A method for preparing 2-acetylpyrazine by electrolysis

A technology of acetylpyrazine and electrolysis, which is applied in the direction of electrolysis components, electrolysis process, electrolysis organic production, etc., can solve the problems of easy change of product properties, reduction of product purity, and low product quality, so as to avoid the use of metal catalysts, The effect of high product purity and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

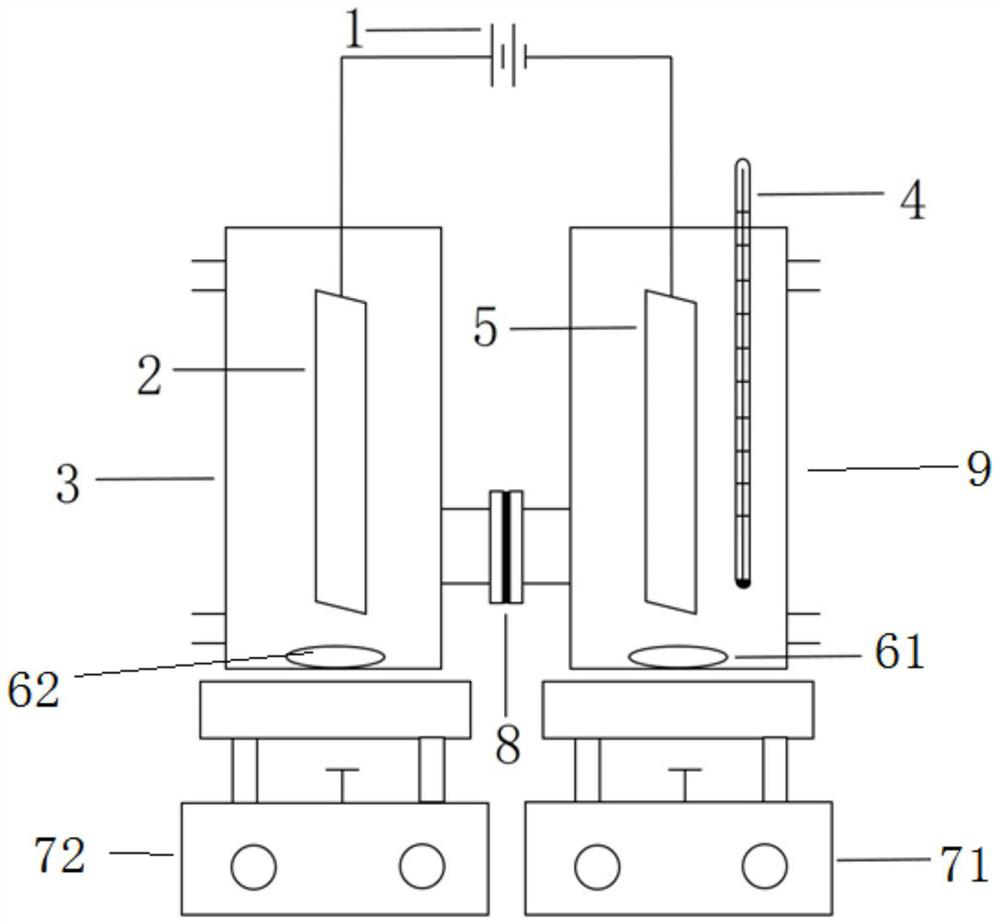

preparation example Construction

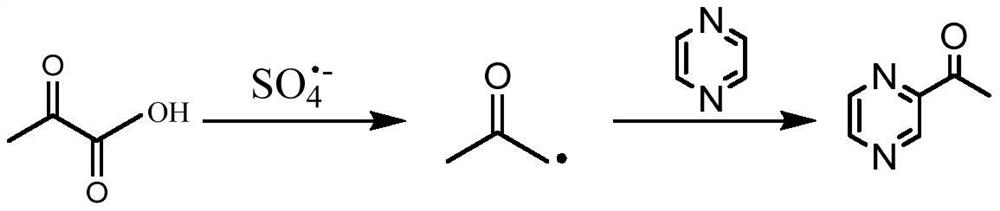

[0031] The relevant electrochemical reaction equation of the preparation method of 2-acetylpyrazine of the present invention is as follows:

[0032] anode:

[0033] 2H 2 O→4H + o 2 +4e -

[0034] cathode:

[0035]

[0036] The generated sulfate radicals participate in the following reactions:

[0037]

[0038] The specific steps of using the device are as follows:

[0039] First, solvent dichloromethane, pyrazine, pyruvic acid, water, ammonium persulfate are added to the cathode chamber, then dimethyl sulfoxide is added, the DC power supply 1 is turned on, and then the first magnetic stirrer 71 is turned on, and the first stirring bar 61 starts Rotate to mix the raw materials, add sulfuric acid solution in the anode chamber, then turn on the second magnetic stirrer 72, the second stirrer 62 starts to rotate, the cation exchange membrane 8 separates the anion and yang chambers, and only NH 4 + and H + Through, a complete current path is formed. The above-mentio...

Embodiment 1

[0041] The H-type electrolytic cell is used as the reactor, the anode is plated with ruthenium-titanium plate, the cathode is lead plate, and the anode chamber and the cathode chamber are separated by cation exchange membrane Nafion PFSA Membranes (N-324).

[0042] Dissolve 0.067 mol of pyrazine and 0.033 mol of pyruvic acid in dichloromethane and dilute to 100 mL, take 100 mL of saturated ammonium persulfate solution, add the above solution into the cathode chamber, and then add 5 g of dimethyl sulfoxide. The substance molar ratio of the pyrazine and pyruvic acid is 2:1, and the concentration of the pyruvic acid dissolved in methylene chloride is 0.33mol L -1 , the concentration of oxidant ammonium persulfate dissolved in water is 1.5mol L -1 , the quality of the dimethyl sulfoxide is 2% of the total mass of the pyrazine / pyruvate solution and the ammonium persulfate solution in the cathode chamber.

[0043] Add 200mL of sulfuric acid solution with a mass fraction of 20% in t...

Embodiment 2

[0045] The H-type electrolytic cell is used as the reactor, the anode is plated with ruthenium-titanium plate, the cathode is lead plate, and the anode chamber and the cathode chamber are separated by cation exchange membrane Nafion PFSA Membranes (N-324).

[0046] Dissolve 0.033 mol of pyrazine and 0.033 mol of pyruvic acid in dichloromethane and set the volume to 100 mL, take 100 mL of saturated ammonium overflow acid solution, add the above solution into the cathode chamber, and then add 5 g of dimethyl sulfoxide.

[0047] The molar ratio of the pyrazine and pyruvic acid substance is 1:1, and the concentration of the pyruvic acid dissolved in methylene chloride is 0.33mol L -1 , the concentration of oxidant ammonium persulfate dissolved in water is 1.5mol L -1 , the quality of the dimethyl sulfoxide is 2% of the total mass of the pyrazine / pyruvate solution and the ammonium persulfate solution in the cathode chamber;

[0048] Add 200mL of sulfuric acid solution with a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com