Preparation method of high-calcium milk, preparation method of high-calcium low-fat milk, high-calcium milk product and high-calcium low-fat milk product

A low-fat milk, high-calcium technology, used in milk preparations, dairy products, and milk preservation, etc., can solve problems such as precipitation and substandard calcium content detection data, and achieve the effect of easy absorption, easy acquisition, and increased selling points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

[0031] A kind of high-calcium low-fat milk comprises the following steps:

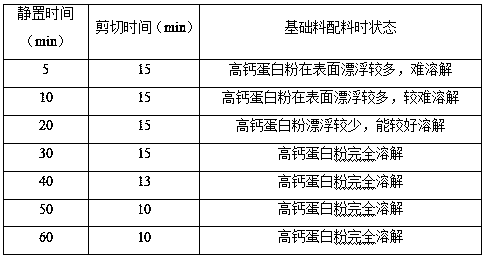

[0032] (1) Prepare the main ingredients first: high-calcium protein powder, sweeteners and milk, wherein the high-calcium protein powder is made by separating and concentrating casein micelles with a calcium content ≥ 2000mg / 100g High-calcium protein powder, based on the total amount of high-calcium milk as 100%, the weight percentage of sweetening substances is 0.5-0.8%. The total content of calcium in the milk is limited to 120mg / 100ml, and the milk is skimmed milk with a calcium content of 95~115mg / 100g after skimming; , and then put them into the preheated milk at 20~30°C, mix well, and make a mixed solution;

[0033] (2) Cool the mixture rapidly to 4~10°C and let it stand for later use;

[0034] (3) Preheat the mixed solution cooled to 4-10°C to 65-70°C, homogenize, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com