Preparation method of manganese phosphate and manganese phosphate product

A manganese phosphate and manganese source technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of complex composition, high price, high production cost, etc., and achieve high product purity, uniform particle size distribution, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

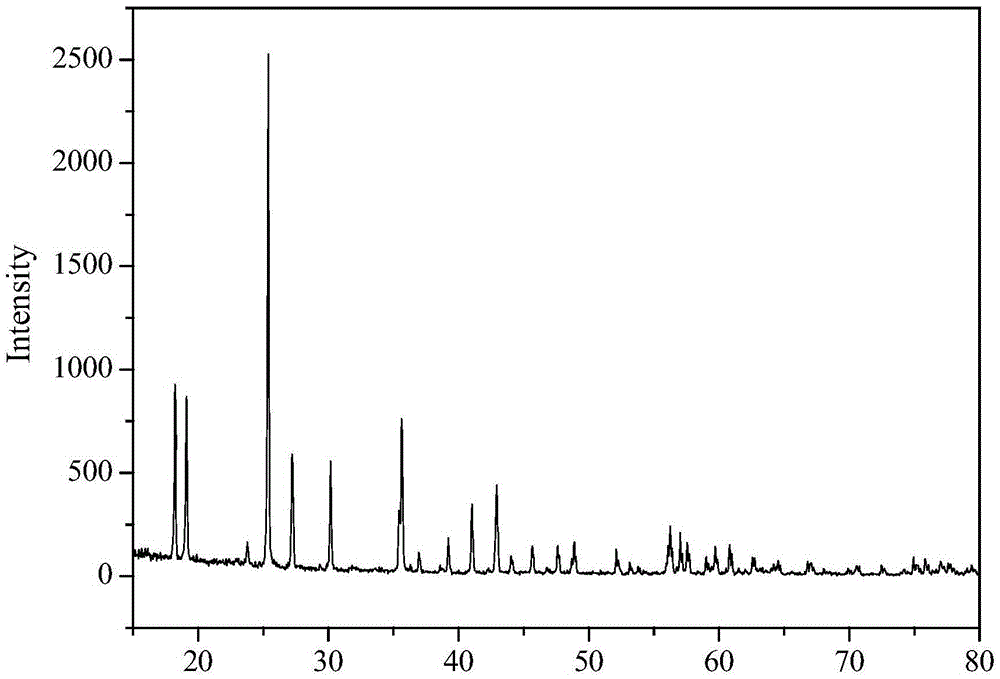

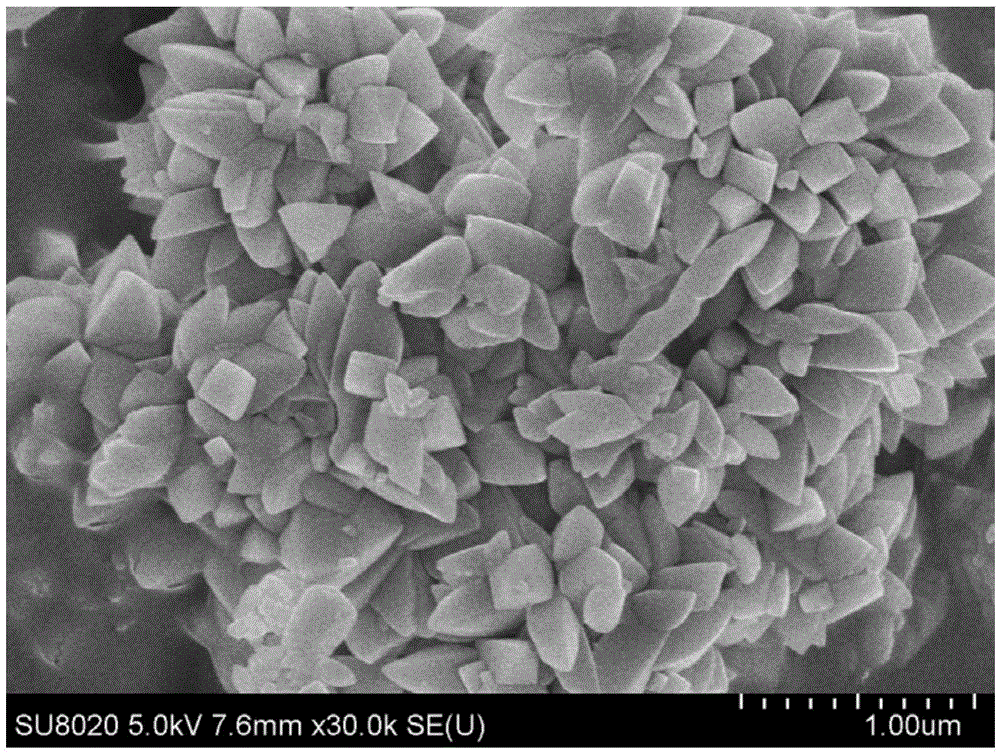

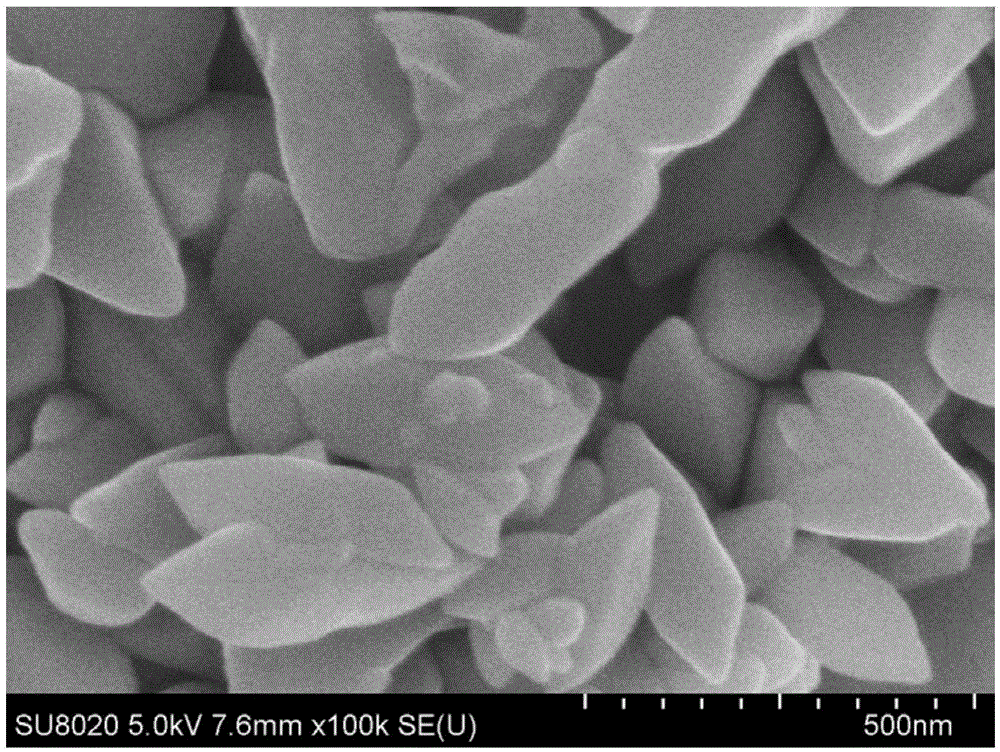

[0026] In the acid-resistant reaction kettle, a manganese sulfate monohydrate solution with a concentration of 0.5 mol / L is configured, a phosphoric acid solution with a concentration of 1 mol / L is added to the reaction kettle, and hydrogen peroxide with a concentration of 0.5 mol / L is then added to the reaction kettle, Wherein the weight ratio of deionized water, manganese source, phosphorus source, organic solvent is 100: 8.45 : 9.80 : 100 , adding nitric acid to adjust the pH value of the solution to be 2.0, the reaction temperature is 60 ° C, the stirring speed is 200r / min, and finally the concentration is 0.5mol / L ethanol solution added to the system, reacted for 5 hours, washed with water, filtered and dried to obtain manganese phosphate ( MnPO 4 ·H 2 O) Products.

Embodiment 2

[0028] In the acid-resistant reaction kettle, a manganese nitrate solution with a concentration of 0.5 mol / L was prepared, a phosphoric acid solution with a concentration of 0.75 mol / L was added to the reaction kettle, and hydrogen peroxide with a concentration of 0.5 mol / L was added to the reaction kettle. , wherein the weight ratio of deionized water, manganese source, phosphorus source, organic solvent is 100: 12.50 : 7.35 : 50 , add sodium hydroxide to adjust the pH value of the solution to 3.0, the reaction temperature is 80 ° C, the stirring speed is 200 r / min, and finally add a concentration of 0.5 mol / L ethylene glycol solution to the system, react for 3 hours, wash with water, filter, and dry, Obtain manganese phosphate (MnPO 4 ·H 2 O) Products.

Embodiment 3

[0030] In the acid-resistant reaction kettle, a manganese sulfate monohydrate solution with a concentration of 0.5 mol / L is configured, a sodium phosphate solution with a concentration of 0.5 mol / L is added to the reaction kettle, and then a sodium phosphate solution with a concentration of 0.5 mol / L is added into the reaction kettle Sodium nitrate, wherein the weight ratio of deionized water, manganese source, phosphorus source, organic solvent is 100: 8.45 : 19.01 : 200 , add sodium hydroxide to adjust the pH value of the solution to 5.0, the reaction temperature is 30 ° C, the stirring speed is 200 r / min, and finally acetone solution with a concentration of 0.5 mol / L is added to the system, react for 2 hours, wash with water, filter, and dry to obtain phosphoric acid Manganese (MnPO 4 ·H 2 O) Products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com