Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Control spawn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

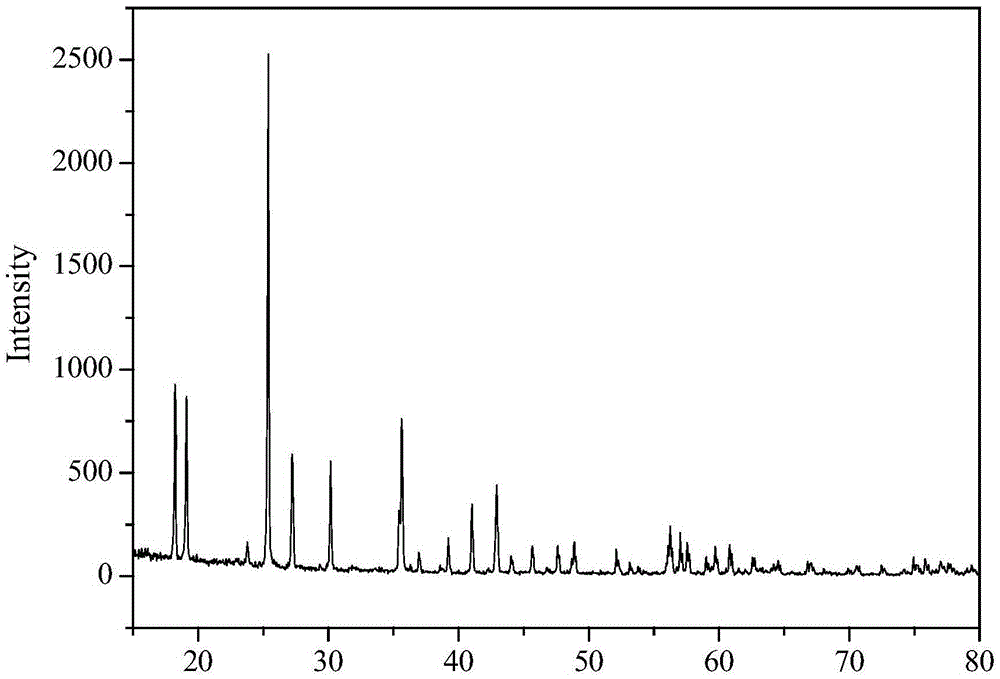

Preparation method of manganese phosphate and manganese phosphate product

InactiveCN105609765AHigh purityUniform particle size distributionCell electrodesSecondary cellsManganeseSlurry

The invention discloses a preparation method of manganese phosphate and a manganese phosphate product. The method comprises the following steps: weighing a soluble phosphorus source compound and a soluble manganese source compound at the molar ratio of P to Mn being (1-2) to 1, dissolving the soluble phosphorus source compound and the soluble manganese source compound into deionized water to prepare solutions; feeding a manganese source solution to an acid-resistant reaction kettle by a metering pump, and then adding a phosphorus source solution for stirring; feeding an oxidant to the acid-resistant reaction kettle by the metering pump, and adjusting the pH value of a system; adding the organic solvent to the acid-resistant reaction kettle, and carrying out stirring reaction at 30-90 DEG C; and naturally cooling the obtained manganese phosphate slurry to a room temperature, carrying out washing, filtering and drying to obtain a manganese phosphate (MnPO<4>.H<2>O) product. According to the method, the manganese deposition rate reaches over 99%; the manganese resource is fully utilized; the product purity is high; the Mn content is greater than 32%; the P content is 18%-19%; the content of a main impurity S is smaller than 0.5%; the content of Na is smaller than 0.02%; the particle size distribution is uniform; and the mean particle size is smaller than 1micron.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

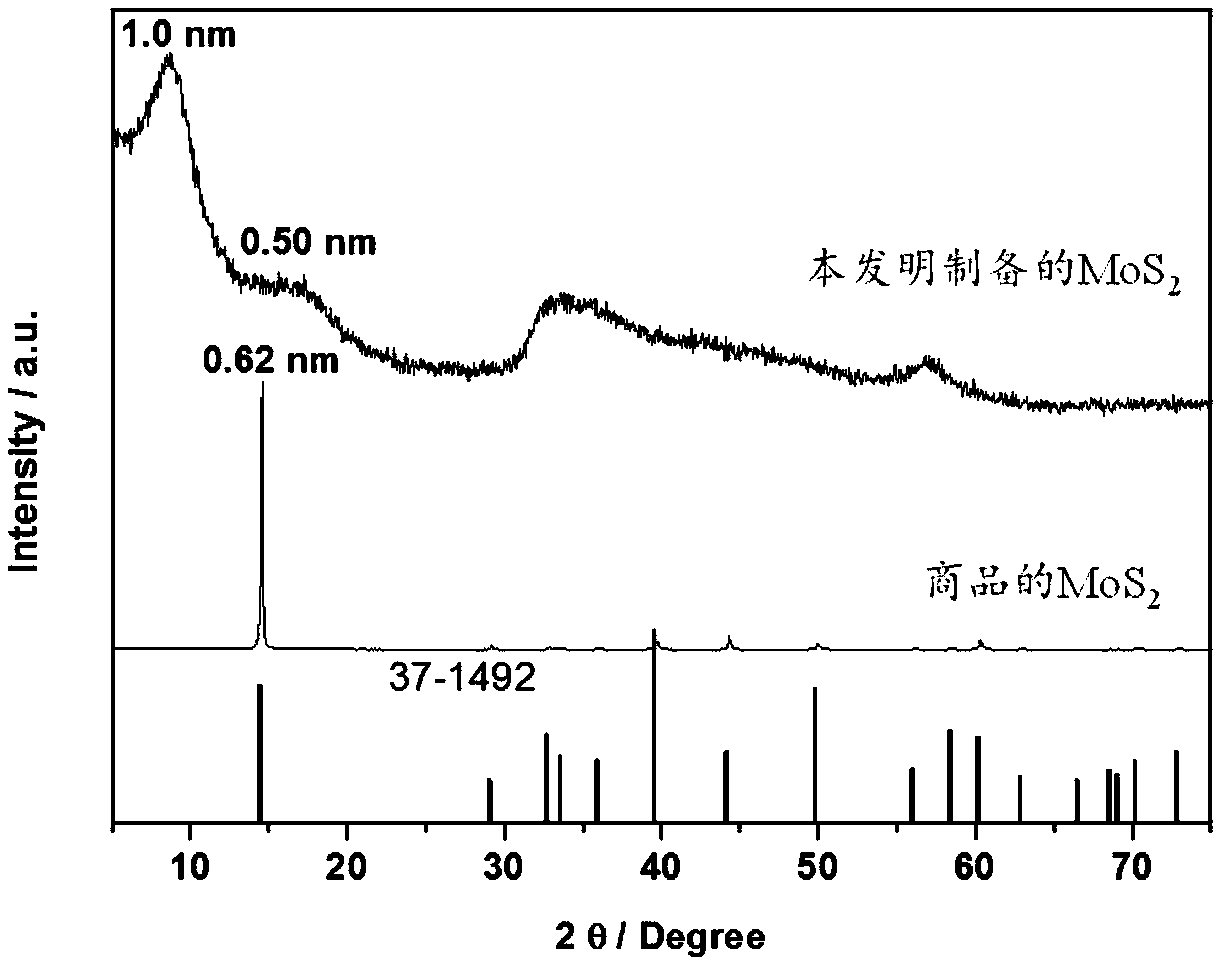

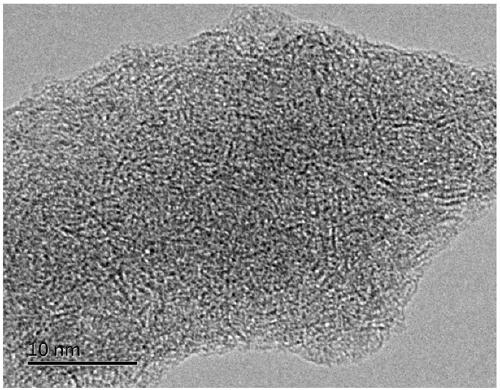

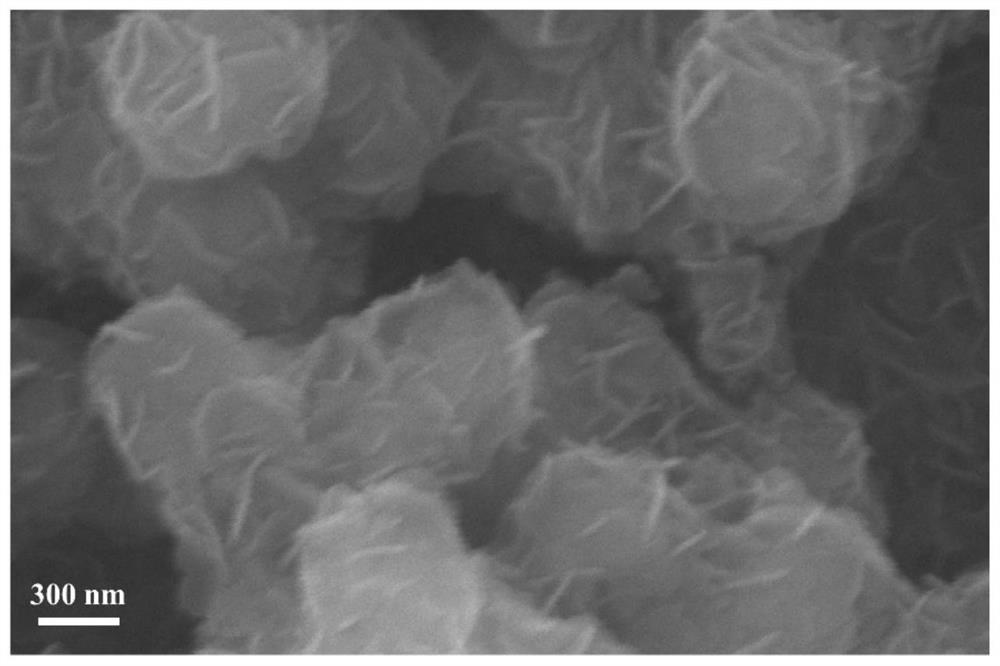

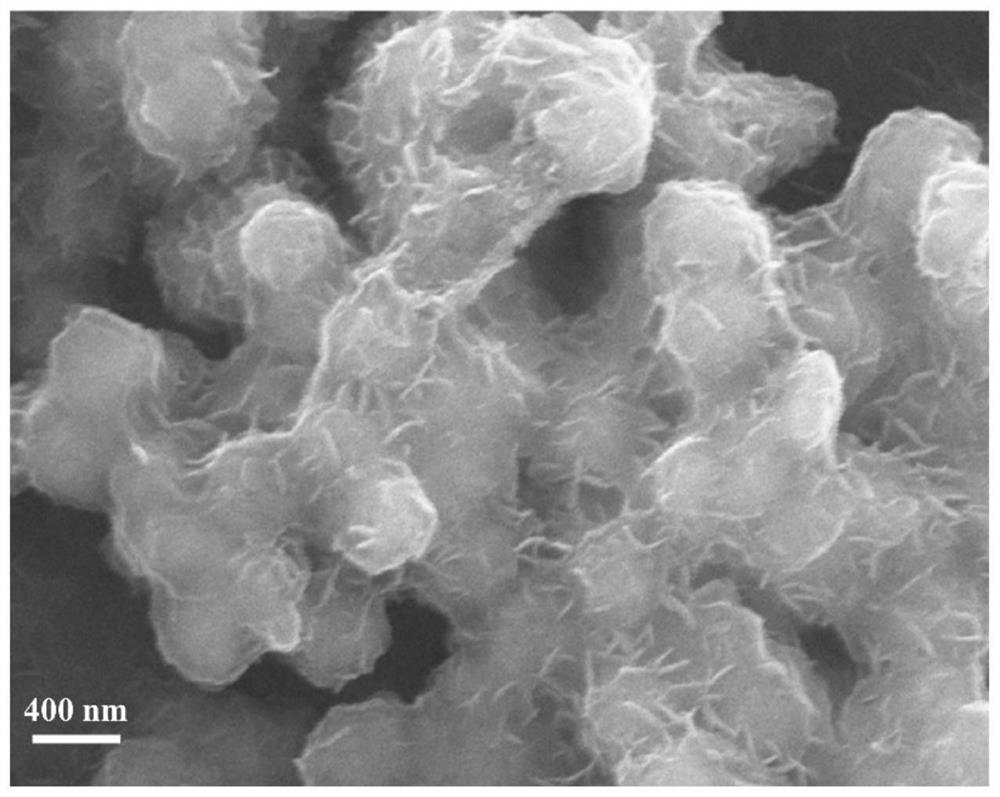

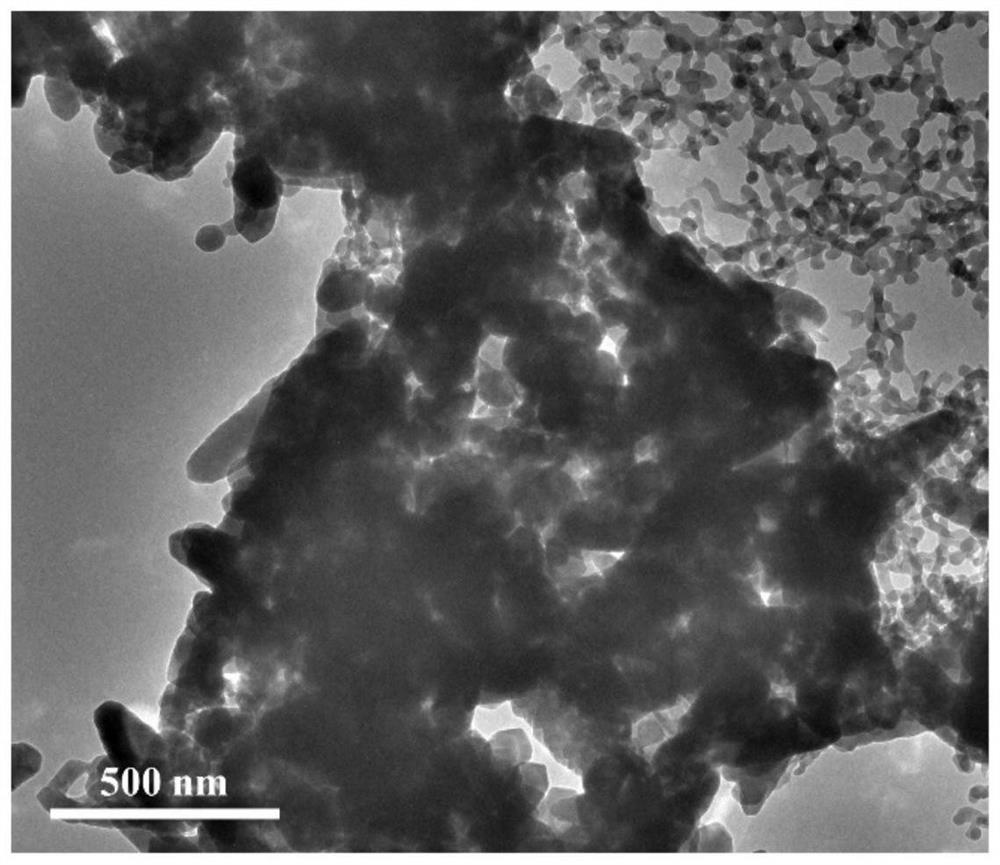

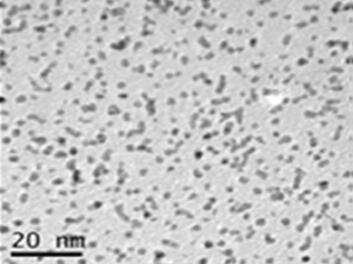

Preparation method of high-activity molybdenum sulfide hydrogenation catalyst

InactiveCN111229258AAvoid reunionAvoid accumulationCatalyst activation/preparationHydrocarbon oils refiningPtru catalystReaction temperature

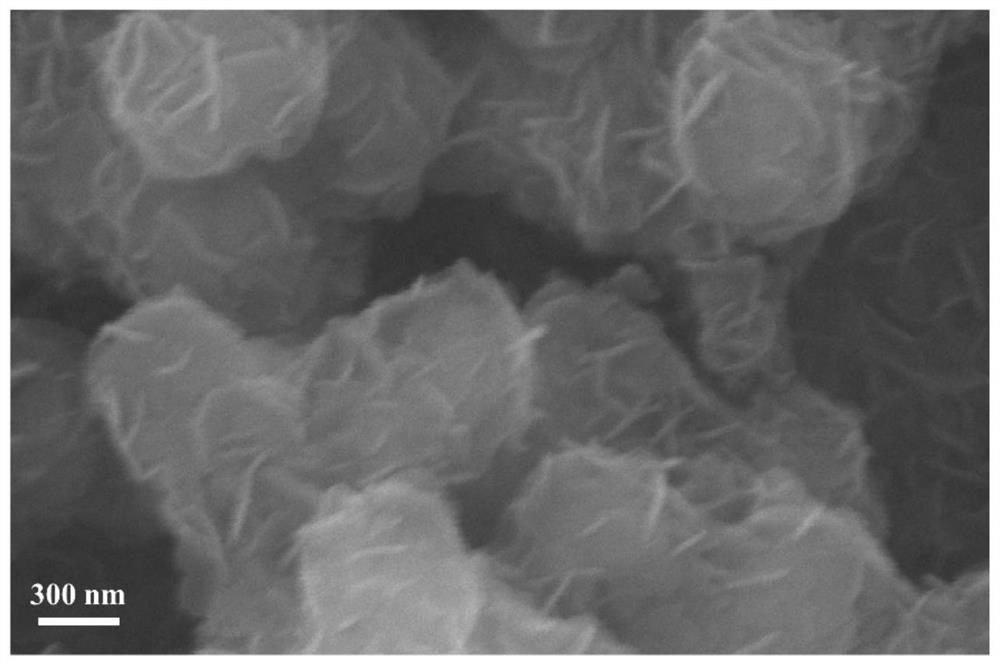

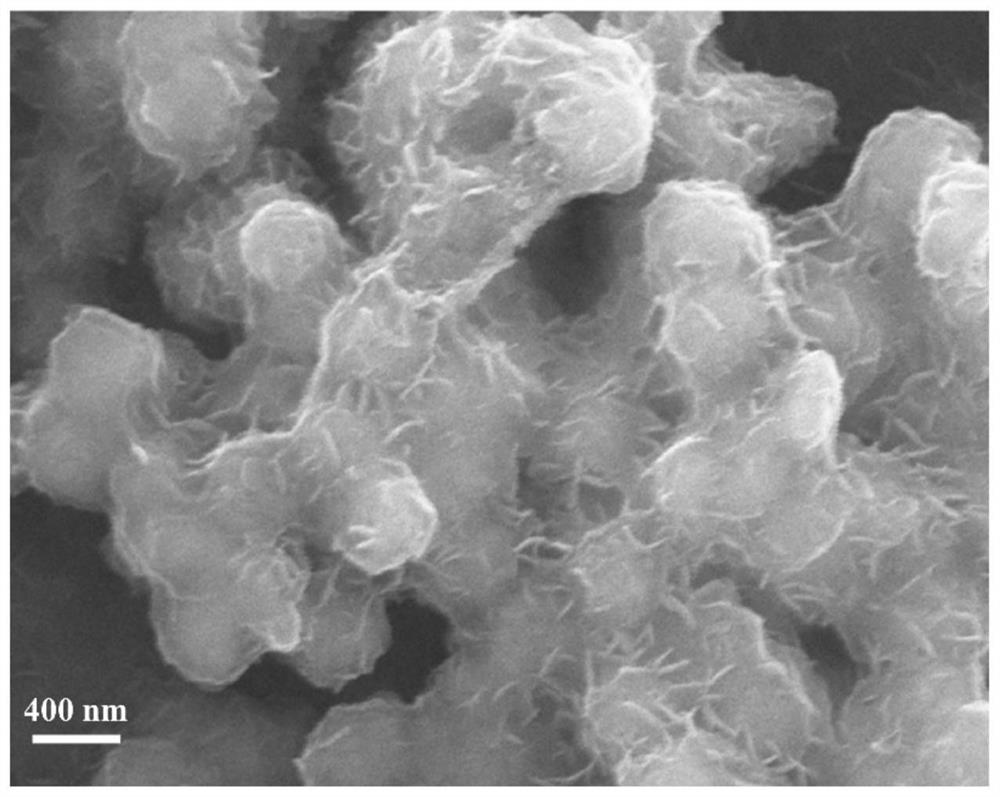

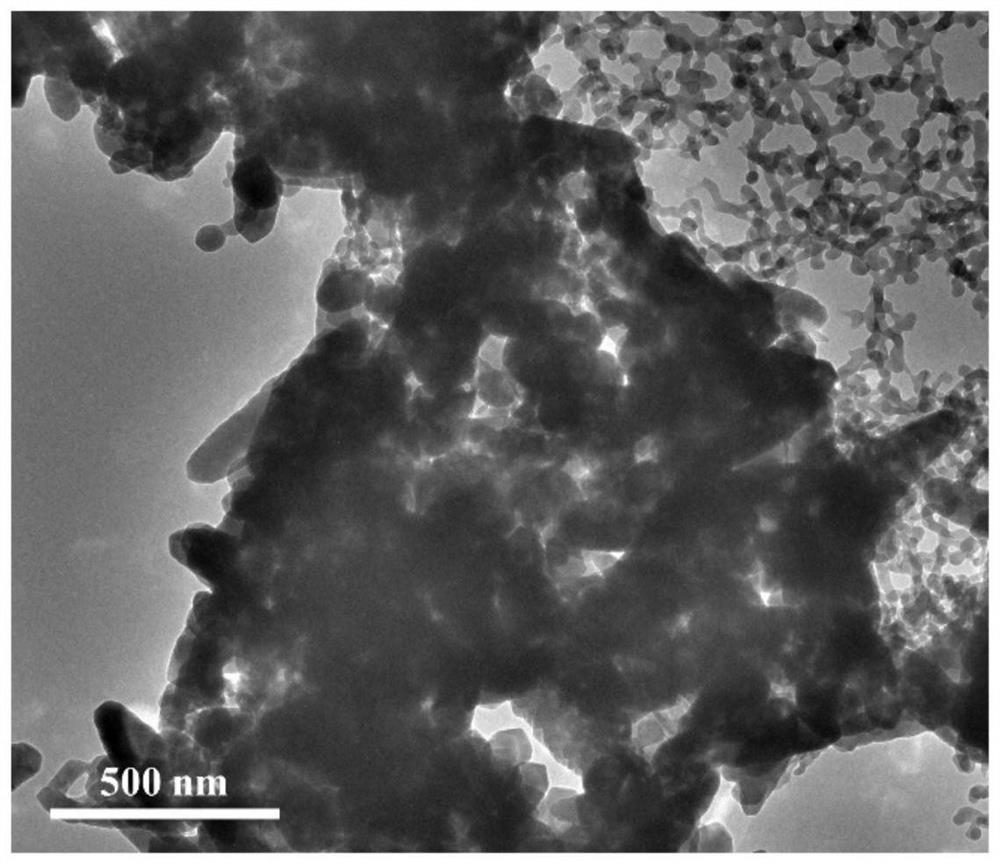

The invention discloses a preparation method of a high-activity molybdenum disulfide (MoS2) hydrogenation catalyst. The method comprises the following steps: dissolving or dispersing a certain amountof molybdenum source and reductive sulfur source in a high-viscosity solution, and adding a reducing agent to obtain a solution or turbid liquid; regulating and controlling the types of the molybdenumsource, the sulfur source and a solvent; putting the prepared solution or turbid liquid into a closed stainless steel reaction kettle, and controlling the reaction temperature to be 120-220 DEG C andthe reaction time to be 3-72 hours; and after the reaction is finished, cooling, separating, washing and drying to obtain the high-activity MoS2 hydrogenation catalyst. The synthesis method disclosedby the invention has the advantages of low temperature, low pressure, no need of adding an additional reducing agent and the like, and the prepared MoS2 hydrogenation catalyst has the advantages thatthe interlayer spacing is enlarged, the accumulation degree is less than 3 layers, and the lamellar length is shorter than 10nm, so that the highest hydrogenation active site exposure rate is achieved. The high-activity exposed nano MoS2 hydrogenation catalyst synthesized by the method disclosed by the invention has extremely high catalytic hydrogenation activity in the field of catalytic hydrogenation of oil products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

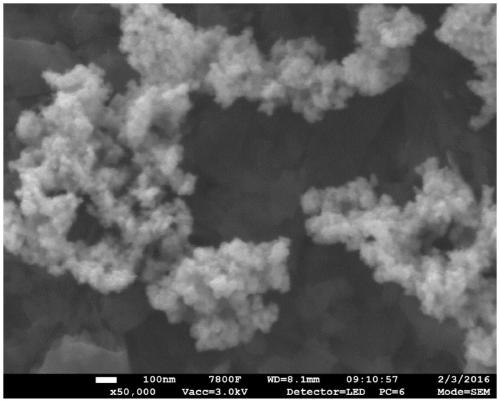

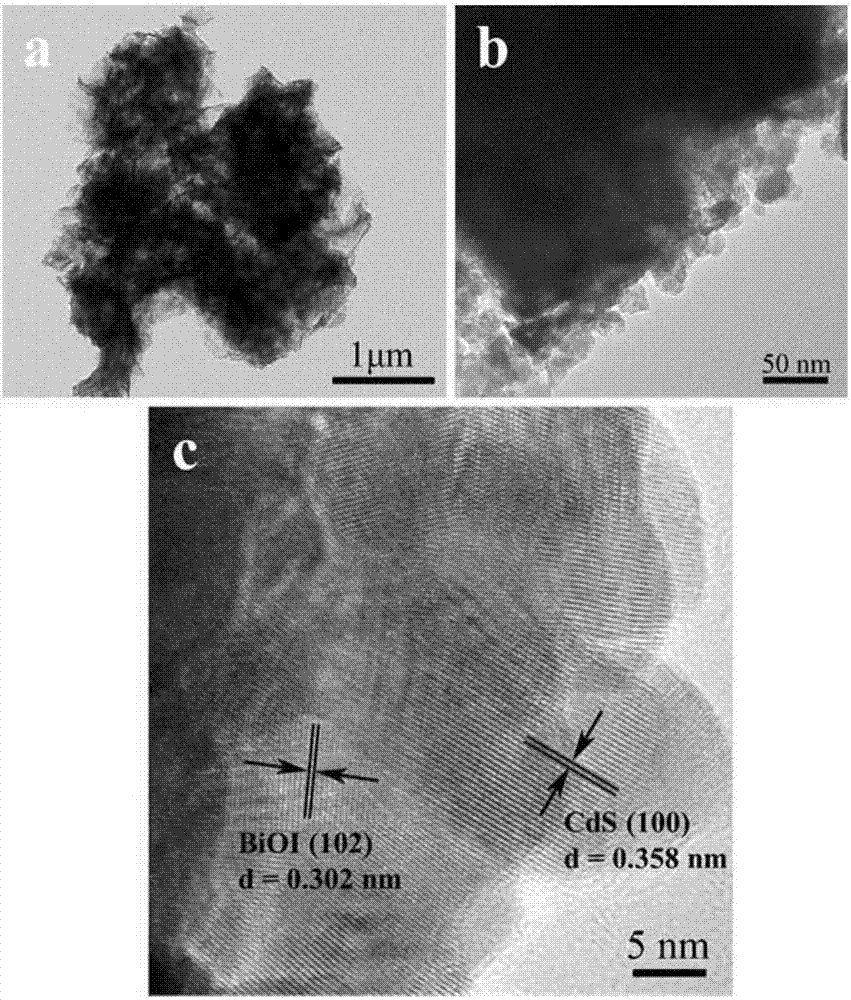

Preparation method and application for cadmium sulfide/bismuth oxyiodide heterojunction photo-catalyst

InactiveCN107362813AEfficient removalImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionSource material

The invention provides a preparation method and an application for a CdS / BiOI heterojunction photo-catalyst. The method comprises the following steps: firstly, respectively dissolving bismuth salt material and iodine source material in glycol, mixing the two solutions and stirring for 1h; transferring a mixed solution into a reaction kettle and reacting for 8-16h at 120-200 DEG C, thereby acquiring an orange red solid; washing, drying and grinding the orange red solid, thereby acquiring dry BiOI powder; dissolving cadmium salt in deionized water, adding BiOI powder and buffer salt in turn and increasing the temperature of the reaction system from room temperature to 30-90 DEG C; adding complexing agent into the system, dropwise adding 50ml solution containing sulfur source material into the system and stirring for 15min, thereby acquiring yellow sediment; and washing, drying and grinding the yellow sediment, thereby acquiring the yellow powder, namely, the CdS / BiOI heterojunction photo-catalyst. The CdS / BiOI heterojunction photo-catalyst prepared according to the invention is used for degrading the organic pollutants in water. Compared with the photo-catalysts, such as, commercial TiO2 (P25), pure phase CdS and pure phase BiOI, the catalyst has higher visible-light catalytic activity.

Owner:YUNNAN UNIV

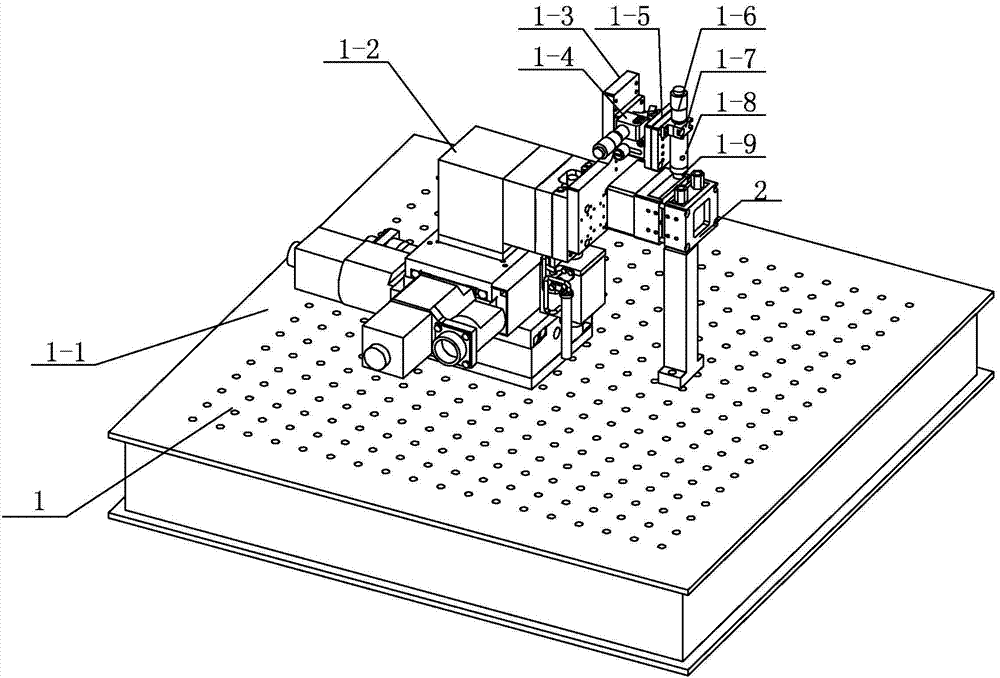

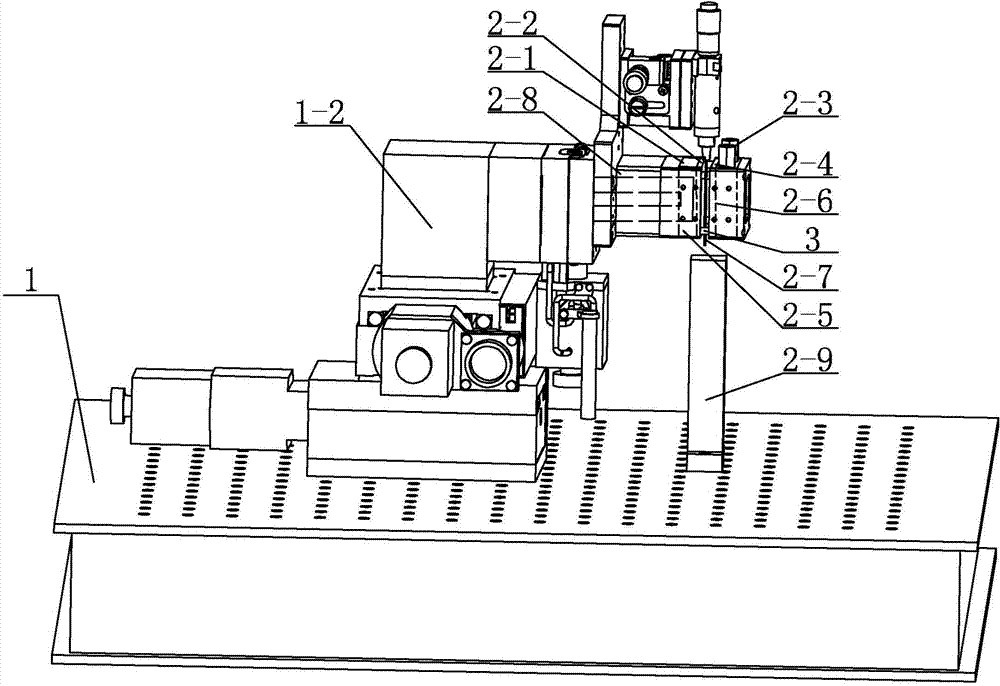

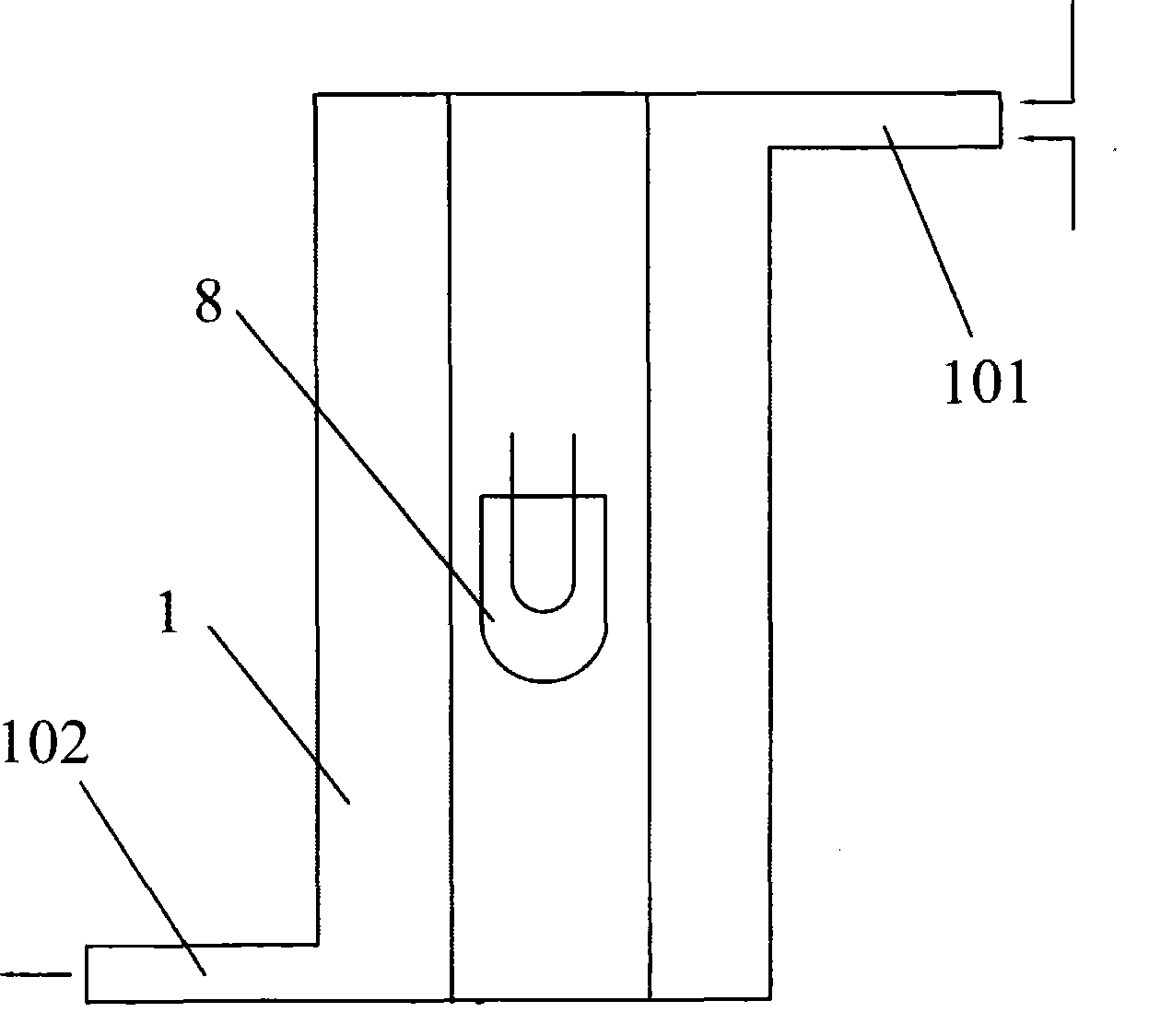

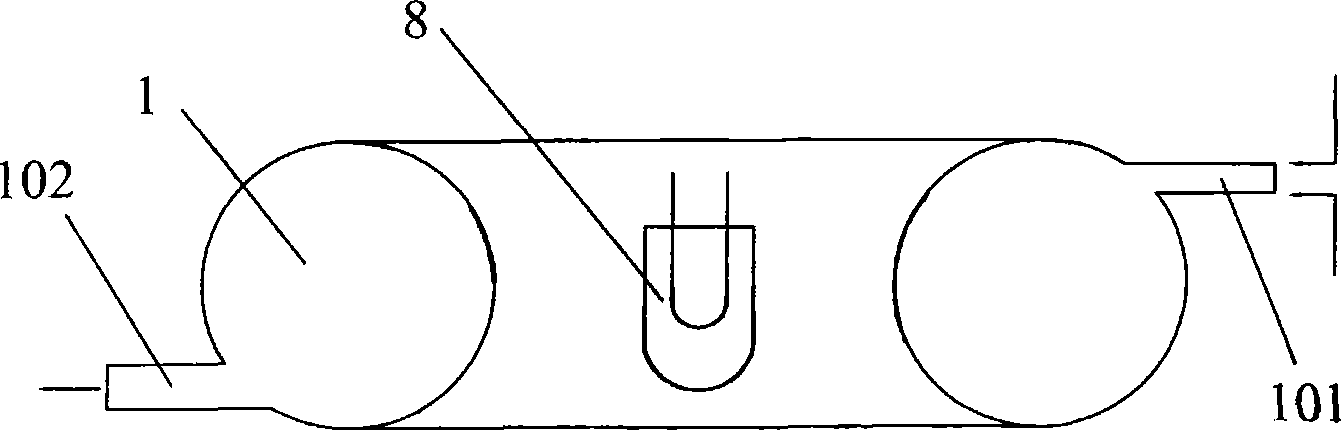

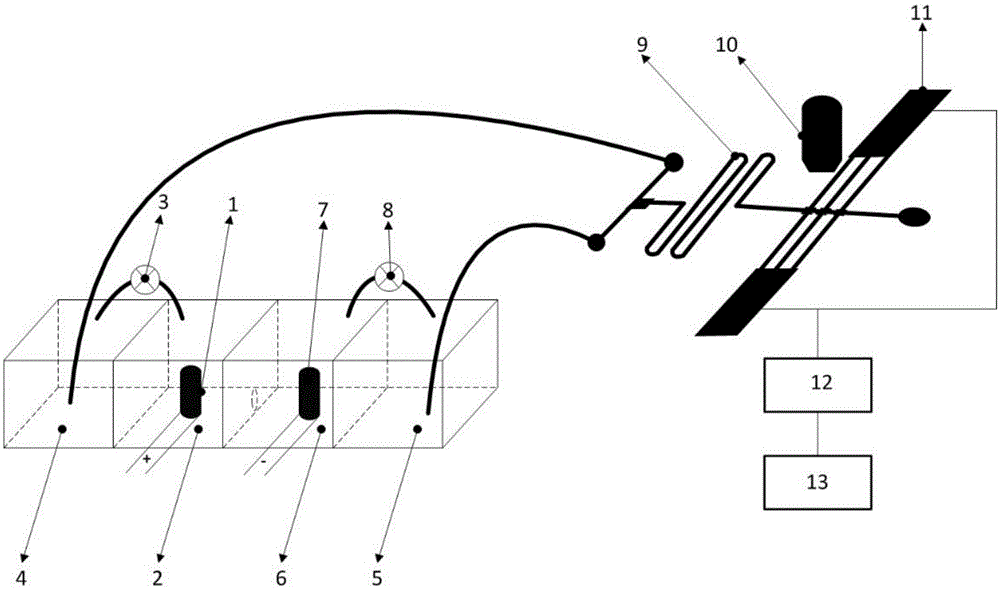

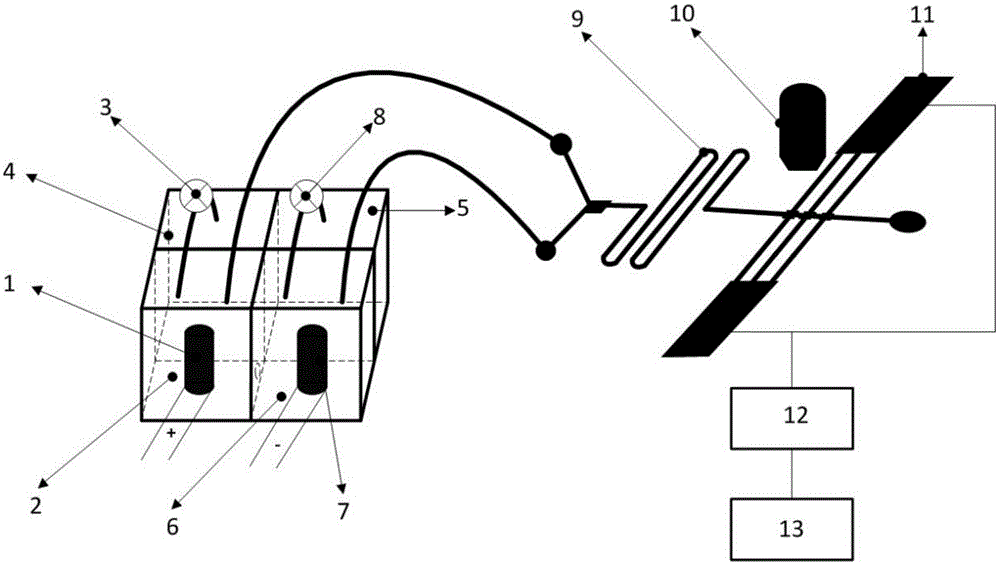

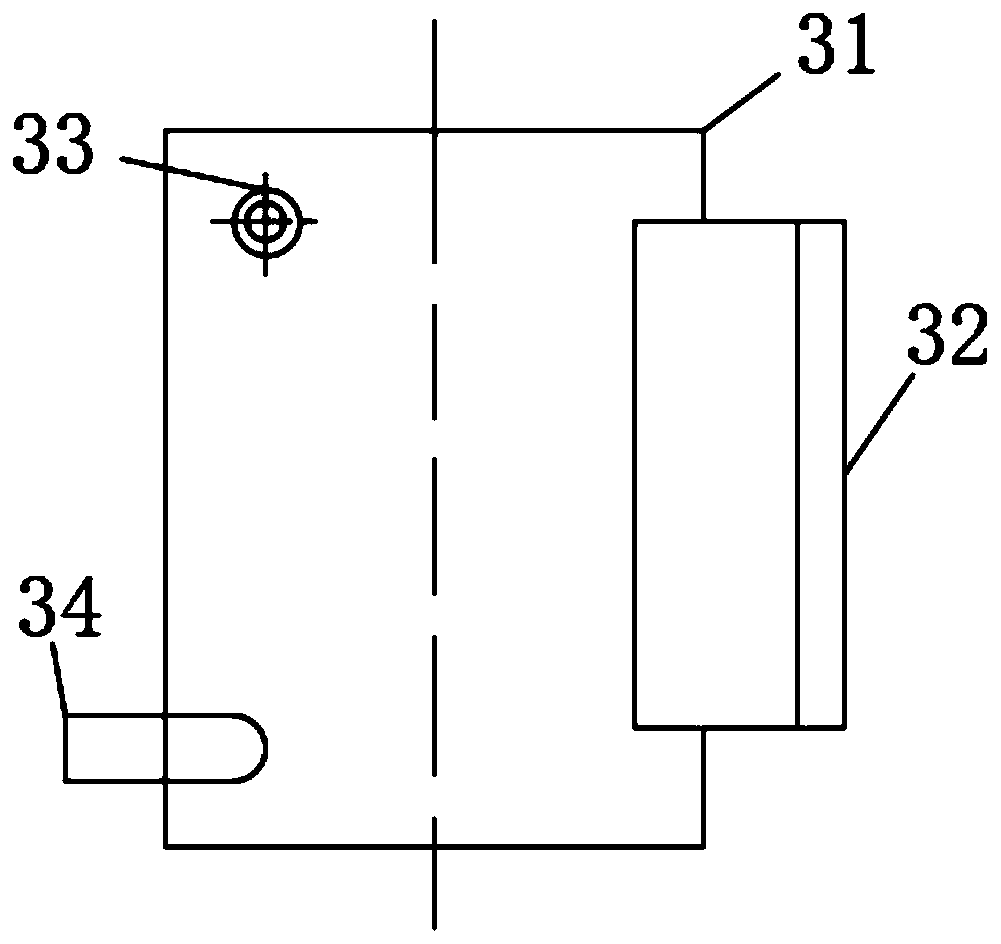

Hydrophobic surface dropwise condensation capillary force pickup and vibration control micro-object operation device and method

ActiveCN104760928AControl volumeEasy to operateIndividual molecule manipulationVibration controlMicrometer

The invention discloses a hydrophobic surface dropwise condensation capillary force pickup and vibration control micro-object operation device and method and relates to a micron-order object operation and micro-assembling technology. The problems that in the prior art, according to a capillary force operation mode, liquid drops remaining at the tail end after a probe is used for dipping are used as operation conditions, the size of the operation liquid drops cannot be controlled effectively, liquid drops which are too large or too small can cause operation task failure, dynamic control over the operation liquid drops after pickup cannot be achieved, and due to the leading role of adhesive force, micro objects adhere to the tail end of the probe after liquid drop disappearing and cannot fall off smoothly are solved. The device comprises a displacement control mechanism, a cooling working operation mechanism and four connecting studs. The displacement control mechanism comprises a vibration isolation table, a three-axis precision electric displacement platform, a connecting bottom plate, a manual displacement lifting table, a vibration module connecting plate, a micrometer head, a micrometer clamp, a piezoelectric ceramic vibration module and a probe clamp. The device and method are used for the field of micron-order object operation.

Owner:HARBIN INST OF TECH

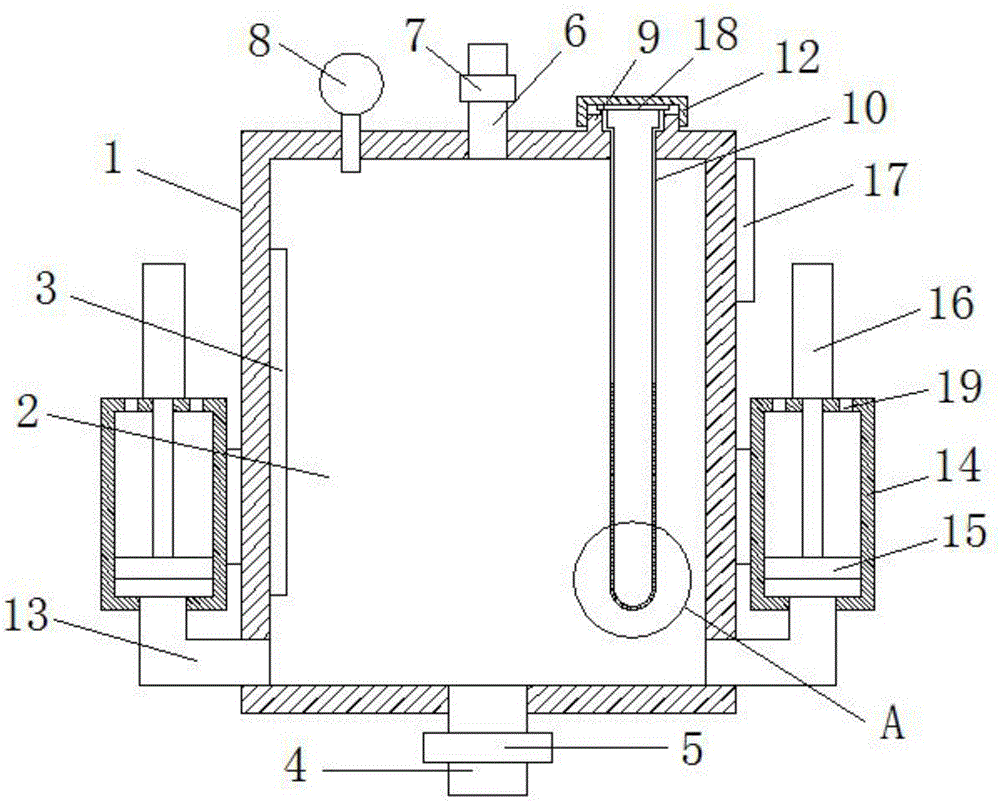

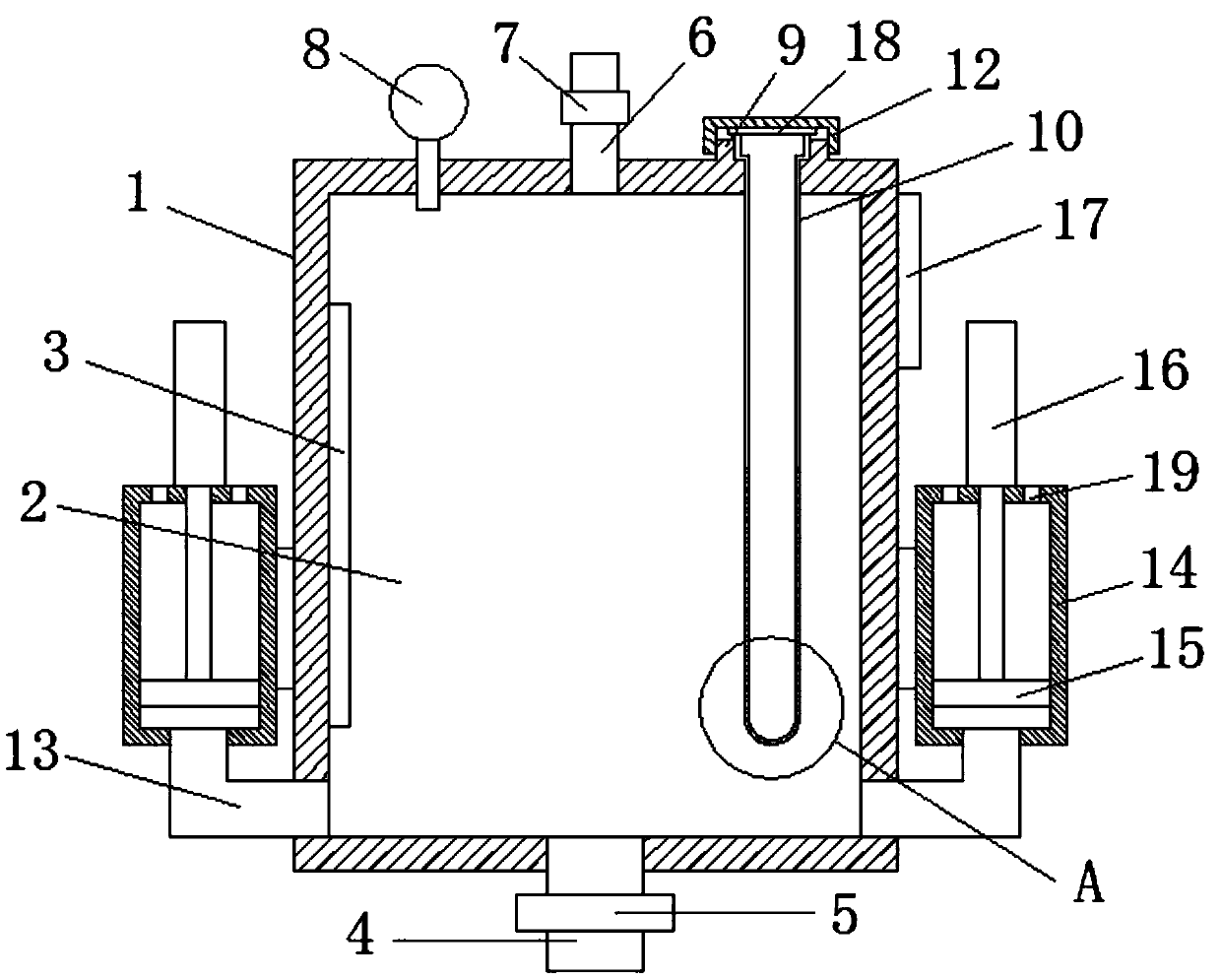

Chemical oxygen generating device

InactiveCN106276806AChange liquid levelChange the contact areaEducational modelsOxygen preparationChemical oxygen demandEngineering

The invention discloses a chemical oxygen generating device. The chemical oxygen generating device comprises a box. A reaction cavity is formed inside the box, a liquid level sensor is arranged on the inner all of the reaction cavity, a discharging opening is formed in the bottom of the box, a first electromagnetic valve is arranged on the discharging opening, an oxygen outlet is formed in the top of the box, a second electromagnetic valve is arranged on the oxygen outlet, and an air pressure gauge is arranged on one side of the oxygen outlet. According to the chemical oxygen generating device, hydrogen peroxide is injected through a feeding opening, pistons are pulled through electric stretchable rods, and the hydrogen peroxide is sucked into piston cylinders and stored, and then is put into a reagent pipe filled with manganese dioxide through the feeding opening; when oxygen needs to be generated, the electric stretchable rods push the pistons to inject the hydrogen peroxide into the reaction cavity, and the hydrogen peroxide is reacted with the manganese dioxide in the reagent pipe; meanwhile, the electric stretchable rods are matched with the pistons, the liquid level height of the hydrogen peroxide in the reaction cavity is changed, the contact area between the hydrogen peroxide and manganese dioxide is changed accordingly, and the oxygen generating rate of the whole device is controlled.

Owner:石宝珏

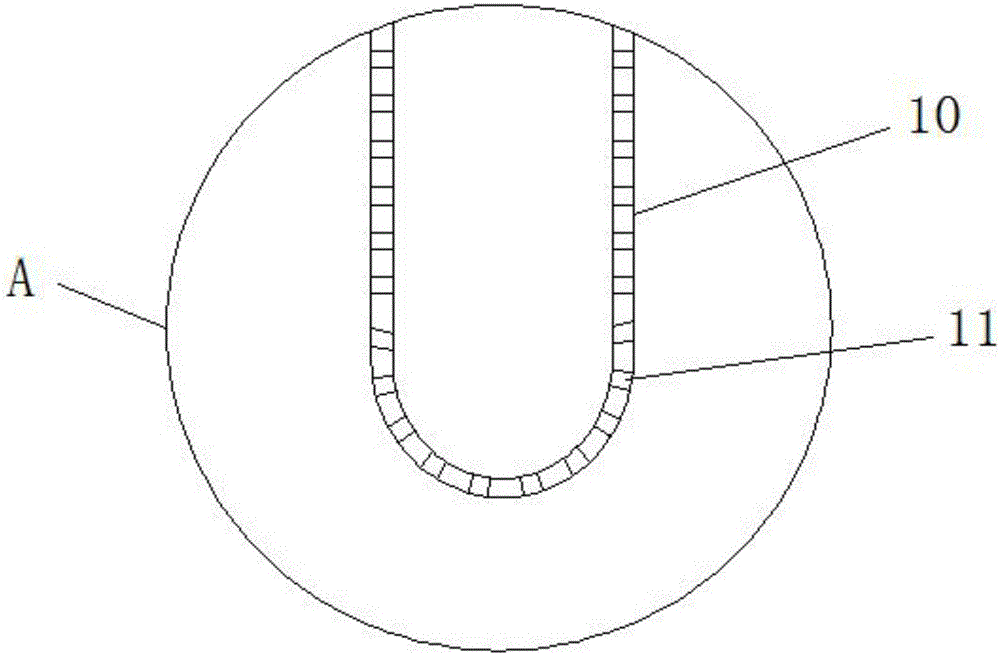

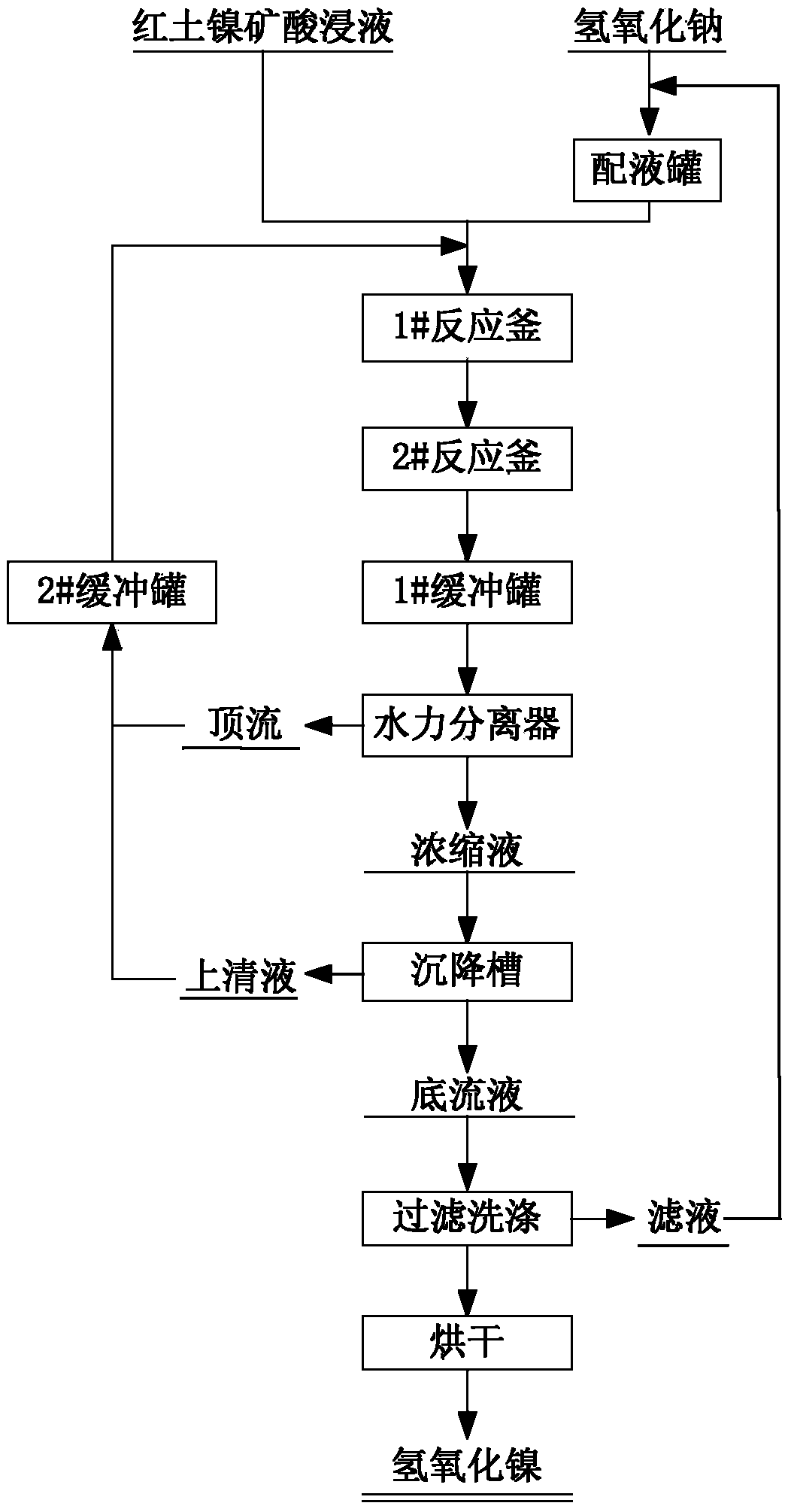

Process for continuously producing nickel hydroxide by using pickle liquor of nickel laterite ore

InactiveCN103771546AEasy to separateImprove filtering effectNickel oxides/hydroxidesNickel oxide hydroxideLaterite

The invention discloses a process for continuously producing nickel hydroxide by using pickle liquor of nickel laterite ore. The process comprises the following steps of: cascade reaction in a 1# reaction kettle and a 2# reaction kettle, ageing in a 1# buffering tank, separation by a hydrocyclone and settlement by a settling groove. The nickel hydroxide crystal with the average particle diameter being more than 22mum and good settling separation and filtering performances is prepared from pickle liquor of the nickel laterite ore and sodium hydroxide solution by a direct precipitation method. The process disclosed by the invention has the advantages that the environmental-friendly effect is achieved, the flow is short, the efficiency is high, the cost is low and the continuous production of the nickel hydroxide can be realized.

Owner:CENT SOUTH UNIV

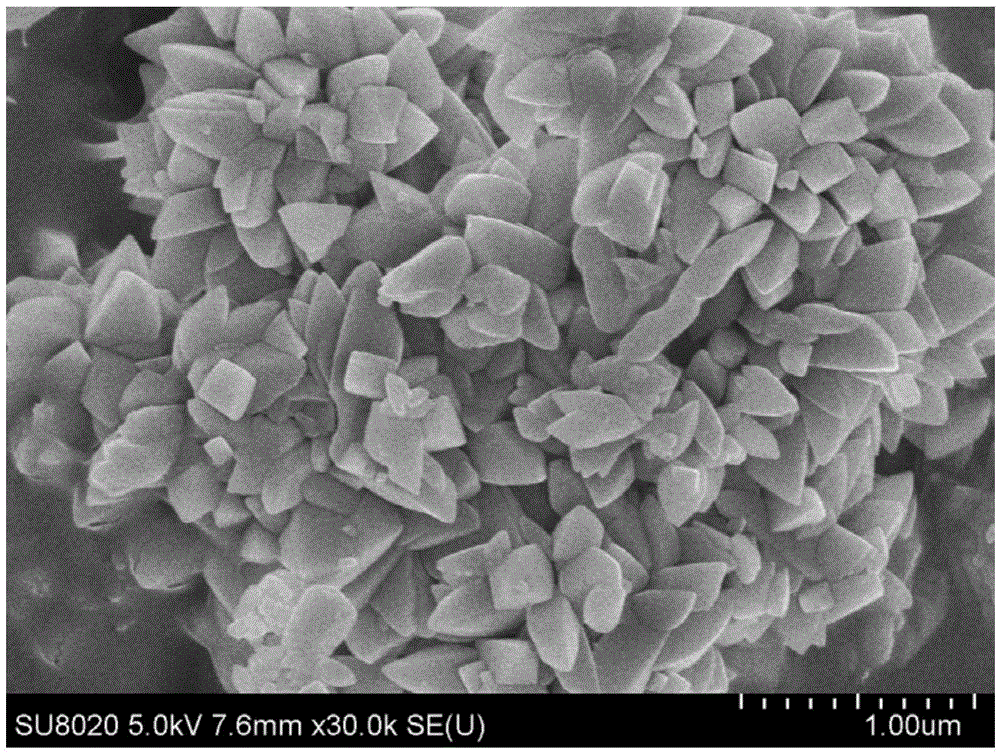

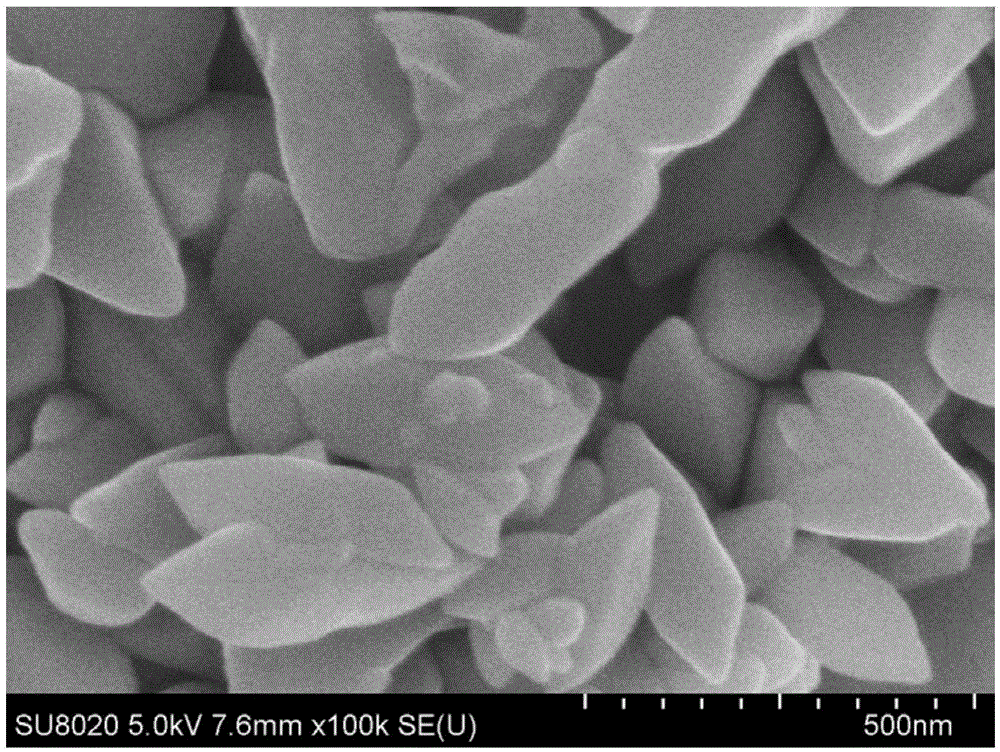

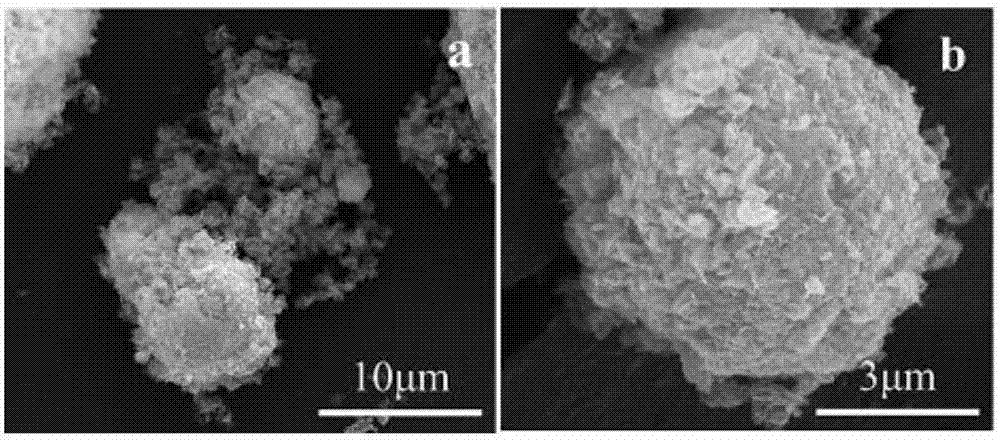

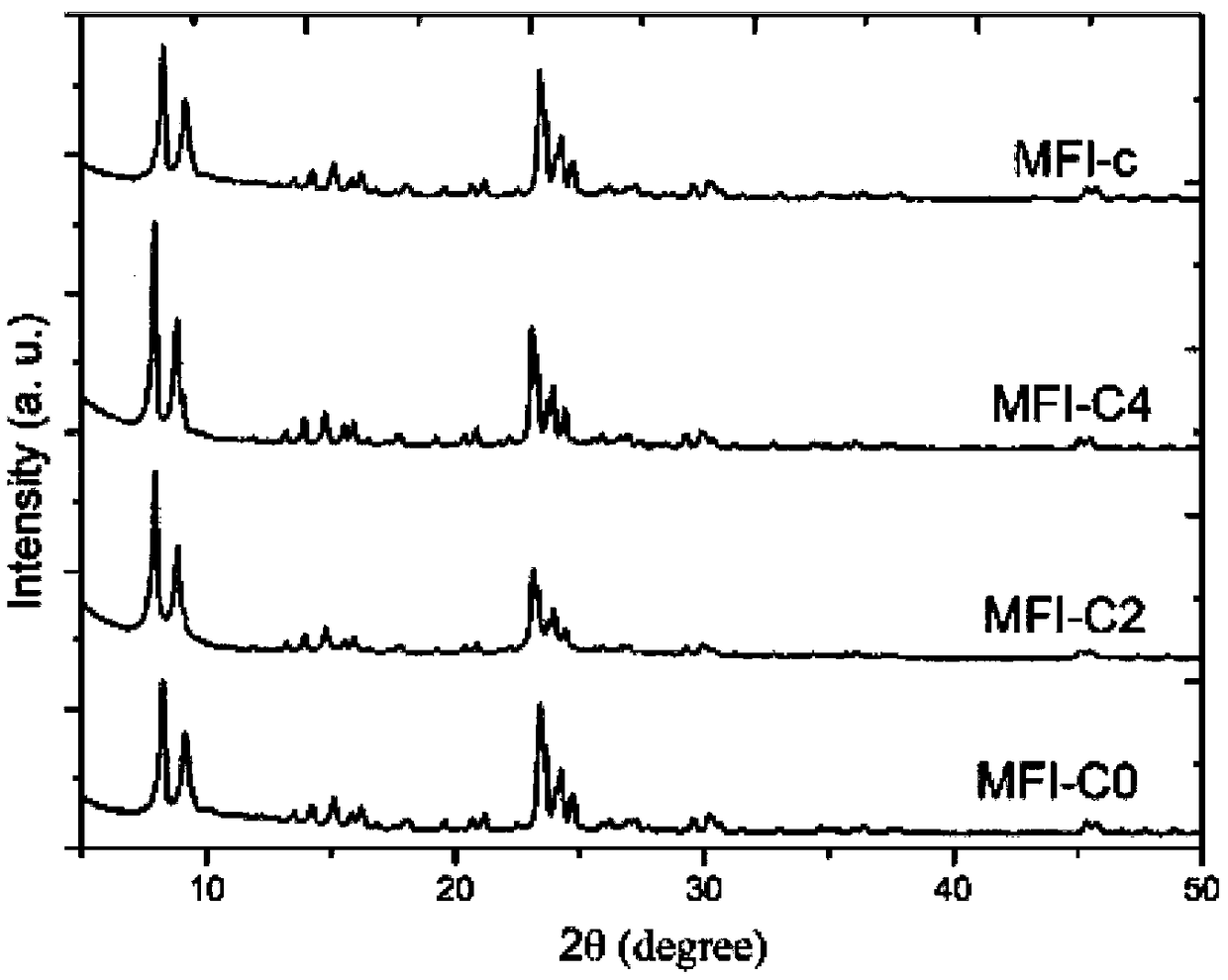

Lamellar ZSM-5 catalyst, and preparation method and application thereof

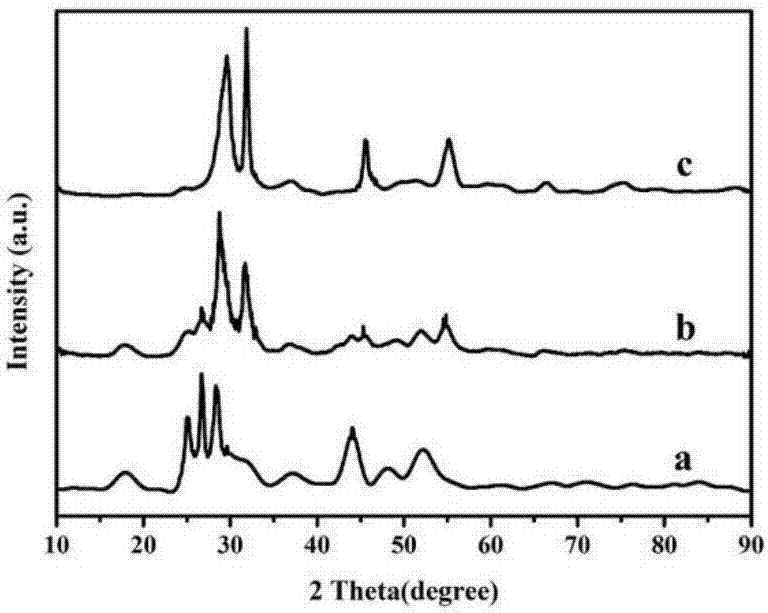

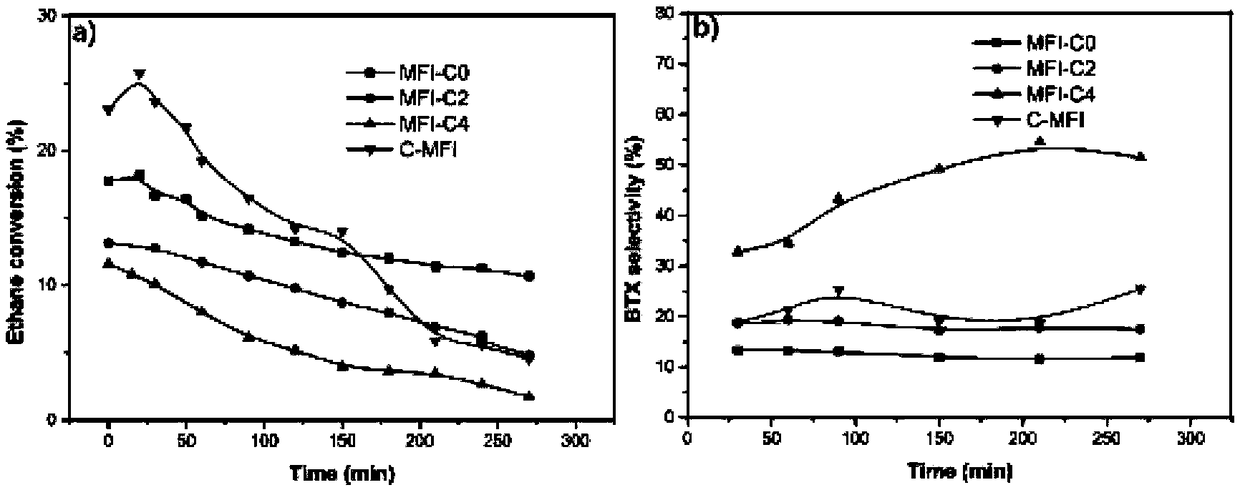

InactiveCN108097294AImprove aromatics selectivityImprove catalytic stabilityMolecular sieve catalystsCatalyst activation/preparationLayer thicknessAromatic hydrocarbon

The invention provides a preparation method of a lamellar ZSM-5 catalyst. Under the action of double template agents, a lamellar ZSM-5 molecular sieve is controllably synthesized by utilizing a function of each template agent. The two template agents have the respective functions: the template agent A is used for synthesizing a lamellar ultrathin molecular sieve, and the template agent B is used for growing the conventional ZSM-5 molecular sieve on the basis of the lamellar molecular sieve. The molecular sieve is characterized by being capable of adjusting and controlling the layer thickness and the Si / Al molar ratio of the lamella ZSM-5 catalyst through controlling the compositional ratio of various raw materials in a precursor solution; the synthesized molecular catalyst has high aromatic hydrocarbon selectivity and carbon deposition resistance on a B acid site, and has high catalytic stability.

Owner:GUANGDONG UNIV OF TECH

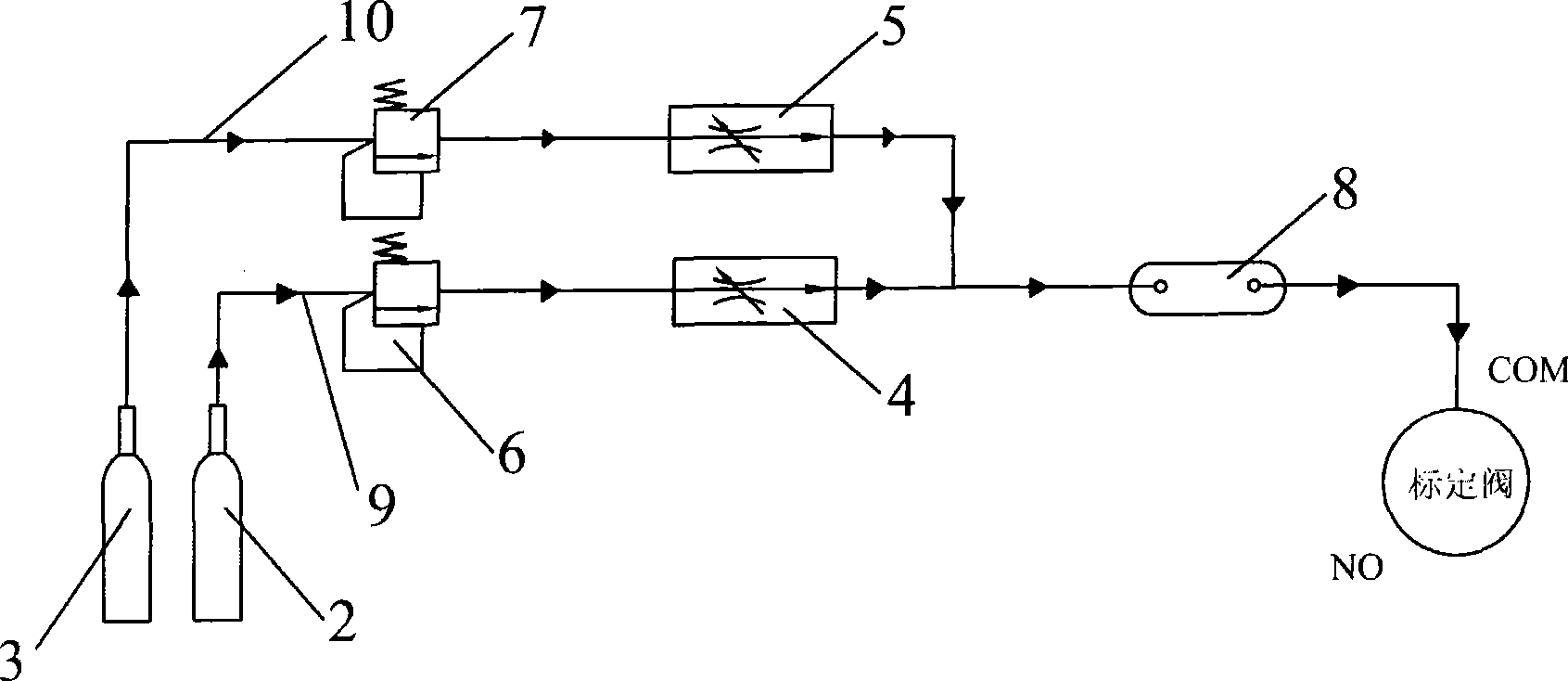

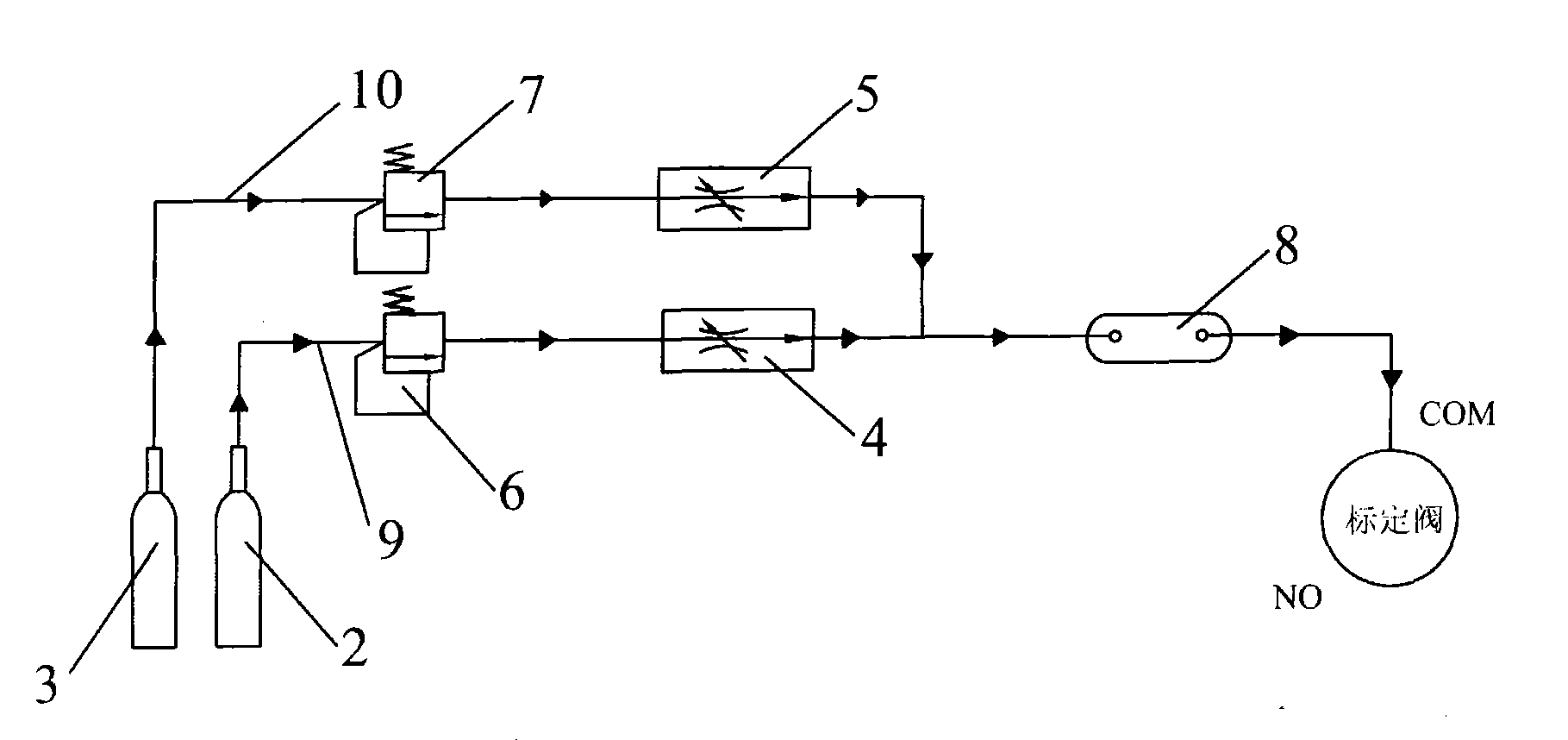

PAN gas generation system and method

ActiveCN101424603ASave experiment cost and timeEasy to operatePreparing sample for investigationProduct gasEngineering

The invention relates to a generation system of PAN (peroxyacetyl nitrate) standard and a method. The system comprises a reaction bin, an NO source, an acetone source and an ultraviolet lamp, wherein the reaction bin is provided with a gas inlet and a gas outlet, the acetone source is accessed in the gas inlet through a first pipeline and is connected with a first quality flow controller, and the acetone source is accessed in the gas inlet through a second pipeline and is connected with a second quality flow controller; the ultraviolet lamp is arranged outside the reaction bin, and the acetone and the NO are pumped in the reaction bin for ultraviolet irradiation. In the method, through the control of the two quality flow controllers, suitable NO and excessive acetone are pumped in the reaction bin; under the irradiation of the ultraviolet lamp, the NO fully participates in a reaction for generating the PAN so as to further calculate the concentration of the generated PAN standard according to the flow of the NO. The invention provides a PAN standard source for a PAN detector to realize online calibration, save experimental cost, lower operation complexity, and provide accurate response factors for the concentration of the PANs (peroxyacetyl nitrate standard) in atmosphere.

Owner:PEKING UNIV

Zinc oxide coated calcium carbonate nano-material and preparation method thereof

ActiveCN111606351AGood coating effectIncrease coverageCalcium/strontium/barium carbonatesZinc oxides/hydroxidesMetallic materialsPhysical chemistry

The invention discloses a zinc oxide coated calcium carbonate nano-material and a preparation method thereof, and belongs to the technical field of novel inorganic non-metallic materials. The preparation of a calcium carbonate@zinc oxide core-shell functional nano-powder material is researched by taking calcium carbonate nano-particles as a core, and a method for preparing CaCO3@ZnO core-shell structure composite nano-particles by combining a hydrothermal method with a heat treatment method is dislcosed. The surface of the CaCO3@ZnO core@shell structure composite nano-particle calcium carbonate prepared by the method is completely covered with zinc oxide, the zinc oxide is in a wire sheet shape, and the coating effect is good. Besides, the preparation method provided by the invention is simple, is suitable for large-scale production, and can effectively reduce the use amount of zinc resources.

Owner:JIANGNAN UNIV +1

Preparation method of pyromellitic dianhydride based on modified vanadium-titanium oxide composite catalysis

InactiveCN109336900AHigh yieldMild reaction conditionsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPyromellitic dianhydrideTitanium oxide

The invention discloses a preparation method of pyromellitic dianhydride based on modified vanadium-titanium oxide composite catalysis. The method comprises the steps of firstly, preparing a modifiedvanadium-titanium oxide composite catalyst from sodium metavanadate and tetrabutyl titanate as raw materials by in-situ modification, melting tetramethylbenzene as a raw material by heating, filteringand introducing into a measuring tank, introducing steam to an inner coil to preserve the heat to 100-105 DEG C, filtering with a filter screen and pumping into a vaporization mixer; preheating the air to 190-200 DEG C, and then introducing the air to the vaporization mixer; reacting the preheated air with the tetramethylbenzene under the catalysis of the composite catalyst prepared above, and cooling the gas generated by the reaction through a heat exchange to obtain crude pyromellitic dianhydride; and then recrystallizing the crude pyromellitic dianhydride with acetone to obtain pyromellitic dianhydride. The method is high in reaction speed and product yield.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

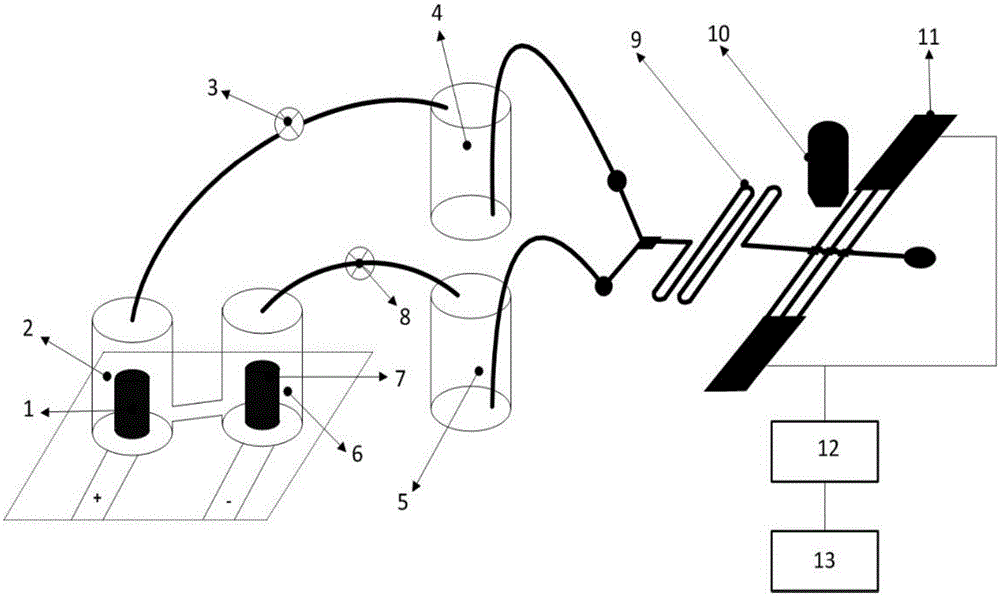

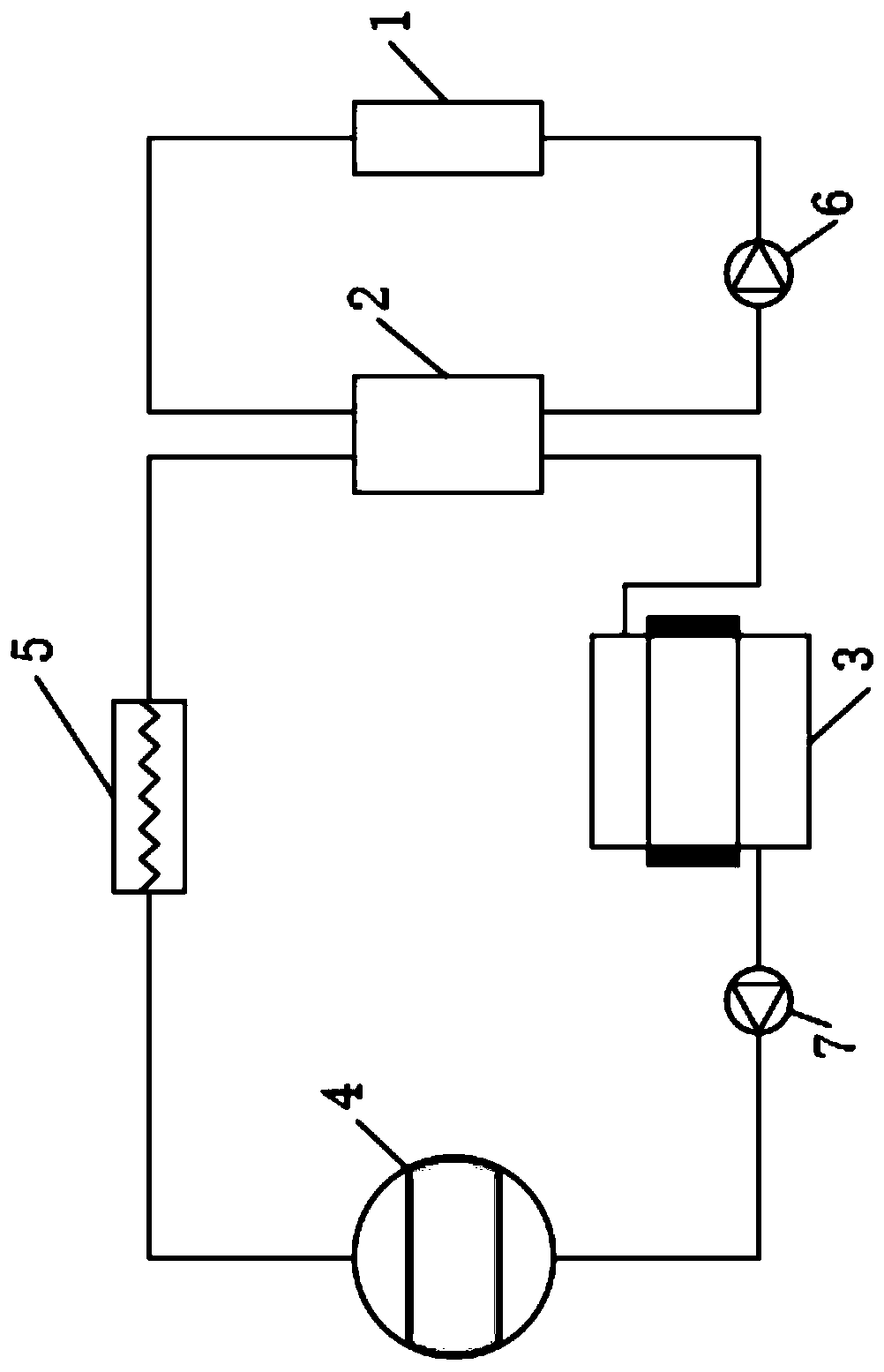

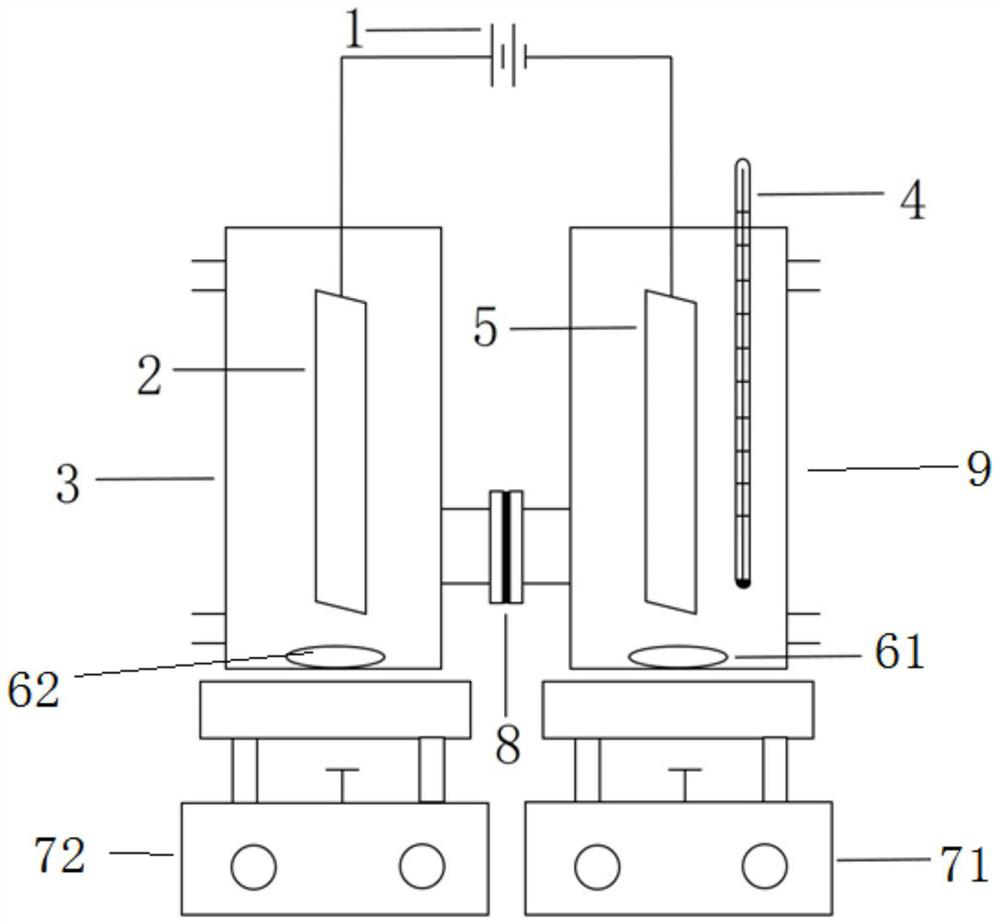

Microfluidic chip droplet generation device

The invention discloses a microfluidic chip droplet generation device. The microfluidic chip droplet generation device is characterized by comprising a first electrode, a first reaction fluid accumulating bottle, a first pressure valve, an oil storage fluid accumulating bottle, a water storage fluid accumulating bottle, a second reaction fluid accumulating bottle, a second electrode, a second pressure valve, a microfluidic chip, a CCD camera, a detection unit, an impedance meter and a pulse counter. The device utilizes a gas produced in reaction as a driving force, and has the characteristics of small volume, convenience in carrying, low cost, simplicity in operation, and capability of achieving feedback control.

Owner:HEBEI UNIV OF TECH

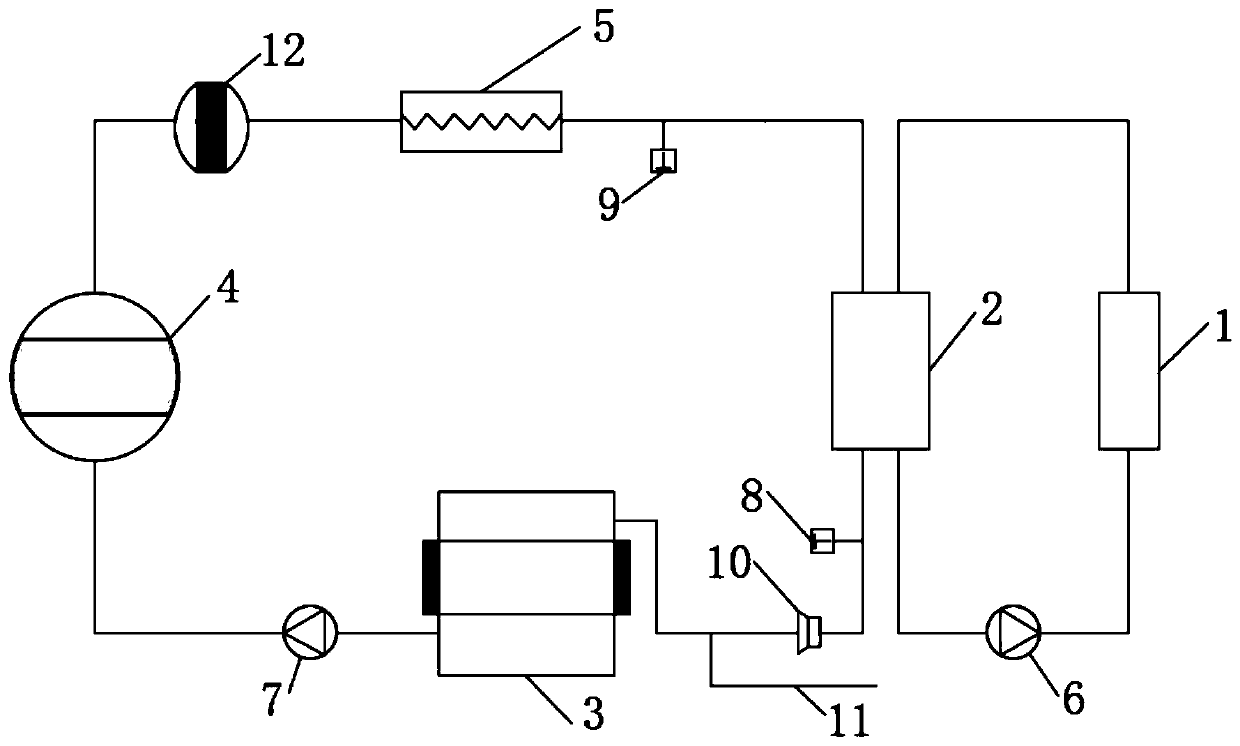

Ice source heat pump system controllable in ice content

InactiveCN110345665AIncrease concentrationLarge latent heat of phase changeHeat pumpsFood processingWater source heat pumpIce water

The invention belongs to the technical field of new energy resources, and particularly relates to an ice source heat pump system controllable in ice content. The ice source heat pump system comprisesan ice-water mixture preparation circulating module which is composed of a supercooled water heat exchanger, an ultrasonic supercooling relieving device and an ice-water mixture separation device. When the system operates, the ice content of a generated ice-water mixture is controlled by controlling working parameters of the ultrasonic supercooling relieving device, and controllable icing is achieved. According to the ice source heat pump system, limitation of a traditional water source heat pump to the fed water temperature is broken, the problem that in a traditional unit, an evaporator is iced and cannot work due to the fed water temperature is too low is solved, in addition, the ice content of the system can be controlled, it can be ensured that the system utilizes latent heat of phasechange to the greatest extent, and the situation that a pipeline is frozen and blocked due to the fact that the ice content is too high in the ice slurry conveying process is prevented.

Owner:HUBEI FENGSHEN CLEAN AIR CONDITIONING EQUIP ENG +1

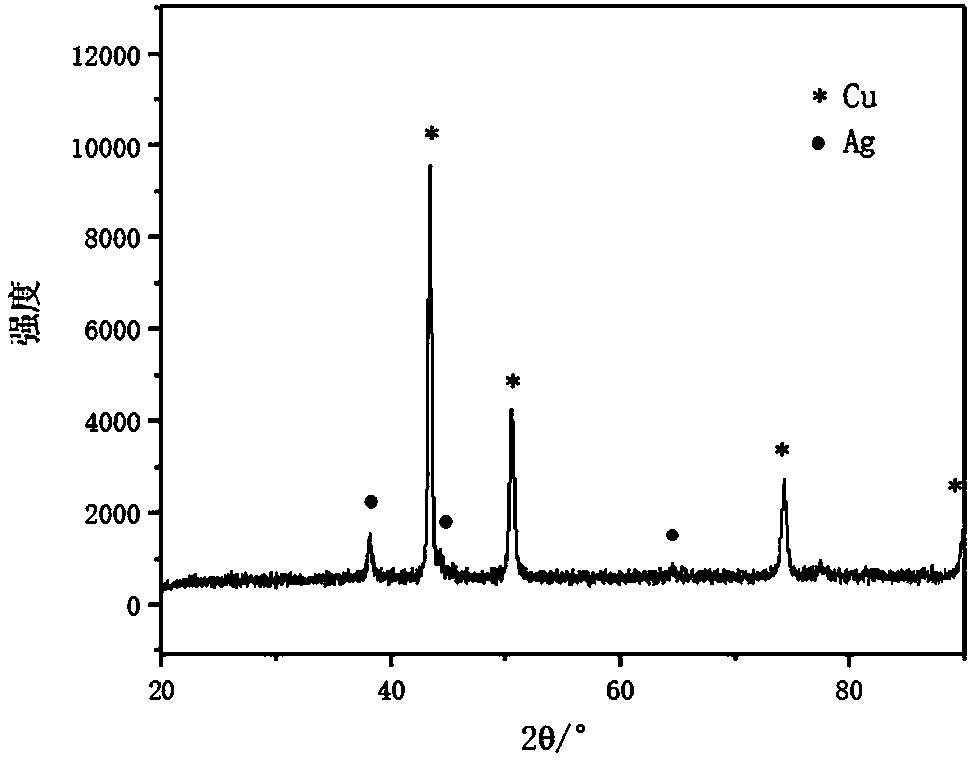

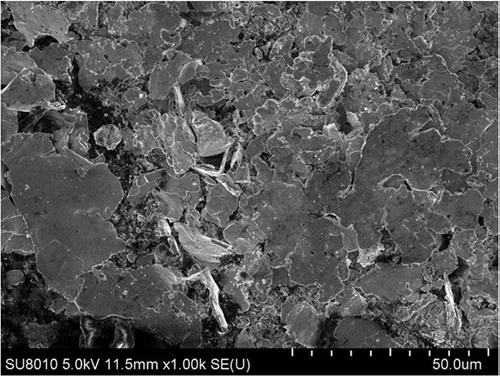

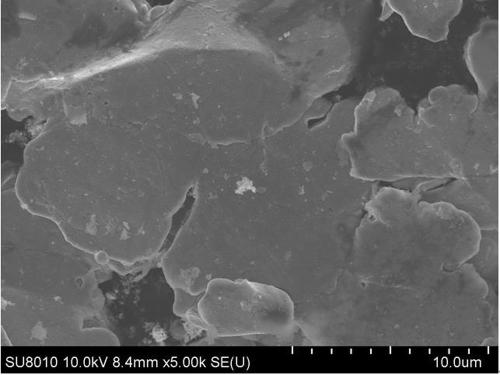

Silver-coated copper powder with core-shell structure and preparation method and application thereof

ActiveCN111318689AImprove adsorption capacityControl spawn rateTransportation and packagingMetal-working apparatusChemical platingIsopropyl alcohol

The invention relates to silver-coated copper powder with a core-shell structure and a preparation method thereof, and belongs to the technical field of materials. The silver-coated copper powder is prepared by adopting copper powder surface treatment, a seed growth method, a heterogeneous nucleation method and a chemical plating method. Specifically, firstly, the surface of Cu is roughened by using FeCl3, seed growth is performed by adopting SnCl2 and TiCl3, and cleaning is conducted by using isopropanol; then heterogeneous nucleation is performed by using AgNO3, and a dispersing agent is added into the resulting solution for dispersing; and finally, a reducing agent, a silver nitrate solution and a complexing agent are added for chemical silver plating, and the silver-coated copper powder is obtained by washing and filtering. The method can be used for preparing the silver-coated copper powder more efficiently, and is easy to operate and suitable for industrial production, and the reaction rate is convenient to control.

Owner:深圳市夏特科技有限公司

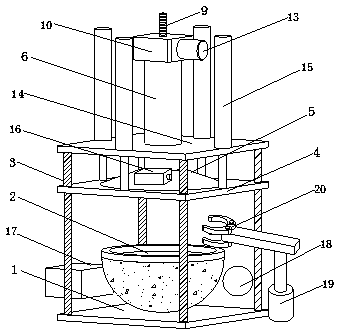

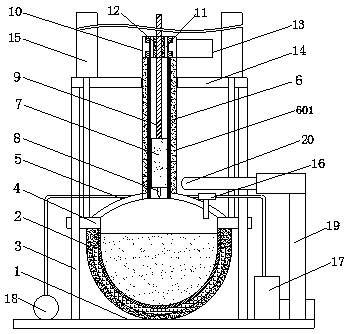

Single crystal silicon refining production process and refining device thereof

InactiveCN110528074AControl spawn rateAffects structural strengthPolycrystalline material growthBy pulling from meltBall screwGraphite

The invention belongs to the technical field of single crystal silicon refining, and particularly relates to a single crystal silicon refining production process and a refining device thereof. The refining device comprises a base; a furnace body is fixedly installed at the middle of the top of the base, and four guide pillars are fixed to the sides of the base. A lifting plate is movably fitted inthe middle portions of the four guide columns. A furnace cover is fixedly fastened to the middle of the lifting plate. The top of the furnace cover is vertically connected with a stretching tube. Theinner wall of the stretching tube is fitted with a graphite piston. The bottom end is vertically connected with a seed rod, and the top end of the graphite piston is vertically fixedly connected witha ball screw. In the invention, the servo motor is driven to rotate the screw nut through the gearbox, and then the ball screw and the graphite piston are screwed down to move along the stretching tune, so that the seed rod can contact the silicon melt, and the rotation speed can be accurately controlled. The necking growth process, the shoulder growth process, the isometric growth process and the tail growth process can be well ensured, and the formation speed of the single crystal silicon rod can be precisely controlled.

Owner:南通晶耀新能源有限公司

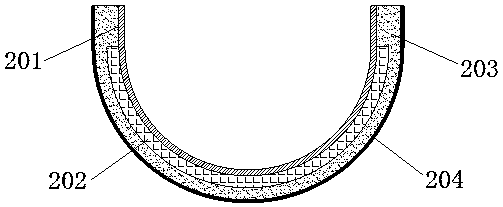

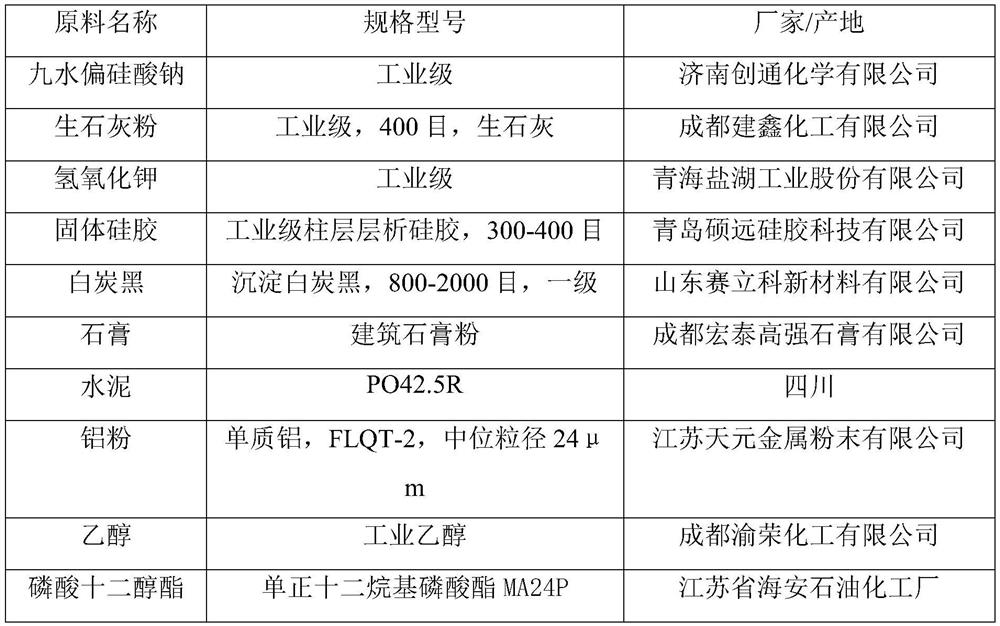

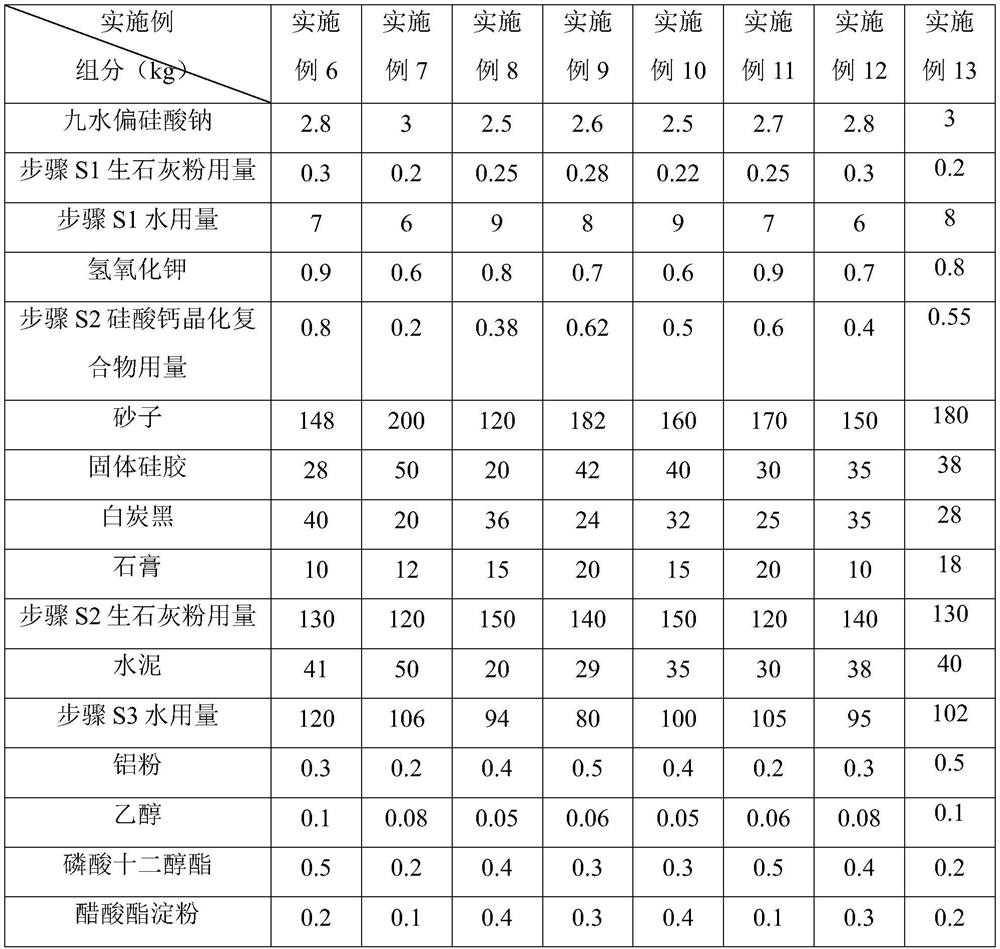

Preparation method of aerated brick with high calcium-silicon ratio and aerated brick with high calcium-silicon ratio prepared by preparation method

ActiveCN114075084AControl spawn rateIncrease reaction rateSolid waste managementCeramicwareCalcium silicateCompressive resistance

The invention discloses a preparation method of an aerated brick with a high calcium-silicon ratio and the aerated brick with the high calcium-silicon ratio prepared by the preparation method, and relates to the technical field of building materials. The preparation method of the aerated brick with the high calcium-silicon ratio comprises the following steps: S1, pre-crystallization: weighing pre-crystallization raw materials, uniformly mixing the pre-crystallization raw materials, transferring the obtained mixture into a high-pressure reaction kettle, and carrying out crystallizing to obtain a calcium silicate crystallized compound; S2, mixing: weighing aerated brick powder, adding the calcium silicate crystallized compound prepared in the step S1, and carrying out uniform mixing to prepare a mixture; S3, slurrying: adding water into the mixture, performing stirring, adding aluminum powder, and continuing stirring to prepare slurry; S4, foaming and standing: injecting the slurry into a mold, conducting foaming, and performing standing to obtain a blank body; and S5, steam curing: cutting the blank body into aerated blocks, and performing steam curing to obtain the aerated brick. The preparation method of the high-calcium-silicon-ratio aerated brick has the advantage that the compressive strength of a product can be improved. The high-calcium-silicon-ratio aerated brick has the advantage of high compressive strength.

Owner:四川滨水上锦绿色建材有限公司

Blocking remover for oil fields and preparation method thereof

ActiveCN111574981ASmall molecular weightIncrease oil productionDrilling compositionDodecaneGlycol synthesis

The invention discloses a blocking remover for oil fields and a preparation method of the blocking remover. The blocking remover comprises a prepad fluid, a main body fluid and a postpad fluid in a mass ratio of 1: 4: 1. The prepad fluid comprises hydrochloric acid, ammonium diethylenetriaminepentaacetate, dodecyl dimethyl betaine, 1-hydroxyethylidene-1, 1-diphosphonic acid, polyacrylamide, a corrosion inhibitor and the balance of water. The main body liquid comprises paraformaldehyde, ammonium chloride, ammonium chloroacetate, butyl cellosolve, dodecyl dimethyl betaine, nitrilotriacetic acid,polyacrylamide, a penetrating agent, a corrosion inhibitor and the balance of water. The postpad liquid comprises an oxidizing agent, hydroxytriacetic acid, sodium hypochlorite, ethylene glycol butylether, a penetrating agent, a corrosion inhibitor and the balance of water. The combination of acid, authigenic acid, an oxidizing agent and the like is adopted, inorganic matter, biological flora, metal corrosives and high-molecular polymers can be thoroughly degraded one by one, then blockages in oil and water wells are thoroughly removed, and the purpose of remarkably improving the oil yield is achieved.

Owner:NORTHWEST UNIV(CN)

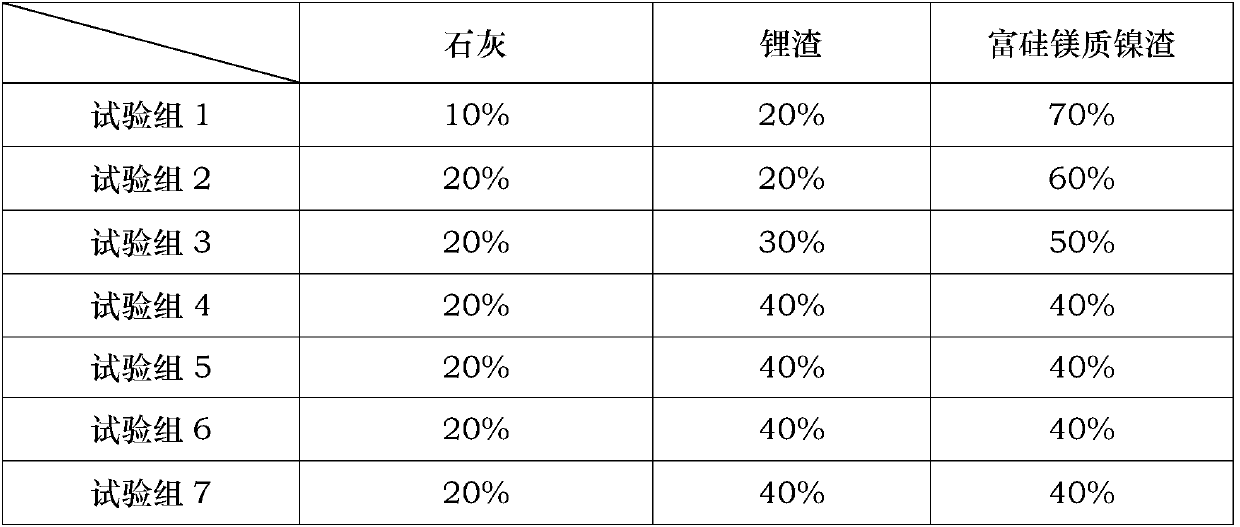

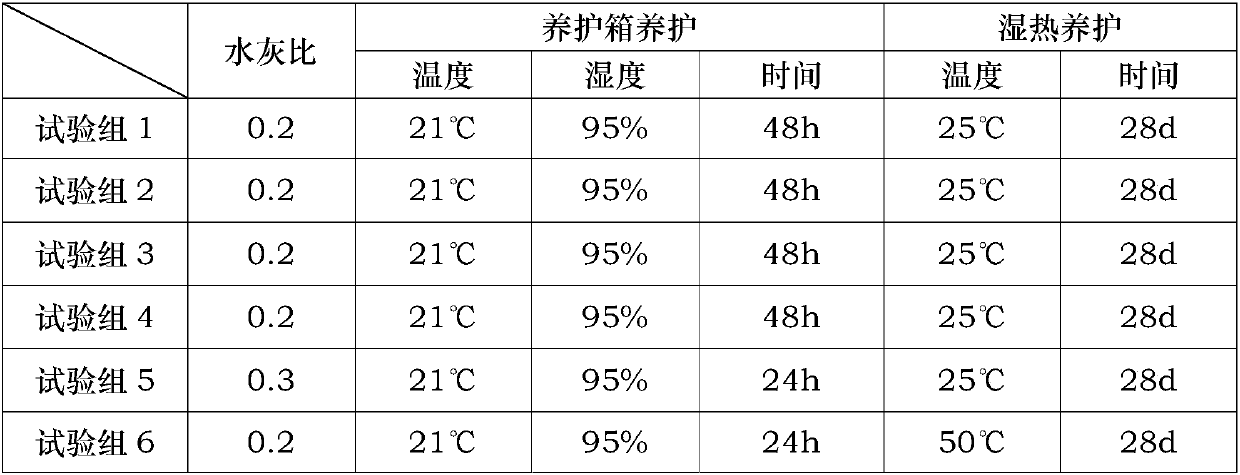

Silicon-rich and magnesium-rich nickel slag clinker-free non-shrinking cement and preparation method thereof

ActiveCN107840586AControl contractilitySimple preparation processCement productionHydration reactionLithium

The invention discloses silicon-rich and magnesium-rich nickel slag clinker-free non-shrinking cement. The silicon-rich and magnesium-rich nickel slag clinker-free non-shrinking cement is prepared from the following components: lime, lithium slag and silicon-rich and magnesium-rich nickel slag, wherein the mass percent of the lime, the lithium slag and the silicon-rich and magnesium-rich nickel slag is 10 percent to 20 percent, 20 percent to 40 percent and 40 percent to 70 percent respectively. According to the silicon-rich and magnesium-rich nickel slag clinker-free non-shrinking cement, thelime and the lithium slag are used as an alkali activator; under a certain temperature condition, a cementing property potential of main minerals in the silicon-rich and magnesium-rich nickel slag isrealized extremely, the hydration activity is improved and a cementing material is obtained. By controlling the doping amounts of the lime and the lithium slag and reaction temperature and respectivereaction speeds of mineral components including clino-enstatite, enstatite and ferrohortonolite, so that a generation speed of Mg(OH)2 in a hydration reaction product is controlled; a principle that the volume of the Mg(OH)2 is increased by utilizing MgO in the minerals is utilized and the shrinkage performance of a cement component is controlled, so that a non-shrinking cement component is prepared; a way for greatly and sufficiently utilizing the nickel slag is provided. Moreover, a preparation technology of the clinker-free cement is simple and is easy to operate.

Owner:YANCHENG GUOTAI CONCRETE

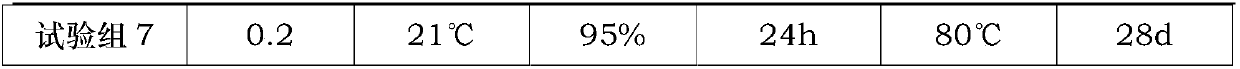

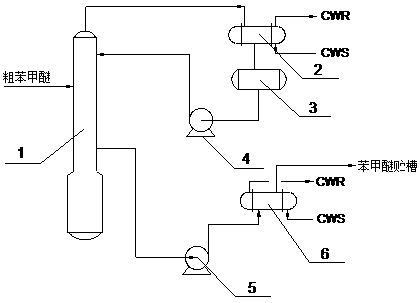

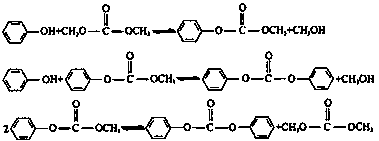

Method for controlling byproduct anisole in diphenyl carbonate production

PendingCN110950759AControl generationControl spawn rateEther separation/purificationPreparation from organic carbonatesSide productAnisole

The invention belongs to the technical field of diphenyl carbonate production, and particularly relates to a method for controlling a byproduct anisole in diphenyl carbonate production. The method forcontrolling the byproduct anisole in diphenyl carbonate production comprises the steps: A, controlling generation of anisole: controlling the concentration of a catalyst for diphenyl carbonate production to be 700 ppm-800 ppm, wherein the average residence time of a disproportionation reaction material for diphenyl carbonate production is 5 h; and B, recovering anisole: controlling anisole in a diphenyl carbonate production system to be less than 2%, and discharging part of anisole in the system when the concentration of anisole in the system reaches 2%. According to the method, the generation rate of anisole is obviously reduced, and the generation of anisole can be effectively controlled.

Owner:四川中蓝国塑新材料科技有限公司 +1

Production method for secondary acid hydrolysis of dimethyl ester glyphoate acid

ActiveCN101550158AReduce concentrationControl spawn rateBiocideGroup 5/15 element organic compoundsAcid hydrolysisHigh energy

The invention relates to a production method for secondary acid hydrolysis acid of dimethyl ester glyphoate acid. After condensation reacting dimethyl ester glyphoate acid, adding 31% of hydrochloric acid at twice in the condensed liquid, at first adding 45-75% of total hydrochloric acid, second, adding the remaining hydrochloric acid when the temperature reaches 105 DEG C. The invention can effectively solve the problems of insufficient production efficiency of hydrolysis kettle, higher energy consumption and low coefficient of recovery in the process of methanol recovery, enable the utilization capacity of hydrolysis kettle to be increased 25%, shorten hydrolysis time about 1 hour, and also improve 25-30% of yield of glyphoate acid when the production cost of glyphoate acid is lowered 5-10%.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

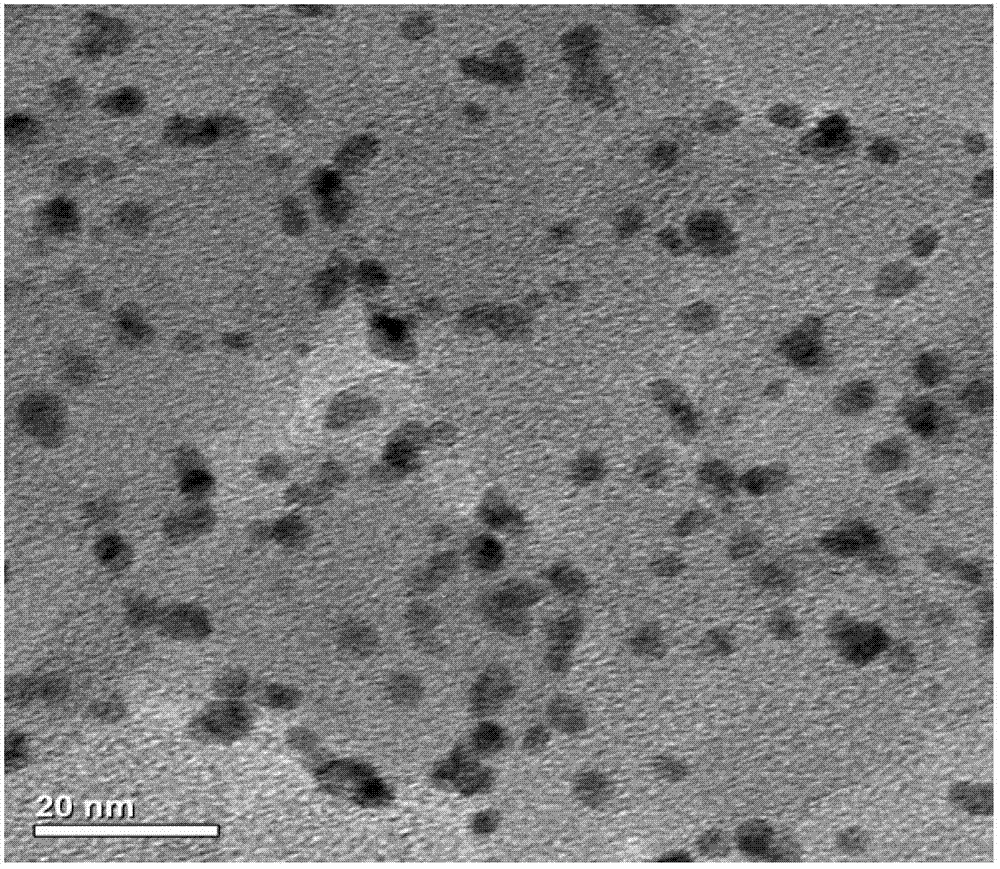

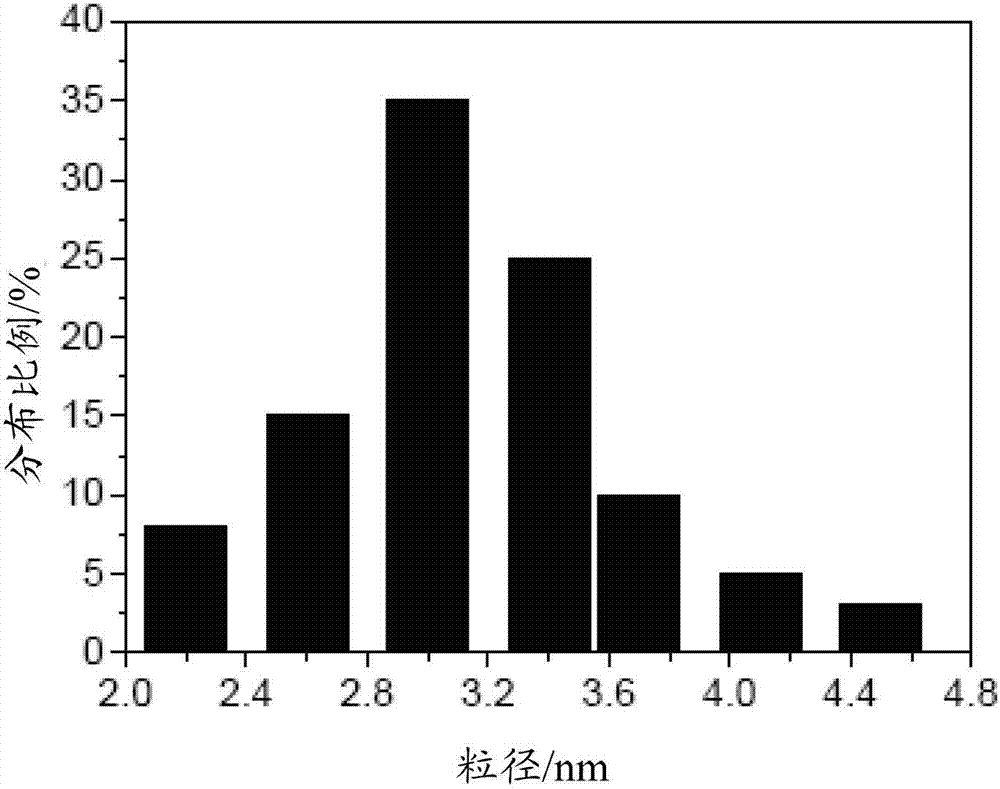

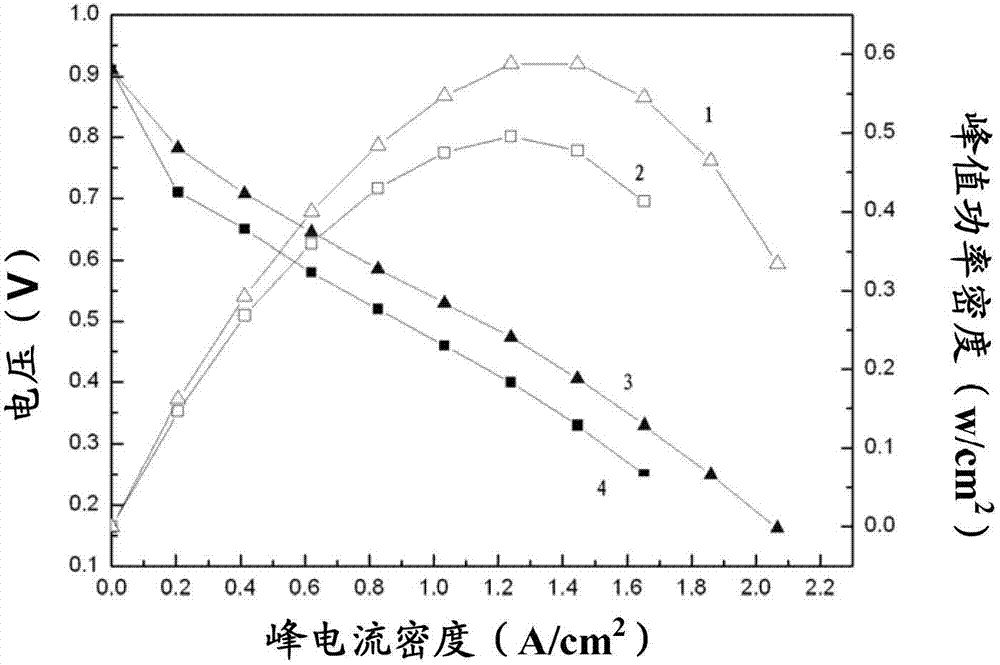

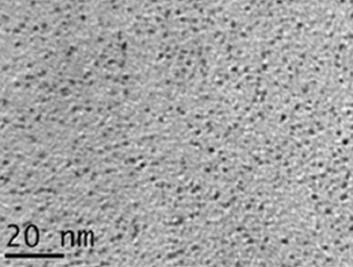

Preparation method of proton exchange membrane fuel cell catalyst

ActiveCN103084167AControl spawn rateSlow downCell electrodesSolid electrolyte fuel cellsCarbon blackPt element

The invention provides a preparation method of a proton exchange membrane fuel cell catalyst. The preparation method comprises the following steps of: mixing a noble metal halide solution and carbon black, adjusting the pH value to 2.5-10.5, and then carrying out ultrasonic wave stirring to obtain precursor liquid, wherein the noble metal halide solution is platinum halide or a mixture of platinum halide and ruthenium halide; adding the precursor liquid to a sodium borohydride solution, and carrying out ultrasonic wave stirring to obtain a mixed liquid; and standing, filtering, washing and drying the mixed liquid to obtain the proton exchange membrane fuel cell catalyst. The proton exchange membrane fuel cell catalyst prepared by the method has uniform particle size and high electrochemical performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

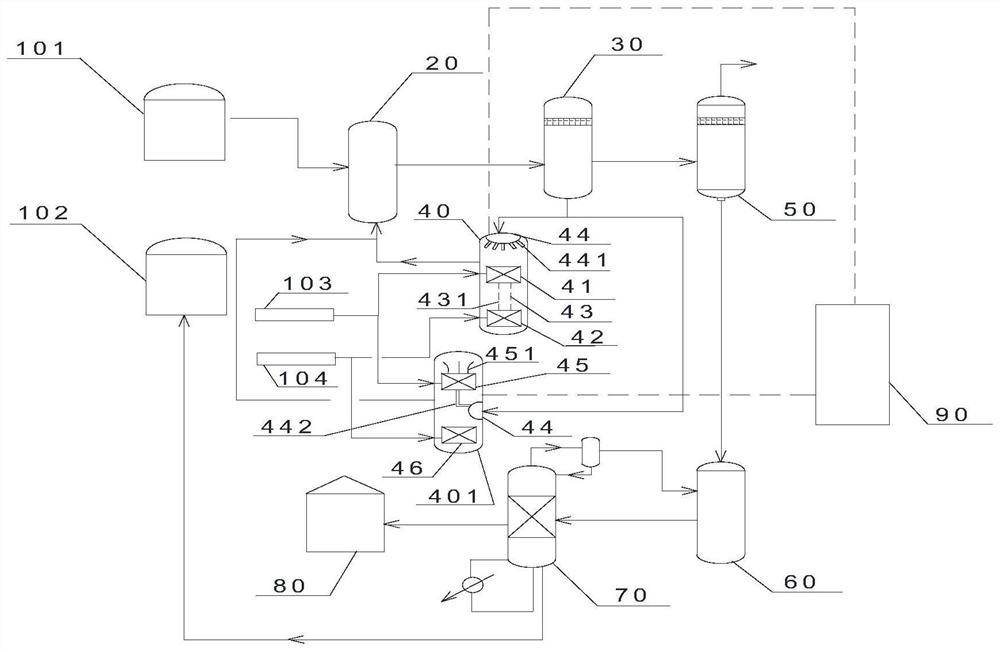

Intelligent micro-interface reaction system and method for preparing ethylene glycol via chloroethanol process

InactiveCN112624900ALow costControl spawn rateProcess control/regulationOrganic compound preparationSodium bicarbonateReaction rate

The invention discloses an intelligent micro-interface reaction system for preparing ethylene glycol via a chloroethanol process. The system comprises a main material reactor, a crystallizer, a first recycling reactor, a second recycling reactor and an intelligent control system, wherein the main material reactor is connected with a sodium bicarbonate storage tank and a chloroethanol storage tank; a product obtained after a reaction in the main material reactor enters the crystallizer; the crystallizer is connected with the first recycling reactor and the second recycling reactor; the first recycling reactor and the second recycling reactor are connected in parallel; a first ammonia gas micro-interface generator and a carbon dioxide micro-interface generator are arranged in the first recycling reactor; a second ammonia gas micro-interface generator and a split-flow type micro-interface generator are arranged in the second recycling reactor; and the intelligent control system controls reaction rates in the first recycling reactor and the second recycling reactor. According to the reaction system, the cost of the reaction process is reduced, and reaction efficiency is enhanced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

PAN gas generation system and method

ActiveCN101424603BRealize online calibrationEasy to operatePreparing sample for investigationResponse factorUltraviolet

Owner:PEKING UNIV

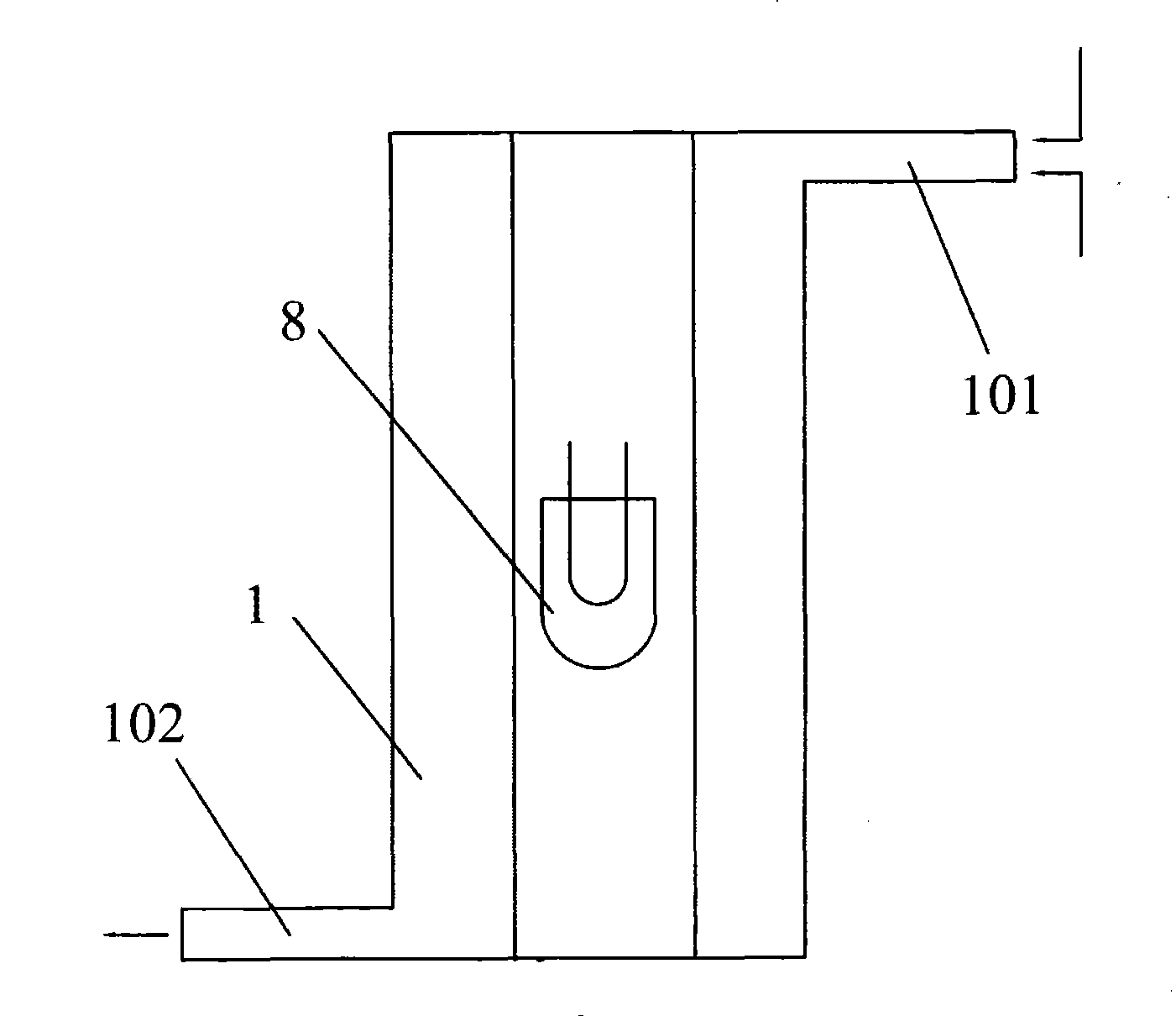

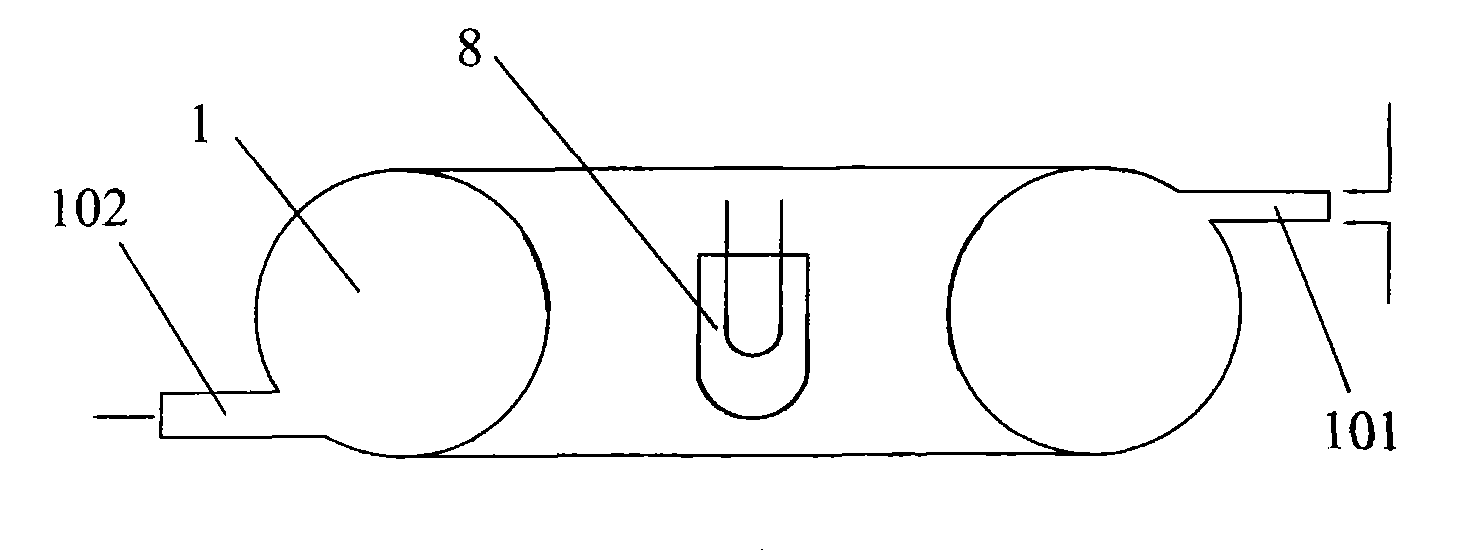

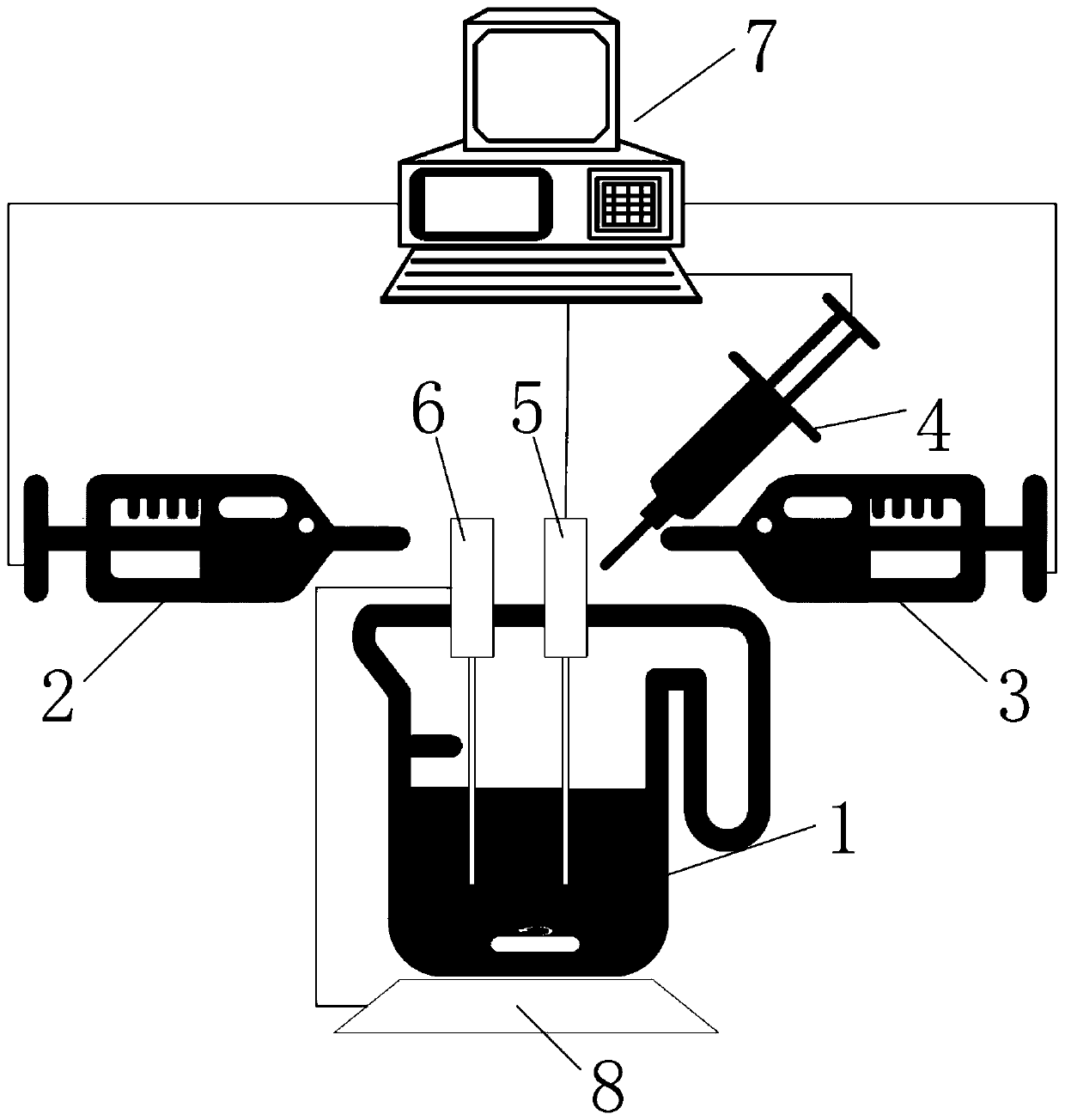

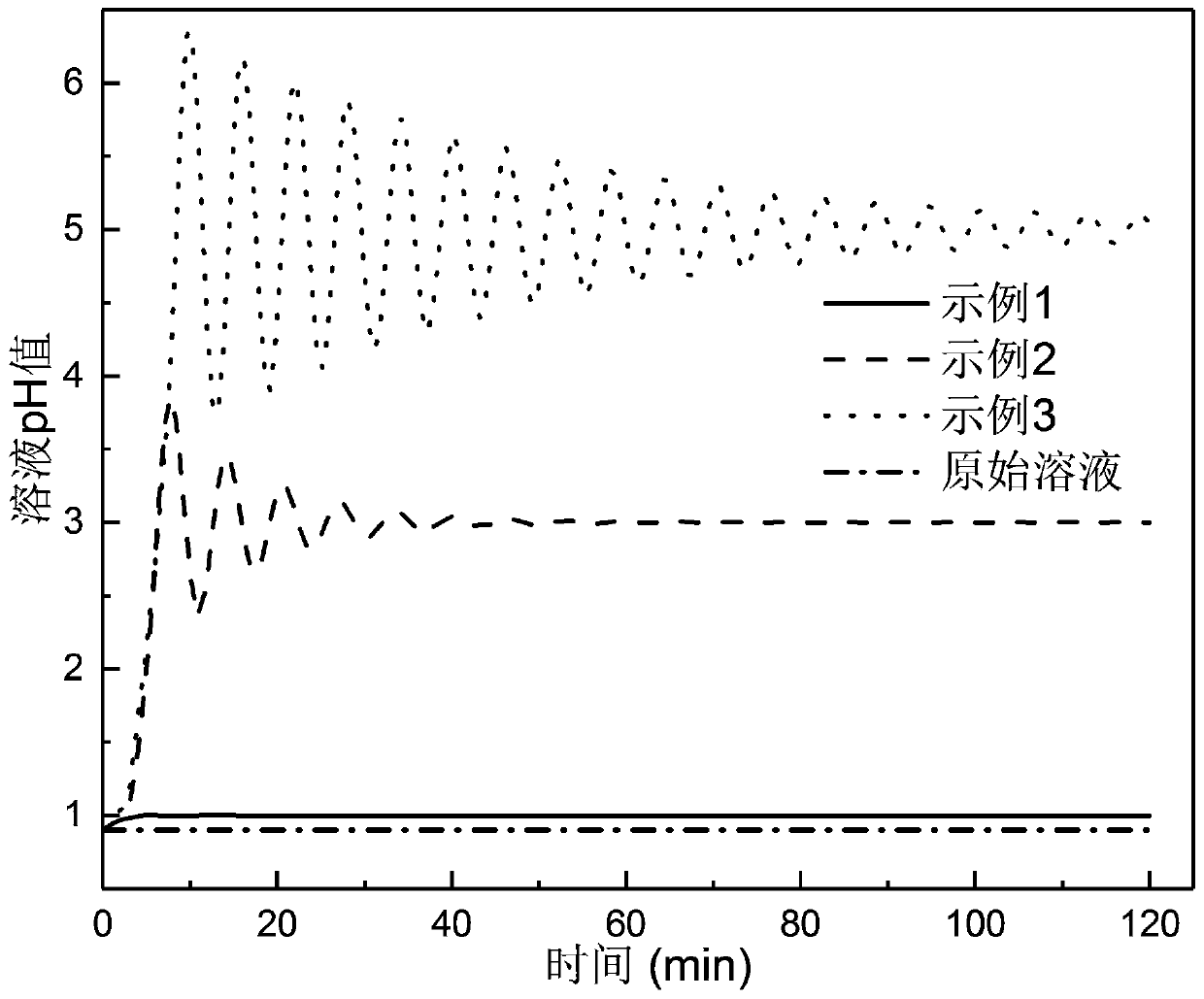

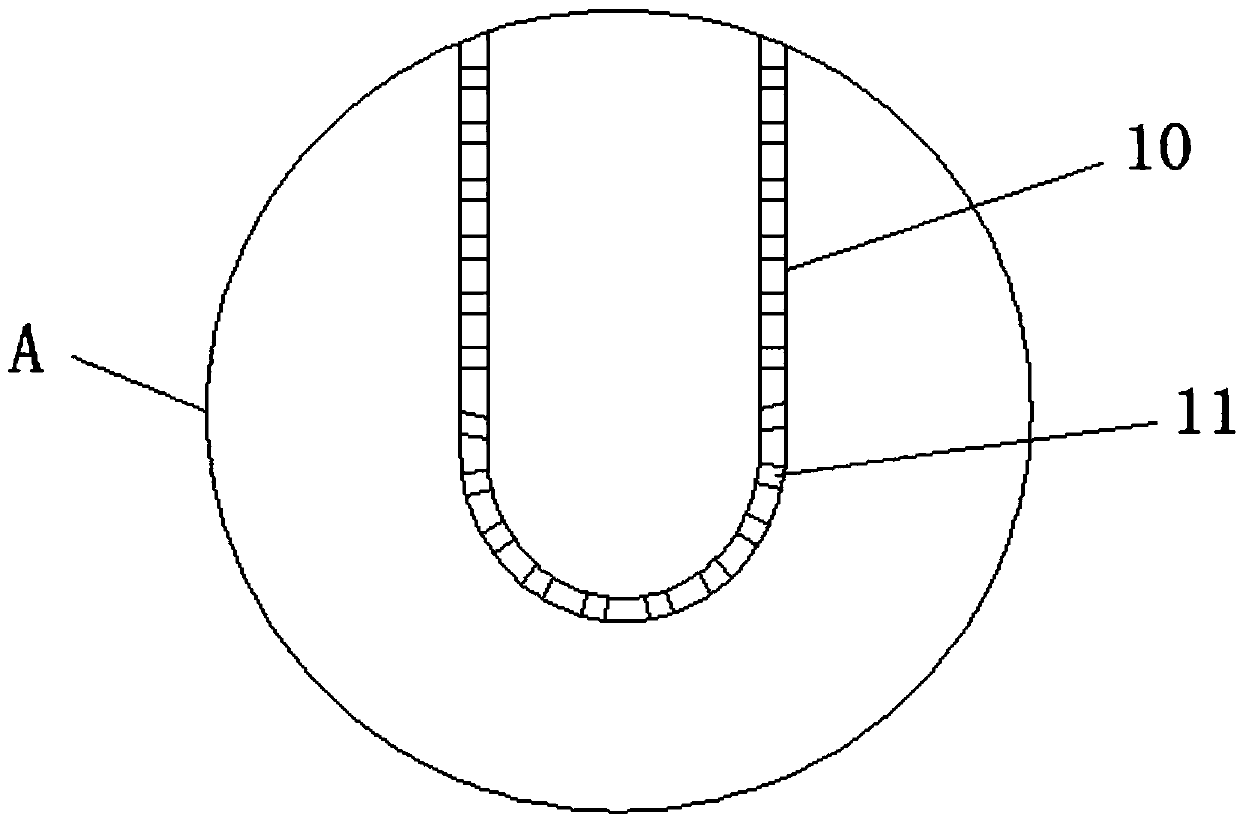

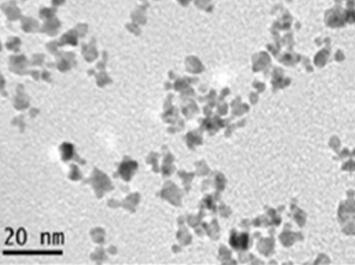

Device and method for synthesizing catalyst by using novel redox coprecipitation method

InactiveCN110756123AReduce reunionEvenly distributedProcess control/regulationChemical/physical/physico-chemical stationary reactorsPtru catalystRedox

The invention discloses a device for synthesizing a catalyst by using a novel redox coprecipitation method. The device is characterized by comprising a reaction tank (1), an oxidant solution injectionpump (2), a reducing agent solution injection pump (3), an alkaline solution injection pump (4), a pH probe (5), a temperature probe (6), an upper computer (7) and a magnetic stirrer (8) with a heating function, wherein the upper computer (7) is used for controlling the ion concentration and the redox reaction speed in the reaction tank (1) through control on the propelling speed of the oxidant solution injection pump (2) and the propelling speed of the reducing agent solution injection pump (3), is used for measuring the pH value of a solution accurately through the pH probe (5) in the reaction tank (1), and is used for controlling the propelling speed of the alkaline solution injection pump (4) so that the pH value of the prepared solution is stabilized within a preset range of the setpH value. Through the device, the pH value in the reaction tank can be controlled with high precision, so that the synthesis reaction speed is controlled, the degree of automation is high, and manualerrors are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of nanometer material of zinc oxide coating calcium carbonate and preparation method thereof

ActiveCN111606351BGood coating effectIncrease coverageCalcium/strontium/barium carbonatesZinc oxides/hydroxidesMetallic materialsPhysical chemistry

The invention discloses a zinc oxide-coated calcium carbonate nano-material and a preparation method thereof, belonging to the technical field of new inorganic non-metallic materials. The present invention uses calcium carbonate nanoparticles as the core to study the preparation of calcium carbonate@zinc oxide core-shell functional nanopowder material, and discloses a hydrothermal method combined with heat treatment method to prepare CaCO 3 A method for composite nanoparticles with @ZnO core@shell structure. The CaCO prepared by the present invention 3 The surface of the @ZnOcore@shell structure composite nanoparticle calcium carbonate is completely covered by zinc oxide, and the zinc oxide is in the shape of a line sheet, and the coating effect is good. In addition, the preparation method provided by the invention is simple, suitable for large-scale production, and can effectively reduce the usage of zinc resources.

Owner:JIANGNAN UNIV +1

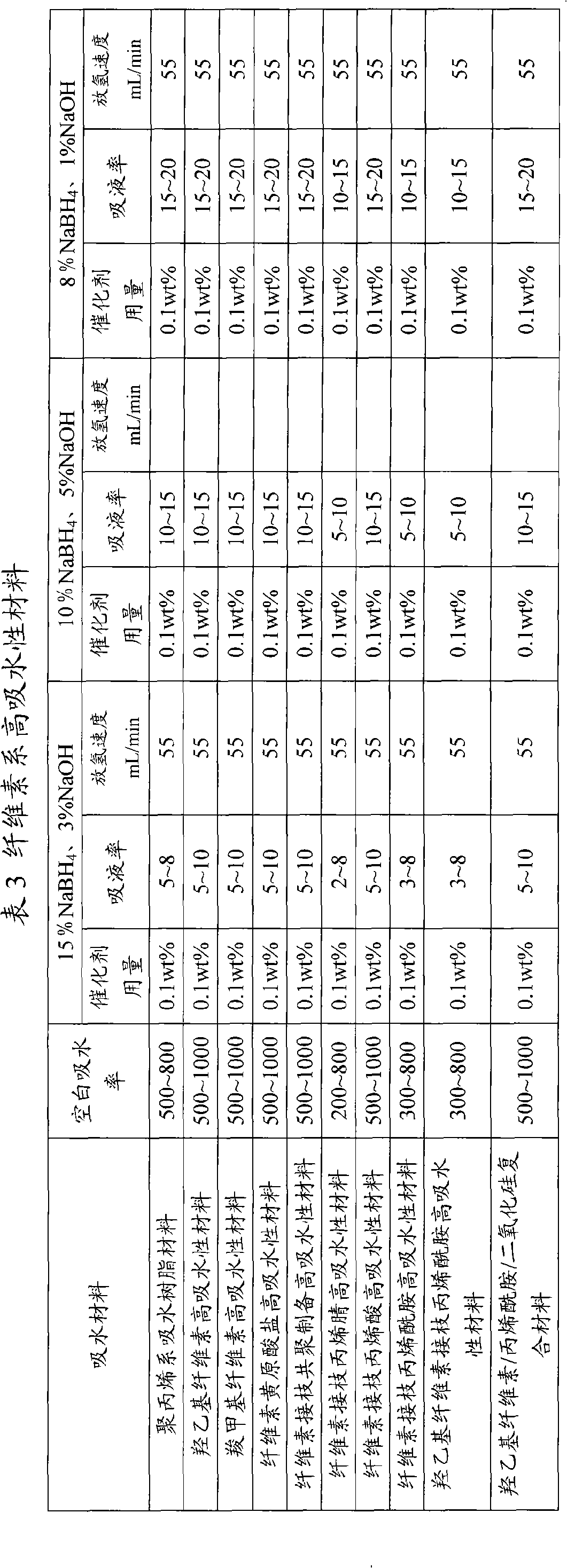

Preparation of hydrogen-storage material used for fuel cell

InactiveCN101249941AImprove conversion rateControl spawn rateHydrogen productionFuel cellsChemistryBorohydride

The invention discloses a method for preparing hydrogen storage materials for fuel cells, which belongs to the field of fuel cells. The method includes uniformly mixing borohydride, hydroxide, water absorption materials and a catalyst. Hydrogen storage materials prepared according to the method provided by the invention have the advantages of stable property, easy storage and portability, which can control hydrogen releasing speed without filtering prepared hydrogen.

Owner:HANERGY TECH

A chemical oxygen generator

InactiveCN106276806BChange liquid levelChange the contact areaEducational modelsOxygen preparationEngineeringOxygen

The invention discloses a chemical oxygen generating device. The chemical oxygen generating device comprises a box. A reaction cavity is formed inside the box, a liquid level sensor is arranged on the inner all of the reaction cavity, a discharging opening is formed in the bottom of the box, a first electromagnetic valve is arranged on the discharging opening, an oxygen outlet is formed in the top of the box, a second electromagnetic valve is arranged on the oxygen outlet, and an air pressure gauge is arranged on one side of the oxygen outlet. According to the chemical oxygen generating device, hydrogen peroxide is injected through a feeding opening, pistons are pulled through electric stretchable rods, and the hydrogen peroxide is sucked into piston cylinders and stored, and then is put into a reagent pipe filled with manganese dioxide through the feeding opening; when oxygen needs to be generated, the electric stretchable rods push the pistons to inject the hydrogen peroxide into the reaction cavity, and the hydrogen peroxide is reacted with the manganese dioxide in the reagent pipe; meanwhile, the electric stretchable rods are matched with the pistons, the liquid level height of the hydrogen peroxide in the reaction cavity is changed, the contact area between the hydrogen peroxide and manganese dioxide is changed accordingly, and the oxygen generating rate of the whole device is controlled.

Owner:石宝珏

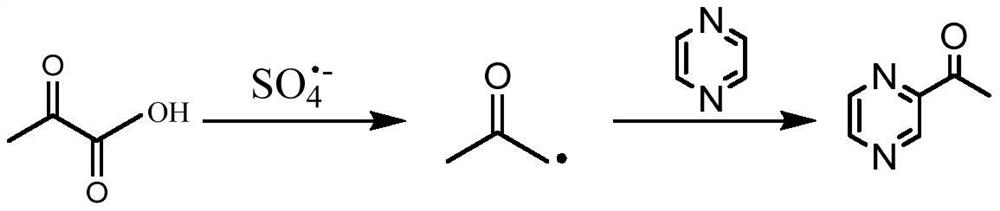

A method for preparing 2-acetylpyrazine by electrolysis

ActiveCN113089004BEasy to separateMaximize utilizationCellsElectrolytic organic productionPyrazineAmmonium sulfate

The invention discloses a method for preparing 2-acetylpyrazine by electrolysis, comprising the following steps: using an H-type electrolytic cell as a reactor, dissolving pyrazine and pyruvic acid in dichloromethane, and dissolving oxidant ammonium persulfate in water , into the cathode chamber, and then add dimethyl sulfoxide; add sulfuric acid solution with a mass fraction of 5-30% in the anode chamber; keep constant temperature, power on and electrolyze, and keep the current density at 10-800A m ‑2 , the energized amount reaches 2F·mol ‑1 Stop energizing afterward, separate organic phase, obtain the dichloromethane solution that contains 2-acetylpyrazine; The present invention solves the high production cost, the low product quality and the Technical problems of polluting the environment.

Owner:EAST CHINA UNIV OF SCI & TECH

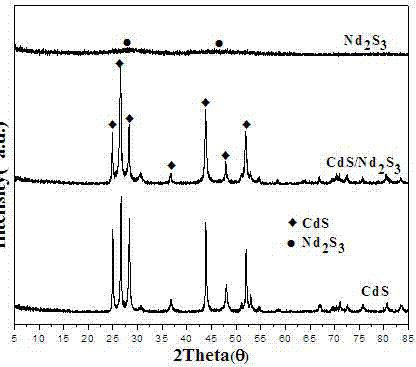

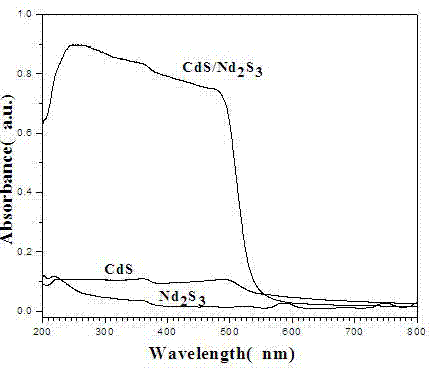

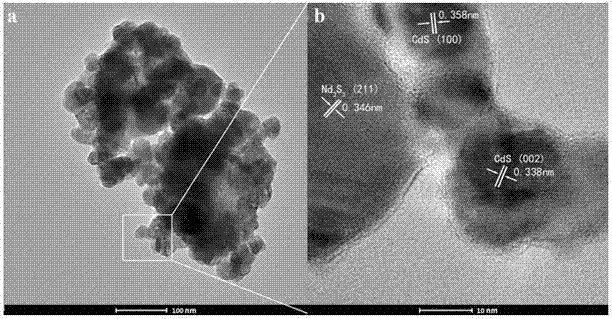

Preparation and application of CdS/Nd2S3 nano composite photocatalytic material with visible-light response

ActiveCN107115873AImprove light responsivenessBroaden the photoresponse rangePhysical/chemical process catalystsWater/sewage treatment by irradiationAlcoholPolyethylene glycol

The invention discloses a preparation method of a CdS / Nd2S3 nano composite photocatalytic material with excellent photocatalytic performance under visible light. The method comprises the following steps: controlling a mass ratio of the substances Cd to Nd to be 100: (0.1-1.0), wherein the addition amount of PEG (Polyethylene glycol) is 2-10% of the mass of the Cd-Nd-S; taking a micro-molecular organic sulfur-containing compound as a sulfur source, wherein the addition ratio of n(M): n(S) is (1.0):(1.0-4.0); taking an alcohol as a solvent, reacting at the temperature of 110-160 DEG C in a reactor for 12-36 hours, washing the product, drying, performing staged temperature programming under gas shield, roasting to the temperature of 300-800 DEG C, and maintaining the temperature for 1-6 hours, thereby obtaining the CdS / Nd2S3 composite sulfide. The invention provides a preparation method of the composite sulfide photocatalytic material, and organic matters can be well degraded under the visible light.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Oilfield plugging remover and preparation method thereof

ActiveCN111574981BSmall molecular weightIncrease oil productionDrilling compositionDodecaneGlycol synthesis

The invention discloses a blockage removing agent for oilfields and a preparation method thereof, which comprises a pre-fluid, a main body fluid and a post-fluid with a mass ratio of 1:4:1; wherein, the pre-fluid includes hydrochloric acid, ethylene glycol Triaminepentaacetic acid amine, dodecyl dimethyl betaine, hydroxyethylidene diphosphonic acid, polyacrylamide, corrosion inhibitor, and the balance is water; the main liquid includes paraformaldehyde, ammonium chloride, Ammonium chloroacetate, ethylene glycol butyl ether, dodecyl dimethyl betaine, aminotriacetic acid, polyacrylamide, penetrating agent, corrosion inhibitor, and the balance is water; Acetic acid, sodium hypochlorite, butyl glycol ether, penetrating agent, corrosion inhibitor, and the balance is water. The present invention adopts the combination of acid + authigenic acid + oxidizing agent +, which can thoroughly degrade inorganic substances, biological bacteria clusters, metal corrosion products and high molecular polymers one by one, and then completely remove blockages in oil and water wells, achieving significant improvement The purpose of oil production.

Owner:NORTHWEST UNIV

Catalyst for synthesizing aromatic amine from aromatic aldehyde and preparation method thereof

ActiveCN109876866BKeep aliveHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystOrganosolv

The invention relates to a catalyst for the synthesis of aromatic amines from aromatic aldehydes and a preparation method thereof. The metal salt main agent, the metal salt auxiliary agent and the non-ionic high molecular compound are dissolved in an alcohol solvent, and heated after mixing to obtain Washing the jelly substance containing metal salt ions; dispersing the washed jelly substance containing metal salt ions in an organic solvent, adding inorganic porous carrier materials, mixing evenly, suction filtering and drying to obtain a catalyst for synthesizing aromatic amines. The method of the invention is energy-saving and environment-friendly, has simple process, and the prepared catalyst has small particle size of precious metals and is not easy to agglomerate, low operating temperature and operating pressure, high main reaction activity, few by-products and good reusability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com