control way can be achieved; in addition, as all modes are output on one same table surface, the modes can be directly coupled with optical fibers, and a multiplexer is not needed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

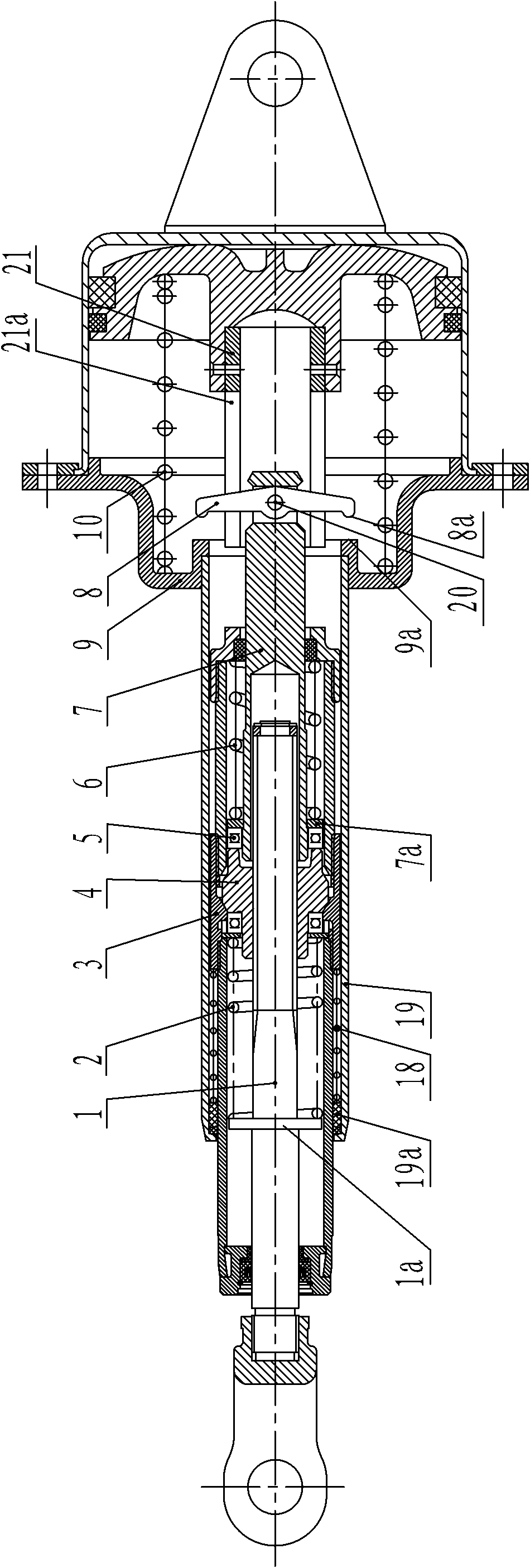

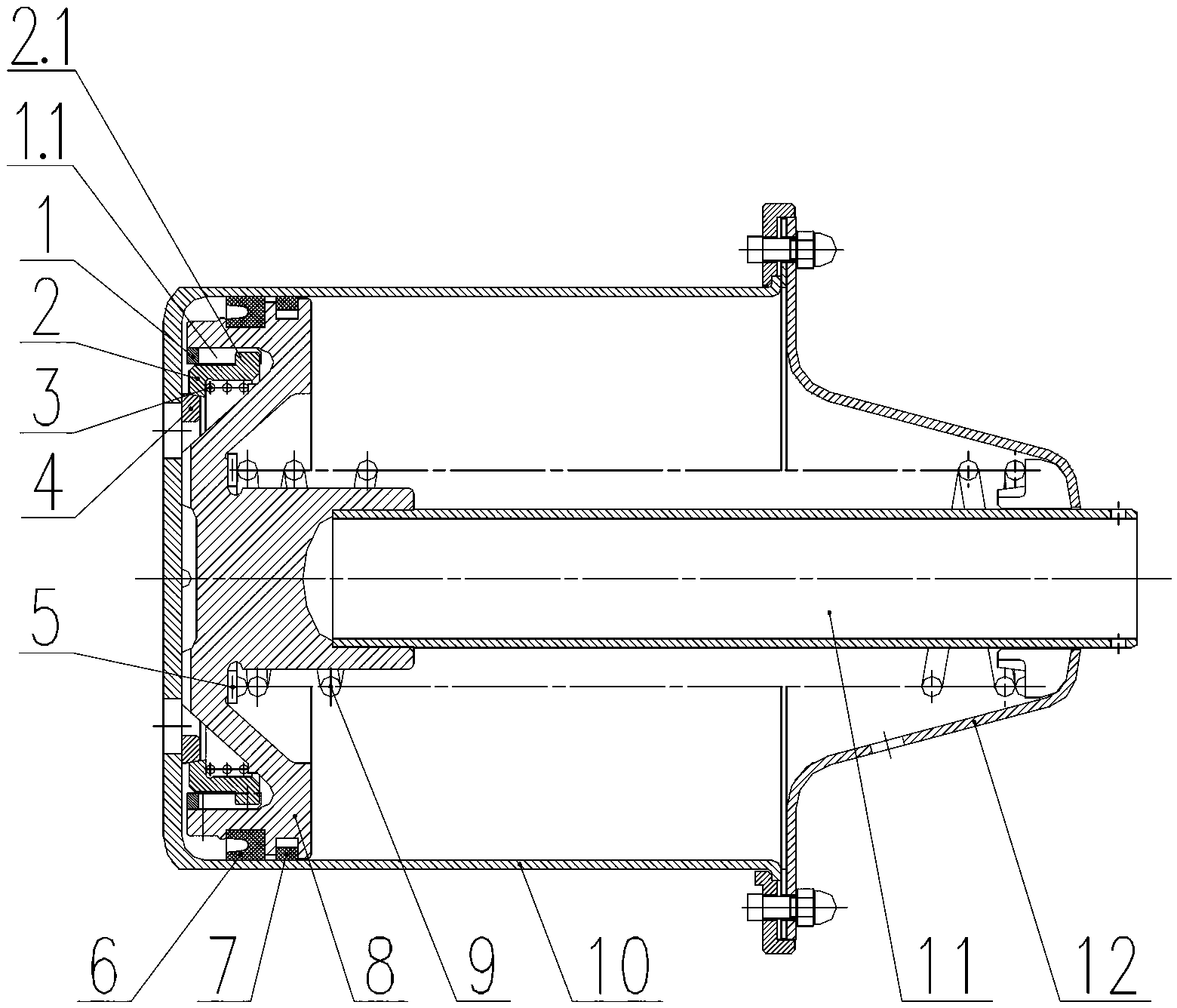

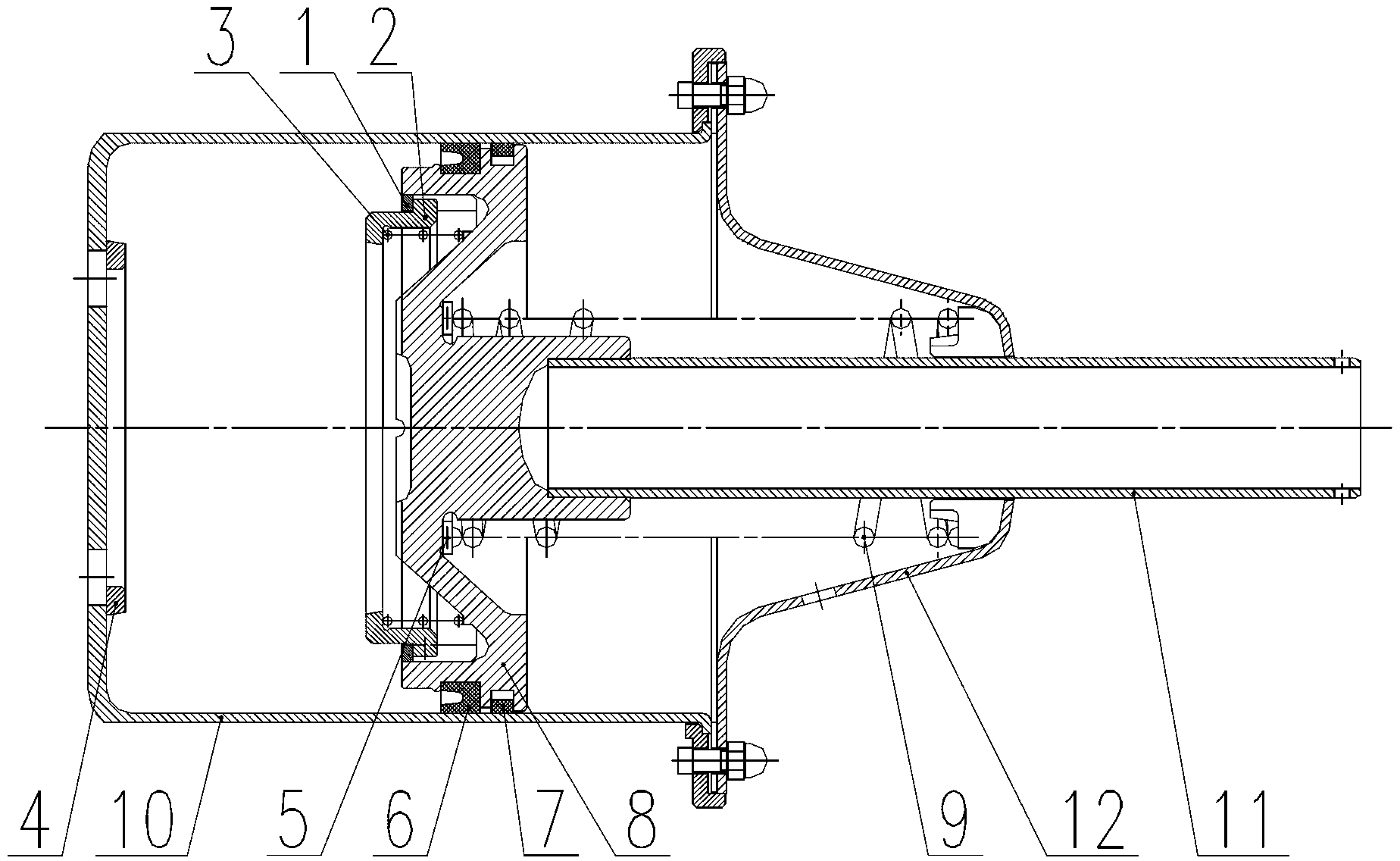

Rotationally lubricating type sealing brake cylinder for railway vehicles

ActiveCN103307151AEvenly lubricatedDoes not affect basic performanceBrake actuating mechanismsActuatorsClutch controlCylinder block

The invention provides a rotationally lubricating type sealing brake cylinder for railway vehicles, which comprises a cylinder body and a front cover assembly, wherein a piston and a piston rod are arranged inside the cylinder body, a sealing ring and a lubricating sleeve are arranged on the outer wall of the piston, a release spring is arranged between the bottom of the piston and the front cover assembly, the piston rod sticks out of the front cover assembly, a guiding ring is fixed on the inner wall of the ring slot in the top of the piston, a guiding sleeve is arranged on the inner side of the guiding ring, a reset spring is arranged between the guiding sleeve and the ring slot of the top of the piston, and a guiding base is fixed at the bottom of the cylinder body; and the guiding ring and the guiding sleeve form a screw rotation mechanism, the guiding sleeve and the guiding base form a clutch mechanism, the reset spring and the release spring form a clutch control mechanism, so as to enable the piston to rotate in only one direction under the action of the three mechanisms, the lubricating grease deposited at the bottom of the cylinder body is brought to mid-upper part of the cylinder body, the grease is pasted on the inner wall of the cylinder body uniformly, uniform lubricating of the piston sealing ring is guaranteed, and harmful or leaking faults are avoided. The rotationally lubricating type sealing brake cylinder provided by the invention has a simple structure, is small in revamping workload, and does not affect the basic performance of the conventional braking device of the vehicle.

Owner:CRRC YANGTZE CO LTD

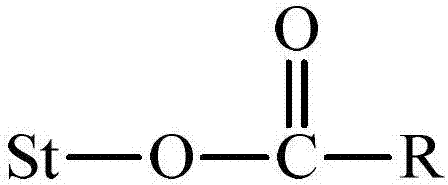

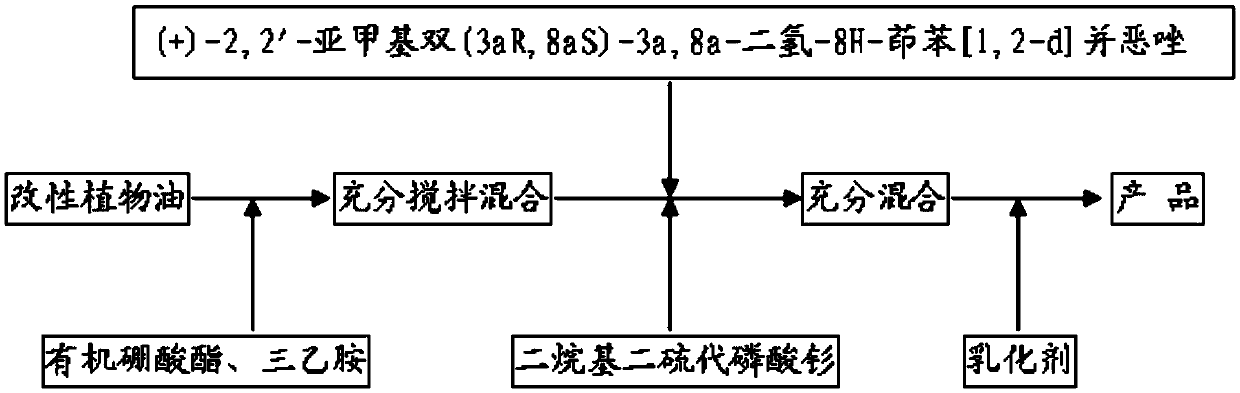

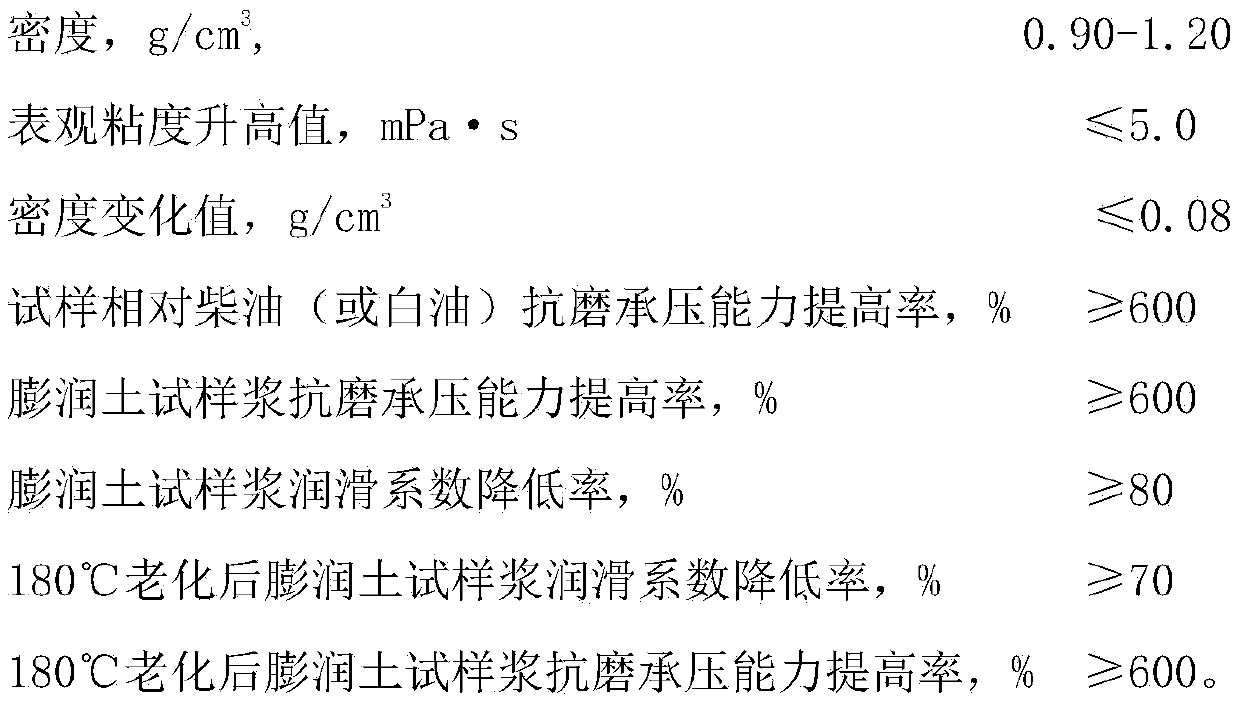

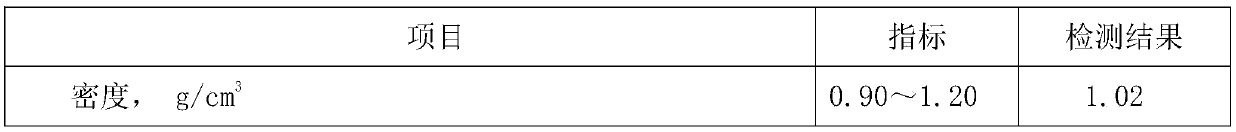

Anti-wear anti-seize lubricant for drilling fluid

ActiveCN105368413AImprove hydrolytic stabilityImprove carrying capacityDrilling compositionWell drillingCarbon chain

The invention discloses an anti-wear anti-seize lubricant for a drilling fluid, and belongs to the field of well drilling. The anti-wear anti-seize lubricant comprises the components: epoxidized (and / or sulfonated) modified vegetable oil, at least two organic boric acid esters with different carbon chains, triethylamine, samarium dialkylphosphorodithiloate, (+)-2,2'-methylenebis[(3aR,8aS)-3a,8a-dihydro-8H-indeno[1,2-d]oxazole, and an emulsifier, wherein the mass ratio of the organic boric acid esters to triethylamine to samarium dialkylphosphorodithiloate is 5 to 5 to 2, the total amount of the three components accounts for 20%-36% of the total mass of the product, and the amount of the emulsifier accounts for 5% of the total mass of the product. The anti-wear anti-seize lubricant for the drilling fluid has stronger anti-wear, anti-friction and high-temperature-resistant performance.

Owner:CHENGDU DEDAO IND

Polylactic acid composite material and preparation method thereof

The invention discloses a polylactic acid composite material and a preparation method thereof. The polylactic acid composite material comprises the following active ingredients respectively in parts by weight: 80-120 parts of polylactic acid, 100-200 parts of inorganic fillers, 15-35 parts of ester copolymer, 0.5-10 parts of polyfunctional group coupling agent, and 0.02-2 parts of radical initiator. According to the preparation method provided by the invention, the filling capacity and dispersity of the inorganic fillers, as well as the interface binding force between the inorganic fillers and the polymer, in the polylactic acid composite material can be remarkably improved. The composite material has the advantages of being excellent in properties, low in cost, biodegradable and the like, and the preparation method is simple, and easy for realization of industrial production.

Owner:苏州梅克兰循环科技有限公司

Safety over-charge prevention cover board for ternary lithium battery

ActiveCN105895835AImprove securityAvoid thermal runawaySecondary cells charging/dischargingCell lids/coversLiquid stateMechanical engineering

The invention provides a safety over-charge prevention cover board for a ternary lithium battery, which comprises a cover board main body, a bottom insulation board, and a positive terminal and a negative terminal which are respectively and fixedly arranged at the upper end face of the cover board main body. The positive terminal is conducted with the cover board main body; an insulating mat is arranged between the negative terminal and the cover board main body; the bottom end face of the negative terminal is connected with a temperature sensor for sensing an internal temperature of the lithium battery; a liquid conducting medium is arranged at the bottom of the temperature sensor; and when the internal temperature of the battery is excessively high, the liquid conducting medium is expanded to ascend to the top end of the battery, so that the negative terminal is conducted with the cover board main body to form an external short circuit. When an over-charge temperature of the battery is risen, the liquid conducting medium is expanded to change the temperature sensor into a conductor, so that the negative terminal is conducted with the cover board to form the external short circuit, thereby preventing thermal runaway in the over-charge process and ensuring over-charge safety of the battery.

Owner:合肥国轩电池有限公司

Thermoplastic vulcanized rubber based on polylactic acid, and preparation method thereof

The invention discloses thermoplastic vulcanized rubber based on polylactic acid, and a preparation method thereof. The rubber comprises the raw materials of, by weight, 50-90 parts of ethylene-vinyl acetate rubber, 10-50 parts of polylactic acid, 0.1-3 parts of peroxide, 0.1-5 parts of a free radical stabilizing agent, 0.05-1 part of an antioxidant, 0.1-3 parts of an anti-aging agent, and 1-20 parts of a plasticizer. With the preparation method provided by the invention, the obtained thermoplastic vulcanized rubber has the characteristics of high biomass content, high strength, high elongation rate, good resilience, partial biodegradability, excellent thermoplasticity, and the like. The preparation method is simple, and industrialization can be easily realized.

Owner:上海英华辰睿新材料有限公司

Preparation method of environment-friendly cigarette adhesive

InactiveCN105111974AImprove bonding performanceIncrease contentMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionVinyl acetate

The invention discloses a preparation method of an environment-friendly cigarette adhesive. The preparation method comprises the following steps: mixing water, a pH buffer agent, polyvinyl alcohol and an emulsifying agent, heating the mixture to 88-92 DEG C until polyvinyl alcohol is completely dissolved, and cooling to 58-62 DEG C; adding one tenth of vinyl monomer mixture and one half of a plasticizer, mixing, heating the mixture to 73-77 DEG C, adding an initiator equal to one third of the initiator after 0.5-1.0 hour, and preserving the temperature for reaction; dropwise adding the remnant vinyl monomer mixture within 4-6 hours after an emulsion emits blue ray, replenishing one third of the initiator when one half of the vinyl monomer mixture is dropwise added, adding the remnant initiator after the vinyl monomer mixture is dropwise added, heating to 88-92 DEG C, and further reacting for 30-60 minutes; continuously stirring to naturally cool to 60-70 DEG C, adding the remnant plasticizer, uniformly mixing, and carrying out vacuumizing for 10-20 minutes; cooling to the room temperature, so as to obtain a component I; mixing the component I with ethylene-vinyl acetate polymers, so as to obtain the environment-friendly cigarette adhesive.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

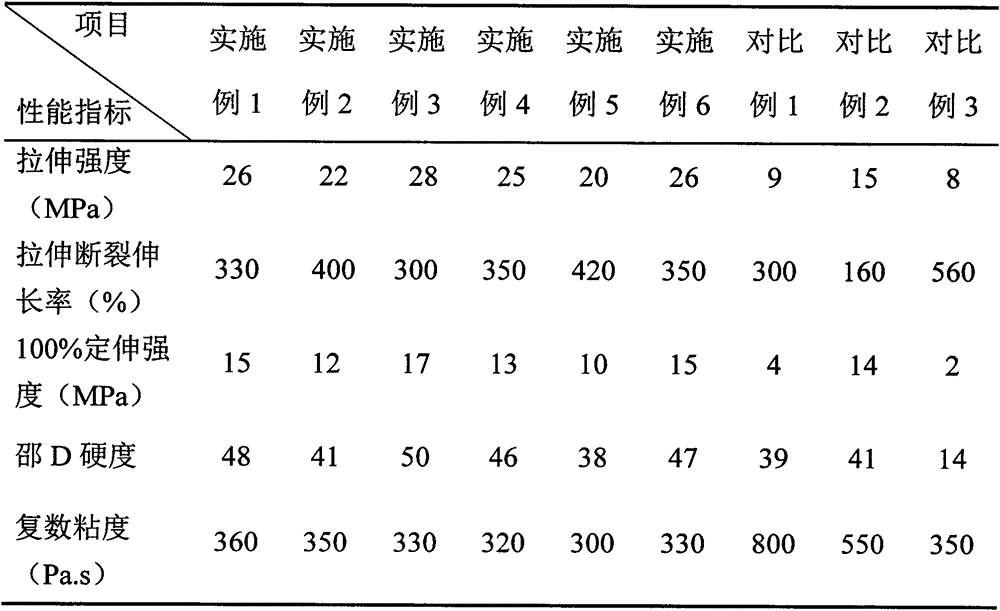

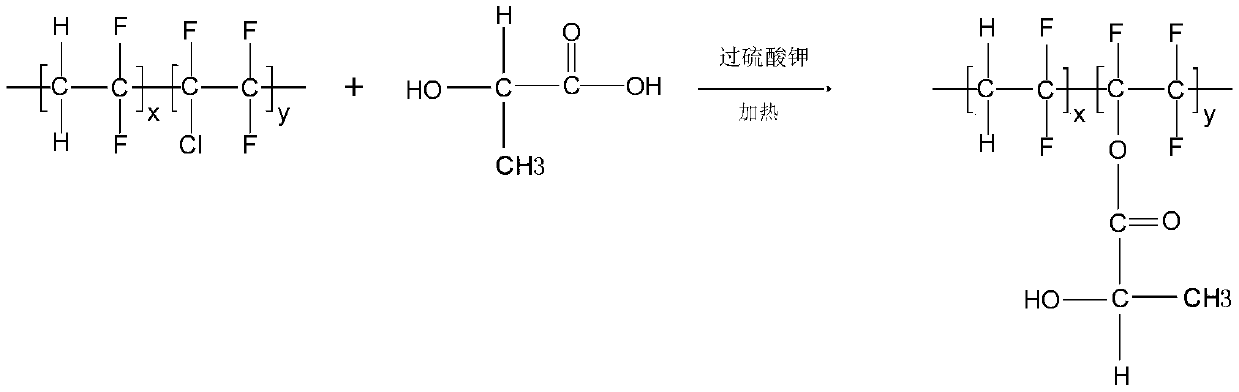

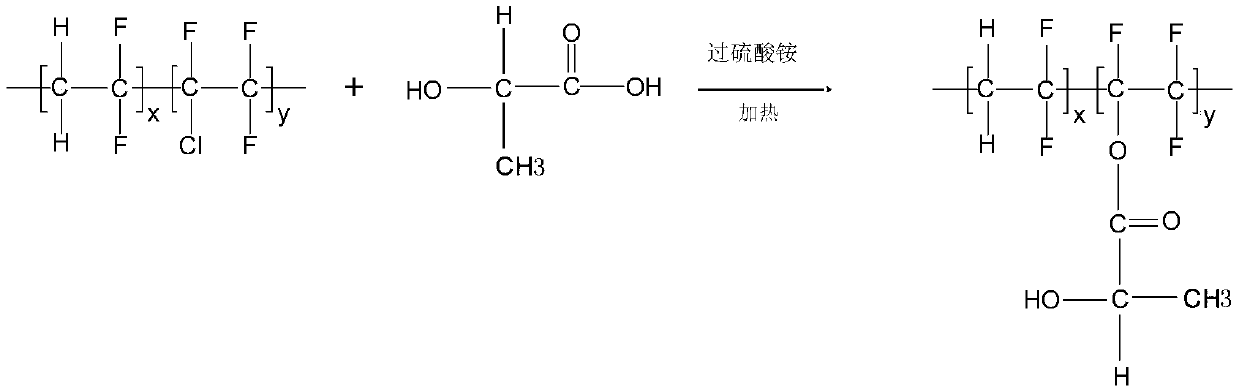

Lithium battery, lithium battery diaphragm and preparation method of lithium battery diaphragm

ActiveCN110061175APromote degradationAccelerated fractureCell seperators/membranes/diaphragms/spacersLi-accumulatorsOrganic solventFluoride

An embodiment of the invention discloses a preparation method of a lithium battery diaphragm. The method comprises the steps of adding 10-15 parts by mass of poly(vinylidene fluoride-chlorotrifluoroethylene) and 2-7 parts by mass of lactic acid into 50-80 parts by mass of an organic solvent, and carrying out stirring and dissolving; adding 0.5-5 parts by mass of an initiator and 2-10 parts of a hydrogenation reducing agent, and then carrying out stirring and reacting; adding a reaction mixture into an alkaline aqueous solution, carrying out stirring and precipitating, and carrying out filtering, washing and drying precipitates to obtain poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin; and preparing the lithium battery diaphragm from the poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin. The lithium battery diaphragm is prepared from the poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin, so that the lithium battery diaphragm has the characteristics of being degradable, resistant to electrolyte corrosion and high in tensile strength.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

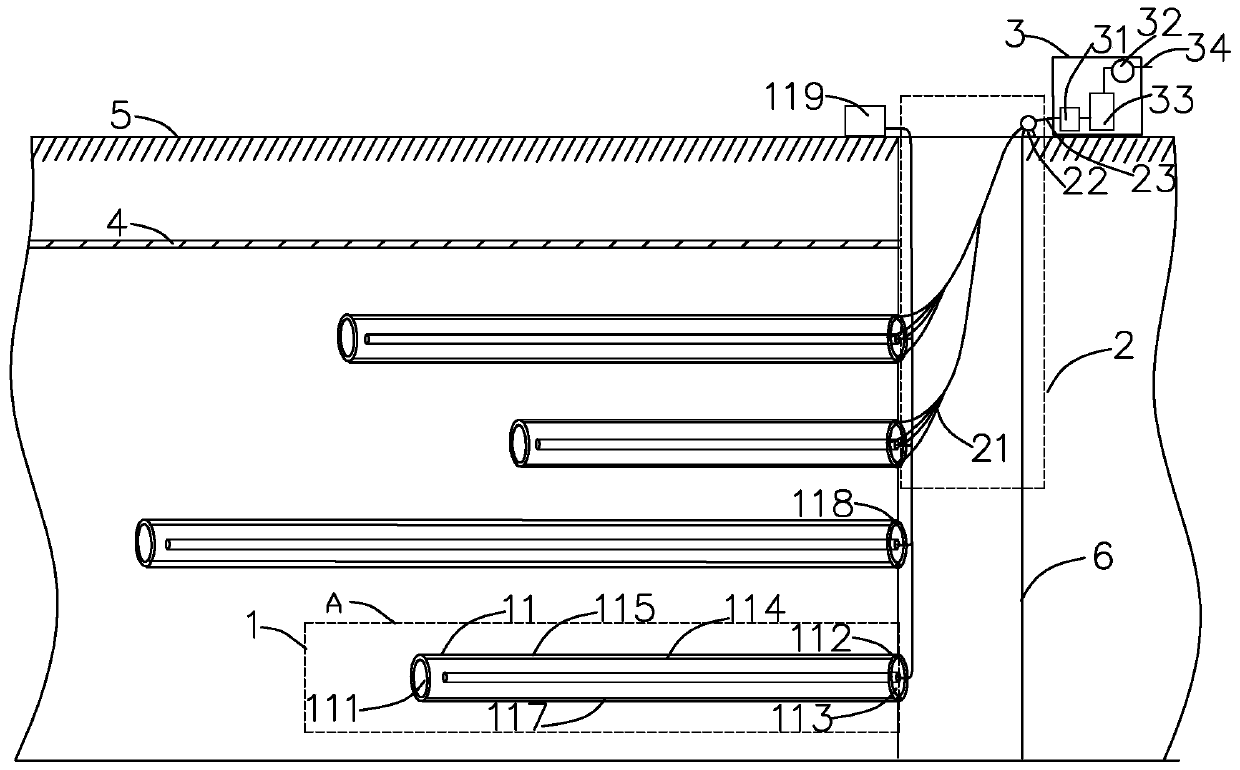

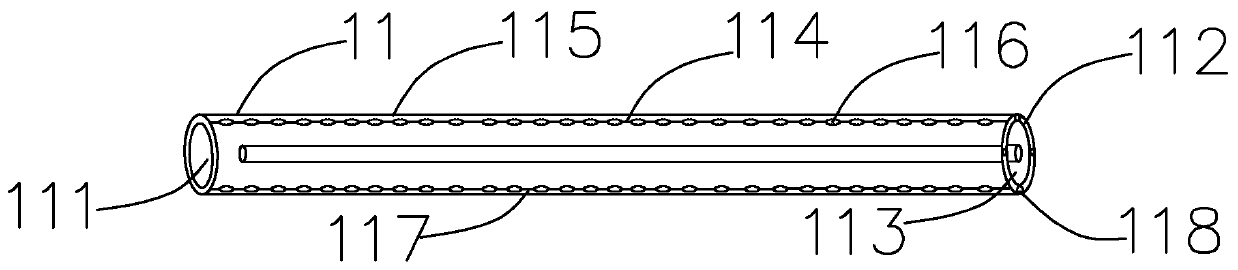

Soil remediation device and method

PendingCN111515237AImprove repair effectQuick fixContaminated soil reclamationSoil remediationWell drilling

The invention discloses a soil remediation device and method. The device comprises a volatile gas capture device, a gas extraction device and a waste gas treatment device. The volatile gas capture device is composed of a plurality of transverse remediation pipes. The method comprises the following steps: investigating the pollution condition; forming a remediation protection layer; digging a vertically downward longitudinal side well on the inner side of a gas station site far away from the traffic road; conducting transverse well point layout, and conducting transverse well building on a pollution source area of the gas station site with the side well as the starting point of well drilling; and starting a heating resistance rod and the gas extraction device, and collecting volatile organic pollutants in the transverse remediation pipes. By means of the method, under the premise that normal use of the site ground gas station is guaranteed, remediation of soil under the ground is achieved, the heat conduction performance of the soil is enhanced, underground water is rapidly remediated, diffusion of pollutants around is cut off, and then the overall remediation effect of the gas station is improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY +2

Hydrogel microsphere containing ellagic acid and preparation method thereof

InactiveCN110327227AReduce hypersecretionPrevent content declineCosmetic preparationsToilet preparationsPreservativeHydrogel microspheres

The invention provides a hydrogel microsphere containing ellagic acid and a preparation method thereof. The hydrogel microsphere containing the ellagic acid is characterized by comprising a core material and a wall material, wherein the wall material wraps the core material; the core material contains ellagic acid, a humectant, an antioxidant and a preservative; and the wall material is hydrogel formed by crosslinking sodium alginate and calcium chloride. The hydrogel microsphere containing the ellagic acid obtained by the invention is applied on the face to reduce melanin deposition in a large area, and has the effects of whitening and moisturizing skins.

Owner:SHANGHAI INST OF TECH

Polyvinylidene difluoride-based thermoplastic vulcanized rubber and preparation method thereof

The invention discloses polyvinylidene difluoride-based thermoplastic vulcanized rubber and a preparation method thereof. The polyvinylidene difluoride-based thermoplastic vulcanized rubber is composed of, by weight parts, 70-90 parts of ethylene-butyl acrylate-glycidyl methacrylate copolymer rubber, 10-30 parts of polyvinylidene fluoride, 0.5-2 parts of amine curing agent, 0.1-5 parts of free radical stabilizer, 0.05-1 part of antioxidant 0.1-3 parts of anti-aging agent and 1-20 parts of plasticizer. The thermoplastic vulcanized rubber obtained according to the preparation method has the advantages of being high in strength, large in elongation, good in resilience and excellent in thermoplasticity and the like. The preparation method is simple, and industrialization is achieved easily.

Owner:JIANGNAN UNIV +1

Cellulose diacetate composite material with semi-interpenetrating network structure and preparation method thereof

The invention discloses a cellulose diacetate composite material with a semi-interpenetrating network structure and a preparation method thereof.The preparation method is characterized in that after cellulose diacetate and epoxy resin are mixed, epoxy resin dispersed in the mixture is cured, and the semi-interpenetrating network structure is formed; the composite material is prepared from, by mass, 100 parts of cellulose diacetate, 5-50 parts of epoxy resin, 5-20 parts of camphor, 100 parts of acetone and 2-20 parts of a curing agent.The tensile strength and breaking elongation of the cellulose diacetate composite material are remarkably improved.Use of plasticizer is avoided, harm of the plasticizer to human bodies and the environment is greatly reduced, high temperature during melting is also avoided, and energy consumption is reduced.The preparation method is simple, industrialization is easy, and the preparation method can be widely used in glass frames, toys for children, table tennis balls, thin films, 3D printing consumables, automobiles, household appliance consumables and other plastic products for daily use.

Owner:JIANGNAN UNIV

Self-lubricating silicone rubber and preparation method thereof

The invention belongs to the technical field of silica gel, and more specifically relates to a self-lubricating silicone rubber, and a preparation method thereof. The self-lubricating silicone rubbercomprises following components, by weight, 100 parts of methyl vinyl silicone rubber, 10 to 30 parts of fumed silica, 1 to 5 parts of vinyl hydroxy silicone oil, 0.10 to 0.15 part of zinc stearate, 10to 30 parts of diphenyl silicone oil, and 2 to 10 parts of calcium oxide. According to the preparation method, rubber physical performance is improved through improvement of rubber ratio; non-reactive silicone oil is added to reduce silica gel surface frictional force after sulfuration; an appropriate amount of calcium oxide is added to improve the stability of silica gel products; special zinc stearate component is added to improve moulding demoulding performance and roller adhesion performance, so that silica gel surface friction force is reduced without influencing silica gel basic performance, product wearing is reduced, silica gel dynamic sealing effect is achieved, and product service life is prolonged.

Owner:HUBEI XINHAIHONG CHEM

Ocean pressure alternating sensitive supramolecular microsphere and synthesis method thereof

InactiveCN108102449ADoes not affect basic performanceImprove stabilityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsMicrosphereSynthesis methods

The invention belongs to the technical field of corrosion prevention of ocean self-repairing coatings and particularly relates to an ocean pressure alternating sensitive supramolecular microsphere anda synthesis method of the microsphere. The ocean pressure alternating sensitive supramolecular microsphere is prepared by wrapping a supramolecular nano mesoporous silicon dioxide sphere with a corrosion inhibitor and grafting and modifying the surface with cyclodextrin. The synthesized nano supramolecular microsphere has characteristics of a nanomaterial, is used as functional filling to prepareanti-corrosive paint, does not influence basic performance of the paint, and has an important application value. The pressure sensitive supramolecular microsphere has the characteristics of good stability, pressure sensitivity characteristic, good fusion with the paint and the like. The microsphere is environment-friendly and pollution-free in a use process. The microsphere is applicable to anti-corrosive coating filling of engineering and equipment such as ocean engineering, ships, deep-ocean engineering and underwater vehicles. The microsphere has the advantages of environmental friendliness, good controllability and easiness in operation and is easy in industrial production.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Infrared thermal detector and manufacturing method thereof

ActiveCN111879419AEasy to manufactureCompact structureRadiation pyrometryHemt circuitsControl circuit

The invention relates to the technical field of detectors, and particularly discloses an infrared thermal detector, which comprises a control circuit; the infrared thermosensitive unit which is connected with the control circuit; the packaging structure which is arranged on the control circuit; The control circuit comprises a signal reading circuit interface and a signal generating circuit interface; the packaging structure comprises a frame, a cap, a heater and a control line. The frame is fixed on the control circuit, and the bottom end of the frame is fixed on the signal generation circuitinterface; the cap is suspended on the frame and forms a closed cavity surrounding the infrared thermosensitive unit together with the frame; the heater is positioned on the cap; the control lines arelocated on the cap and in the frame respectively, and the heater is electrically connected with the signal generation circuit interface through the control lines. The invention further discloses a manufacturing method of the infrared thermal detector. The infrared thermal detector provided by the invention can realize radiation response self-test under simulated black body infrared thermal-electric conversion on the basis of not influencing the basic performance of the detector.

Owner:WUXI INNOVATION CENT CO LTD

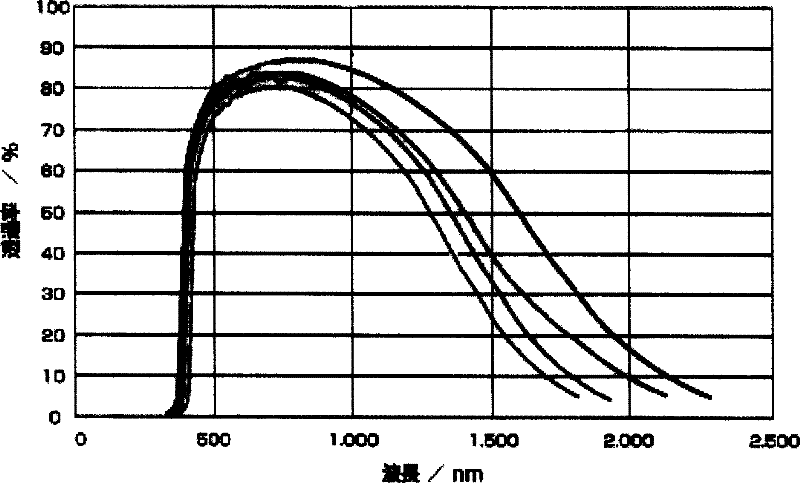

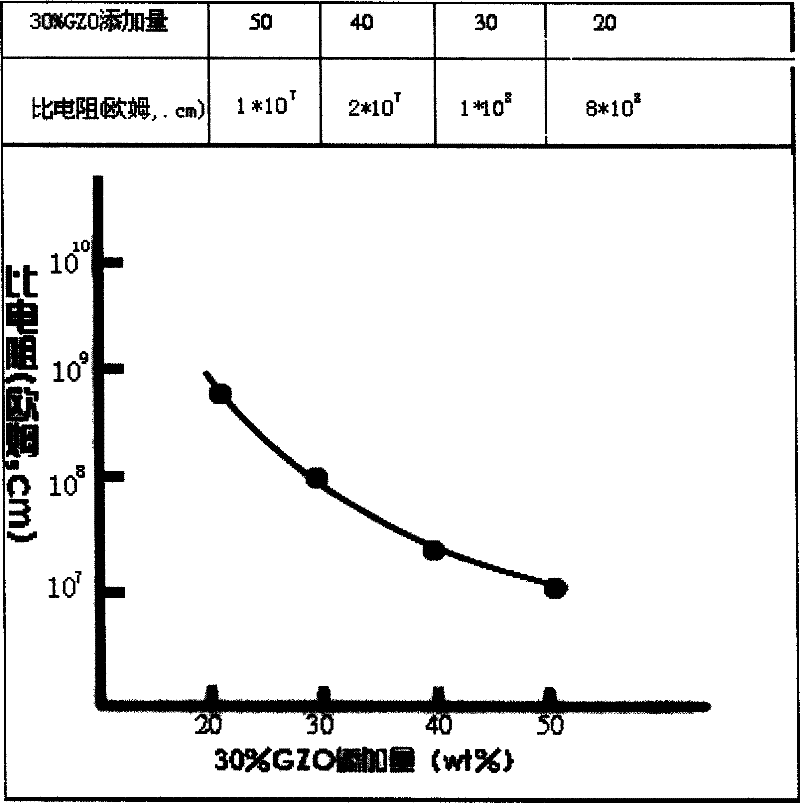

Transparent electric conductive heat insulating glass

ActiveCN101239788BWith transparent conductive heat insulation functionDoes not affect basic performanceZincOxide coating

Owner:上海沪正实业有限公司

Treatment method for increasing carbon yield of phenolic fibers

InactiveCN107217335AHigh carbon residue rateDoes not affect other basic performanceFibre typesMonocomponent synthetic polymer artificial filamentFiberHeat resistance

The invention relates to a preparation method for increasing the carbon yield of phenolic resin-based fiber carbonization. A phenolic resin-based solidified fiber first undergoes vacuum impregnation, and is then further treated by high temperature in an ethanol solution of B, P and S inorganic acids and organic borate ester, so that the heat resistance of the fiber is greatly enhanced, and thereby a carbonized phenolic resin-based fiber with high carbon yield is prepared. The method does not affect the basic properties of the solidified fiber, but can greatly increase the heat resistance of the fiber. After carbonization, the carbon yield of the fiber under 800 DEG C (under N<2> atmosphere) can reach 63 to 70 percent, the carbon yield under 1000 DEG C is more than 60 percent, and the thermal decomposition separation peak of the fiber is relatively gentle.

Owner:颜笑宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com