Micro-crosslinking viscosity-reducing mud-resistant polycarboxylic acid water reducer and preparation method thereof

A mud-resistant, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of loss of workability, high viscosity of high-mud concrete, not easy to pump, loss of slump retention, etc., to achieve excellent construction performance, promote application and Promote and reduce the effect of water absorption and swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

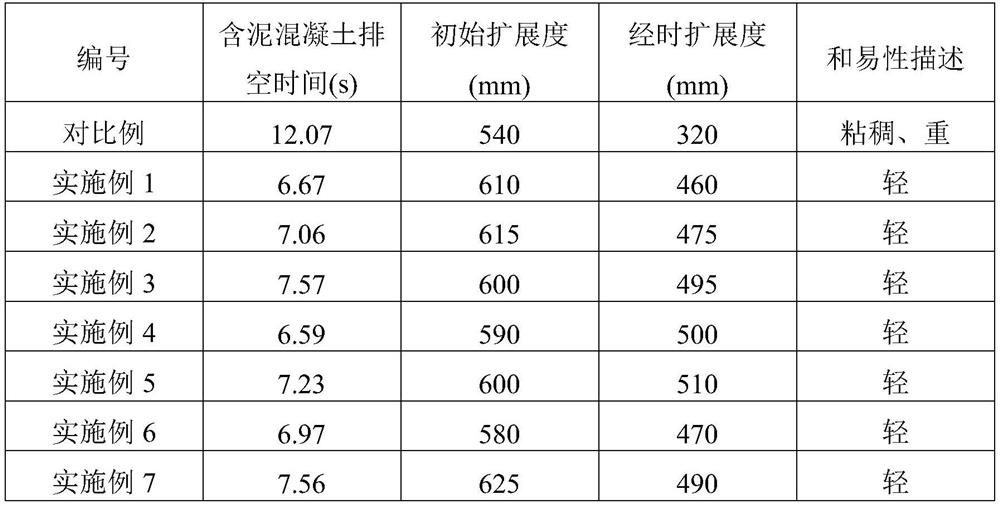

Examples

Embodiment 1

[0031] 1.1 Raw materials (by weight)

[0032] 200 parts of unsaturated polyether macromonomer; 30 parts of unsaturated acid (anhydride) small monomer; 3 parts of unsaturated silane monomer; 5 parts of chain transfer agent; 15 parts of single-electron oxidant; 250 parts of deionized water.

[0033] In this embodiment, the unsaturated polyether macromonomer is methallyl polyoxyethylene ether (molecular weight is 2400);

[0034] The unsaturated acid (anhydride) small monomer is acrylic acid;

[0035] The unsaturated silane monomer is 3-methacrylamide-propyltrimethylsilane;

[0036] The chain transfer agent is mercaptoethanol;

[0037] The one-electron oxidizer is ceric ammonium nitrate.

[0038] 1.2 Preparation method

[0039] (1) take each raw material by proportioning;

[0040] (2) Configure liquid A and liquid B;

[0041] Mix 10 parts (by weight) of unsaturated acid (anhydride) small monomers, unsaturated silane monomers, chain transfer agent and 35 parts (by weight) of ...

Embodiment 2

[0047] The difference between this embodiment and Example 1 is: 6 parts of unsaturated silane monomers (by weight);

[0048] All the other are the same as Example 1, and obtain the finished product of micro-crosslinked viscosity-reducing anti-mud type polycarboxylic acid deionized water agent.

Embodiment 3

[0050] The difference between this embodiment and Example 1 is: 9 parts (by weight) of unsaturated silane monomer;

[0051] All the other are the same as Example 1, and obtain the finished product of micro-crosslinked viscosity-reducing anti-mud type polycarboxylic acid deionized water agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com