Fluorescent detection method of ion concentration in transformer oil

A technology of transformer oil and ion concentration, which is applied in chemical instruments and methods, fluorescence/phosphorescence, preparation of test samples, etc. Avoid operating steps and testing instruments, and have the effect of fast detection response and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Utilize the DMF solution of MOF-525 to detect the copper ion concentration in transformer oil by extraction method, and its concrete synthesis method is as follows:

[0028] Accurately weigh 1.35 g of benzoic acid and 105 mg of zirconium oxychloride, dissolve in 8 mL of DMF, and place the resulting solution in an oven at 80° C. to react for 2 hours. After cooling to room temperature, 47 mg of tetrakis(4-carboxyphenyl)porphyrin (TCPP) was dissolved by sonication. Next, the mixed solution was heated to 80° C. and reacted for 24 hours, cooled, centrifuged, and washed three times with DMF. After cleaning, 10 mL of DMF was added to the centrifuge tube, and 6000 mg / L MOF-525 solution was obtained after sonication. Subsequently, the above MOF-525 solution was diluted to 6 mg / L with DMF solvent to obtain a DMF solution of MOF-525 for detecting copper ions in transformer oil.

[0029] This solution was mixed with transformer oil containing different concentrations of copper io...

Embodiment 2

[0034] Utilize the aqueous solution of MOF-525 to detect the copper ion concentration in transformer oil by extraction method, and its specific synthetic route is as follows:

[0035]Accurately weigh 1.35g of benzoic acid and 105mg of zirconyl chloride, dissolve them in 8mL of DMF, and place the resulting solution in an oven at 80°C for 2 hours to react. After cooling to room temperature 47 mg tetrakis(4-carboxyphenyl)porphyrin (TCPP) was dissolved and sonicated. Next, the mixed solution was heated to 80° C. and reacted for 24 hours. After cooling, it was centrifuged and washed three times with deionized water. After cleaning, 10 mL of deionized water was added to the centrifuge tube, and a 6000 mg / L MOF-525 solution was obtained after ultrasonication. Subsequently, the above MOF-525 solution was diluted to 6 mg / L with deionized water to obtain an aqueous solution of MOF-525 for detecting copper ions in transformer oil.

[0036] Mix this solution with transformer oil contain...

Embodiment 3

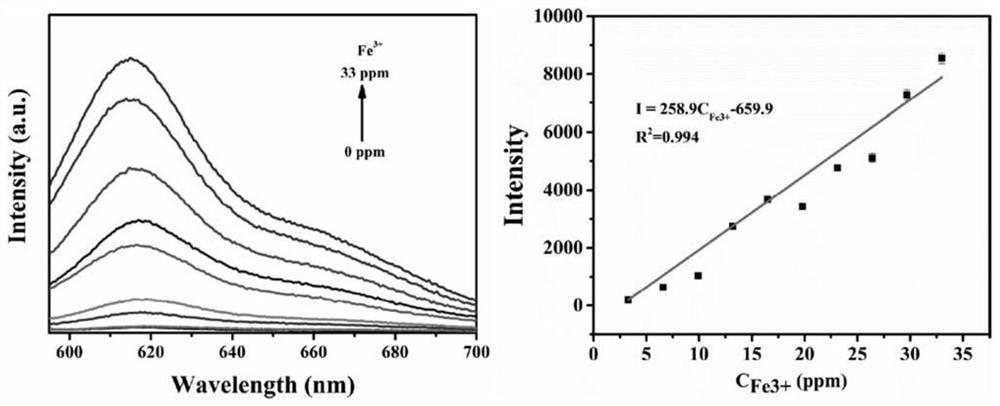

[0039] Using the aqueous solution of R101@ZIF-67 to detect the concentration of iron ions in transformer oil by extraction method, the specific synthesis route is as follows:

[0040] Accurately weigh 0.1g of cobalt nitrate hexahydrate and dissolve it in 8mL of deionized water, add 300μL of an aqueous solution with a concentration of 1mg / mL rhodamine 101 and stir for 20 minutes, and accurately weigh 0.2g of 2-methylimidazole and dissolve it in 8mL of deionized water , the two solutions were mixed and stirred at room temperature for 6 h. After the reaction was completed, they were collected by centrifugation and washed three times with deionized water. After cleaning, take 6 mg of sample, add 10 mL of deionized water, and obtain a high-concentration R101@ZIF-67 aqueous solution after ultrasonication. Then the above R101@ZIF-67 solution was diluted to 6 mg / L with deionized water to obtain an aqueous solution of R101@ZIF-67 for detecting iron ions in transformer oil.

[0041] Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com