Transparent electric conductive heat insulating glass

A technology of transparent conductive and heat-insulating glass, applied in the field of glass, can solve the problems of glass heat-insulation and transparency without electrical conductivity, etc., and achieve the effects of improving the electrical conductivity and heat-insulating performance, the preparation method is simple, and the transparency is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

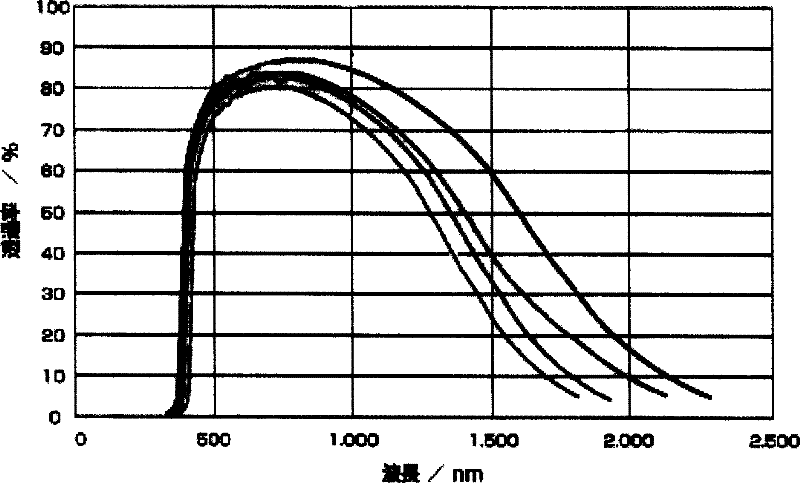

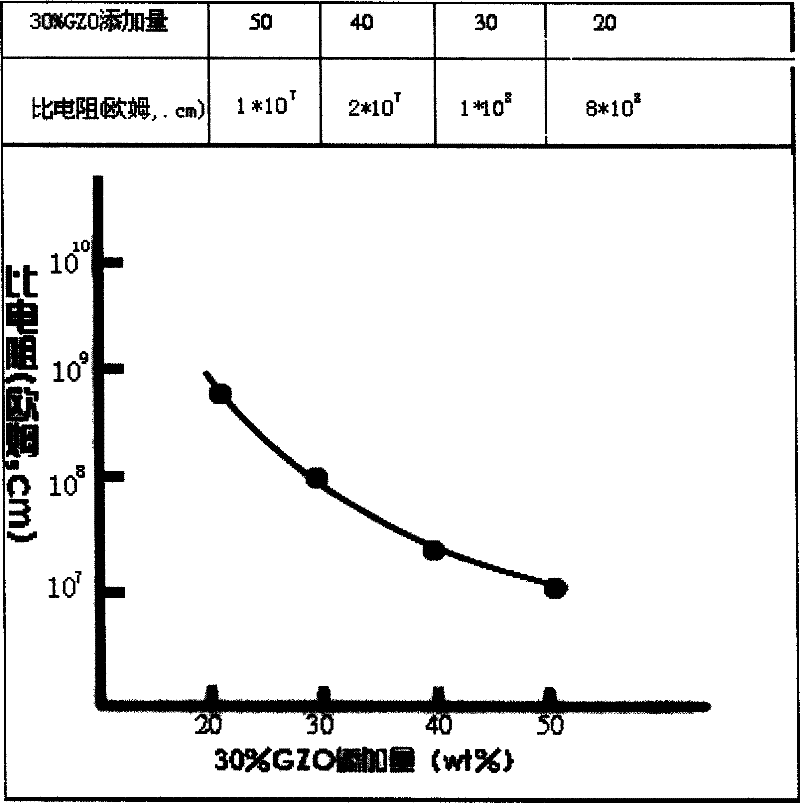

[0028] Such as figure 1 As shown, the single-layer coated transparent conductive heat-insulating glass proposed by the preferred embodiment of the present invention is composed of a layer of ordinary glass substrate 2 and a layer of nanometer transparent conductive heat-insulating coating 1, and the thickness of the coating film is 3- 5 μm. The composition and structure of transparent conductive heat insulating glass are shown in Table 1 and Table 2:

[0029] Table 1. Structure of single-layer coated transparent conductive insulating glass

[0030]

[0031] Table 2. Composition of transparent conductive thermal barrier coatings

[0032]

[0033] The transparent conductive heat-insulating coating is coated on the glass by brushing, and dried under certain film-forming conditions to form a glass coated with a transparent conductive heat-insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com