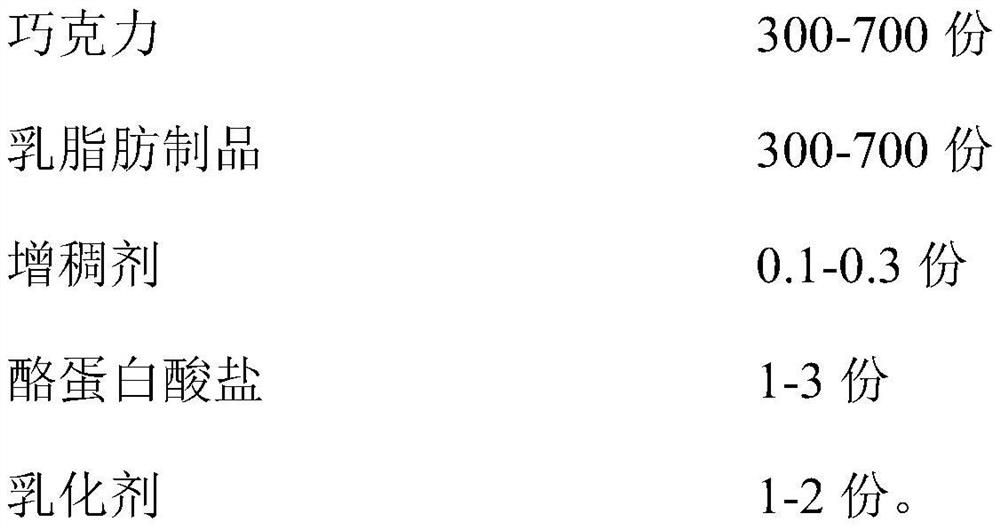

A kind of chocolate composition, aerated chocolate and its preparation method and frozen drink containing it

A technology for aerated chocolate and frozen drinks, which is applied in the field of food processing, can solve the problems of fine and uniform bubbles and poor foamability, and achieves the effects of high bubble stability, improved foamability and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example provides a chocolate composition, which is composed of 300g dark chocolate, 691g butter, 0.1g carrageenan, 3g sodium caseinate, 1g lecithin, 0.01g pigment and 4g food flavor, wherein the butter is the milk fat content It is 80wt% cream, and the water content in the above-mentioned chocolate composition is 10wt%;

[0039] The above-mentioned chocolate composition is whipped and aerated to obtain aerated chocolate;

[0040] The preparation method of above-mentioned aerated chocolate comprises the steps:

[0041] 1) Soften the butter at 22°C, then whip for 24 minutes at a whipping speed of 220rpm;

[0042] 2) mixing the sodium caseinate, pigment, food flavor, carrageenan and lecithin into dark chocolate at a temperature of 45° C., fully stirring and dispersing to obtain a chocolate mixture;

[0043] 3) adding the butter treated in step 1) to the chocolate mixture, and continuously stirring and mixing at 37° C. and 80 rpm to obtain the chocolate composition; ...

Embodiment 2

[0046] This embodiment provides a chocolate composition, which is composed of 691g milk chocolate, 300g butter, 0.2g carrageenan, 2g sodium caseinate, 1.5g soybean lecithin, 0.05g pigment and 1g food flavor, wherein the butter is milk fat Cream with a content of 85% by weight, the water content in the above chocolate composition is 6% by weight;

[0047] The above-mentioned chocolate composition is whipped and aerated to obtain aerated chocolate;

[0048] The preparation method of above-mentioned aerated chocolate comprises the steps:

[0049] 1) Soften the butter at 20°C, then whip for 30 minutes at a whipping speed of 300rpm;

[0050] 2) mixing the sodium caseinate, pigment, food flavor, carrageenan and soybean lecithin into milk chocolate at a temperature of 55° C., fully stirring and dispersing to obtain a chocolate mixture;

[0051] 3) adding the butter treated in step 1) to the chocolate mixture, and continuously stirring and mixing at 35° C. and 120 rpm to obtain the ...

Embodiment 3

[0054] The present embodiment provides a kind of chocolate composition, and it is made up of 450g white chocolate, 542.5g butter, 0.3g carrageenan, 1g sodium caseinate, 2g ammonium phosphate fat, 0.2g pigment and 4g food essence, wherein butter is milk Cream with a fat content of 75% by weight and a water content of 14% by weight in the above chocolate composition;

[0055] The above-mentioned chocolate composition is whipped and aerated to obtain aerated chocolate;

[0056] The preparation method of above-mentioned aerated chocolate comprises the steps:

[0057] 1) Soften the butter at 25°C, then whip for 20 minutes at a whipping speed of 150rpm;

[0058] 2) mixing the sodium caseinate, pigment, food flavor, carrageenan and ammonium phosphate into white chocolate at a temperature of 35° C., fully stirring and dispersing to obtain a chocolate mixture;

[0059] 3) adding the butter treated in step 1) to the chocolate mixture, and continuously stirring and mixing at 45° C. and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com