Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Avoid insoluble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of water dispersed fine emulsion of fluorine acrelate copolymer for anti-oil and anti-water agent

Aqueous dispersible fine emulsion of complete acrylic ester copolymer as oil- and water-resisting agent is prepared by: preparing complete alkyl copolymerized monomer fine emulsion dispersed uniformly, and then polymerizing without organic solvent and emulsifying to aid it. It is stable for restore or dilution, and can be used for substrate materials of fabrics, leathers or paper as waterproof and oil-proof finishing agent.

Owner:ZHEJIANG UNIV

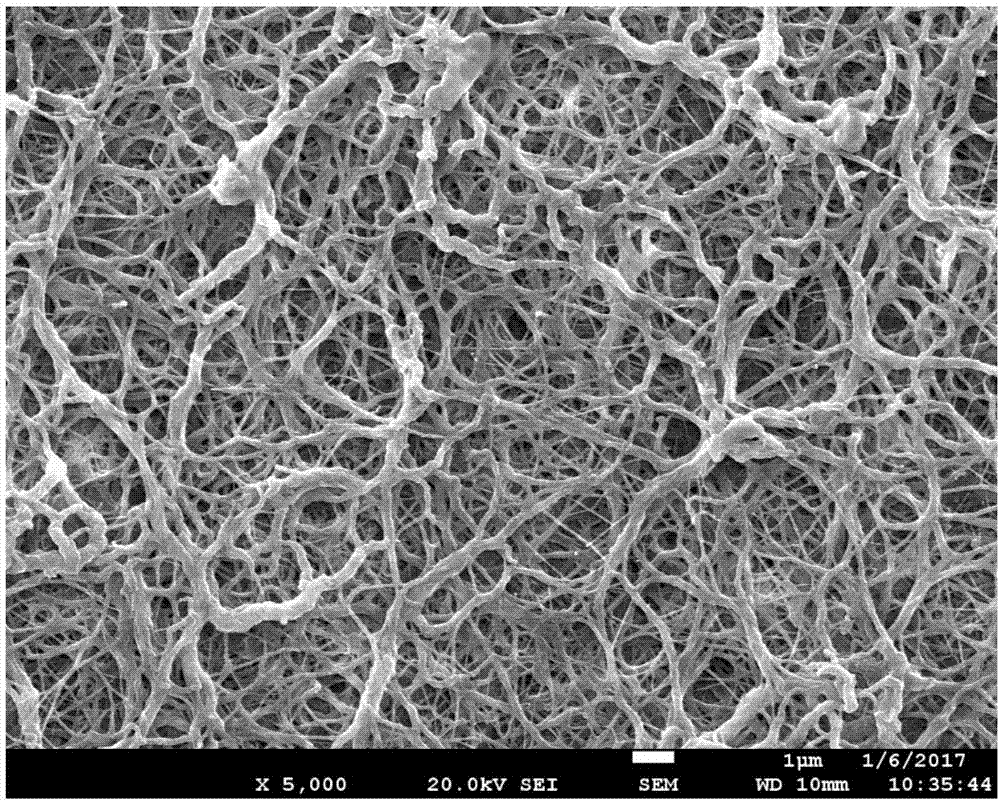

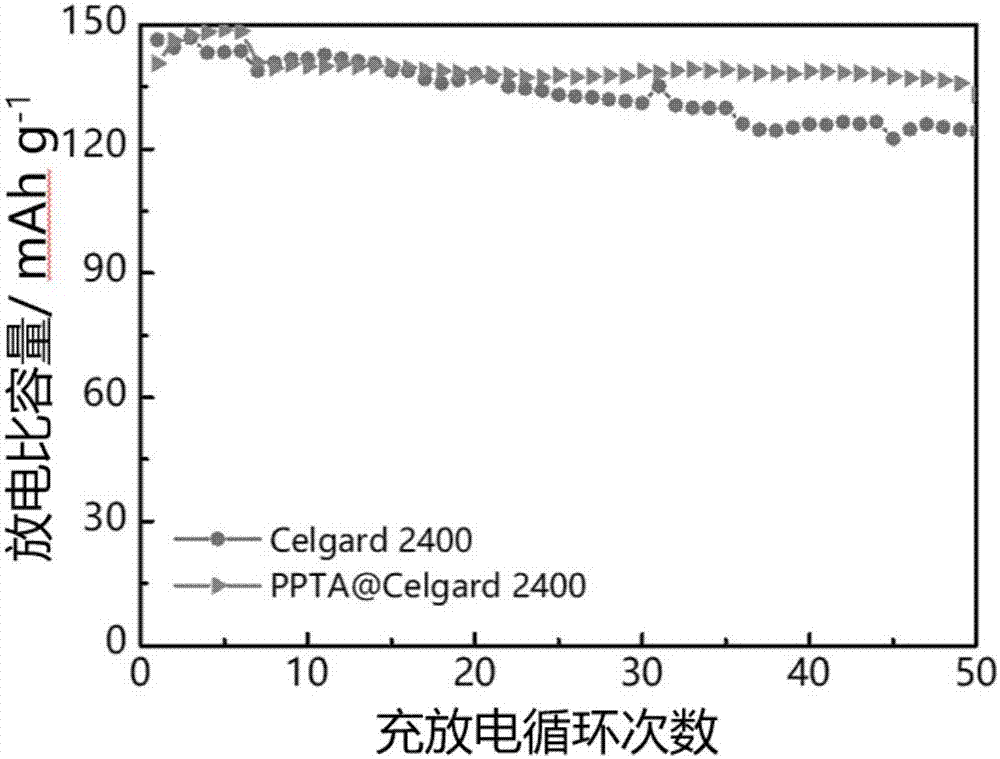

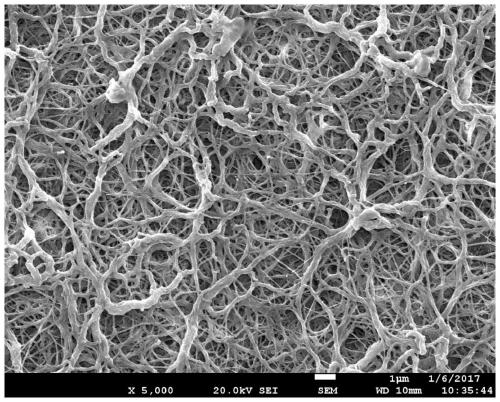

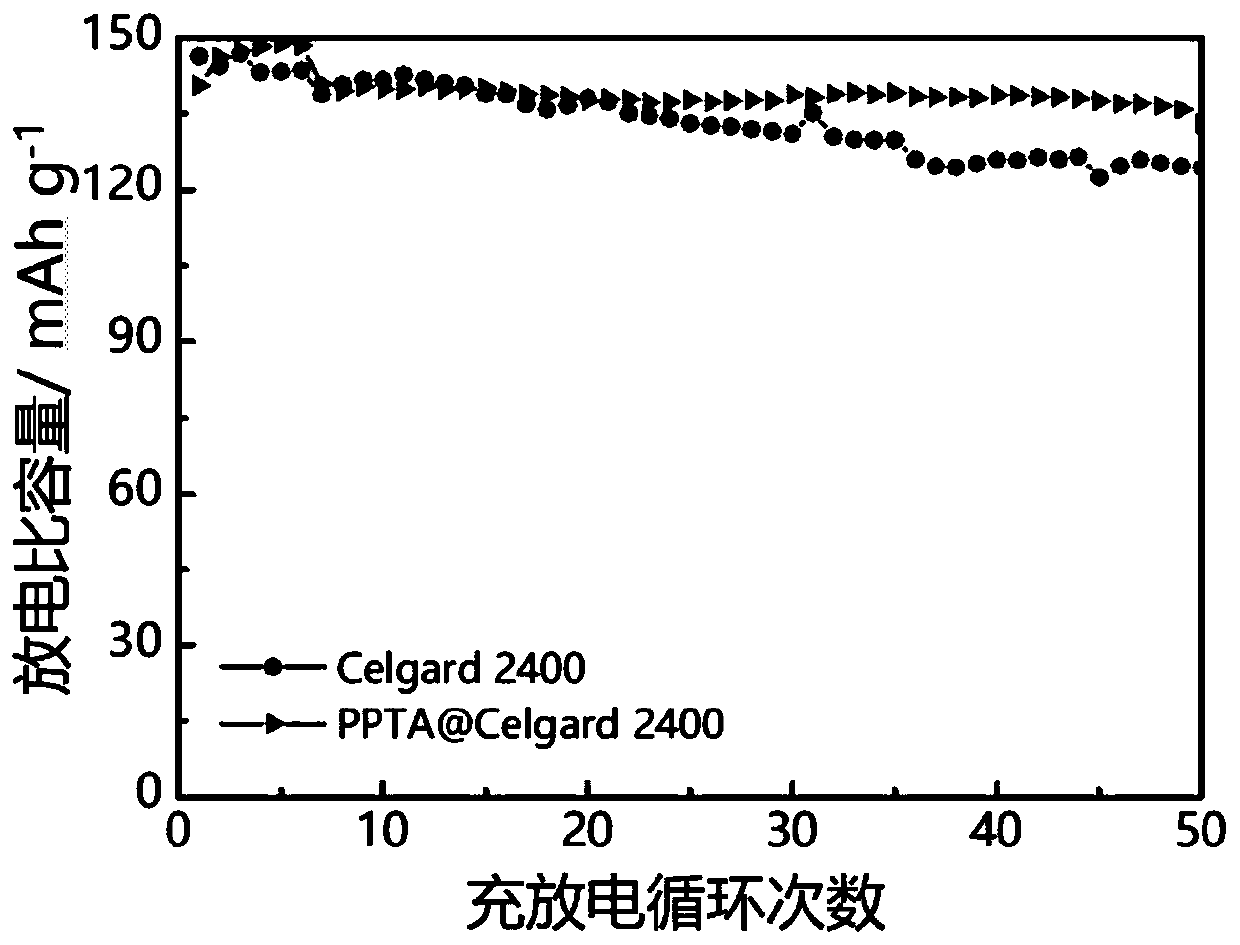

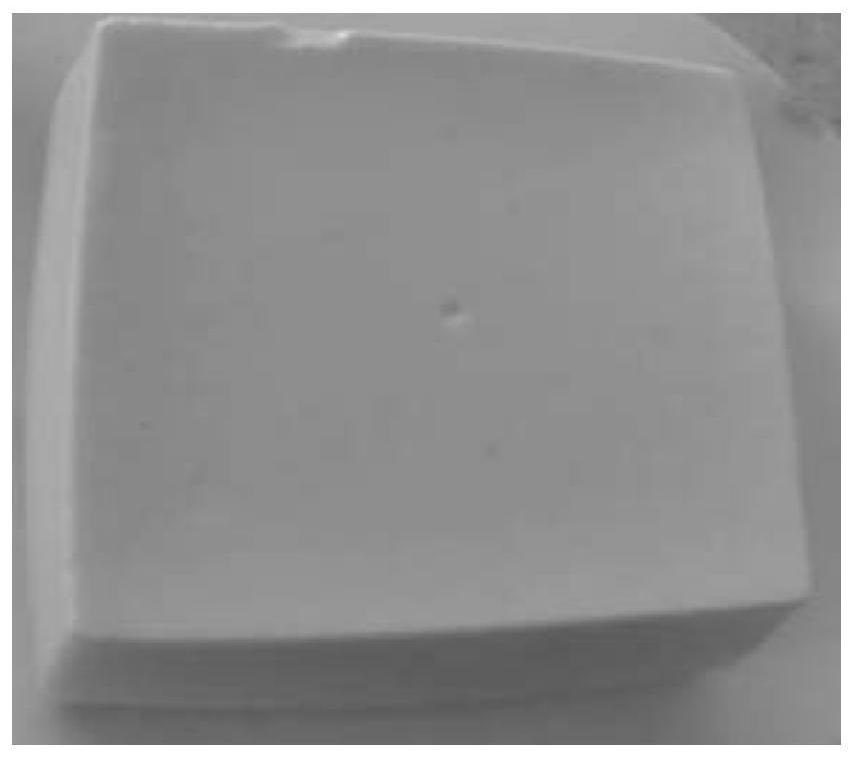

Preparation method of para-aramid nanometer fiber composite lithium ion battery separator

The invention relates to a preparation method of a para-aramid nanometer fiber composite lithium ion battery separator, and belongs to the technical field of a high polymer material. The preparation method comprises the steps of preparing para-aramid polymer paste, coating the para-aramid polymer paste on a surface of a base membrane by a coating method, and solidifying the coating film in coagulation bath comprising N-methly-2-pyrrolidone and water to obtain the para-aramid nanometer fiber composite lithium ion battery separator; and washing and drying the para-aramid nanometer fiber composite lithium ion battery separator to obtain a finished product of the para-aramid nanometer fiber composite lithium ion battery separator. Compared with the prior art, the preparation method has the advantages that a solvent and an energy source are saved, energy consumption is also reduced, and unfavorable influence of impurity on battery performance is prevented; and moreover, the preparation process is simple, and the high-temperature resistant performance of the separator is improved, the prepared separator has favorable ion conductivity and can obtain relatively good performance when used as the lithium ion battery separator.

Owner:TSINGHUA UNIV

Method for recycling platinum group metal from ineffective automobile catalysts

ActiveCN106011477AHigh reactivityFully dispersedProcess efficiency improvementWater immersionBiological activation

The invention discloses a method for recycling platinum group metal from ineffective automobile catalysts. The method includes the steps of (1) mechanical activation, (2) high-temperature roasting, (3) ball-milling water immersion, (4) diluted acid leaching and (5) platinum group metal refining. Platinum group metal enriched products obtained in the step (4) are processed according to existing refining processes, so that platinum group metal products are obtained. The ineffective automobile catalysts are processed through the method of combining mechanical activation, sodium salt roasting, water immersion and acid leaching, the reaction activity of materials is improved through mechanical activation, phase transformation of catalyst carrier components occurs due to sodium salt roasting, insoluble residues are enriched with the platinum group metal after water immersion and acid leaching, and separation between carriers and the platinum group metal is achieved. Equipment needed for the method is conventional metallurgical equipment, the technological process is simple, industrial implementation is easy, and the total recovery rate of the platinum group metal is larger than 98%.

Owner:KUNMING INST OF PRECIOUS METALS

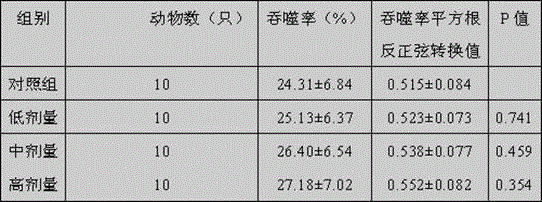

Production method of oligose and beverage containing same

The invention refers to a method of producing oligose by wheat bran and the drink with the oligose. The method includes: dry the wheat bran and then crust; add in deionized water to drip; make homogeneous process; adds in the compound enzyme preparation including phytase, fibrin enzyme, protease and oligosaccharidase to make enzymolysis and adjust pH; making sterilization; centrifuge and filter to get the clear liquid with oligose; make vacu9um concentration on the clear liquid to get the concentrated mixture with dissoluble oligose soild. The components' dosage in the compound enzyme preparation: phytase 10-30 U / g bran, fibrin enuzyme 10-20 U / g bran, protease 30-40 U / g bran and oligosaccharidase 20-30U / g bran.

Owner:李全宏

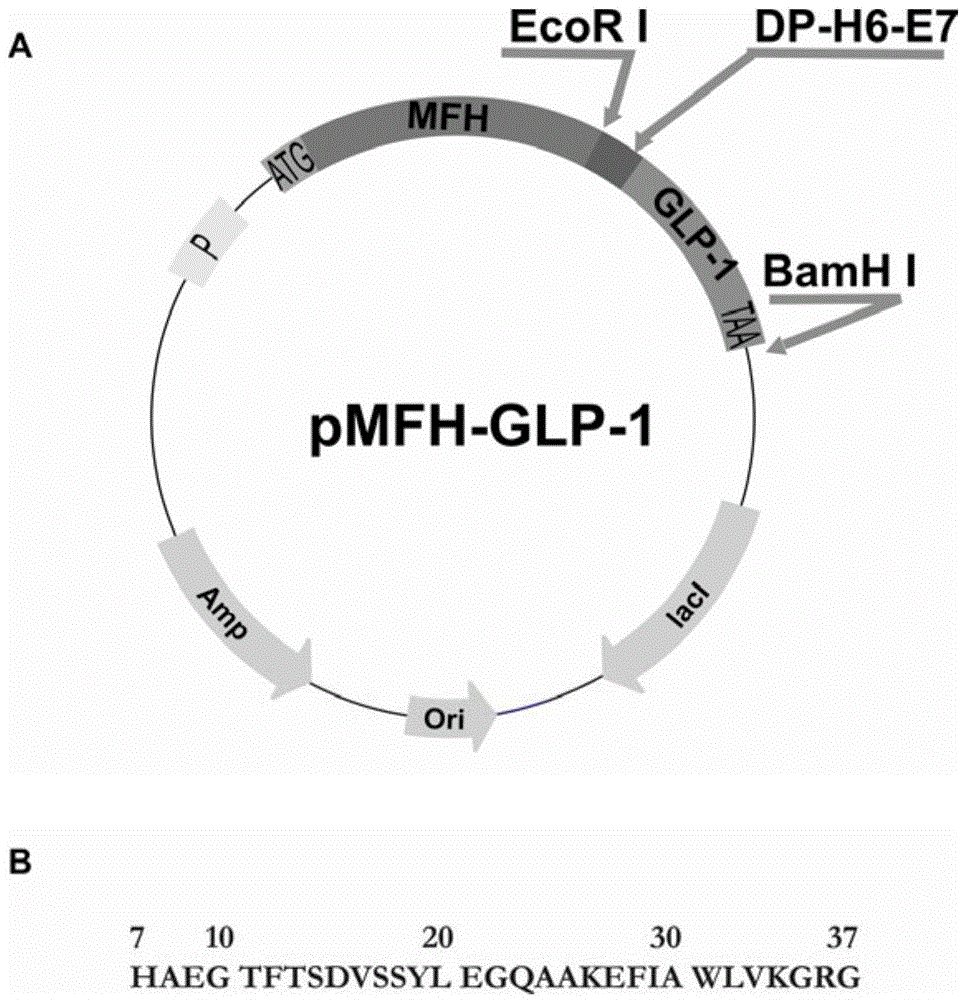

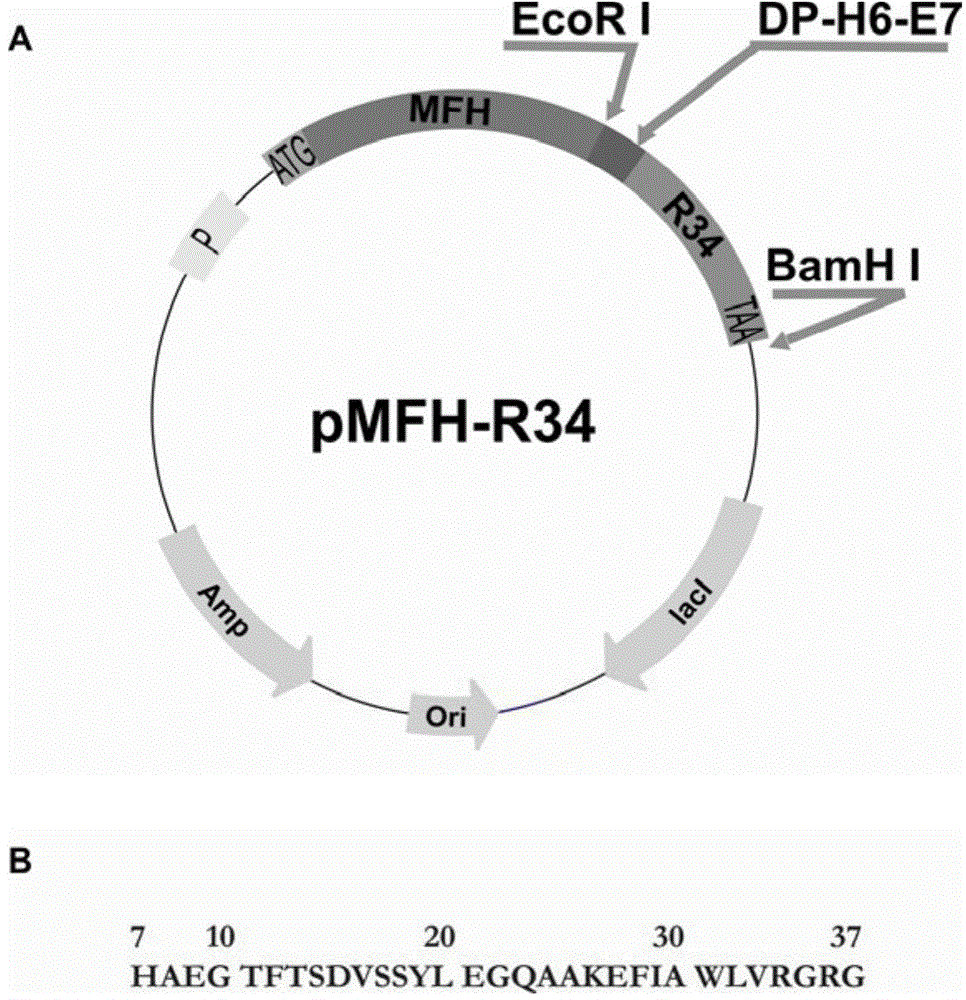

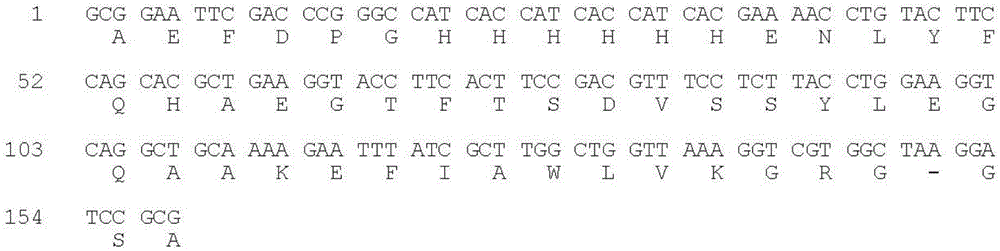

Method for preparation of GLP-1 polypeptide or analogue thereof through MFH fusion protein and application of GLP-1 polypeptide or analogue thereof

ActiveCN104098702AAvoid insolubleAvoid the disadvantages of multiple impuritiesPeptide/protein ingredientsMetabolism disorderEscherichia coliStructural formula

The invention discloses a method for preparation of GLP-1 polypeptide or an analogue thereof through MFH fusion protein and application of the GLP-1 polypeptide or the analogue thereof, and belongs to the field of biotechnology. The structural formula of the MFH fusion protein of the GLP-1 polypeptide or the analogue thereof is MFH-DP-H6-E7-PEP, wherein the MFH is a protein fusion vector, DP is a formic acid hydrolysis site, H6 is a histidine label, E7 is a special protease cutting site and PEP is the GLP-1 polypeptide or the analogue thereof. The DNA of the code DP-H6-E7-PEP is connected to pMFH plasmid to obtain pMFH-PEP plasmid and then the pMFH-PEP plasmid is transferred into escherichia coli, MFH-DP-H6-E7-PEP fusion protein is obtained through prokaryotic expression, and formic acid hydrolysis, special protease hydrolysis and affinity chromatography are performed, so that GLP-1 polypeptide or the analogue thereof is obtained. According to the invention, the purposes of large-scale efficient expression of polypeptide, less steps of a peptide release process, mild condition and low production cost are achieved, and the GLP-1 polypeptide or the analogue thereof is suitable for industrial production.

Owner:HUBEI UNIV OF TECH

Process for synthesizing duloxetine hydrochloride

InactiveCN102070602AOvercoming low optical purityInhibit side effectsOrganic chemistryButanoneHydrochloride

The invention belongs to the field of medicine synthesis, relates to a process for synthesizing duloxetine hydrochloride, and solves the technical problem to provide a new process for synthesizing the duloxetine hydrochloride, which makes raw materials dissolved completely and reduced thoroughly. The synthetic process comprises the following steps of: 1, preparing 2-thienyl-2-dimethylaminomethyl butanone hydrochloride; 2, preparing N,N-dimethyl-3-hydroxy-3-(2-thienyl)propanamine; 3, preparing (S)-N,N-dimethyl-3-hydroxy-3-(2-thienyl)propanamine; 4, preparing (S)-N,N-dimethyl-3-(1-naphthalenyloxy)-3-(2-thienyl)propanamine; 5, preparing (S)-N-methyl-3-(1-naphthalenyloxy)-3-(2-thienyl)propanamine; and 6, preparing (S)-N-methyl-3-(1-naphthalenyloxy)-3-(2-thienyl)propanamine hydrochloride. By the six steps of the process, the total synthetic yield is 24.1 percent.

Owner:王念军

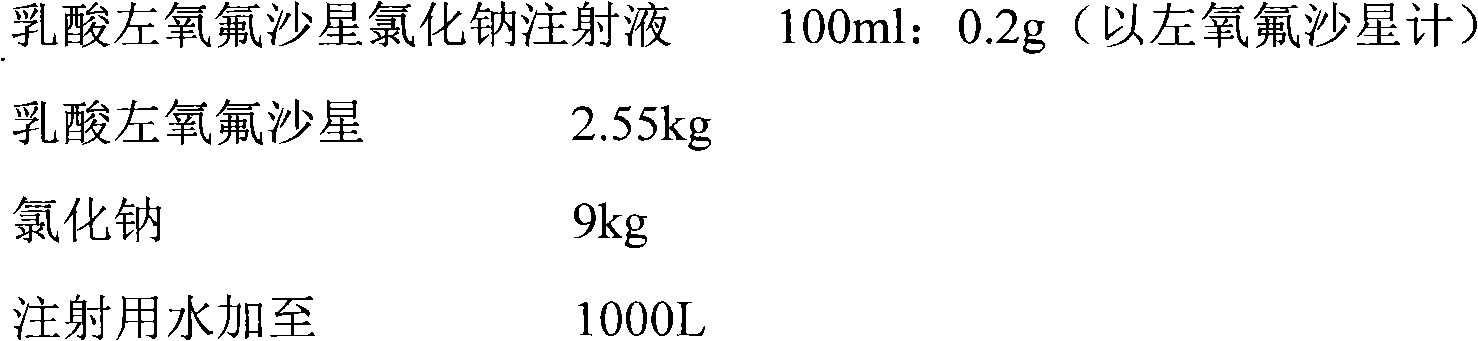

Preparation method of levofloxacin lactate and sodium chloride injection

InactiveCN102319203AImprove solubilityGuaranteed stabilityAntibacterial agentsOrganic active ingredientsSodium Chloride InjectionLevofloxacin

The invention relates to a preparation method of a levofloxacin lactate and sodium chloride injection, and the method comprises the steps such as dense preparing, heating, filtering, diluted preparing, pH value regulating, filtering, filling, sealing, sterilizing, inspecting and the like. The levofloxacin lactate and sodium chloride injection prepared by the preparation method has good stability, and can completely be packaged by adopting a plastic bottle.

Owner:ANHUI GLOBAL PHARM CO LTD

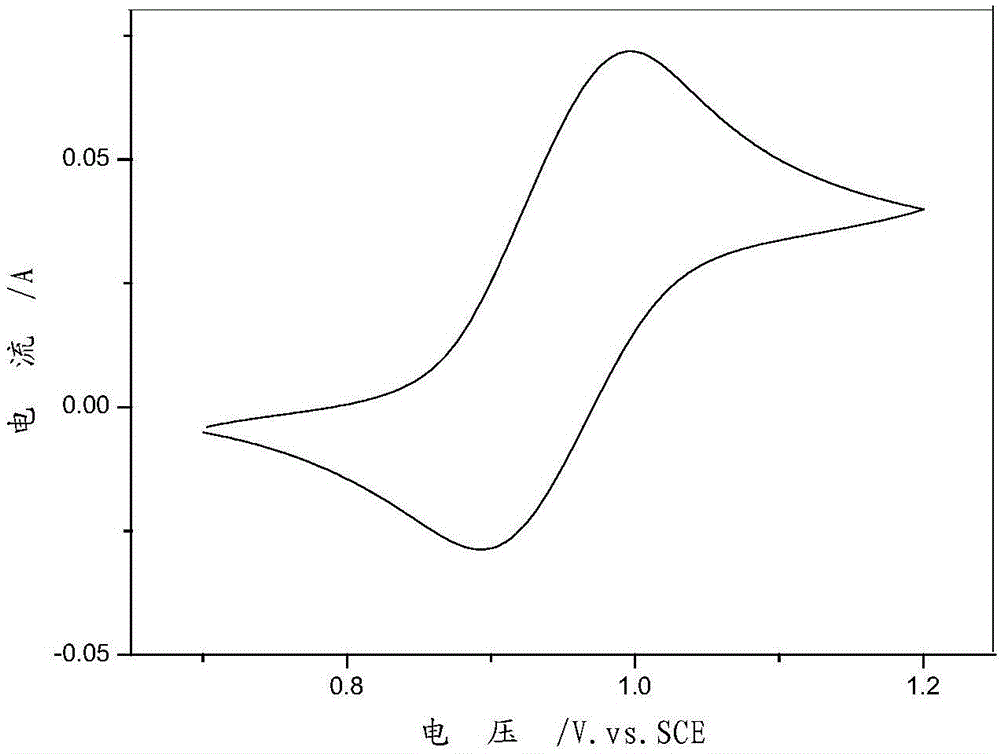

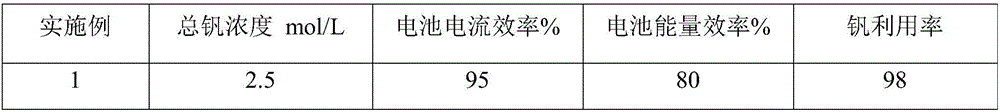

Method for directly preparing electrolyte for vanadium cell by using vanadium pentoxide

ActiveCN104577173AIncrease concentrationImprove dispersionRegenerative fuel cellsElectrolytesVanadium(V) oxideSulfuric acid

The invention relates to the preparation field of electrolytes, and in particular relates to a method for directly preparing an electrolyte for a vanadium cell by using vanadium pentoxide. The invention provides a method for directly preparing the electrolyte for the vanadium cell by using vanadium pentoxide, the method comprises the following steps: a. preparing a vanadium pentoxide solution by using a wet method, namely firstly adding water in the vanadium pentoxide, adding sulfuric acid under stirring to dissolve vanadium pentoxide to form a vanadium pentoxide-sulfuric acid solution, wherein the proportion of vanadium pentoxide to water is (0.886-2)g / ml to 1g / ml, the mass concentration of sulfuric acid in the obtained solution is 0.736g / ml-0.92g / ml; b. electrolyzing, namely by using the vanadium pentoxide-sulfuric acid solution obtained in the step a as a catholyte solution, and using sulfuric acid with volume concentration of 0.613g / ml-0.736g / ml as an anodolyte solution, electrolyzing. The method provided by the invention is free from additives, the concentration of the electrolyte is 2.5-5mol / L, and the cell current efficiency is greater than 90%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Environment-friendly dust suppressant and preparation method thereof

The invention discloses an environment-friendly dust suppressant and a preparation method thereof. The environment-friendly dust suppressant is prepared from the following raw materials in parts by weight: 8 to 12 parts of modified starch, 10 to 15 parts of carboxymethyl cellulose, 5 parts of xanthan gum, 5 parts of guar gum, 15 to 20 parts of potassium sulfate, 15 to 20 parts of sodium sulfate, 8to 12 parts of magnesium sulfate, 2 to 5 parts of hydroxypropyl methyl cellulose and 0.5 to 1 part of a surfactant. The prepared dust suppressant is wide in raw material source and simple in preparation process, can bond and solidify dust on the surface of bare soil, effectively inhibit the phenomenon of dust raising on the surface of bare soil, is naturally degradable, does not pollute the soil,contains various mineral elements which can be absorbed by the soil, and can increase the fertility and promote the growth of plants.

Owner:QINGDAO UNIV OF SCI & TECH +1

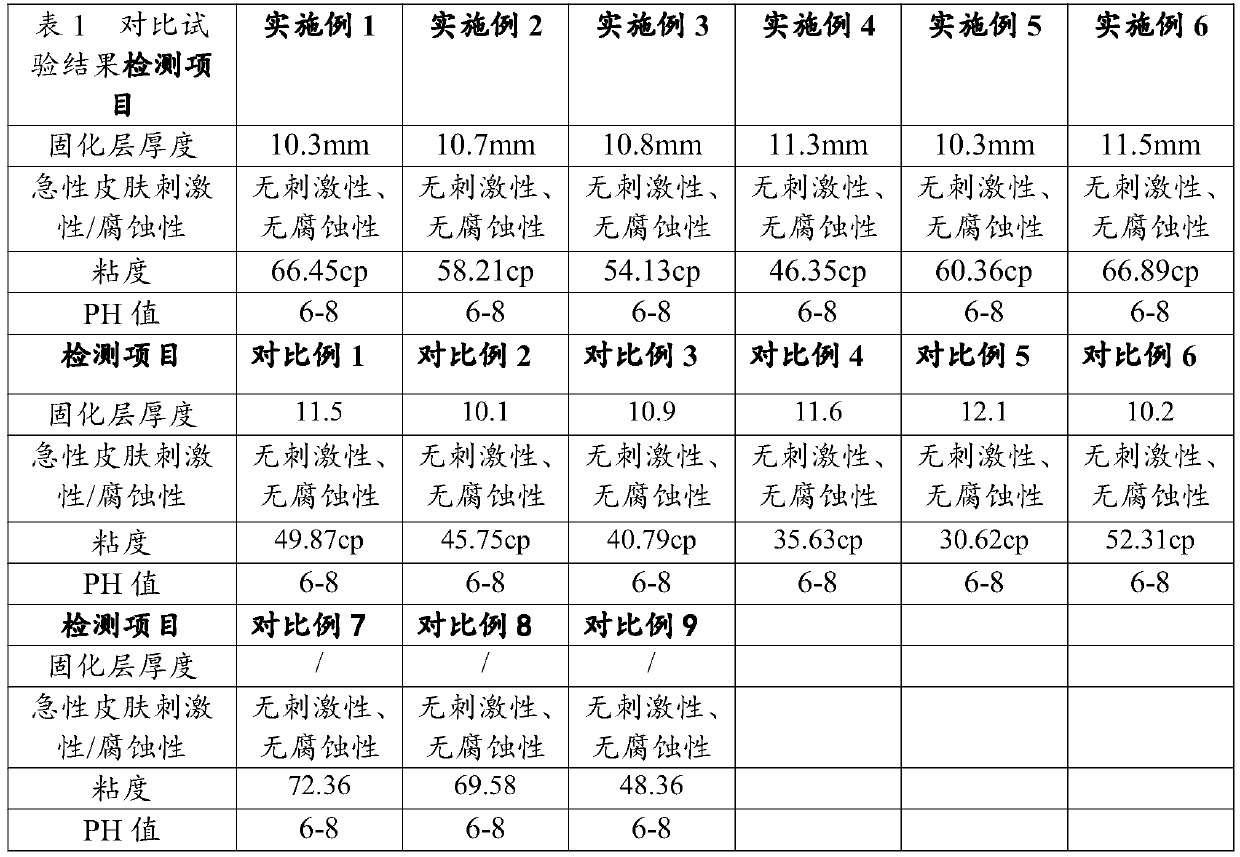

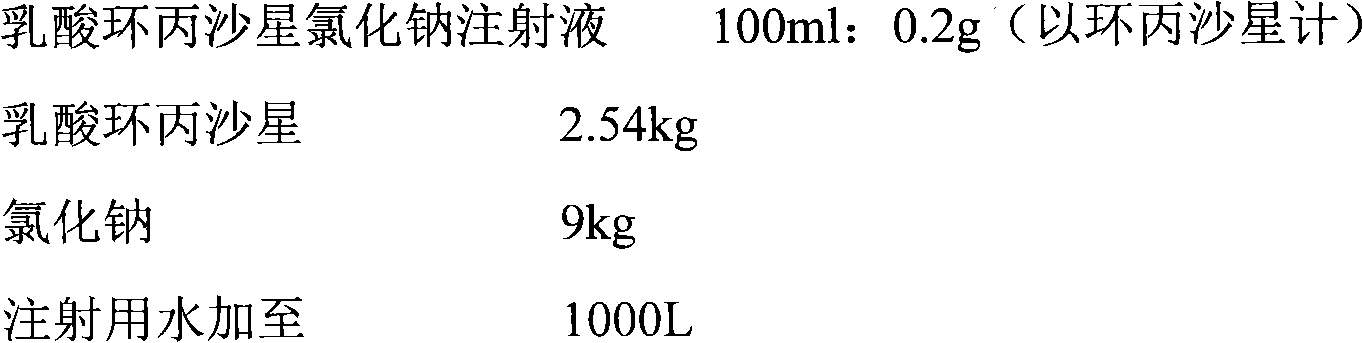

A kind of preparation method of ciprofloxacin lactate sodium chloride injection

InactiveCN102274169AImprove solubilityGuaranteed stabilityAntibacterial agentsOrganic active ingredientsCiprofloxacin lactateFiltration

The invention relates to a preparation method of ciprofloxacin lactate and sodium chloride injection, which comprises the steps of concentrated preparation, heating, filtration, dilution, adjustment of pH value, filtration, filling, sealing, sterilization, inspection and the like. The ciprofloxacin lactate sodium chloride injection prepared by the preparation method has good stability and can be packaged in plastic bottles.

Owner:ANHUI GLOBAL PHARM CO LTD

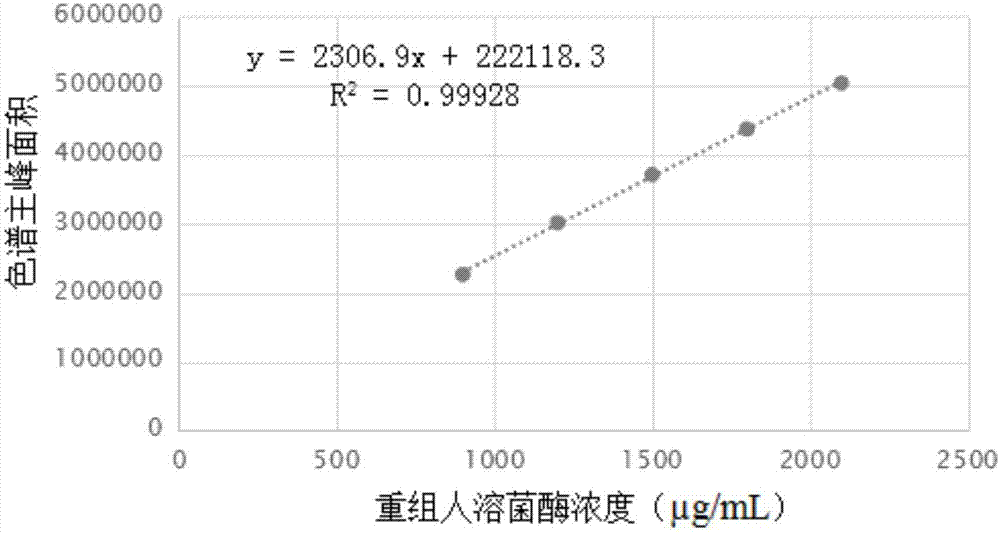

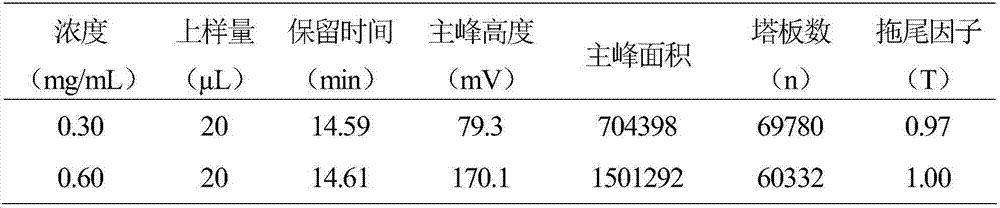

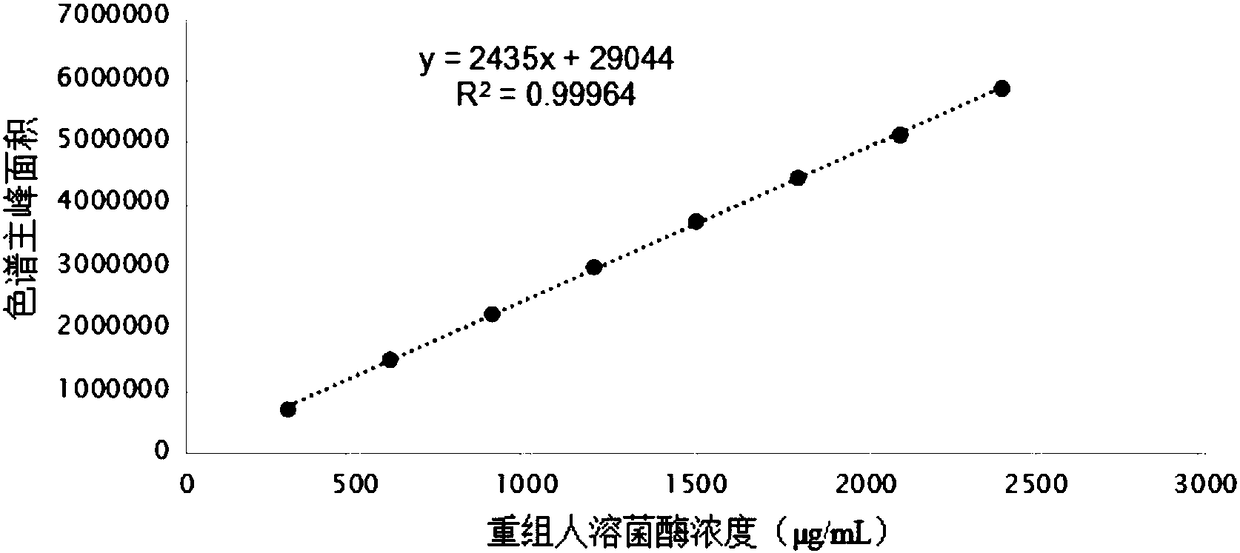

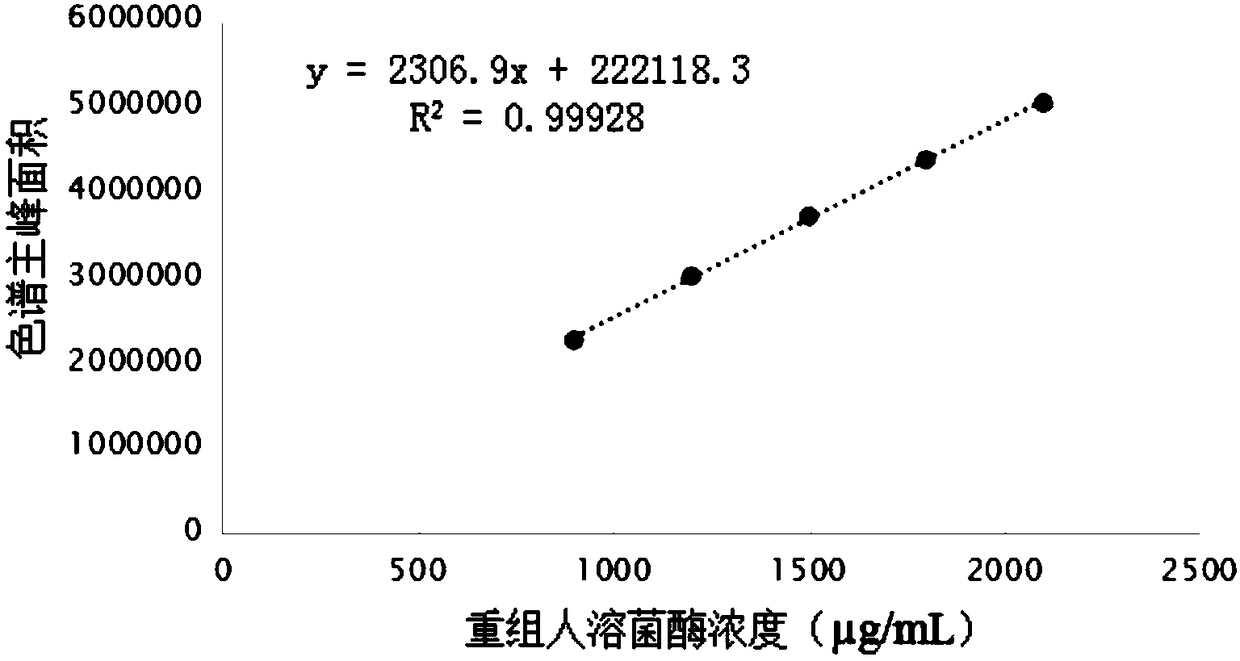

Reversed-phase high-performance liquid-phase chromatographic analysis method of recombinant human lysozyme

ActiveCN106872633AGuaranteed SolubilityGuaranteed number of pedalsComponent separationSolubilitySilica gel

The invention discloses a reversed-phase high-performance liquid-phase chromatographic analysis method of recombinant human lysozyme. The method adopts octadecyl silane bonded silica gel with an aperture of 20 to 50 nm and a particle size of 2 to 10 micrometers as a chromatographic column filler, so that not only can the macromolecular proteins such as the recombinant human lysozyme have a certain retention on the column, but also the excessively strong combination between the proteins and the filler can be prevented from leading to the incapability of elution; and the sodium chloride is added into a flow phase, so that the solubility of the recombinant human lysozyme in the reversed-phase high-performance liquid-phase chromatographic analysis process is ensured, the recombinant human lysozyme can be completely blended with the flow phase, a step number, symmetry, repetition and accuracy in quantitative analysis of the chromatographic peak are ensured, and the method is used for analyzing and quantitatively detecting the recombinant human lysozyme.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

Preparation method for waterproof protective perfluoro-acrylate copolymer aqueous dispersion miniemulsion for wood

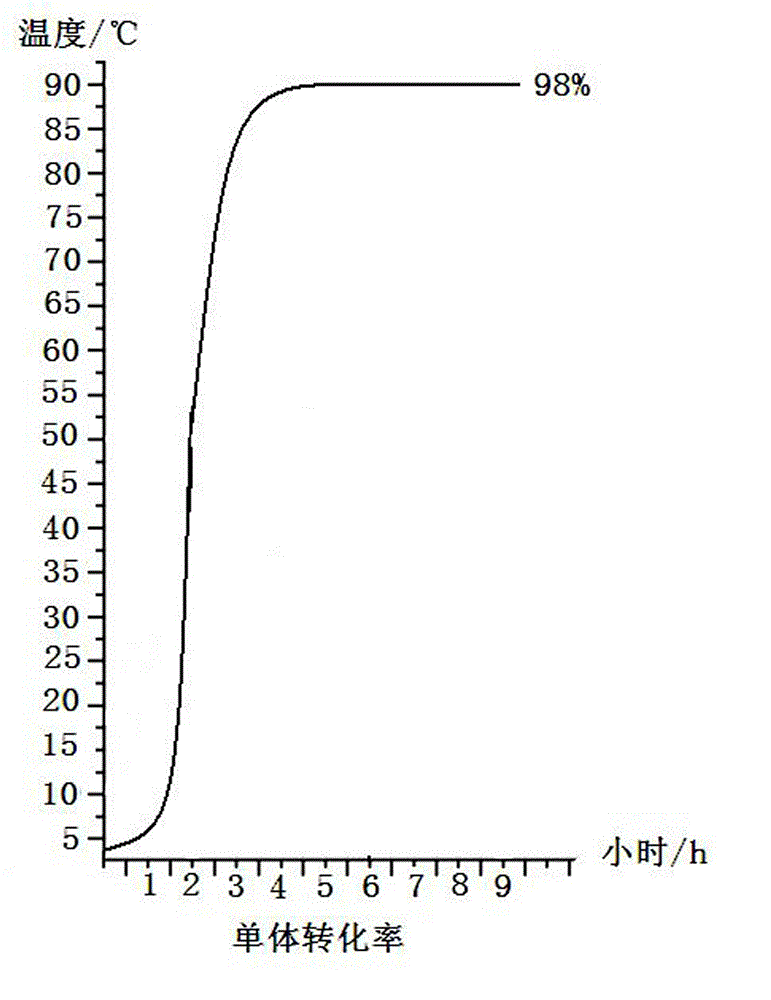

InactiveCN105294928AAvoid insolubleImprove waterproof performanceFibre treatmentCoatingsOrganic solventEmulsion

The invention discloses a preparation method for a waterproof protective perfluoro-acrylate copolymer aqueous dispersion miniemulsion for wood. The preparation method particularly comprises the following steps: mixing and stirring a comonomer mixture, an emulsifier and deionized water to obtain a pre-emulsion; performing ultrasonic treatment on the obtained pre-emulsion in an ultrasonic machine to obtain a stable monomer miniemulsion; placing the monomer miniemulsion subjected to fine emulsification treatment in a reaction still, separately adding a transfer agent and an initiating agent, heating to initiate polymerization, performing a reaction, insulating, cooling to the room temperature till a monomer conversion rate reaches 95.0% or above, and filtering to obtain the miniemulsion. The water and oil repellent (namely the waterproof protective perfluoro-acrylate copolymer aqueous dispersion miniemulsion) obtained according to the preparation method does not need an organic solvent, and is safe and environmentally friendly; the prepared miniemulsion is high in storage stability and dilution stability; a copolymer miniemulsion coating formed by the water and oil repellent is high in film-forming property, water resistance and oil resistance.

Owner:HARBIN SHENGSHI HUALIN TECH

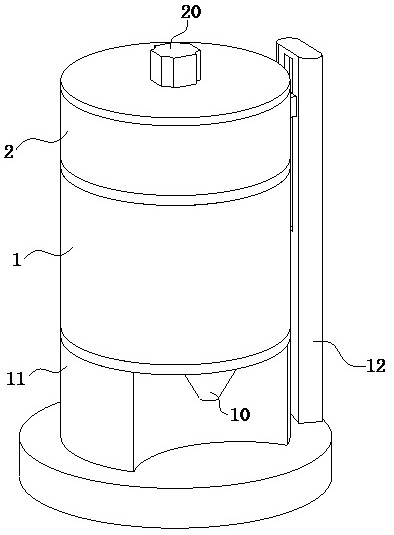

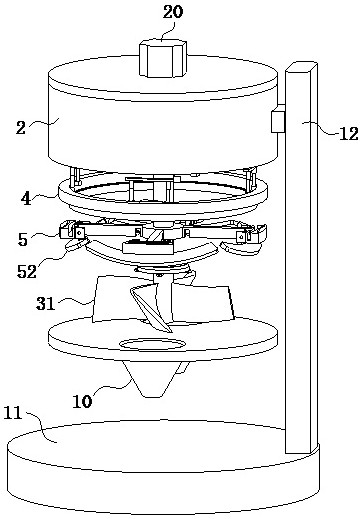

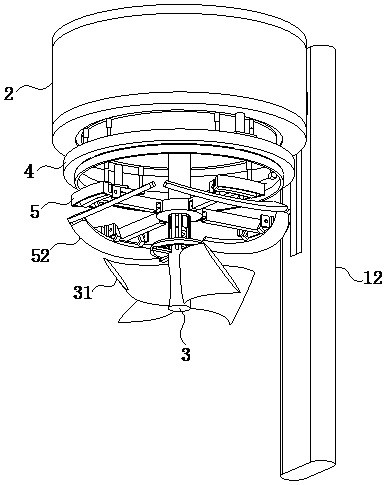

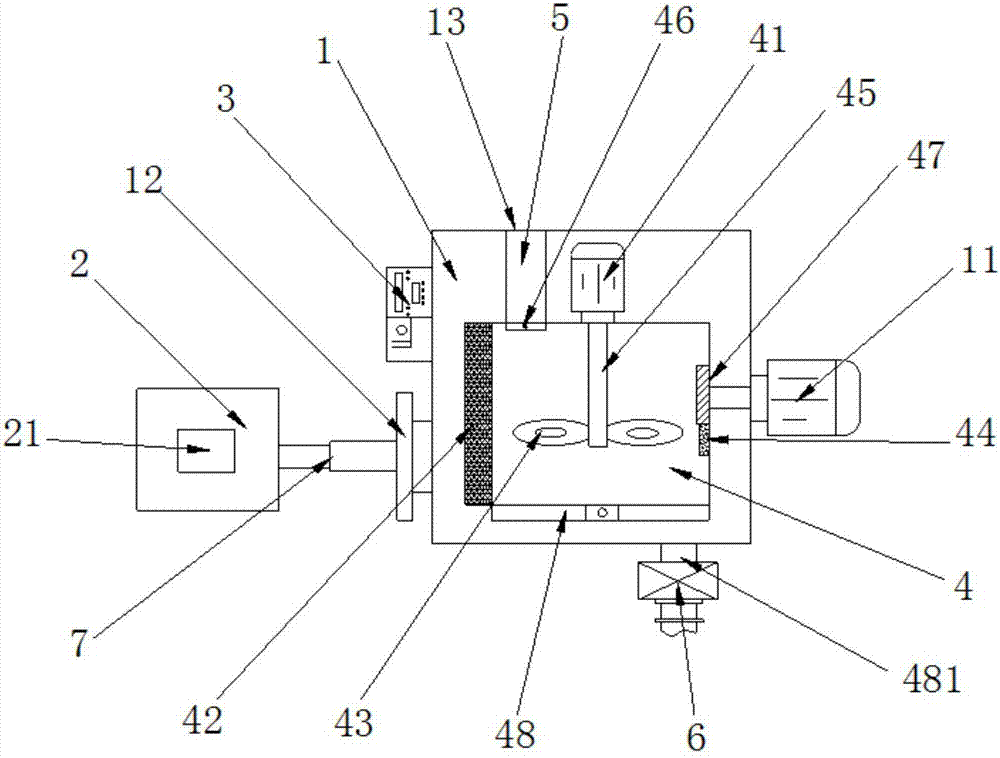

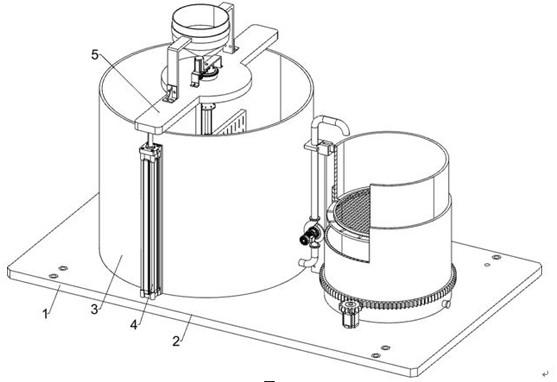

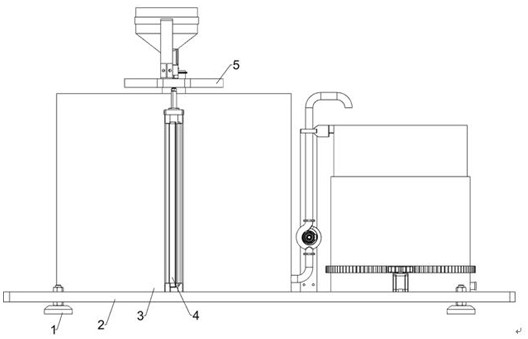

Rapid diluting and mixing device for agricultural chemicals

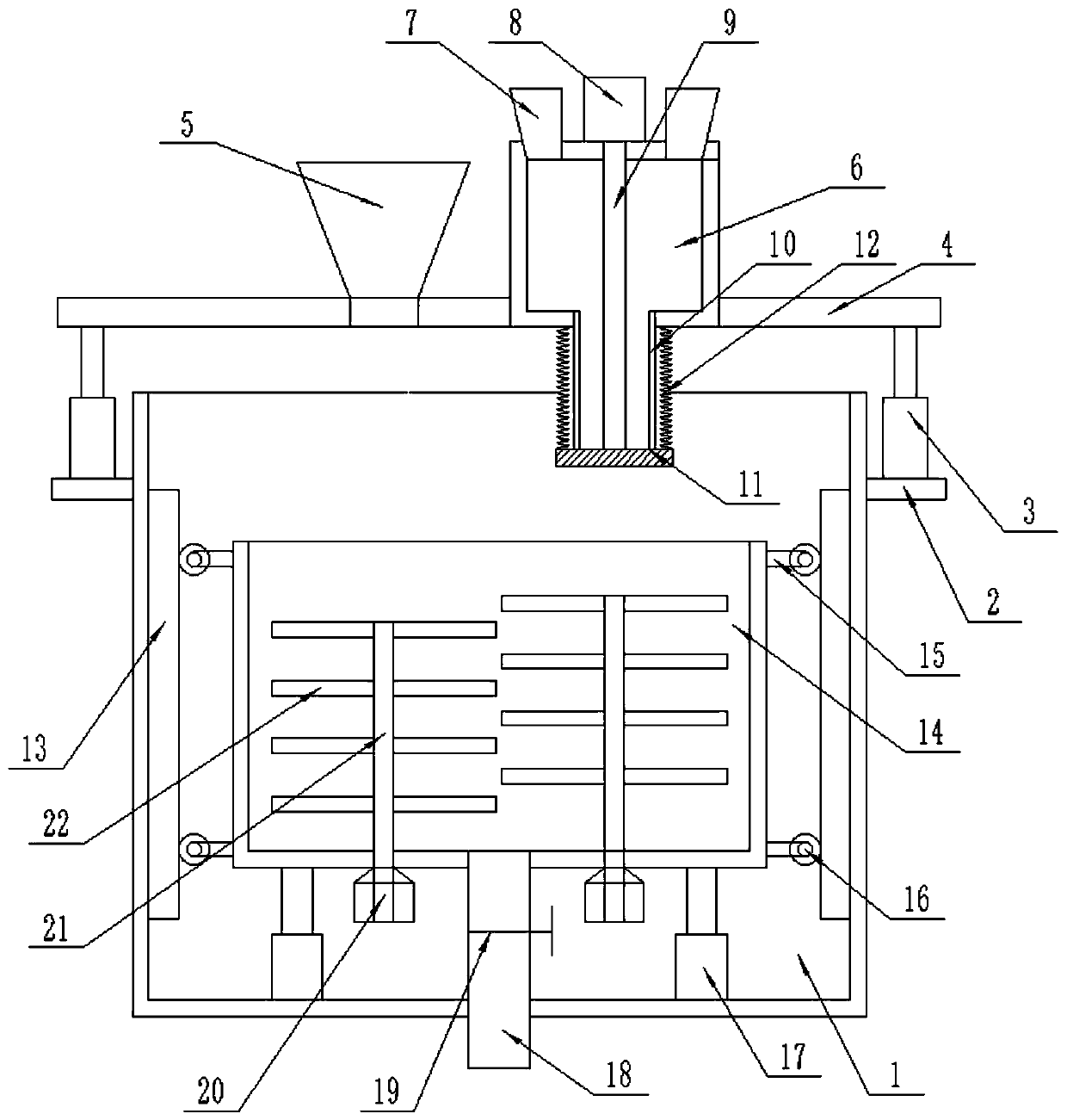

InactiveCN110038471AImprove the mixing effectSimple and reasonable structureShaking/oscillating/vibrating mixersTransportation and packagingCompound (substance)Engineering

The invention discloses a rapid diluting and mixing device for agricultural chemicals. The rapid diluting and mixing device comprises a covering shell, a platform, a first air pressure rod, a liftingplate, a large feeding nozzle, a liquid storage chamber, a small feeding nozzle, a second air pressure rod, a press rod, a liquid discharging pipe, a liquid abutting plate, a first spring, a sliding rail, a mixing chamber, a pulley rod, a pulley, a third air pressure rod, a mixing chamber liquid discharging pipe, a valve, a first motor, rotating shafts, mixing rods and the like. The rapid dilutingand mixing device disclosed by the invention has the advantages of reasonable and simple structure, low production cost and convenience in installation; liquid chemicals can be fully stirred by mixing rods on the two rotating shafts in the mixing chamber, so that a liquid chemical mixing effect is improved, and the liquid chemicals are ensured to be evenly mixed; water in the liquid storage chamber of the rapid diluting and mixing device disclosed by the invention is controlled by the second air pressure rod, manual operation is avoided, and pollution is avoided; the rapid diluting and mixingdevice disclosed by the invention can be further applied to grinding solid chemicals, so that the situation that the moistened and clustered solid chemicals cannot be dissolved is avoided.

Owner:林时本

Method for removing precious metal impurities in iridium-containing feed liquid

PendingCN114196836AAvoid insolubleReduce dispersionProcess efficiency improvementIridiumAmmonium sulphide

The invention relates to the technical field of precious metal metallurgy, in particular to a method for removing precious metal impurities in iridium-containing feed liquid, which comprises the following steps: S1, oxidizing aqua regia: oxidizing and removing organic matters in the iridium-containing feed liquid by using a strong oxidant; s2, hydrolysis: in the process of oxygenolysis of organic matters by aqua regia, a small amount of organic matters are not decomposed, meanwhile, a large amount of soluble salts exist in the iridium waste liquid, and residual organic matters and most of the soluble salts are removed through hydrolysis; s3, oxidizing and precipitating iridium; s4, hydrazine hydrate reduction dissolution; s5, ammonium sulfide purification; s6, calcining and hydrogen reduction; organic matters are oxidized and damaged by aqua regia according to the special properties of materials, transformation of a solution medium is achieved, the problem that iridium is difficult to dissolve is avoided, chloroiridic acid is directly calcined to produce the iridium powder in the production process of the iridium powder, dispersion and loss of iridium are reduced, precious and base metals are ingeniously removed by using the characteristic that ammonium chloride is used for precipitating iridium after a sub-oxidant is added, and the production cost is reduced. The purity of the prepared iridium powder is good, and the recovery rate reaches up to 99.95%.

Owner:泸西县扩铂贵金属有限公司

A preparation method of para-aramid nanofiber composite lithium-ion battery separator

The invention relates to a method for preparing a para-aramid nanofiber composite lithium-ion battery diaphragm, and belongs to the technical field of polymer materials. First prepare the para-aramid polymerization slurry, and use the coating method to coat the para-aramid polymerization slurry on the surface of the base film, and carry out the coating film in a coagulation bath composed of N-methyl-2-pyrrolidone and water. solidification to obtain a para-aramid nanofiber composite lithium-ion battery diaphragm; the para-aramid nanofiber composite lithium-ion battery diaphragm is washed and dried to obtain a para-aramid nanofiber composite lithium-ion battery diaphragm. Compared with the prior art, the method saves solvent and energy, reduces energy consumption and avoids adverse effects of impurities on battery performance. Moreover, the preparation process is simple, and at the same time, the high temperature resistance performance of the diaphragm is improved. The prepared diaphragm has good ion conductivity, and can obtain better performance when used as a lithium ion battery diaphragm.

Owner:TSINGHUA UNIV

Health-protection product with functions of supplementing calcium and enhancing immunity and preparation method for health-protection product

InactiveCN103976216AGood calcium supplementPromote absorptionFood preparationFood ingredient as mouthfeel improving agentCelluloseEngineering

The invention relates to the technical field of health-protection products, and in particular relates to a health-protection product with functions of supplementing calcium and enhancing the immunity and a preparation method for the health-protection product. The health-protection product with the functions of supplementing the calcium and enhancing the immunity comprises milk minerals, casein phosphopeptides, whey proteins, taurine, yeast beta-glucosan, D-mannite, xylitol citric acid, sodium carboxymethylcellulose and magnesium stearate. The preparation method for the health-protection product with the functions of supplementing the calcium and enhancing the immunity comprises the following steps of 1, performing weighing the materials and mixing the materials; 2, performing smashing and screening; 3, preparing a sodium carboxymethylcellulose solution with the mass percentage of 0.5%; 4, performing granulation and drying; 5, performing finishing; 6, performing blending; and 7, performing tabletting. The health-protetcion product prepared by adopting the preparation method disclosed by the invention has an extremely good effect of supplementing the calcium, and the effect of enhancing the immunity is good; furthermore, the health-protection product is favorable for human body absorption and has a good taste; the health-protection product is suitable for patients suffering from diabetes, and the phenomenon that children easily get tooth decay can be avoided.

Owner:GUANGDONG APOLLO GRP

Nutrient solution mixing and stirring device convenient for heat preservation for gastrointestinal clinical nursing

InactiveCN114082326AAvoid insolublePrevent sticking to the inner wallRotary stirring mixersTransportation and packagingChemistryClinical nursing

The invention discloses a nutrient solution mixing and stirring device convenient for heat preservation for gastrointestinal clinical nursing in the technical field of stirring devices. The device comprises a stirring part, a liquid surface wall scraping part which floats on the liquid surface and rotates coaxially with the stirring part, and a vertical wall scraping part. The liquid surface wall scraping part is provided with a wetting part for spraying liquid to wet the inner wall of a stirring barrel above the liquid surface. The vertical wall scraping part is in sliding contact with the liquid surface wall scraping part in the downward-moving wall scraping process and presses the liquid level wall scraping part downwards to vertically move downwards along the shaft wall of a rotating shaft. Before the vertical wall scraping part is in sliding connection with the liquid surface wall scraping part, a water spraying triggering mechanism installed on the vertical wall scraping part triggers the wetting part to conduct water spraying action. A buckling mechanism which is buckled to the vertical wall scraping part and the liquid surface wall scraping part into a whole is arranged between the vertical wall scraping part and the liquid surface wall scraping part. The problem that undissolved powder and foam gather on the inner wall of the stirring barrel and are not easy to dissolve in the stirring process can be solved, the situation that the powder is pasted on the inner wall can be effectively prevented in a wetting and scraping mode, and the scraping and separating efficiency of the powder on the inner wall is improved.

Owner:PEOPLES HOSPITAL OF HENAN PROV

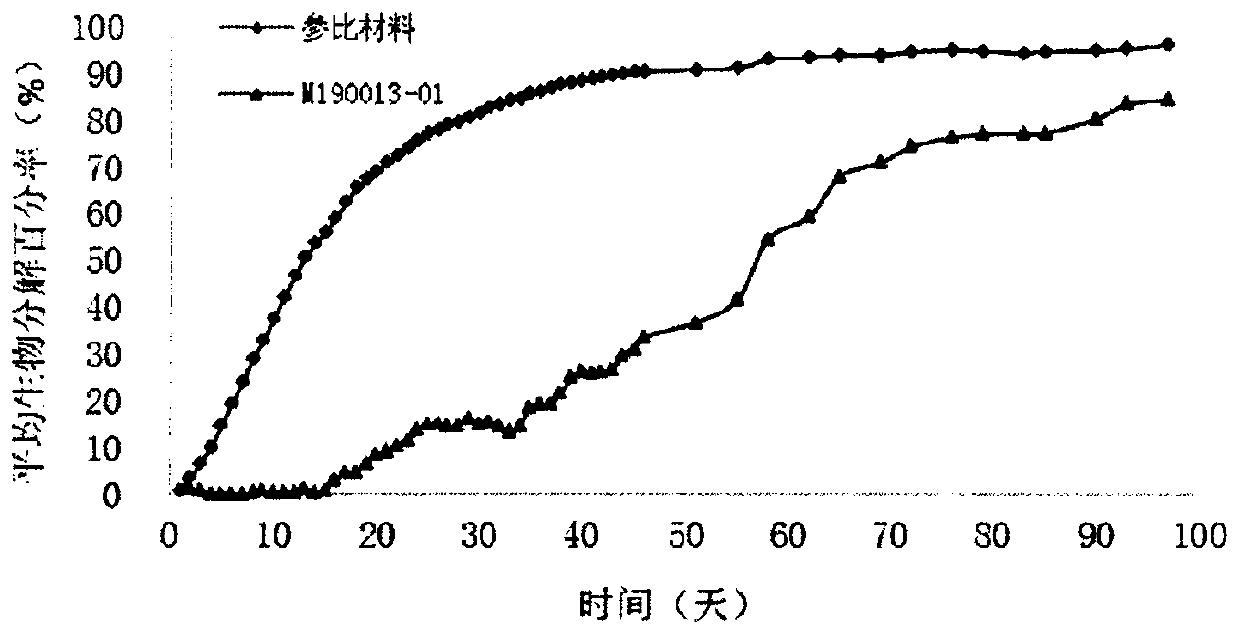

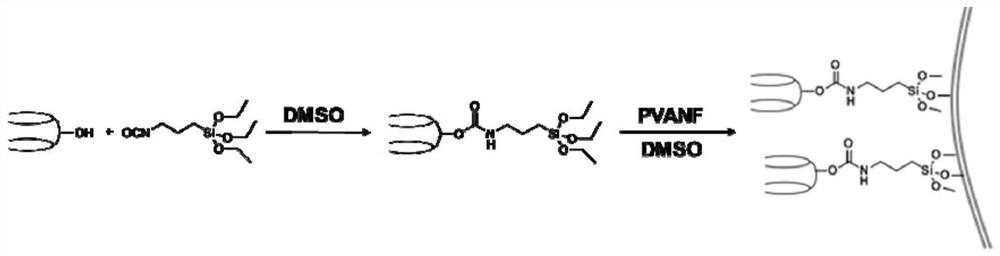

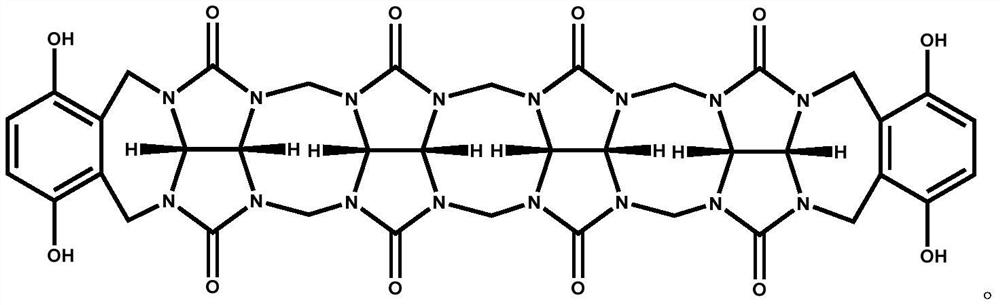

Easily desorbed and regenerated open-chain cucurbituril-based material for treating phenolic wastewater and preparation method thereof

PendingCN112915985AHigh tensile strengthHigh modulusOther chemical processesWater contaminantsPolyvinyl alcoholStrong acids

The invention relates to an easily desorbed and regenerated open-chain cucurbituril-based material for treating phenolic wastewater and a preparation method of the easily desorbed and regenerated open-chain cucurbituril-based material. The preparation method comprises the following steps: carrying out electrostatic spinning by taking polyvinyl alcohol and dialdehyde as main raw materials, and then performing cross-linking in a strong acid methanol solution to form a membrane; and grafting and modifying the open-chain cucurbituril to the surface of the nanofiber membrane, wherein the open-chain cucurbituril is of a structure with a carbamido repeating unit of 4. The open-chain cucurbituril-based material prepared by the method disclosed by the invention is good in mechanical property, the tensile strength is 50-80 MPa, and the elastic modulus is 2000-3000 MPa; the material has high adsorbability on phenolic substances such as phenol, p-methoxyphenol and parachlorophenol, and the maximum adsorption rate reaches 90% or above; the material is easy to desorb and regenerate, desorption can be completed through washing with benzyl alcohol and water, and the adsorption rate is still 80% or above after five times of adsorption-desorption cycles. The preparation method is efficient and practical; the material prepared by the method disclosed by the invention has good mechanical properties and high adsorbability and is easy to desorb and regenerate.

Owner:JIANGSU NEW HORIZON ADVANCED FUNCTIONAL FIBER INNOVATION CENT CO LTD

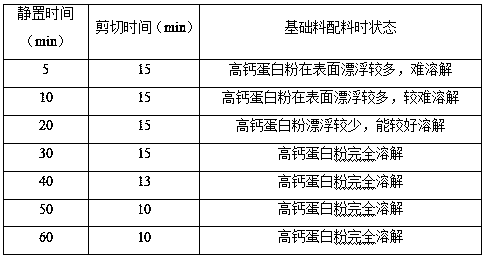

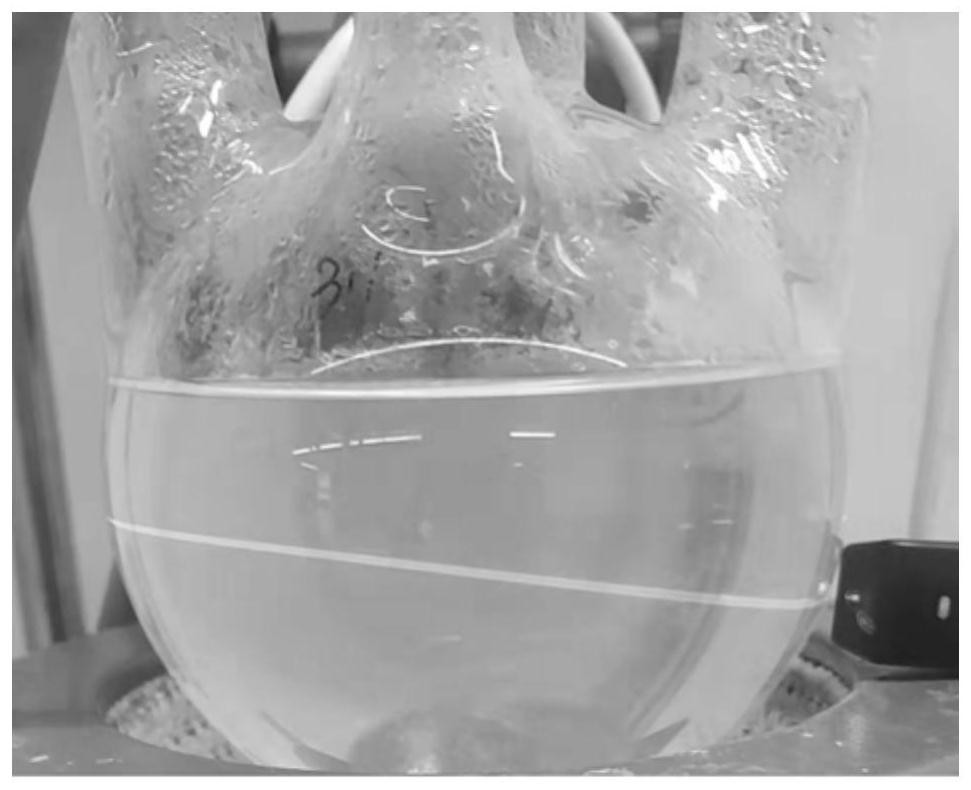

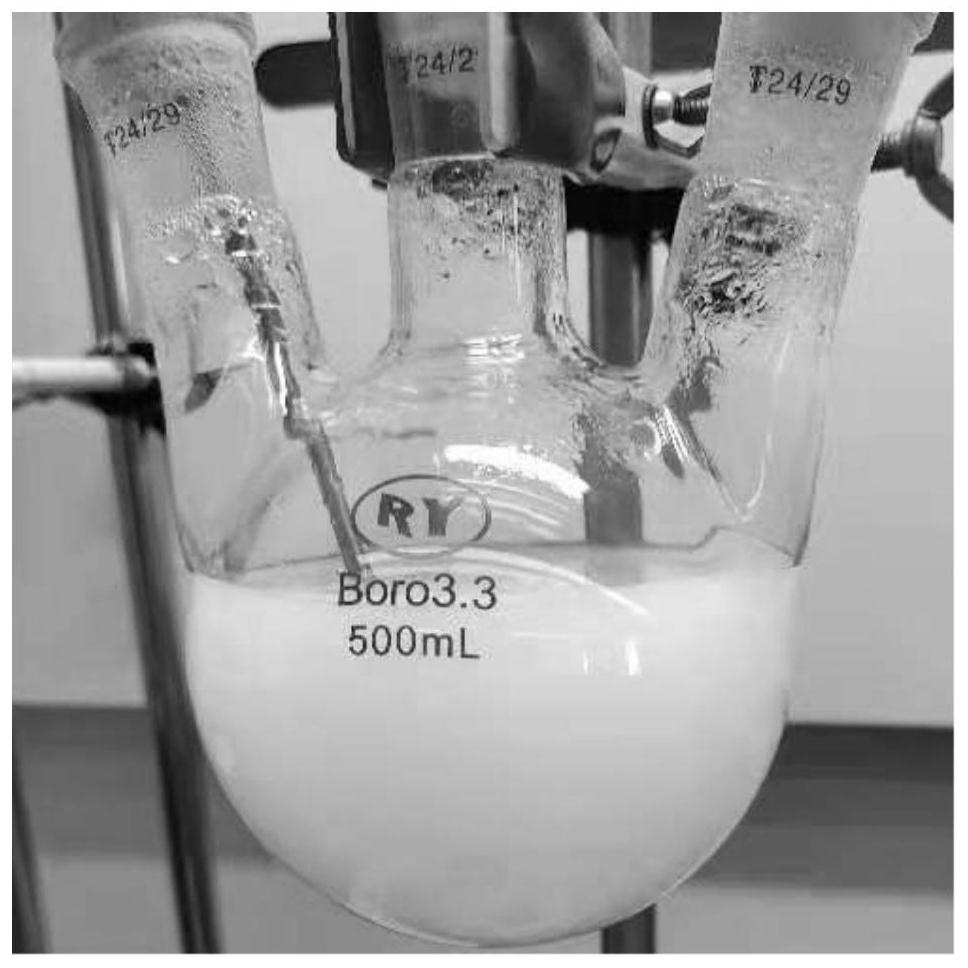

Preparation method of high-calcium milk, preparation method of high-calcium low-fat milk, high-calcium milk product and high-calcium low-fat milk product

ActiveCN110495497AMeet health needsIncreased proportion of hydrophilic groupsMilk preparationMilk preservationBiotechnologyCalcium protein

The invention provides a preparation method of high-calcium milk, a preparation method of high-calcium low-fat milk, a high-calcium milk product and a high-calcium low-fat milk product. The preparation method of the high-calcium milk and the preparation method of the high-calcium low-fat milk comprise the following steps of firstly preparing high-calcium protein powder, sweetening substances and milk, wherein high-calcium protein powder which is obtained by separating and concentrating micellar casein, and of which the calcium content is greater than or equal to 2000mg / 100g is used as the high-calcium protein powder, based on the total amount of the high-calcium milk being 100%, the percentage by weight of the sweetening substances is 0.5-0.8%, the total content of the high-calcium proteinpowder and the milk is within the limit that the content of calcium in the high-calcium protein powder and the milk in finished products of the high-calcium milk is greater than or equal to 120mg / 100ml, and full fat raw milk of which the calcium content is 95-115mg / 100g is used as the milk; during preparation, firstly, uniformly mixing the high-calcium protein powder with the sweetening substances to obtain a mixture, then pouring the mixture into milk which is preheated to 20-30 DEG C in advance, and performing uniform mixing; then performing rapid cooling to 4-10 DEG C; and finally, performing preheating to 65-70 DEG C, performing homogenizing, performing sterilizing, performing cooling and performing filling to obtain finished products. The high-calcium milk product can meet health requirements of consumers for pure milk products free from food additives.

Owner:FUJIAN CHANGFU DAIRY

Process for producing biodiesel from high acid number grease

InactiveCN101307247AIncrease chance of contactAids in emulsificationFatty acid chemical modificationBiofuelsOil and greaseAlcohol

The invention relates to a method for making biological diesel oil, in particular to a method for making biological diesel oil by grease with high acid value, belonging to the renewable energy resource technical field. The production formula of the method in weight portion is as follows: 100 portions of grease, 20 portions of bridle chain alcohol, 1 to 10 portions of fatty acid methyl ester, 0.5 to 4 portions of catalyst and 0.1 to 5 portions of alkalescent buffer substances. The concrete steps are as follows: the grease is put in a reaction kettle provided with a high speed blending device, added with the bridle chain alcohol and the fatty acid methyl ester, and undergoes high speed stirring at the room temperature for 1 to 4 hours so as to form emulsion, and the emulsion is added with the alkalescent substances and undergoes high speed stirring for 1 t0 4 hours; KOH or NaOH is dissolved in methyl alcohols to prepare the KOH or NaOH methanol solution with mass percentage concentration between 8 and 10 percent, which is used as catalyst; the emulsion is added with the catalyst and undergoes back flow reaction for 0.5 to 4 hours; after the reaction, reactants are cooled down to the temperature of 40 DEG C and then undergo standing separation to remove side products such as glycerin, etc. on the lower layer, and coarse products of the biological diesel oil are obtained; the coarse products of the biological diesel oil undergo normal pressure distillation to recover excessive bridle chain alcohols and undergo molecular distillation to obtain the qualified biological diesel oil. The method of the invention has the advantages of simple production process, mild condition, easy post treatment, low manufacturing cost, good economical efficiency of process and easy realization of industrialization, and has a good prospect for large-scale popularization and application.

Owner:陈登龙 +4

Preparation of water dispersed fine emulsion of fluorine acrelate copolymer for anti-oil and anti-water agent

Aqueous dispersible fine emulsion of complete acrylic ester copolymer as oil- and water-resisting agent is prepared by: preparing complete alkyl copolymerized monomer fine emulsion dispersed uniformly, and then polymerizing without organic solvent and emulsifying to aid it. It is stable for restore or dilution, and can be used for substrate materials of fabrics, leathers or paper as waterproof and oil-proof finishing agent.

Owner:ZHEJIANG UNIV

Water-soluble polymer and application thereof in composite spinning

ActiveCN113881038AReduce crystallinityImprove permeabilityTextile/flexible product manufactureConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention relates to a water-soluble polymer and application thereof in composite spinning. The water-soluble polymer is a polyesteramide polymer, and the molecular chain of the water-soluble polymer comprises a polyester structural unit and a polyamide structural unit. The polyester structural unit comprises a structural unit I composed of aromatic dibasic acid residues and aliphatic dihydric alcohol residues, a structural unit II composed of aliphatic dibasic acid residues and aliphatic dihydric alcohol residues, a structural unit III composed of aliphatic dibasic acid residues and dihydroxy salt residues, and a structural unit IV composed of aromatic dibasic acid residues and dihydroxy salt residues. The polyamide structural unit comprises a structural unit V composed of aliphatic dibasic acid residues and aliphatic diamine residues in a molar ratio of 2: 1. According to the application, a sea-island fiber is prepared by taking the water-soluble polymer as a sea component and a water-resistant meltable polymer as an island component. The water-soluble polymer disclosed by the invention is easily soluble in water and has low requirements on the quality of water for dissolving, so that the problems in the prior art are effectively solved.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

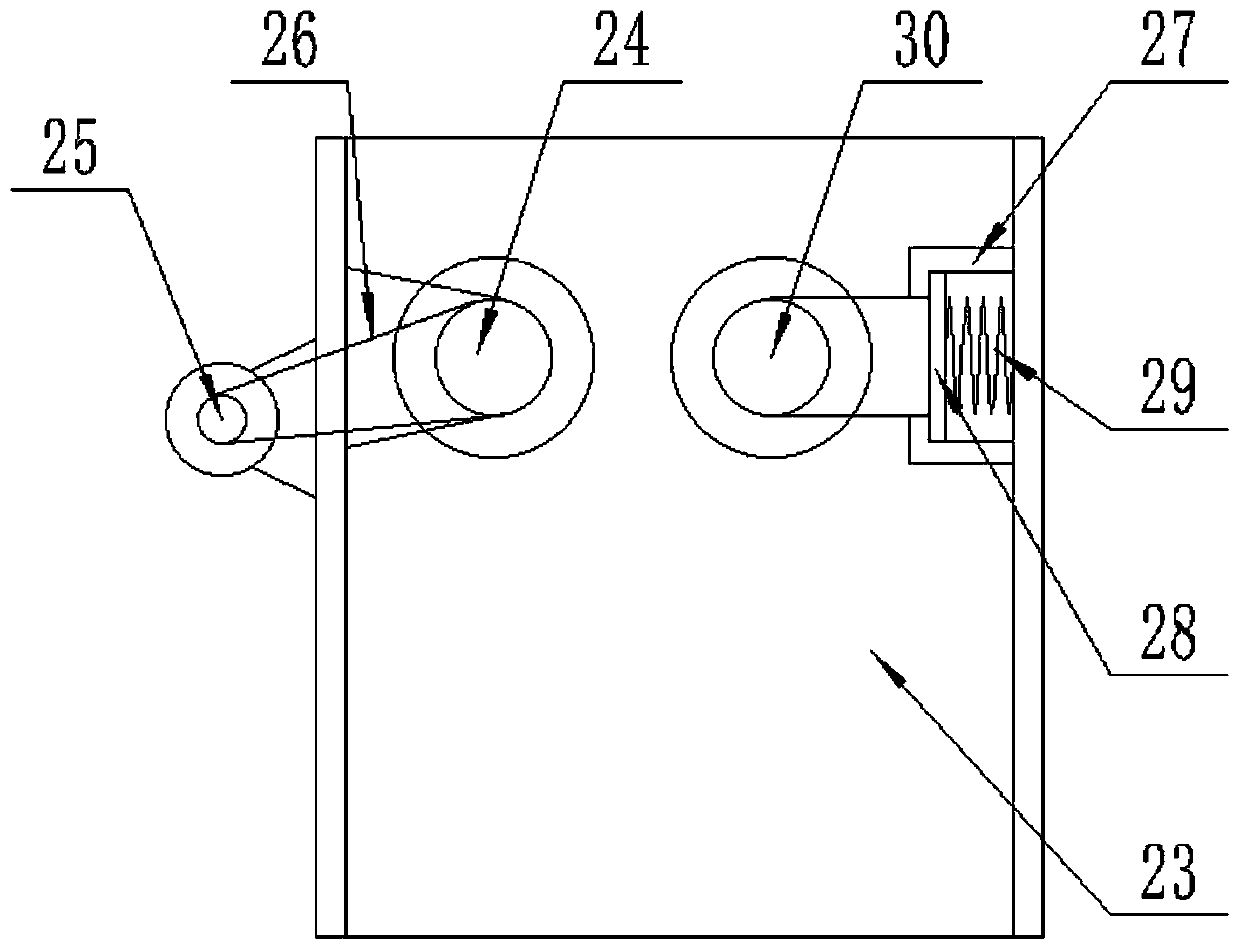

Traditional Chinese medicine facial mask stirring device and working method thereof

InactiveCN107096440AWell mixedAvoid precipitation and incomplete dissolutionRotating receptacle mixersTransportation and packagingElectricityEngineering

The invention provides a traditional Chinese medicine facial mask stirring device which comprises a tank body, a solar battery panel, a controller and a stirring cylinder, wherein the stirring cylinder is arranged inside the tank body; a first driving device and a second driving device are arranged on the tank body; the output shaft of the first driving device penetrates through the tank body and is connected with the stirring cylinder; the solar battery panel is connected with the output shaft of the second driving device; a third driving device and a heater are arranged on the stirring cylinder; the stirring cylinder is internally provided with stirring blades and a temperature sensor; the third driving device is connected with the stirring blades through a connecting shaft; the first driving device, the second driving device, the third driving device, the heater and the temperature sensor are electrically connected with the controller, respectively. By adopting the traditional Chinese medicine facial mask stirring device, traditional Chinese medicines can be thoroughly stirred, the time and the labor can be saved, solar energy can be effectively converted into electric energy, relatively low energy consumption is achieved, and a high automatic degree is achieved. A working method of the stirring device is simple in process and reliable in principle, and a traditional Chinese medicine facial mask can be sufficiently stirred.

Owner:广州依露美化妆品有限公司

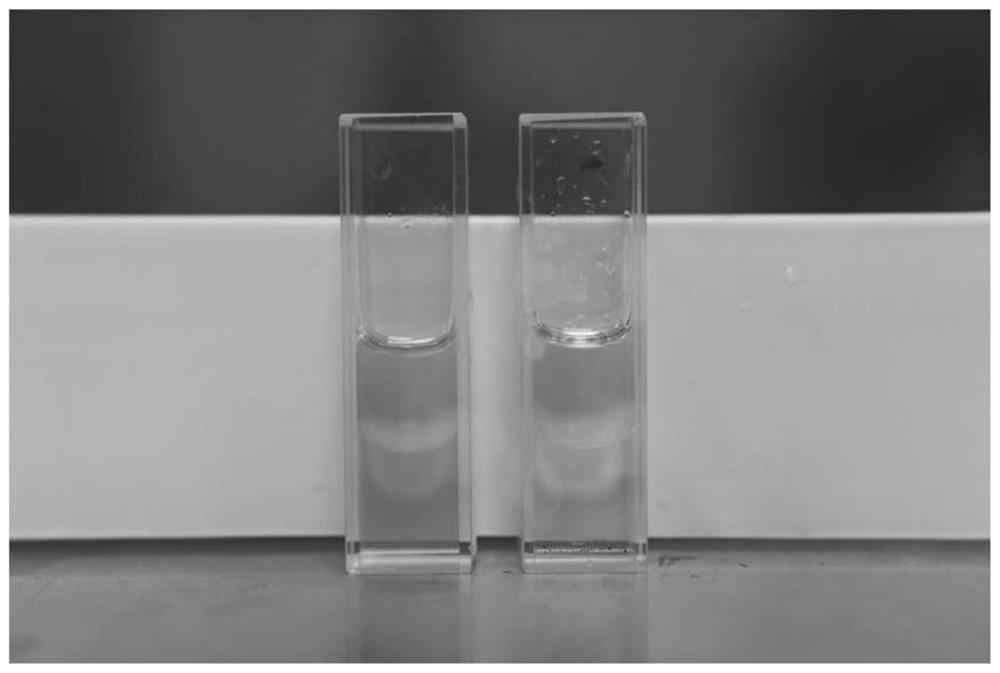

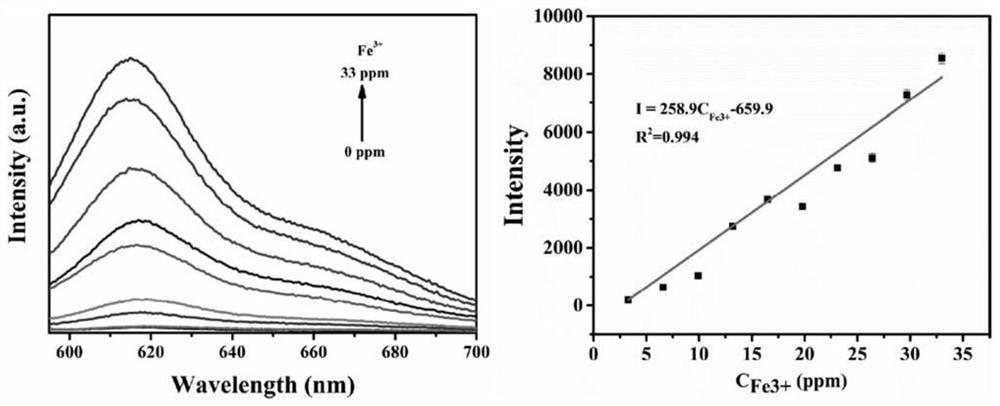

Fluorescent detection method of ion concentration in transformer oil

ActiveCN111398232BAvoid Interference from Autofluorescent LuminescenceAvoid insolublePreparing sample for investigationFluorescence/phosphorescenceTransformer oilReagent

The invention discloses a fluorescence detection method for the concentration of ions to be measured in transformer oil. The method is to extract the ions in the transformer oil into a detection reagent by using an extraction method, and realize the specific fluorescence response of the detection reagent to the ions in the oil. ion detection. The specific method is as follows: the metal-organic framework material capable of specific fluorescent detection of ions is mixed with a solvent to obtain a detection reagent, and after being fully mixed with the transformer oil to be tested, the change in the fluorescence intensity of the solution is tested, so as to realize the detection of the ions to be tested in the oil and detection of its content. The method is easy to operate, low in cost, accurate in measurement results, free from complex electromagnetic environment interference, and can effectively avoid the interference of oil autofluorescence and the problem that fluorescent materials are difficult to dissolve in oil, and has good practical application prospects.

Owner:ZHEJIANG UNIV

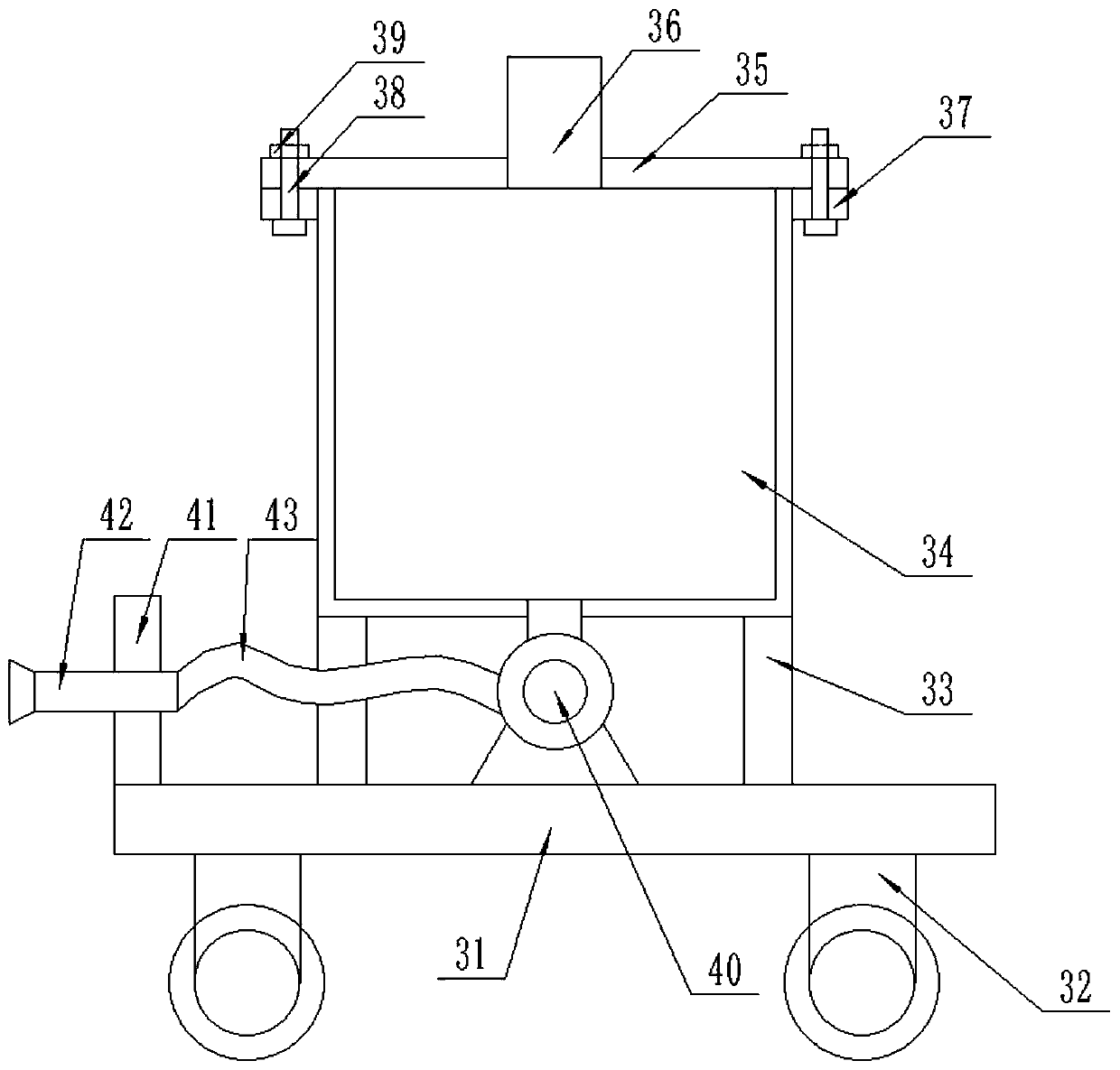

Integrated mechanical equipment capable of applying fertilizer for agricultural planting

InactiveCN112314132AReasonable structureIncrease planting speedTransportation and packagingMixersAgricultural scienceAgricultural engineering

The invention discloses integrated mechanical equipment capable of applying fertilizer for agricultural planting, and relates to the technical field of agricultural mechanical equipment. The integrated mechanical equipment comprises a moving vehicle, wherein a crushing box is arranged at the top of the moving vehicle; a water tank is arranged at the top of the moving vehicle, a mixing box is fixedly connected to the top of the moving vehicle, the water tank is connected with the mixing box through a water outlet pipe, and the crushing box is connected with the mixing box through a dischargingpipe; a liquid outlet pipe is fixedly connected to the side wall of the bottom position of the mixing box, and a plurality of branch pipes are fixedly connected to the side wall of the liquid outlet pipe; and a fixing plate is arranged at the top of one side of the moving vehicle, a placement box is arranged at the top of the fixing plate, and a plurality of mounting holes are formed in the top ofthe fixing plate. The integrated mechanical equipment capable of applying the fertilizer for agricultural planting is reasonable in structure, manual planting, fertilizer applying and soil filling one by one are not needed, so that time and labor are saved, the planting speed is increased, and planting, fertilizer applying and soil filling are integrated.

Owner:德清凯晶光电科技有限公司

A kind of preparation method of nut tofu

ActiveCN112471409BIncrease profitHigh nutritional valueCheese manufactureFood sciencePulp and paper industrySoya bean

Owner:NANCHANG UNIV

A reversed-phase high-performance liquid chromatography analysis method for recombinant human lysozyme

ActiveCN106872633BGuaranteed SolubilityGuaranteed number of pedalsComponent separationSolubilityRetention time

The invention discloses a reversed-phase high-performance liquid-phase chromatographic analysis method of recombinant human lysozyme. The method adopts octadecyl silane bonded silica gel with an aperture of 20 to 50 nm and a particle size of 2 to 10 micrometers as a chromatographic column filler, so that not only can the macromolecular proteins such as the recombinant human lysozyme have a certain retention on the column, but also the excessively strong combination between the proteins and the filler can be prevented from leading to the incapability of elution; and the sodium chloride is added into a flow phase, so that the solubility of the recombinant human lysozyme in the reversed-phase high-performance liquid-phase chromatographic analysis process is ensured, the recombinant human lysozyme can be completely blended with the flow phase, a step number, symmetry, repetition and accuracy in quantitative analysis of the chromatographic peak are ensured, and the method is used for analyzing and quantitatively detecting the recombinant human lysozyme.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

Heparin sodium colored impurity removing device

PendingCN114870495AFast dissolutionImprove efficiencyTransportation and packagingRotary stirring mixersHeparin sodiumSODIUM CHLORIDE GRANULES

The invention relates to a colored impurity removing device for heparin sodium. The technical problems that when sodium chloride solids are added into a solution to be stirred by existing equipment, relative movement of part of the sodium chloride solids and the solution is not obvious, so that the dissolution speed of sodium chloride is low, and even the phenomenon of incomplete dissolution occurs are solved. According to the technical scheme, the heparin sodium colored impurity removing device comprises a linkage plate, a stirring assembly and the like; a stirring assembly is mounted in the middle of the linkage plate. During use, the dissolving speed of sodium chloride particles is increased by increasing the relative speed of a solution and the sodium chloride particles through the stirring blades, the efficiency is greatly improved, the phenomenon of incomplete dissolution is avoided, meanwhile, the sodium chloride particles in the round pipe are rapidly pushed into the cavities of the stirring blades through the pushing blocks, the material distribution efficiency is improved, and therefore the dissolving speed is increased, and the material distribution efficiency is improved. Meanwhile, the splashed solution is blocked through the conical barrel, and the phenomenon that the solution is splashed into the first pipeline to cause blockage is avoided.

Owner:扬州金丽生物科技有限公司

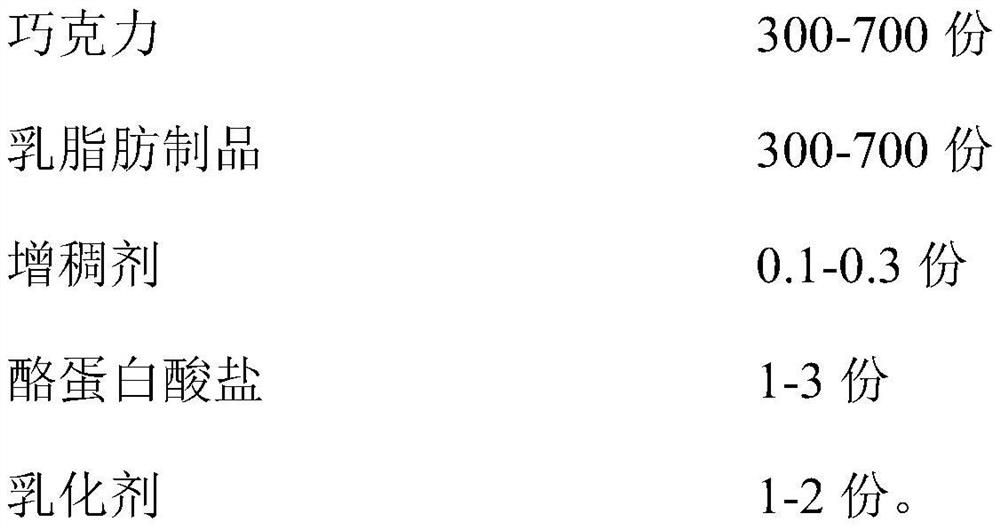

A kind of chocolate composition, aerated chocolate and its preparation method and frozen drink containing it

ActiveCN108271897BImprove stabilityAvoid gatheringFood ingredient as thickening agentFood ingredient as colourProcess engineeringAir bubble

The invention discloses a chocolate composition, aerated chocolate, a preparation method thereof and a frozen drink containing the same. The chocolate composition selects chocolate, milk fat products, thickeners, caseinates and emulsifiers, and rationally configures the ratio of each component to make it work synergistically, thereby ensuring that it can be used without adding casein. When it is inflated and sent, the air bubbles in it have high stability and will not break and collapse. At the same time, it has excellent foamability. After it is inflated and sent, the air bubbles formed in it are fine and uniform. Among them, by adding a specific amount of caseinate, the foamability is improved, and at the same time, it is combined with a low-content thickener, and the thickener is used to stabilize the bubbles to prevent the bubbles from agglomerating or breaking, which is conducive to the formation of fine and uniform small Air bubbles; by adding milk fat products, it is beneficial to inflate them, improve their foamability and ensure the expansion rate at the same time.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Method for directly preparing electrolyte solution for vanadium batteries by using vanadium pentoxide

ActiveCN104577173BOvercoming acidity should not lead to low concentration and other problemsAvoid insolubleRegenerative fuel cellsElectrolytesVolume concentrationElectrolyte

The invention relates to the preparation field of electrolytes, and in particular relates to a method for directly preparing an electrolyte for a vanadium cell by using vanadium pentoxide. The invention provides a method for directly preparing the electrolyte for the vanadium cell by using vanadium pentoxide, the method comprises the following steps: a. preparing a vanadium pentoxide solution by using a wet method, namely firstly adding water in the vanadium pentoxide, adding sulfuric acid under stirring to dissolve vanadium pentoxide to form a vanadium pentoxide-sulfuric acid solution, wherein the proportion of vanadium pentoxide to water is (0.886-2)g / ml to 1g / ml, the mass concentration of sulfuric acid in the obtained solution is 0.736g / ml-0.92g / ml; b. electrolyzing, namely by using the vanadium pentoxide-sulfuric acid solution obtained in the step a as a catholyte solution, and using sulfuric acid with volume concentration of 0.613g / ml-0.736g / ml as an anodolyte solution, electrolyzing. The method provided by the invention is free from additives, the concentration of the electrolyte is 2.5-5mol / L, and the cell current efficiency is greater than 90%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com