Modification method of regenerated cellulose fibre

A technology of regenerated cellulose and fiber, applied in the direction of rayon made of viscose, can solve the problems of high production cost, poor durability, poor fastness, etc., to offset internal stress, improve boiling water shrinkage, reduce The effect of small water swellability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Viscose solution (8.1% cellulose, 5.9% total alkali, 2.5% total sulfur) prepared by conventional methods. Dope preparation and spinning process are as follows:

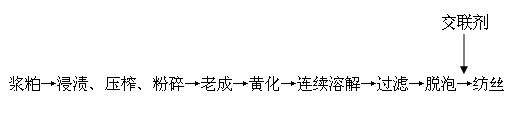

[0026] Pulp→dipping, pressing, crushing→aging→yellowing→continuous dissolving→filtering→degassing→spinning

[0027] Preparation of pre-crosslinking solution (taking vegetable protein modified viscose fiber as an example): ethylene glycol glycidyl ether (trade name; Denakol EX-810), propylene glycol diglycidyl ether (trade name; Denakol EX-931) Or add one of the glycerol polyglycidyl ethers to a protein solution prepared with an alkali solution, the protein concentration is 30-50%, of which ethylene glycol glycidyl ether, propylene glycol diglycidyl ether or glycerol polyglycidyl ether The amount of the added amount accounted for 1.05% of the protein weight, stirred at a low speed for 3 hours, and filtered at a temperature of 32°C. The pH of the solution is 7-9.

[0028] The injection method is used 20 minute...

Embodiment 2

[0036] With the viscose solution (8.1% of cellulose, 5.9% of total alkali content, 2.5% of total sulfur content) prepared by conventional method, preparation method is the same as example 1.

[0037] The cross-linking agent described in Example 1 is added to the protein solution prepared with alkaline solution, the protein concentration is 30-50%, and the cross-linking agent addition accounts for 0.5%, 1.0%, 1.5%, 2.0%, 2.5%, 3.0%, 3.5%, low-speed stirring, the time is 3h, the temperature is 32-33 ℃, filter. The pH of the solution is 7-9.

[0038] The injection method is used 20 minutes before spinning, specifically, the pre-crosslinked functional additive solution is quickly mixed with the viscose solution before continuous degassing. The reference flow of the spinning process is shown in the attached drawing. The protein solution is mixed with the viscose solution, wherein the protein solution is added at a rate of 15% by protein to methyl cellulose weight ratio.

[0039] ...

Embodiment 3

[0045] With the viscose solution (8.1% of cellulose, 5.9% of total alkali content, 2.5% of total sulfur content) prepared by conventional method, preparation method is the same as example 1.

[0046] Add the cross-linking agent described in Example 1 into the protein solution prepared with alkaline solution, the protein concentration is 30-50%, the amount of cross-linking agent added accounts for 1.5% of the protein weight, stir at low speed, time is 3h, temperature is 32-33°C, filter. The pH of the solution is 7-9.

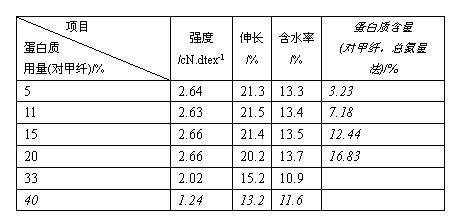

[0047] The injection method is used 20 minutes before spinning, specifically, the pre-crosslinked functional additive solution is quickly mixed with the viscose solution before continuous degassing. The reference flow of the spinning process is shown in the attached drawing. The protein solution is mixed with the viscose solution, wherein the protein solution is added at a rate of 5%, 11%, 15%, 20%, 33%, 40% by weight of the protein to methyl cellulose.

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com