Method for directly preparing electrolyte for vanadium cell by using vanadium pentoxide

A vanadium pentoxide and vanadium battery technology, applied in electrolytes, fuel cells, regenerative fuel cells, etc., can solve problems such as environmental pollution, and achieve the effect of high dispersion and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

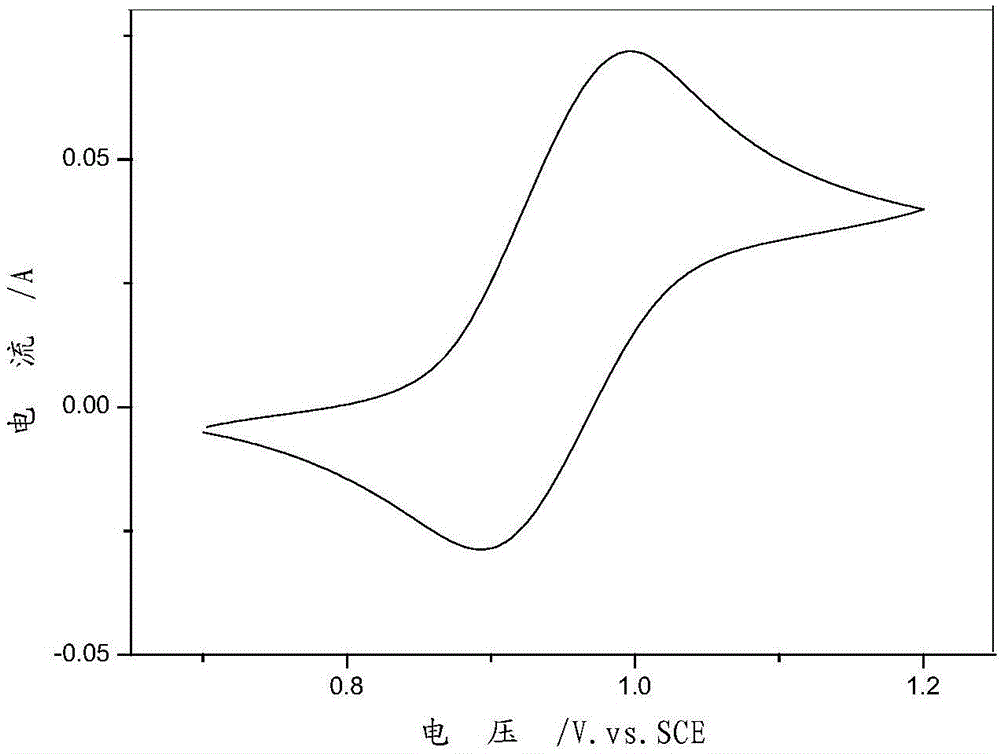

Image

Examples

Embodiment 1

[0037] V 2 o 5 : Standard high-purity grade (concentration greater than 99.99%) self-made by Panzhihua Iron and Steel (15 impurity elements are all below a certain standard range)

[0038] h 2 SO 4 : Analytical pure, mass concentration ≥ 98%, d = 1.84g / mL

[0039] Weigh 265.8g of high-purity vanadium pentoxide, pour it into the reactor, add 250mL of water into the reactor, add 200mL of concentrated sulfuric acid into the reactor under stirring, and set the solution to 500mL; as catholyte.

[0040] Measure 330mL of water, slowly add 170mL of concentrated sulfuric acid under the condition of stirring, as anolyte.

[0041] The electrolysis process uses an electrolytic cell for electrolysis, and the cathode uses a graphite plate as the electrode plate, and its specific surface area is 80×130×5mm 2 ; The anode uses platinum sheet as the electrode plate, and its specific surface area is 20×30×0.1mm 2 . Using constant current electrolysis, the rated current of electrolysis is ...

Embodiment 2-3

[0048] Examples 2-4 are the same as Example 1 except that the proportions of the materials and ultrasonic treatment conditions are different from those of Example 1. The specific proportions and conditions are shown in Table 1. The properties obtained are shown in Table 2.

Embodiment 4

[0050] Embodiment 4 is only that ultrasonic treatment is not used in the electrolysis process, and the others are the same as Embodiment 1, and the obtained properties are shown in Table 2. A large number of experiments have shown that the higher the concentration, the worse the effect of the electrolyte obtained without ultrasound, and the electrochemical performance of the vanadium battery without ultrasound above 2.0M does not meet the basic requirements.

[0051] Table 1 Ratio of materials and conditions of ultrasonic treatment

[0052]

[0053] Table 2 Electrolyte concentration and battery performance

[0054] Example

[0055] 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com