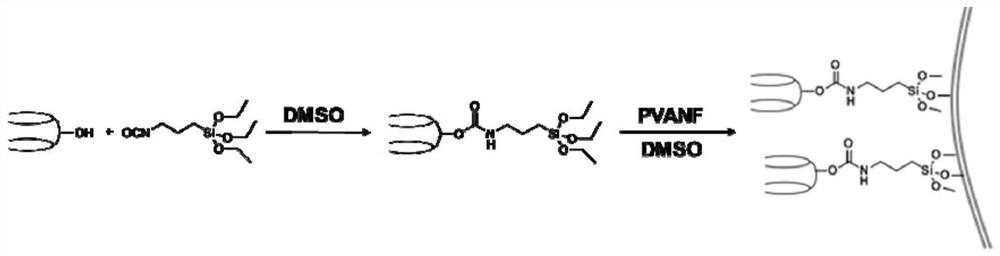

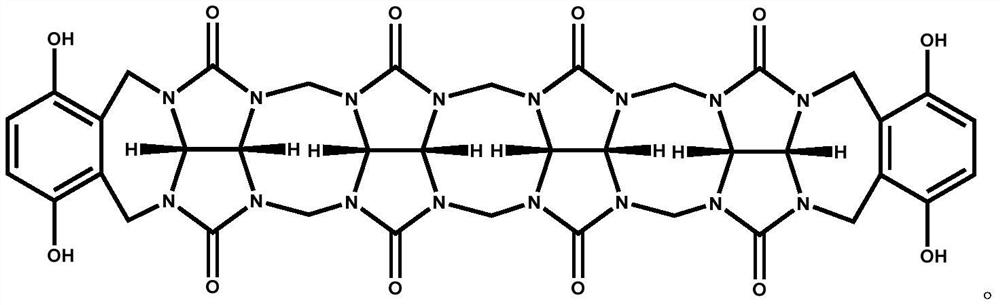

Easily desorbed and regenerated open-chain cucurbituril-based material for treating phenolic wastewater and preparation method thereof

A technology for cucurbituril and phenol wastewater, which is applied in separation methods, filter regeneration, water/sewage treatment, etc., and can solve problems such as poor environmental adaptability, unstable product quality, and poor performance of desorption and regeneration of phenolic pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for preparing an easily desorbed and regenerated open-chain cucurbituril-based material for treating phenol-containing wastewater, specifically as follows:

[0061] (1) Preparation of cross-linked polyvinyl alcohol electrospun nanofiber membrane:

[0062] (1.1) Dissolving polyvinyl alcohol in deionized water, heating to 90°C and mixing under constant temperature conditions to obtain a homogeneous solution with a mass fraction of 10%;

[0063] (1.2) Add glutaraldehyde into the homogeneous solution, and stir for 0.5h to obtain spinning solution; wherein, the mass ratio of polyvinyl alcohol to glutaraldehyde is 4:1;

[0064] (1.3) Use a constant flow syringe pump to deliver the spinning solution at a flow rate of 0.5mL h -1 Transport the polymer solution, set the voltage to 13kV, use the aluminum foil as the receiving screen, the receiving distance between the needle and the aluminum foil is 15cm, and the inner diameter of the flat needle is 0.7mm; electrospinnin...

Embodiment 2

[0077] A method for preparing an easily desorbed and regenerated open-chain cucurbituril-based material for treating phenol-containing wastewater, specifically as follows:

[0078] (1) Preparation of cross-linked polyvinyl alcohol electrospun nanofiber membrane:

[0079] (1.1) Dissolving polyvinyl alcohol in deionized water, heating to 85°C and mixing under constant temperature conditions to obtain a homogeneous solution with a mass fraction of 8%;

[0080] (1.2) Add glutaraldehyde into the homogeneous solution, and stir for 0.5h to obtain spinning solution; wherein, the mass ratio of polyvinyl alcohol to glutaraldehyde is 2:1;

[0081] (1.3) Use a constant flow syringe pump to deliver the spinning solution at a flow rate of 0.3mL h -1 Transport the polymer solution, set the voltage to 10kV, use the aluminum foil as the receiving screen, the receiving distance between the needle and the aluminum foil is 15cm, and the inner diameter of the flat needle is 0.7mm; electrospin und...

Embodiment 3

[0090] A method for preparing an easily desorbed and regenerated open-chain cucurbituril-based material for treating phenol-containing wastewater, specifically as follows:

[0091] (1) Preparation of cross-linked polyvinyl alcohol electrospun nanofiber membrane:

[0092] (1.1) Dissolving polyvinyl alcohol in deionized water, heating to 89°C and mixing under constant temperature conditions to obtain a homogeneous solution with a mass fraction of 15%;

[0093] (1.2) Add adipaldehyde into the homogeneous solution, and stir for 0.5h to obtain spinning solution; wherein, the mass ratio of polyvinyl alcohol to adipaldehyde is 3:1;

[0094] (1.3) Use a constant flow syringe pump to deliver the spinning solution at a flow rate of 0.4mL h -1 Transport the polymer solution, set the voltage to 14kV, use the aluminum foil as the receiving screen, the receiving distance between the needle and the aluminum foil is 15cm, and the inner diameter of the flat needle is 0.7mm; electrospinning at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com