Water-soluble polymer and application thereof in composite spinning

A water-soluble polymer and polymer technology, applied in the direction of conjugated synthetic polymer artificial filament, chemical post-treatment of synthetic polymer artificial filament, single-component polyamide artificial filament, etc., can solve flocculation, insufficient and other problems, to achieve the effect of accurate introduction, low water quality dependence, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

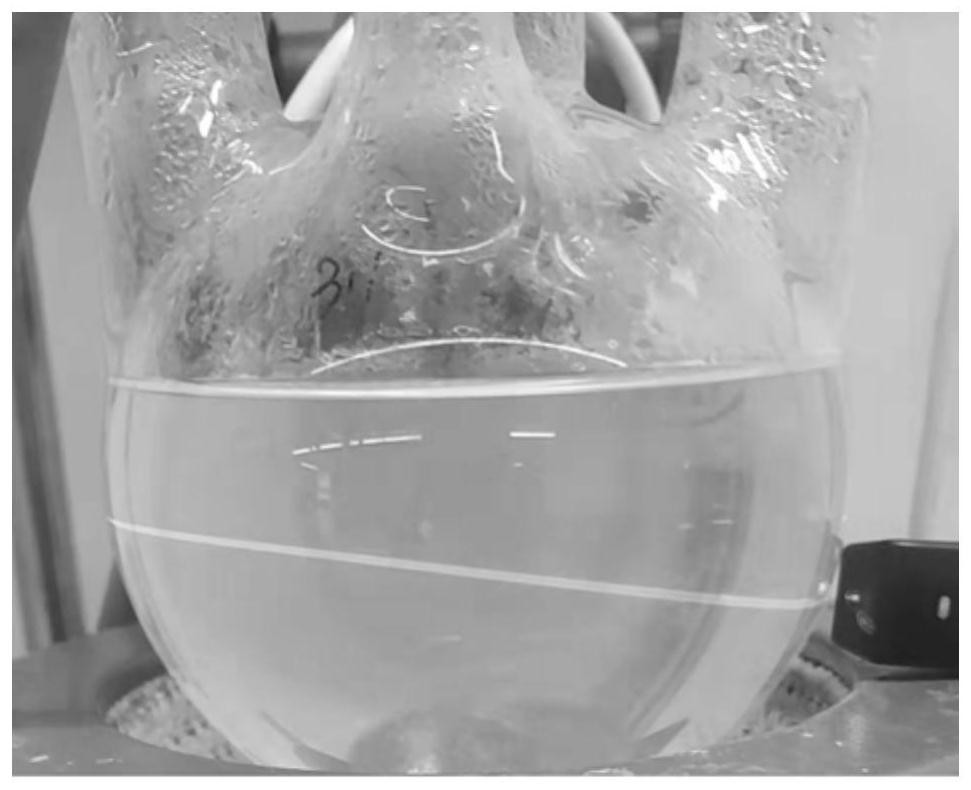

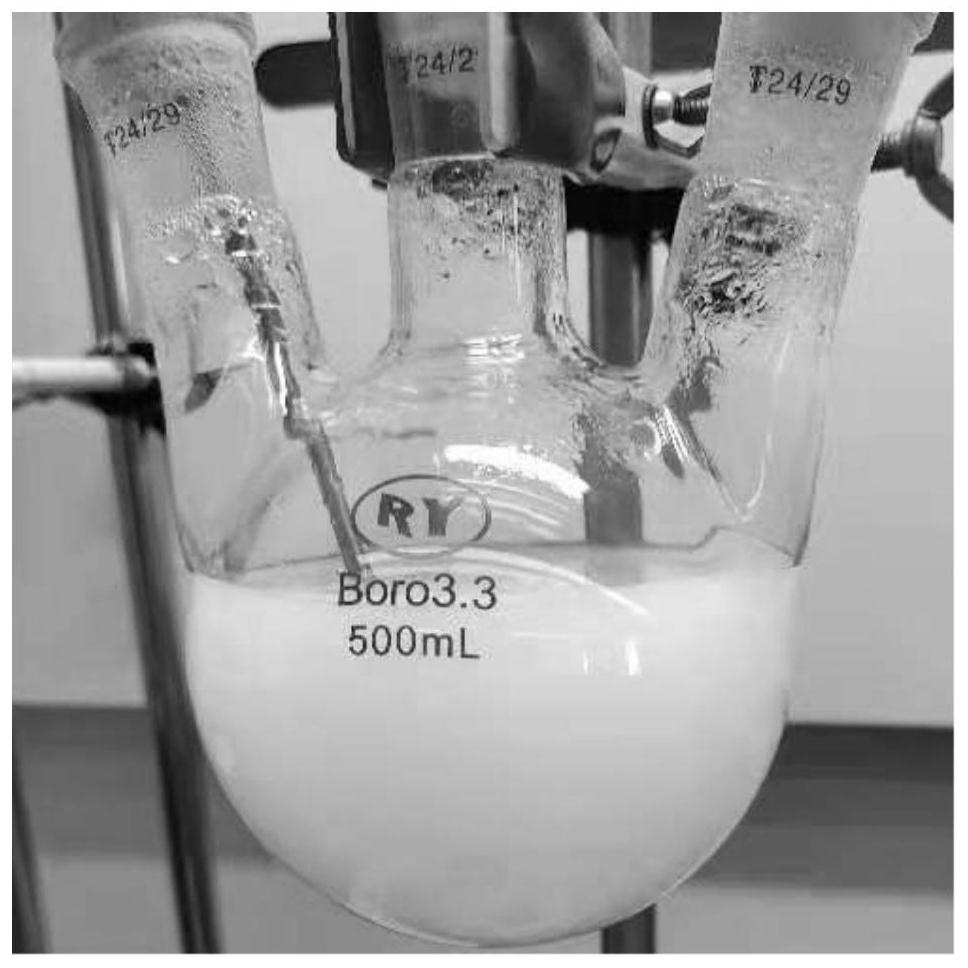

Image

Examples

Embodiment 1

[0058] A preparation method of a water-soluble polymer, the steps are as follows:

[0059] (1) put the aliphatic dibasic acid (succinic acid) and the aliphatic dibasic amine (hexamethylene diamine) in the molar ratio of 2.2:1 into the reactor, add deionized water as the solvent simultaneously, at a temperature of 85° C. and Under the condition of pressure of 0.1MPa, react until the pH value of the solution no longer rises, and the reaction generates a V-structure amide compound containing double-end carboxyl groups. After the reaction is completed, the excess unreacted aliphatic dibasic acid is removed, and the product is purified;

[0060] (2) put the aliphatic dibasic acid (succinic acid) and bishydroxy salt (bis(2-hydroxyethyl) dimethyl ammonium chloride) of mol ratio 2.2:1 into another reactor, add The tetra-n-butyl titanate of total feeding amount 300ppm is reacted to no distillate in the system under the condition that temperature is 160 ℃ and pressure is 60kPa, reaction...

Embodiment 2

[0076] A preparation method of a water-soluble polymer, the steps are as follows:

[0077] (1) put the aliphatic dibasic acid (oxalic acid) and aliphatic dibasic amine (butanediamine) in the molar ratio of 2.3:1 into the reactor, add deionized water as the solvent simultaneously, at a temperature of 90° C. and Under the condition of pressure of 0.1MPa, react until the pH value of the solution no longer rises, and the reaction generates a V-structure amide compound containing double-end carboxyl groups. After the reaction is completed, the excess unreacted aliphatic dibasic acid is removed, and the product is purified;

[0078] (2) put the aliphatic dibasic acid (oxalic acid) and bishydroxy salt (bis (2-hydroxyethyl) methyl ethyl ammonium chloride) of mol ratio 2.3:1 into another reactor, add simultaneously The tetra-n-butyl titanate that accounts for 350ppm of the total feeding amount is reacted to no distillate in the system under the condition that the temperature is 168 ° C...

Embodiment 3

[0086] A preparation method of a water-soluble polymer, the steps are as follows:

[0087] (1) put the aliphatic dibasic acid (glutaric acid) and the aliphatic dibasic amine (ethylenediamine) in the molar ratio of 2.4:1 into the reactor, add deionized water as the solvent simultaneously, at a temperature of 95°C and Under the condition of pressure of 0.1MPa, react until the pH value of the solution no longer rises, and the reaction generates a V-structure amide compound containing double-end carboxyl groups. After the reaction is completed, the excess unreacted aliphatic dibasic acid is removed, and the product is purified;

[0088] (2) put the aliphatic dibasic acid (malonic acid) and bishydroxy salt (bis(2-hydroxyethyl) methylethylammonium bromide) of mol ratio 2.4:1 into another reactor, add simultaneously The tetra-n-butyl titanate that accounts for 400ppm of the total feeding amount is reacted to no distillate in the system under the condition that the temperature is 170 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com