Preparation method of aerated brick with high calcium-silicon ratio and aerated brick with high calcium-silicon ratio prepared by preparation method

An air-entrained brick and high-calcium technology, which is applied in the field of building materials, can solve the problems affecting the compressive strength of aerated bricks and the adverse effects of the compressive strength of air-entrained bricks, so as to improve the sound insulation performance and thermal insulation performance, reduce the Particle size, the effect of accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

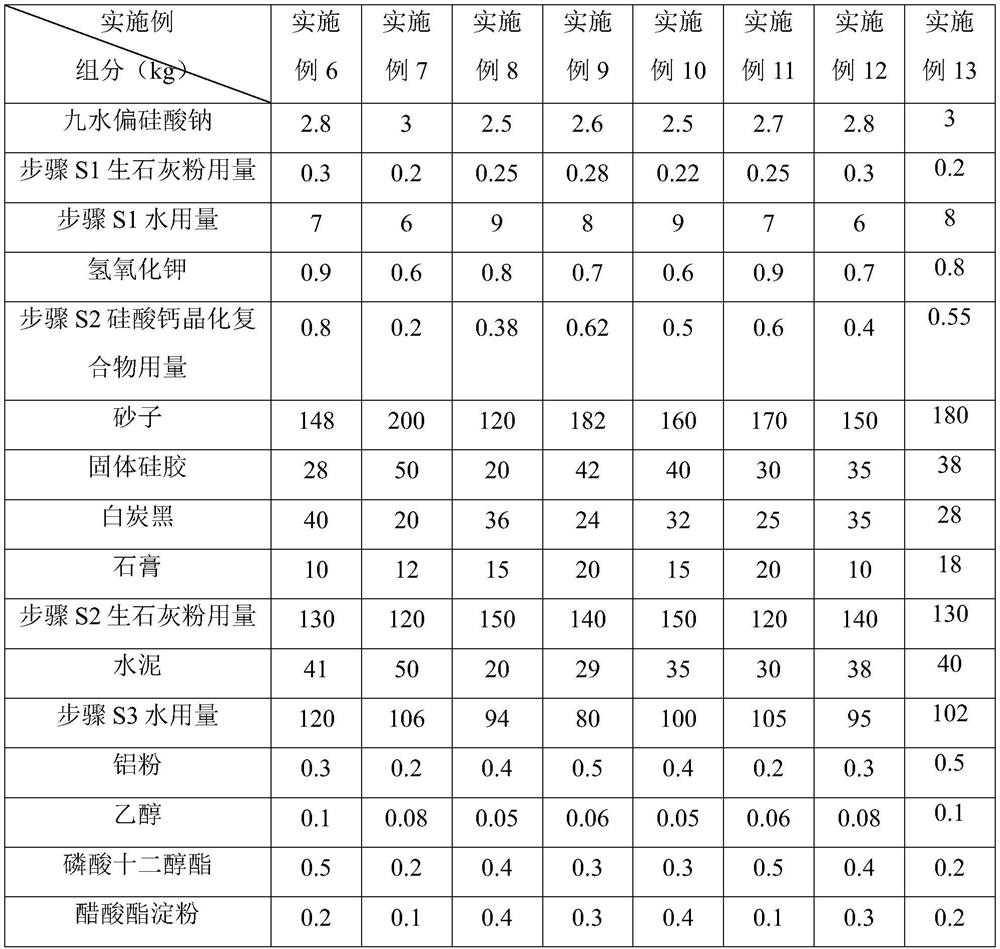

Examples

Embodiment 1

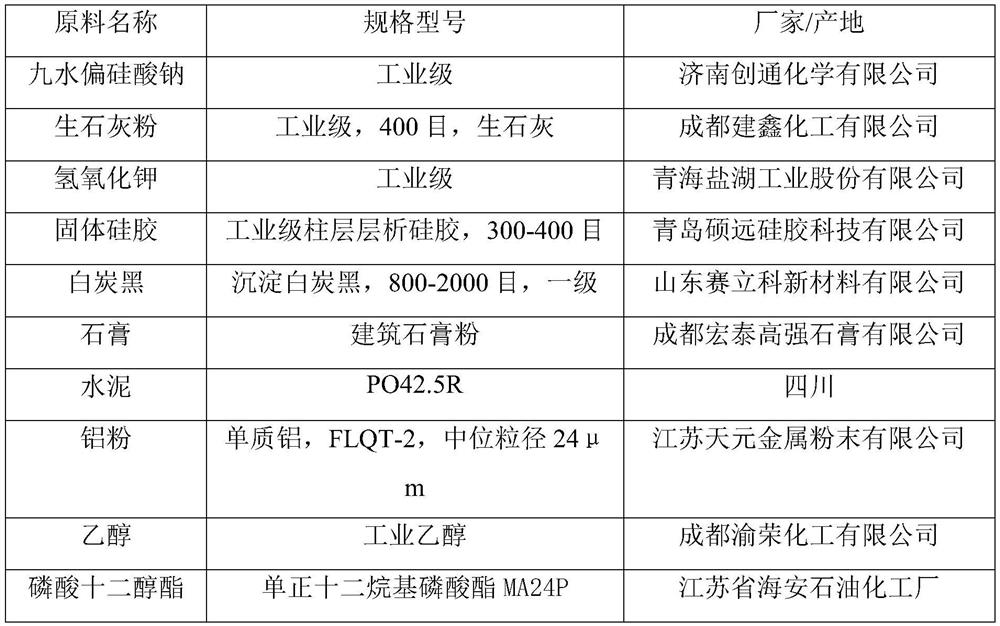

[0041] Embodiment 1: a kind of preparation method of high calcium silicon ratio aerated brick, comprises the following steps:

[0042] S1 pre-crystallization: Weigh 7.5kg of water, add 2.8kg of sodium silicate, 0.25kg of quicklime powder, 0.8kg of potassium hydroxide and 0.05-0.1kg of ethanol, mix well, transfer to a 15L high-pressure reactor, seal it, and Stir at a speed of rpm, heat to 170°C to crystallize for 5 hours, cool down to room temperature, discharge the material, filter with suction, rinse the filter cake with 10Kg water, transfer the filter cake to a drying oven, and dry at 80°C for 180 minutes to obtain a dry material , the dry material is pulverized with a pulverizer, sieved with a sieve with a pore size of 20 μm, and the particles with a particle size greater than 20 μm are continuously pulverized until the particle size is not greater than 20 μm, and a calcium silicate crystallization compound is obtained.

[0043] S2 Mixing: Screen the sand with a sieve with ...

Embodiment 2

[0048] The difference between Example 2 and Example 1 is that no ethanol is added in Step S1 of Example 2, and the others are consistent with Example 1.

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is that embodiment 3 does not add lauryl phosphate, and the others are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com