Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Avoid degradation of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

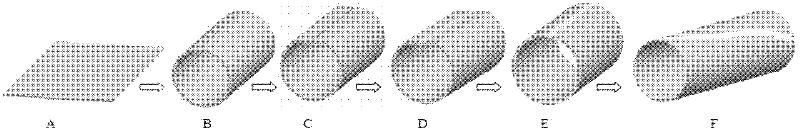

Preparation method of large-diameter aluminum alloy tube

InactiveCN102416413AImprove welding strengthImprove plasticityNon-electric welding apparatusFriction weldingProduction rate

The invention relates to a preparation method of a large-diameter aluminum alloy tube, relating to a preparation method of an aluminum alloy tube and aiming to solve the problems in the prior art that the large-diameter aluminum alloy tube with the tube wall thickness less than 2mm and with an excellent performance cannot be prepared with low cost and high production efficiency. In the method, an aluminum alloy rolled plate is obtained at first through blanking with a plate shearing machine, a cylindrical tube blank is prepared with a plate rolling machine, a tube blank to be welded is obtained through clamping with a clamp, mixing friction welding is carried out for welding, a cylindrical welded tube is obtained through rounding, and the large-diameter aluminum alloy tube is obtained finally sequentially through spinning and thermal treatment. The invention has the advantages that: 1, a high-quality spinning blank can be obtained; 2, a large-diameter tube can be prepared; 3, the mechanical properties are good; 4, the number of spinning procedures is reduced, no annealing treatment is needed in the procedures, the production cycle is shortened, and the cost is decreased; and 5, the dimensional accuracy is high. The method is mainly applied in production of the large-diameter aluminum alloy tube.

Owner:HARBIN INST OF TECH

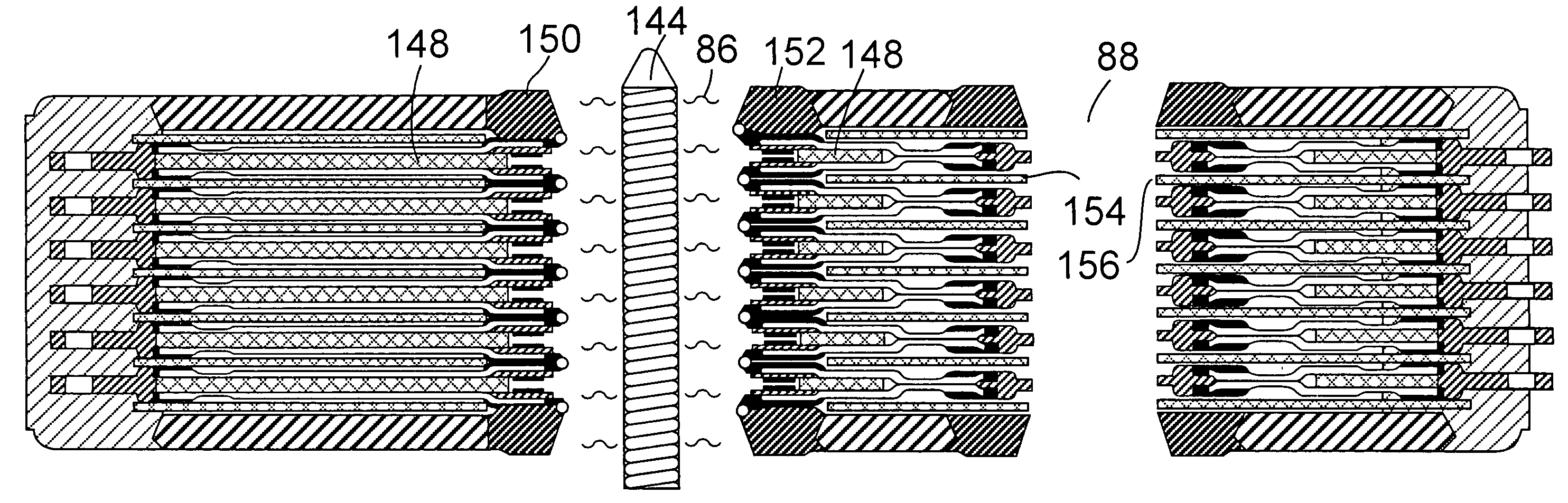

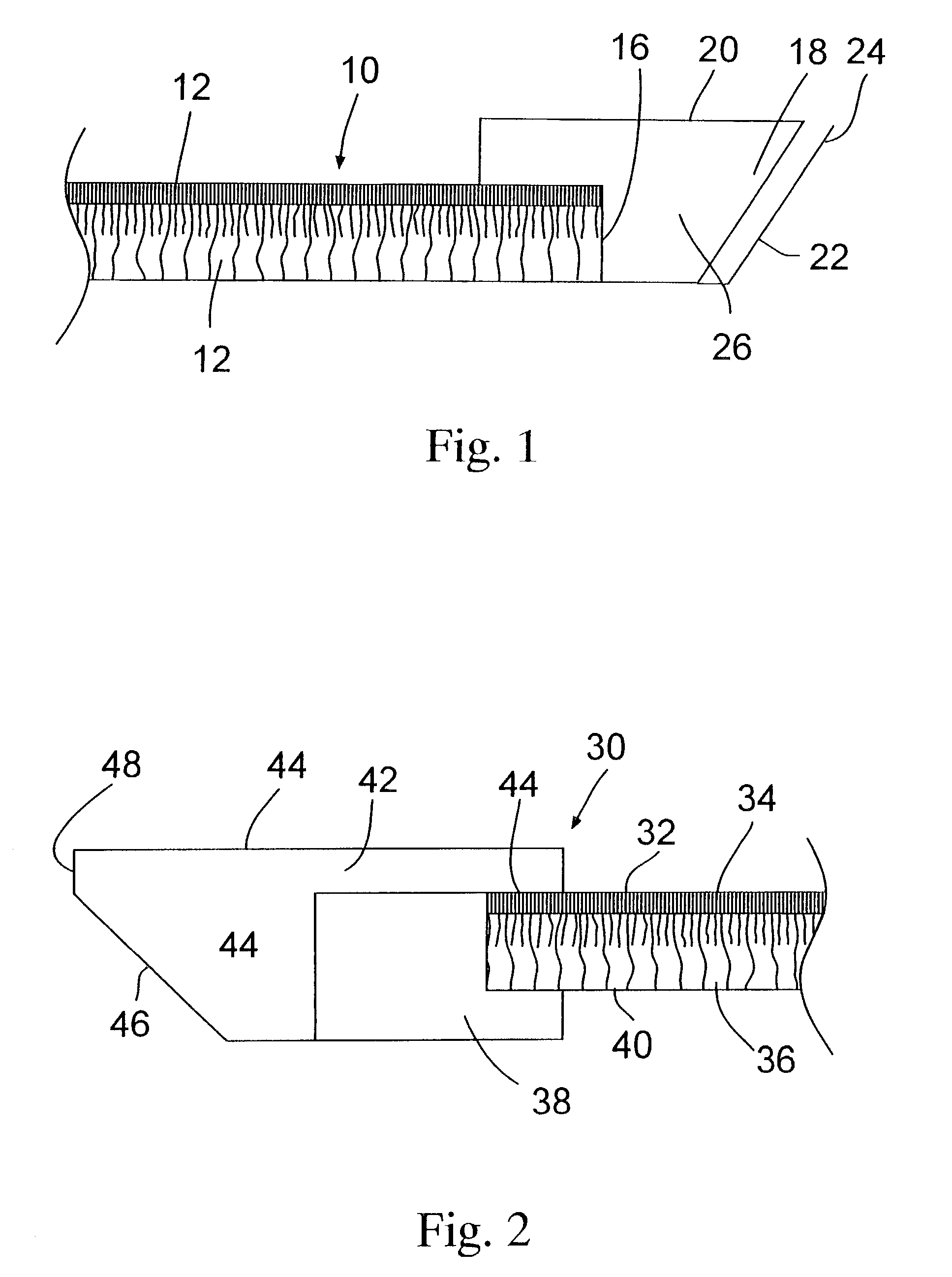

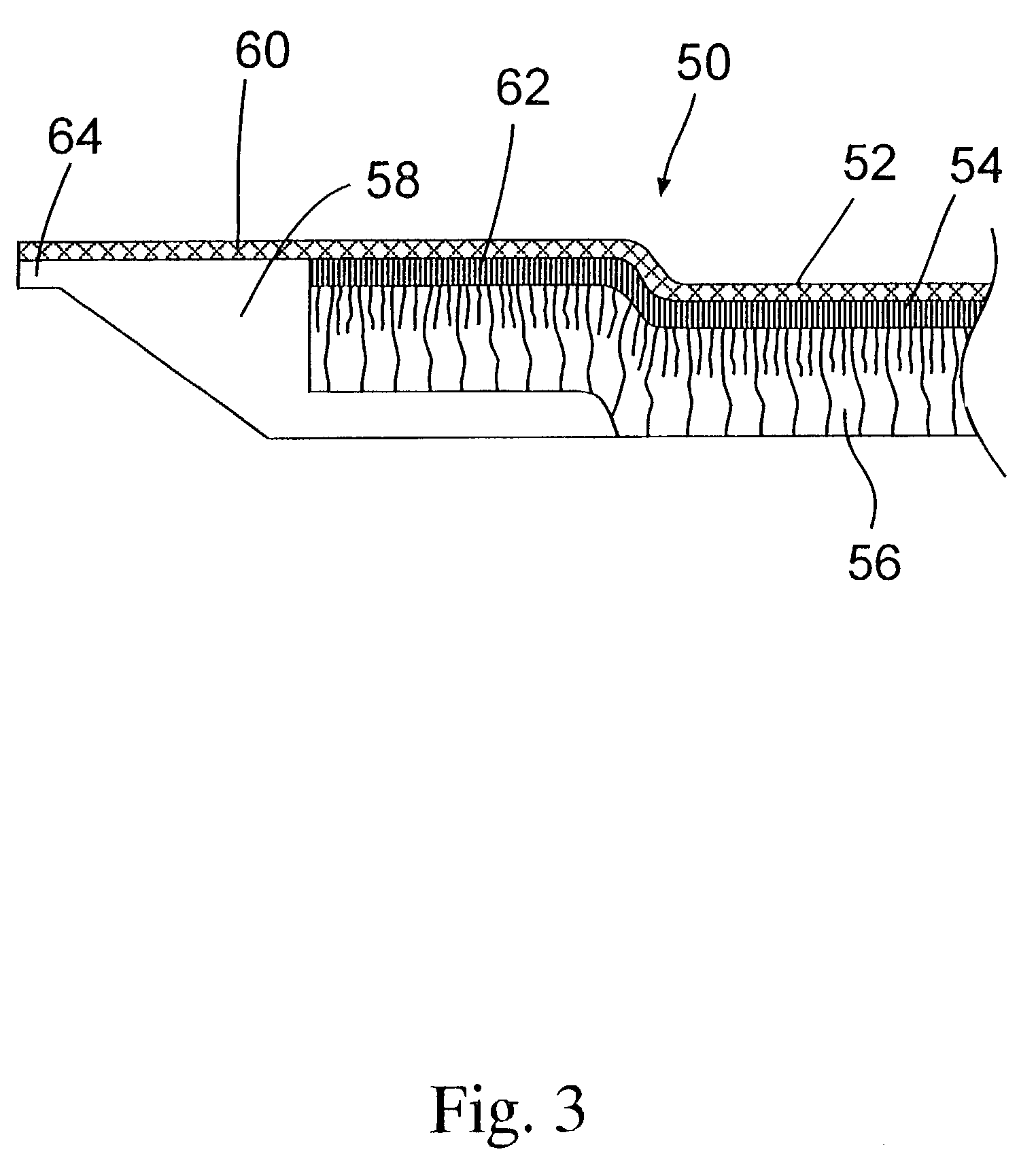

Process for making a fluid processing module

InactiveUS7097800B2Improve sealingAvoid degradation of mechanical propertiesSemi-permeable membranesOther chemical processesPorous layerFiltration

A process for making a fluid processing module is provided wherein a plurality of filtration elements is alternated with a fluid porous layer to form a stack. The filtration elements comprise a membrane sheet having a thermoplastic element bonded to a portion of an edge of the membrane. An opening is provided either through the membrane or through the thermoplastic element. A portion of the thermoplastic element extends into the opening and can be sealed to an adjacent positioned thermoplastic element to seal the porous sheet positioned between adjacently positioned membranes from fluid communication with the opening. Sealing can be effected by extending a heating element through the opening of the stack to effect simultaneous sealing of a plurality of thermoplastic elements.

Owner:MILLIPORE CORP

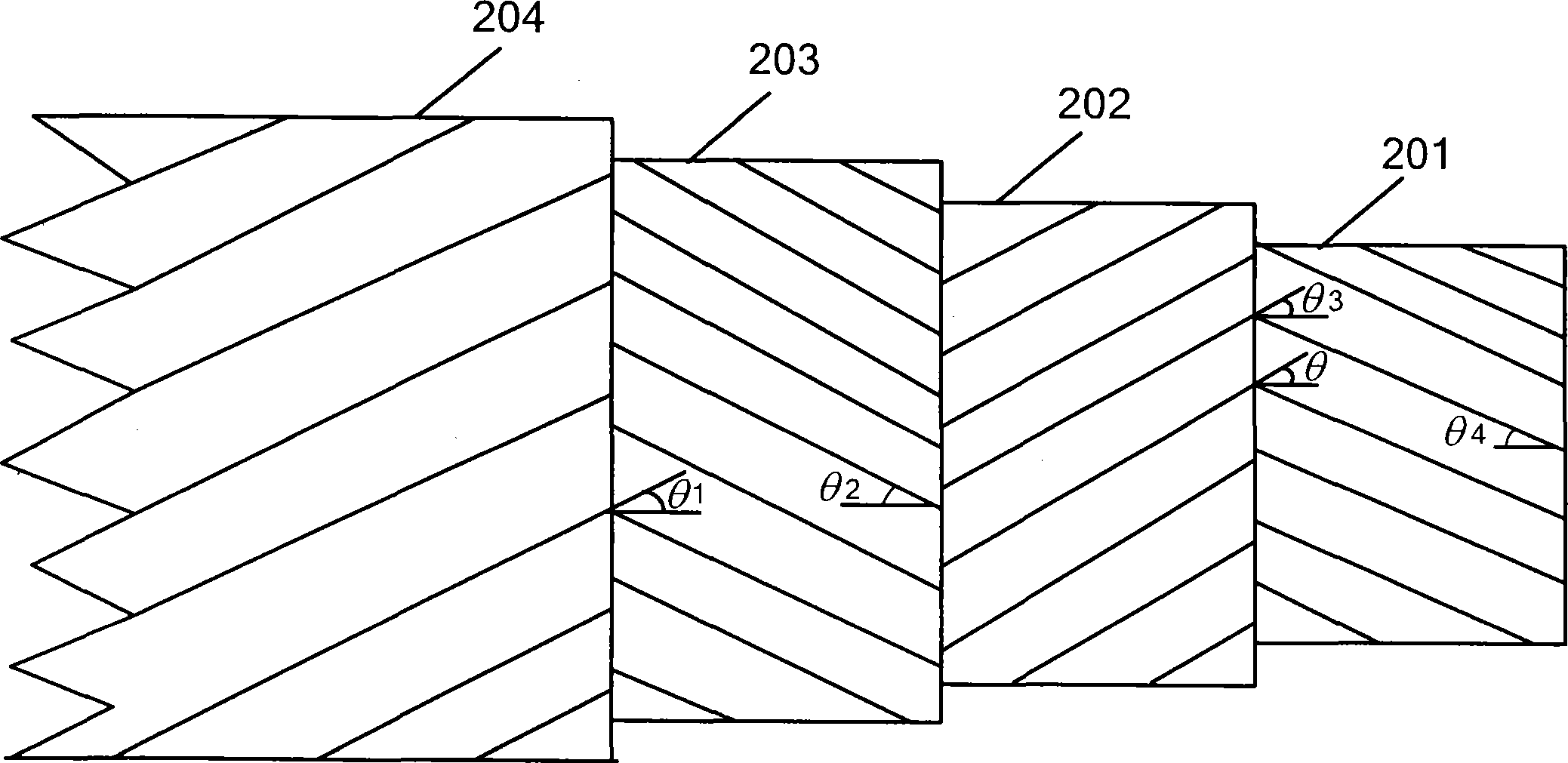

Design method of high-temperature superconducting cable/busbar main body

InactiveCN101246767AImprove performanceReduce the difficulty of winding processSuperconductors/hyperconductorsSuperconductor devicesElectric power systemHigh temperature superconducting

The invention relates to a design method of a superconducting cable / bus body, belonging to the field of power system transmission and transformation. The method comprises the steps of: creating an equivalent circuit model of the superconducting cable / bus; determining the winding helix angle of the superconducting cable / bus body, according to the mechanical property of a superconducting tape; determining the magnetic field type (magnetic filed size and direction) distribution on each layer of the superconducting cable / bus body by the anisotropy of the superconducting tape critical current, according to the running current; iterative computing the winding screw pitch to get the winding screw pitch parameters, based on the principle of equation of the running current and the critical current in each layer. The method makes use of the mechanical and electromagnetic property of the superconducting tape, the designed superconducting cable / bus body has no increased winding difficulty, the superconducting cable / bus tape has improved utility efficiency, and the loss is low. The method also has the advantages of simplicity and practicality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

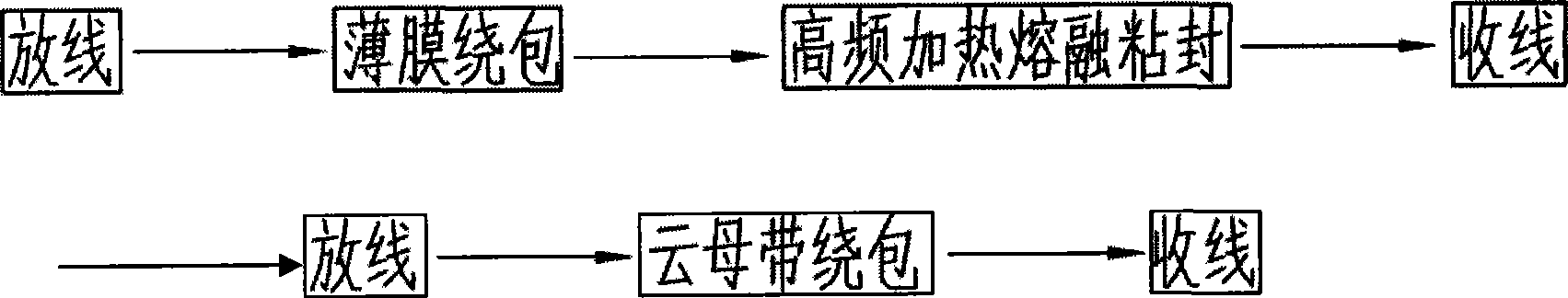

Polyimide film sintered powder mica bend coated flat copper cord and manufacturing process thereof

ActiveCN101383198AAvoid degradation of mechanical propertiesMeet the use requirementsPlastic/resin/waxes insulatorsInsulated cablesWind drivenElectrical conductor

The invention relates to a polyimide film sintering powder and mica tape winding copper flat wire and a preparation method thereof. Two layers of insulation materials are wound outside a metal wire, the inner layer is a sintered polyimide film, and the outer layer is a mica tape. The electromagnetic wire has good voltage and heat resistance, high mechanical strength and strong corona resistance. The preparation method comprises the following technical routes: conductor straightening, conductor polishing, film winding, high-frequency heating, melting, adhesive sealing, mica tape winding and rolling. The invention integrates the production technical routes by improving a high-frequency device, a mica winding device and other devices, the quality of the copper flat wire is ensured, meanwhile, the mechanical property of the copper flat wire is increased, the production flow is shortened, and the production efficiency is increased. The invention is suitable for composite insulation winding coils of large-sized motors and electric appliances, such as wind driven generators, and the like.

Owner:株洲兆源机电科技有限公司

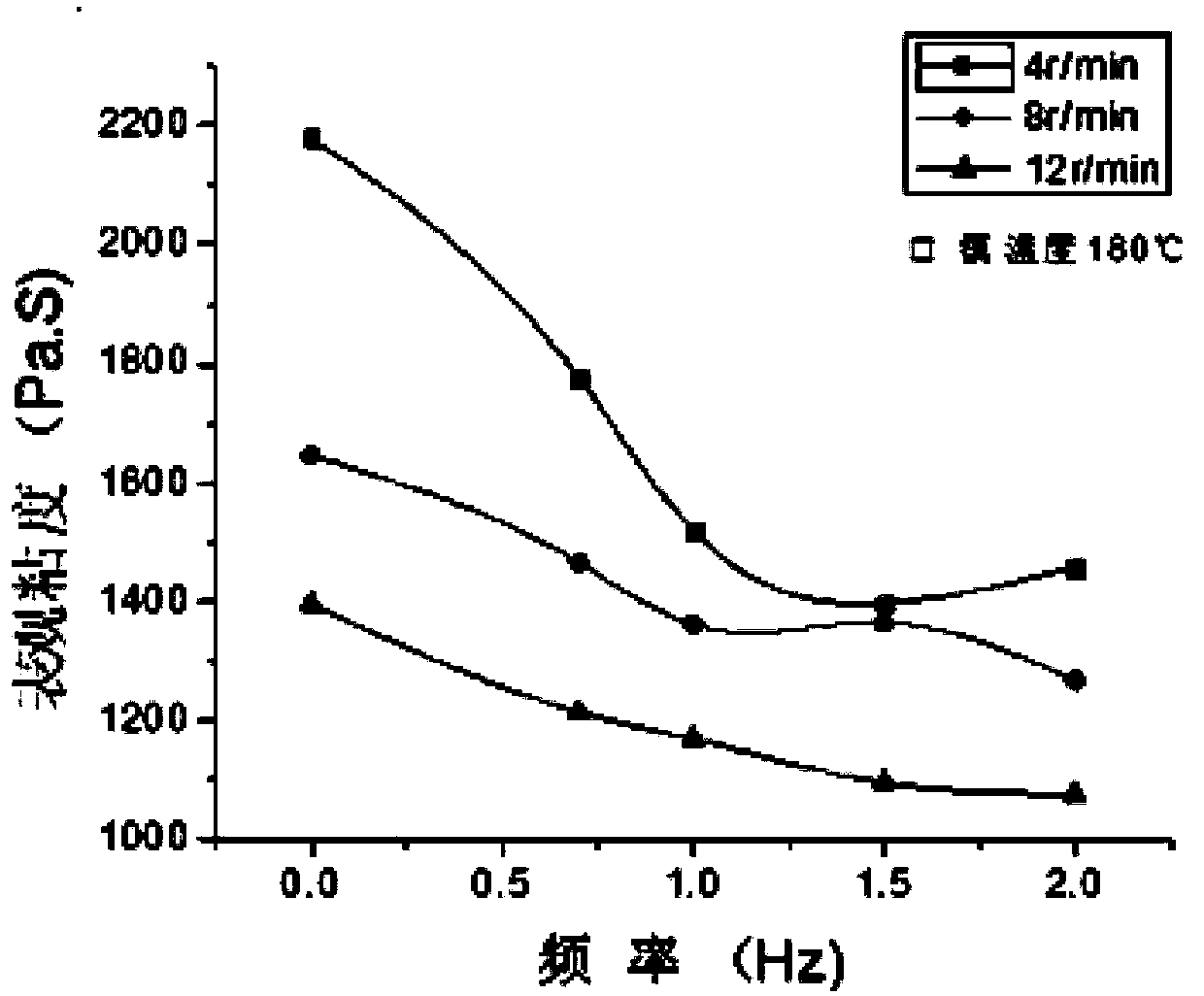

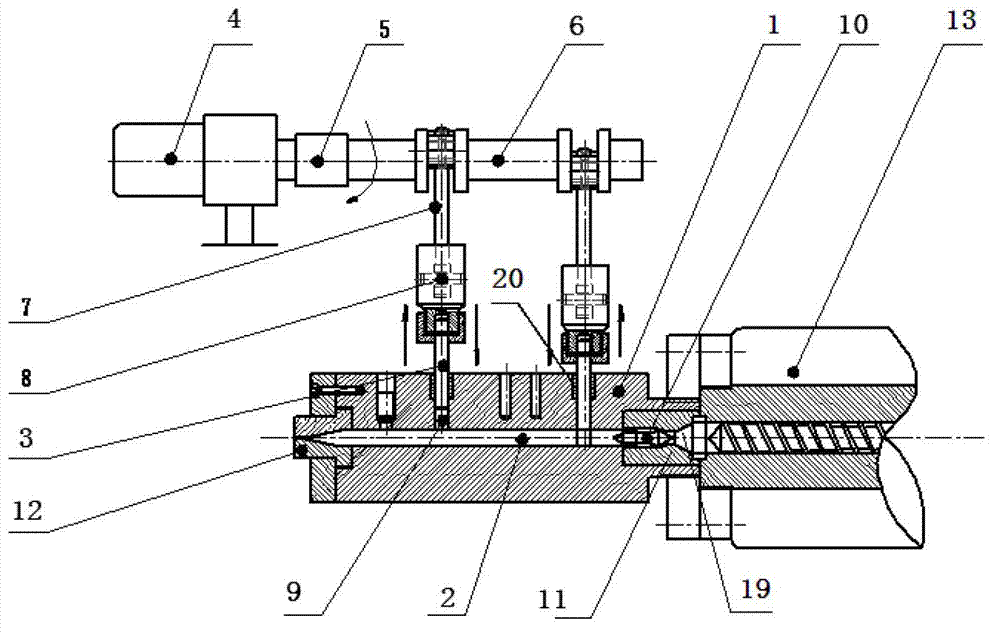

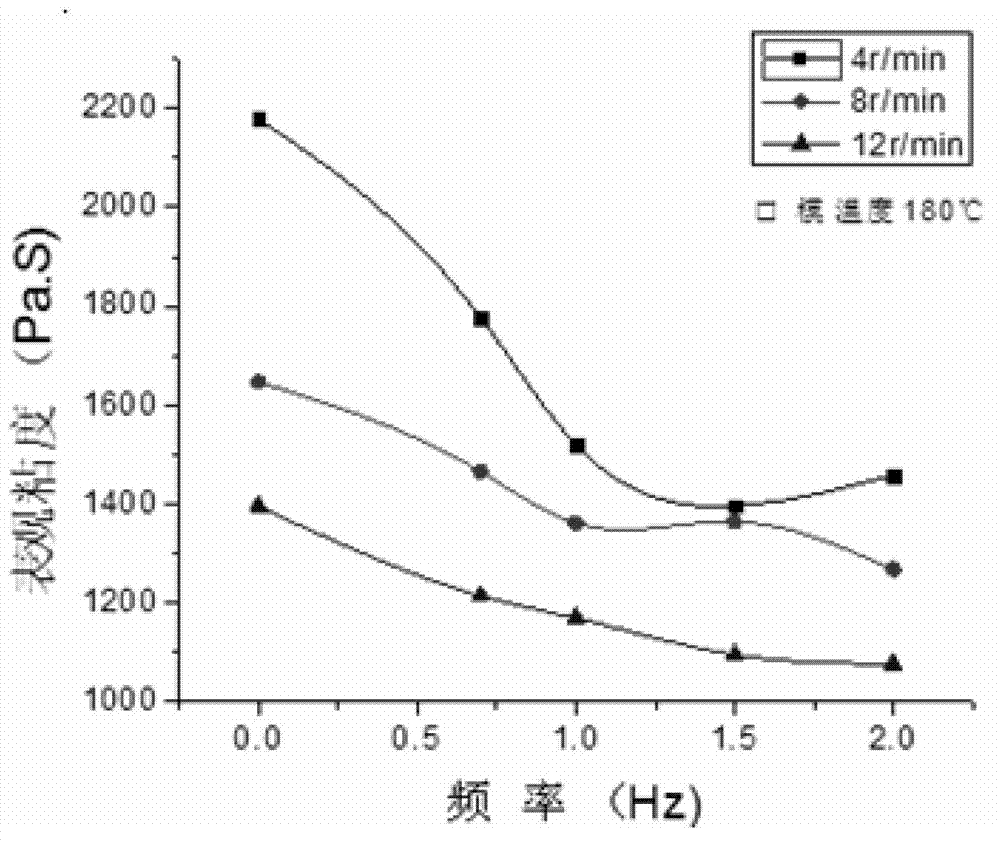

Polymer melt shear vibration extrusion molding device

The invention provides a polymer melt shear vibration extrusion molding device which comprises an extruding machine 13, an extrusion head 1 connected with the extruding machine through a flange plate, a mouth mould 12, a stock mould 14, a cooling water tank 15, a traction device 16 and a cutting device 17, and is characterized by further comprising a crank connecting rod shear vibration system 18 and a melt runner vibration chamber 2, wherein the crank connecting rod shear vibration system 18 is arranged above the extrusion head 1; the melt runner vibration chamber 2 is arranged inside the extrusion head 1; the crank connecting rod shear vibration system is composed of a crank connecting rod mechanism and a reciprocating vibration rod 3; the reciprocating vibration rod 3 is positioned in a through hole 9 formed in the extrusion head 1; the through hole 9 is communicated with the melt runner vibration chamber 2. The device provided by the invention not only can simultaneously promote polymer molecule chain orientation, shish-kebab structure generation and polymer crystalline grain refinement, and improve mechanical property of products, but also can reduce extrusion resistance and improve production efficiency.

Owner:SICHUAN UNIV

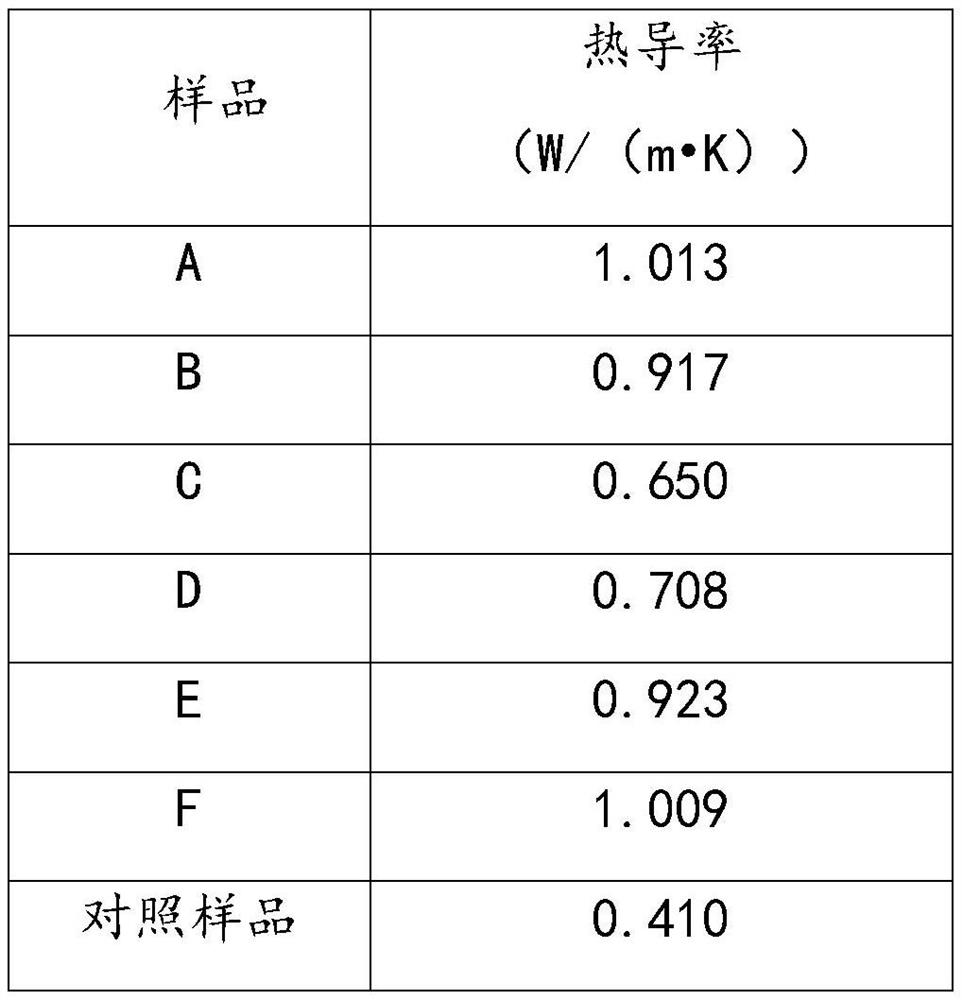

High thermal conductivity acrylic fiber and preparation method thereof

ActiveCN104862807AIncrease contentEasy to processMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceDissolution

The present invention relates to a high thermal conductivity acrylic fiber and a preparation method thereof. The high thermal conductivity acrylic fiber is prepared by adding graphene concentrate during the dissolving of polyacrylonitrile to uniformly disperse the graphene in the polyacrylonitrile spinning stock solution, and conducting wet spinning on the stock solution. The method is as below: first mixing, heating and stirring polyacrylonitrile, graphene concentrate and solvent according to weight ratio until complete dissolution of polyacrylonitrile, and then filtering and removing bubbles to obtain polyacrylonitrile spinning stock solution; and finally conducting wet spinning on the stock solution to obtain the high thermal conductivity acrylic fiber. The high thermal conductivity acrylic fiber contains uniformly dispersed specially treated ultrafine graphene, and the treated graphene have uniform particles, few layers and high activity, does not generate agglomeration phenomenon during addition, and can be well combined with the polyacrylonitrile, thereby significantly improving the thermal performance of acrylic fiber.

Owner:ZHEJIANG TAISUO TECH

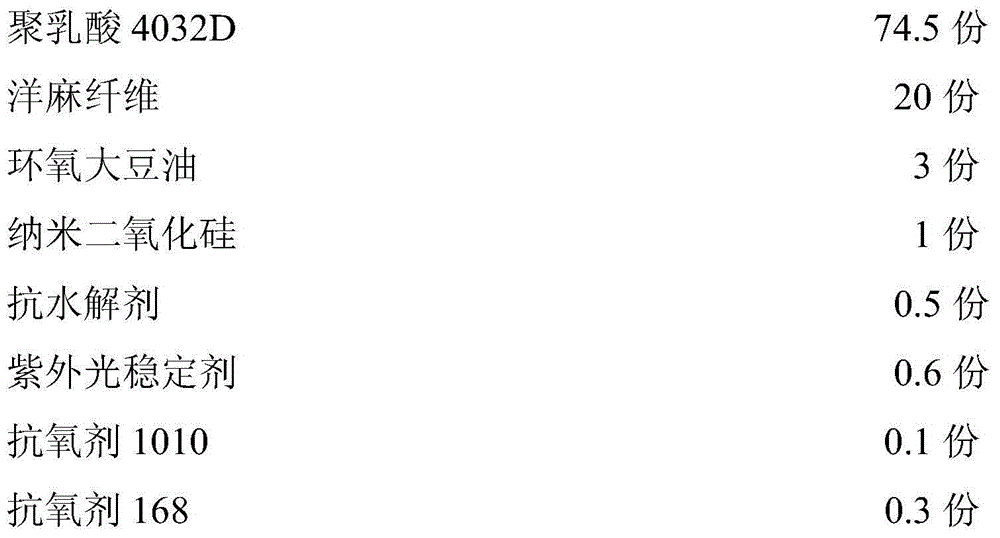

Biological full-degradable polylactic acid/plant fiber composite material as well as preparation method and application thereof

The invention discloses a biological full-degradable polylactic acid / plant fiber composite material as well as a preparation method and an application thereof. The biological full-degradable polylactic acid / plant fiber composite material is prepared from the following raw materials in percentage by weight: 50%-78% of polylactic acid, 20%-35% of a plant fiber, 1%-9% of biological epoxy compounds, 0.5%-4% of inorganic nanoparticles and 0.5%-2% of an assistant. The polylactic acid, the plant fiber and the biological epoxy compounds are all from renewable biomass, have biodegradation characteristics, and completely conform to the requirements of low-carbon, environment-friendly and sustained economic development. The composite material has excellent mechanical properties of high strength and high tenacity, and excellent hydrophobic property, can be prepared by fusing and extruding once; and the method is simple, easy to operate and suitable for industrialized production. In addition, the composite material disclosed by the invention can be applied to preparation of automobile components, can also be applied to the field of preparation of high-grade products such as polylactic acid infant feeding bottles and water glasses, and has a wide application prospect.

Owner:NINGBO HOMELINK ECO ITECH CO LTD

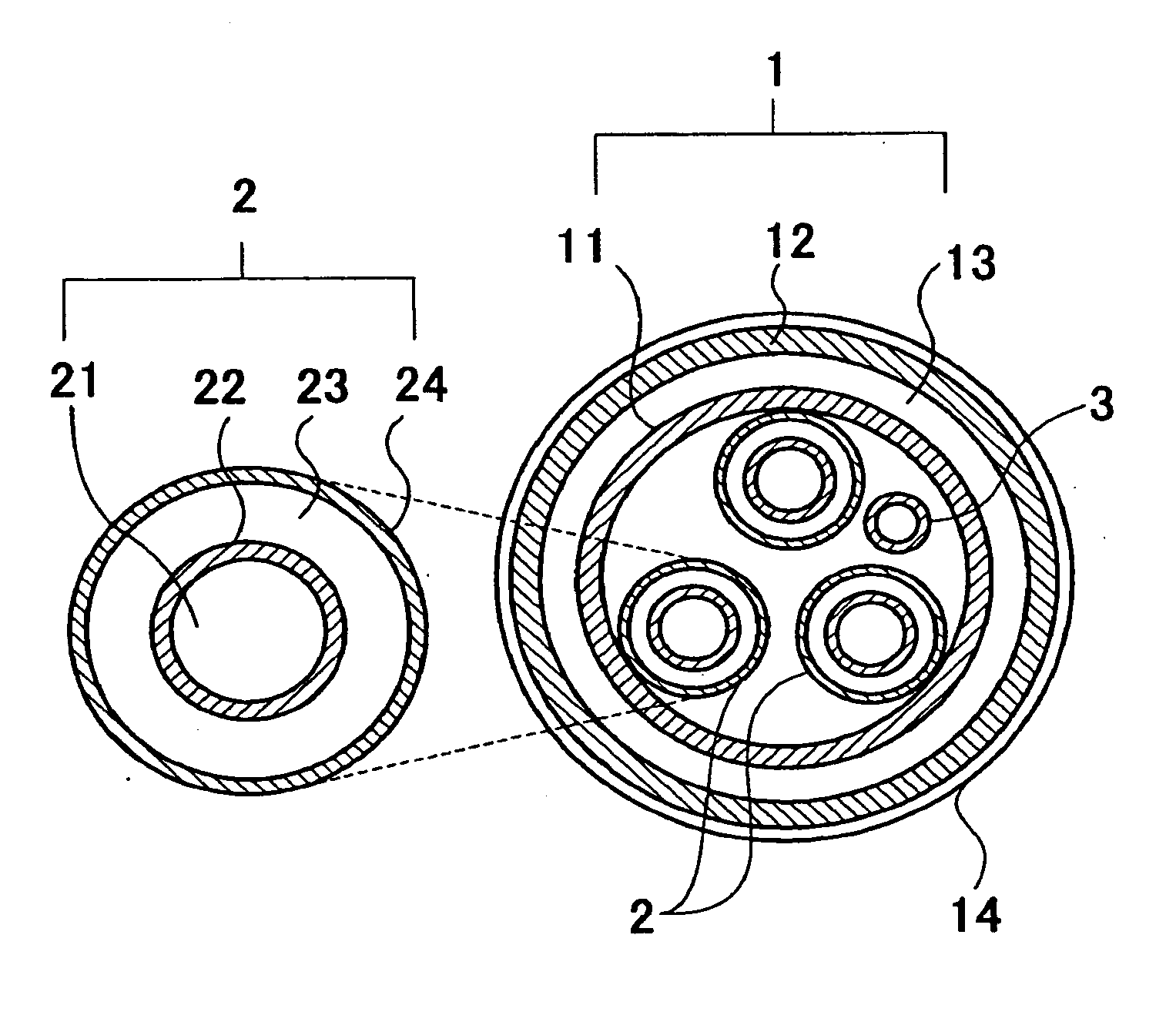

Superconducting cable

InactiveUS20050079980A1Reduce heat lossCompact spaceSuperconductors/hyperconductorsConductive materialNuclear engineeringThermal insulation

A superconducting cable includes: a cable core having a superconducting conductor; a thermal insulation pipe accommodating the cable core and functioning as a forward path of a coolant channel; and a coolant return pipe disposed beside the cable core in the thermal insulation pipe and functioning as a backward path of the coolant channel. A coolant is passed through a space formed between the thermal insulation pipe and the cable core / the coolant return pipe, and cools the cable core and the coolant return pipe. The coolant that has cooled the cable core, etc., returns through the coolant return pipe. Thus, the heat loss of a coolant in the superconducting cable can be minimized, and the space needed for coolant piping can be made compact.

Owner:SUMITOMO ELECTRIC IND LTD

Self-repairing energy generating element using shape memory polymer

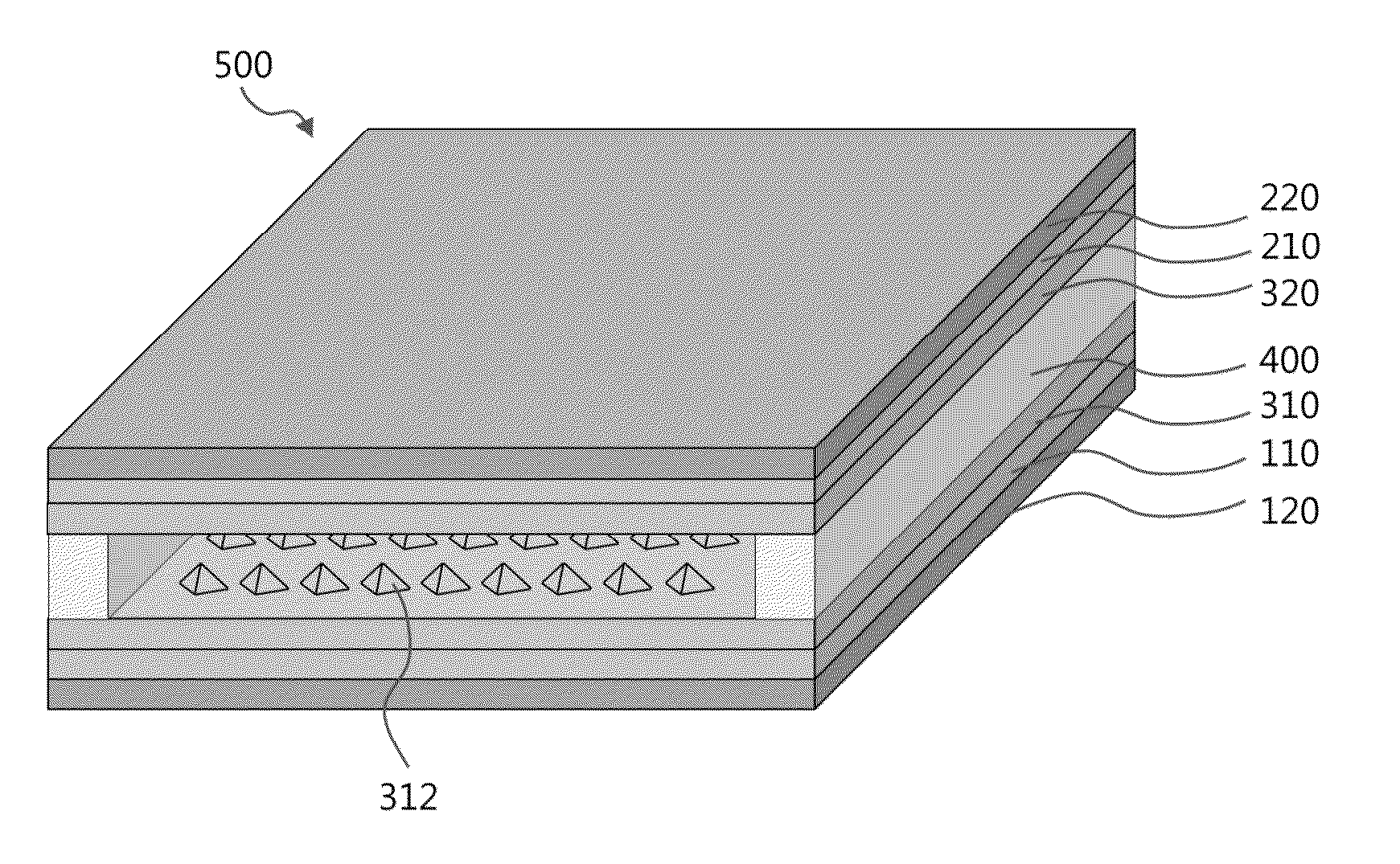

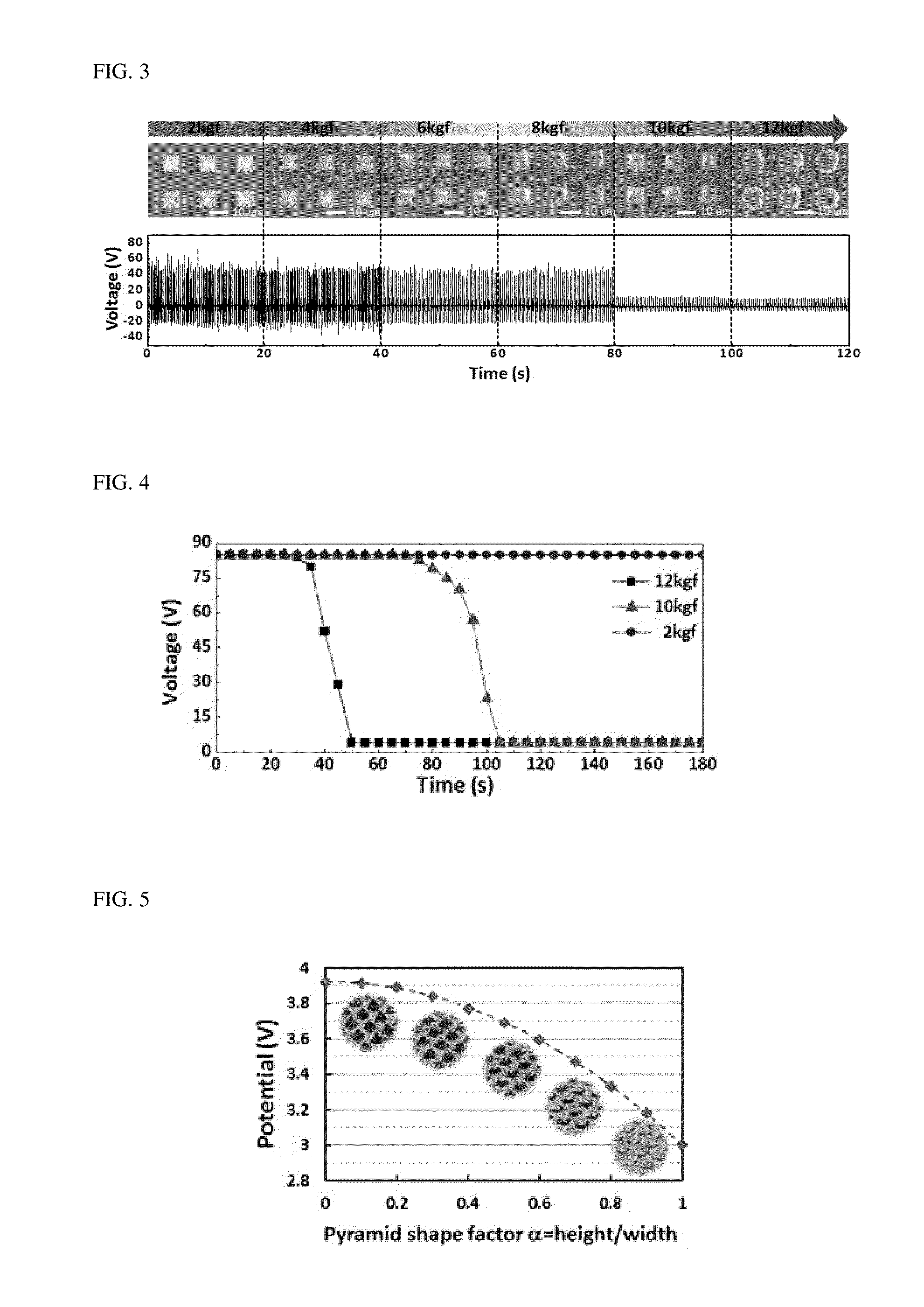

ActiveUS20160087552A1Avoid degradation of mechanical propertiesFriction generatorsEngineeringSelf repair

Provided is a self-repairing energy generating element using a shape memory polymer, including a first electrode; a shape memory friction layer made of the shape memory polymer on the first electrode and having a microbump pattern formed on a surface thereof; a second electrode disposed apart from the shape memory friction layer; and an opposing layer formed on the second electrode and configured to face the shape memory friction layer.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Method for improving Seebeck coefficient of carbon fiber cement-based composite material

The invention provides a method for improving Seebeck coefficient of a carbon fiber cement-based composite material. According to the method, Fe2O3 and / or Bi2O3 powders are added during preparing the carbon fiber cement-based composite material; a linear relation is generated between the thermoelectromotive force and the temperature difference of the carbon fiber cement-based composite material, and the Seebeck coefficient of the carbon fiber cement-based composite material is increased along with the increasing of the quantity of added Fe2O3 and / or Bi2O3 powders, so that the obtained carbon fiber cement-based composite material is high in Seebeck coefficient, stable in thermoelectric property, high in mechanical property, and simple in preparation technology, and avoids the problem that the Seebeck coefficient of the composite material is unstable due to the application of lightweight aggregate, steel slag or crystalline flake graphite; the carbon fiber is free from the technical processing of bromine intercalation, so that the problem due to environmental pollution caused by bromine vapor can be avoided, and the problem that the mechanical property of the cement-based composite material is reduced due to adoption of the lightweight aggregate, the steel slag or the intercalation crystalline flake graphite also can be avoided; and the cement-based composite material can be uniformly dispersed in a cement matrix.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

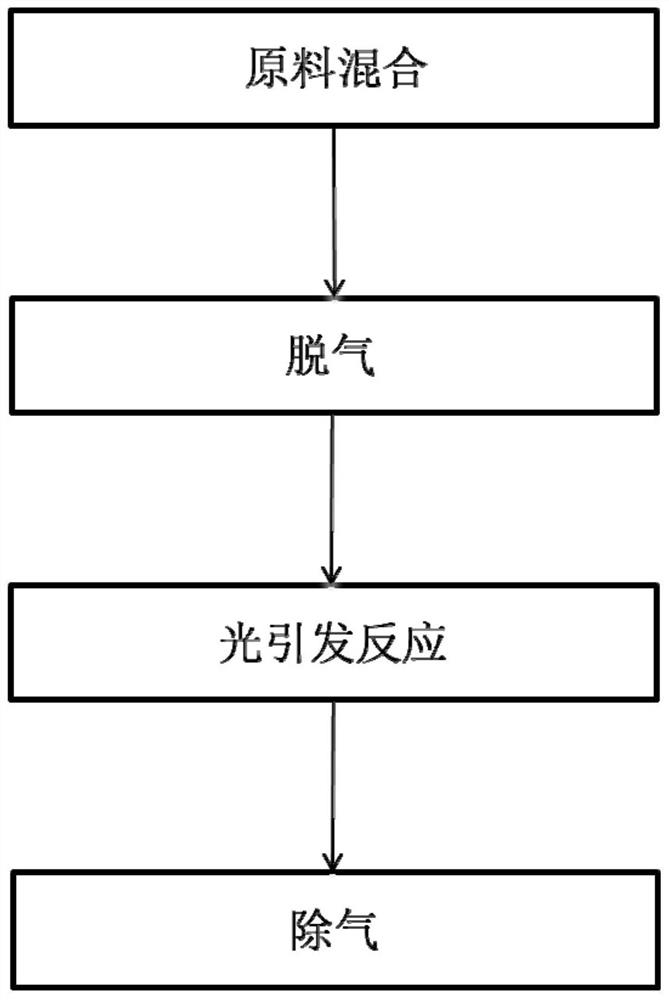

Method for preparing silk fibroin sodium alginate composite fiber

InactiveCN108193311AIncrease the number ofHigh densityConjugated cellulose/protein artificial filamentsPeptidesFiberHydrolysate

The invention discloses a method for preparing a silk fibroin sodium alginate composite fiber and belongs to the technical field of natural macromolecule composite materials. The method comprises thefollowing steps: firstly, mixing, stirring and dissolving silk fibroin with water, performing dialysis, and performing centrifugal separation so as to obtain a pretreated silk fibroin solution; mixingelastinase and the pretreated silk fibroin solution, adjusting the pH value, and performing constant-temperature stirring enzymolysis so as to obtain enzymatic hydrolysate; mixing phospholipid with the enzymatic hydrolysate, performing ultrasonic dispersion, further adding sodium alginate, plant essential oil and monosaccharide, performing a constant-temperature stirring reaction so as to obtaina reaction liquid, mixing the reaction liquid with Carbomer, performing a constant-temperature stirring reaction so as to obtain a spinning solution, performing vacuum defoaming, spinning, washing with water, and performing traction, coiling and drying, thereby obtaining the silk fibroin sodium alginate composite fiber. The silk fibroin sodium alginate composite fiber prepared by using the methodhas good mechanical properties.

Owner:常州凯奥机电科技有限公司

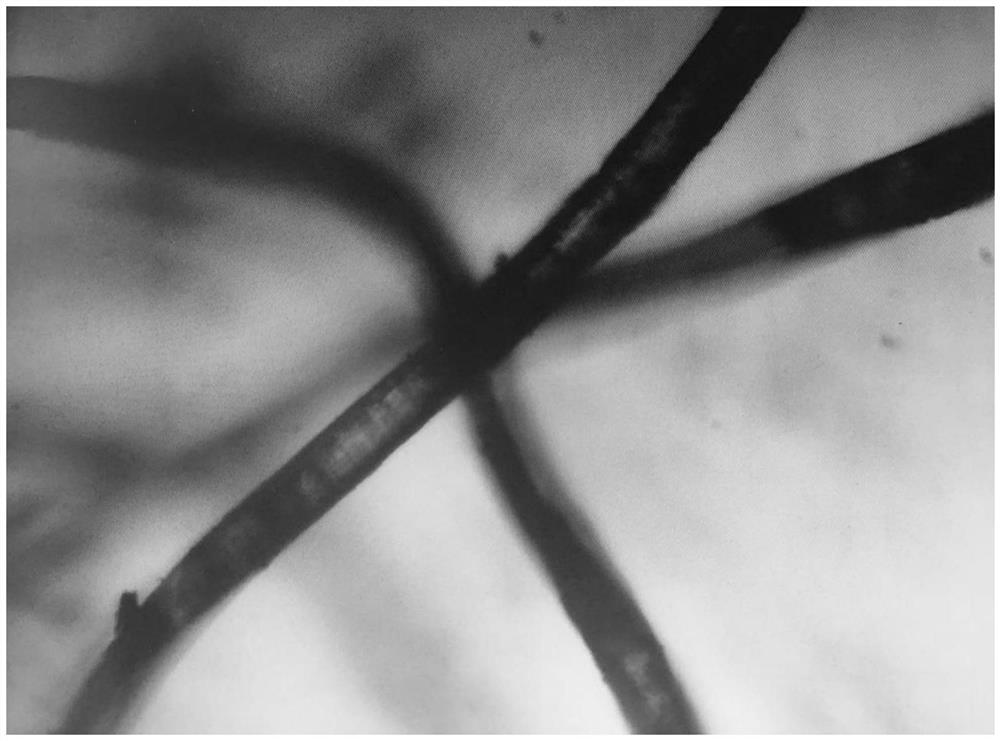

Preparation method and product of biomedical porous implantation body

InactiveCN101617965AAvoid degradation of mechanical propertiesResolve porositySurgeryProsthesisArtificial jointsReticular formation

Aiming to solve the problems that the mechanical property of the implant is reduced and that the mineralization bone is not easily formed in the implant existing in the technology for preparing the biomedical porous implant, the invention provides a biomedical porous implant and a method for preparing the same. The method comprises the following steps of: interweaving threads of the implant material to form a netty structure; pressing the netty structure into an implant coarse blank with a special shape; sintering the implant coarse blank so as to allow the material threads at cross points in the netty structure to form melting connection to prepare the implant. The plantation body prepared by the method can be used for preparing biomedical porous nickel-titanium alloy implants such as denda, artificial joints and the like and realizing the deep freezing treatment of hemangioma, ecphymata and keloid by carrying liquid nitrogen.

Owner:BEIJING SMART TECH

Super-toughened polyamide resin and preparation method thereof

The invention provides super-toughened polyamide resin and a preparation method thereof. The super-toughened polyamide resin comprises the following production raw materials: 20 to 65 parts of dicarboxylic acid, 20 to 70 parts of aliphatic diamine, 3 to 30 parts of an elastic component, 0.01 to 0.06 part of a first catalyst, 0.01 to 0.06 part of a second catalyst and 30 to 160 parts of deionized water. The super-toughened polyamide resin prepared by using the method provided by the invention has good mechanical properties and melt fluidity; in addition, compared with the toughness of ordinarypolyamide resin, the toughness of the super-toughened polyamide resin is significantly improved.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

A preparation process of inorganic diaphragm based on mesoporous material

PendingCN109244315AImprove securityAvoid membrane brittlenessSecondary cellsCell component detailsSolventMolecular sieve

The invention provides a preparation process of an inorganic diaphragm based on mesoporous material, which comprises the following steps of: dissolving silicon oxide and mesoporous material in a preset mass ratio in a solvent and uniformly stirring to obtain a suspension; adding a suitable amount of bind and dispersant into that suspension, and performing fully stirring at a preset stirring speedto obtain the inorganic coat slurry; coating a surface of that battery substrate with the inorganic coating slurry, and performing drying at a preset temperature for a period of time to prepare an electrode-supported inorganic diaphragm. The invention combines ceramic powder with mesoporous molecular sieve to prepare diaphragm slurry, which not only ensures high safety of inorganic diaphragm, butalso avoids defects of brittleness and polycrystallinity of diaphragm, and is beneficial to improving liquid-retaining capacity of diaphragm and energy density of battery. The synthesized diaphragm has the characteristics of ultra-light, good adhesion with the substrate, and good flexibility, can effectively avoid the problem that the mechanical properties of the diaphragm become worse when the inorganic diaphragm is made of a single ceramic material.

Owner:CHINA ELECTRIC POWER RES INST +2

High-temperature-resistant and flame-retardant organic glass

InactiveCN109096672APrevent extensionAvoid problems that degrade mechanical propertiesTemperature resistanceOrganic glass

The invention discloses high-temperature-resistant and flame-retardant organic glass which comprises, by weight parts, 80-100 parts of methyl methacrylate, 10-15 parts of styrene, 15-20 parts of alpha-fluoromethyl acrylate, 20-25 parts of rubber particles, 10-15 parts of composite flame retardant, 1-2 parts of initiator and 2-3 parts of crosslinking agent. The high temperature resistance of the high-temperature-resistant and flame-retardant organic glass is improved by introducing fluorine element and styrene and adding modified silicone rubber, the flame retardancy of the high-temperature-resistant and flame-retardant organic glass is improved by adding a suitable flame retardant system, the impact resistance of the high-temperature-resistant and flame-retardant organic glass is improvedthrough the combined action of the modified silicone rubber, a silane coupling agent, modified nano magnesium hydroxide and a crosslinking agent, and the problem of reduced mechanical properties of the organic glass is solved.

Owner:蚌埠承永玻璃制品有限公司

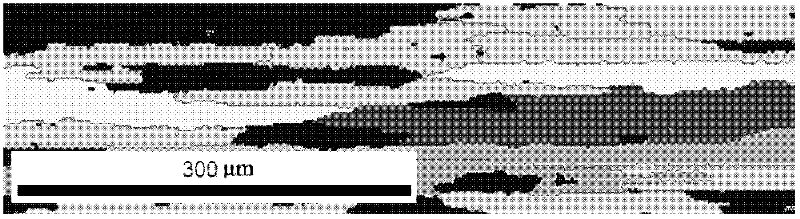

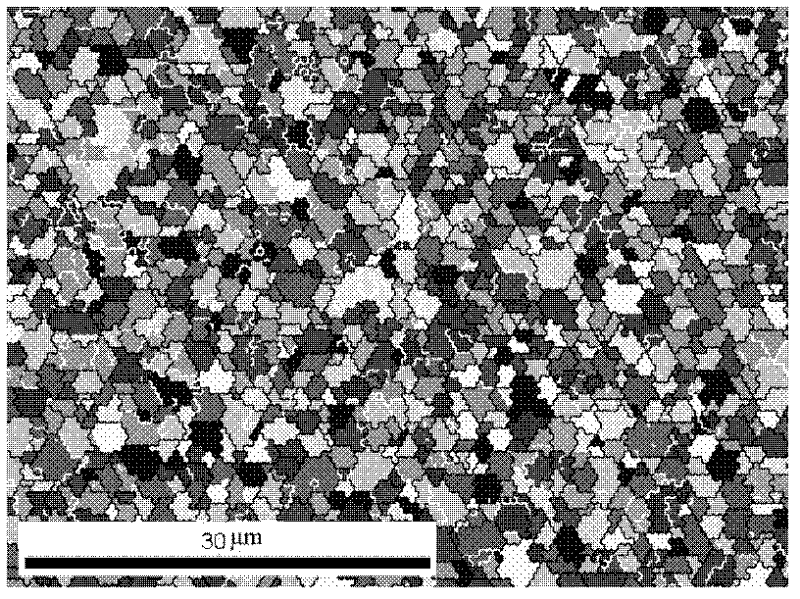

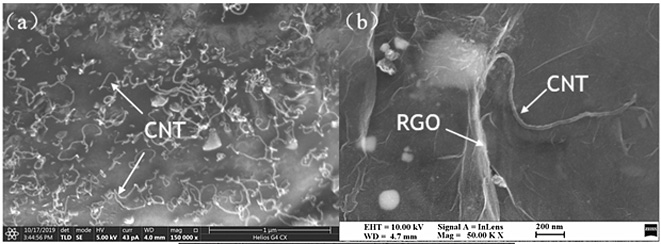

Three-dimensional carbon nanophase composite reinforced aluminum-based material and preparation method thereof

ActiveCN111996418AGuaranteed decentralizationAvoid mechanical degradationTransportation and packagingMetal-working apparatusEthylenediaminesBisphenol

The invention discloses a three-dimensional carbon nanophase composite reinforced aluminum-based material and a preparation method thereof. The preparation method comprises the steps of firstly, immersing aluminum powder into ethanol solutions containing bisphenol A diglycidyl ether and nickel nitrate hexahydrate, magnetically stirring, and dropwise adding ethylenediamine to obtain the aluminum powder with the surface treated; then, mixing the aluminum powder with the surface treated after reduction and graphene oxide, and ball-milling the mixtures at low speed, and obtaining the aluminum powder coated with three-dimensional carbon nanophases after reduction; and finally performing SPS sintering and cold-rolling for the aluminum powder to obtain the three-dimensional carbon nanophase composite reinforced aluminum-based material. The preparation method is simple process, easy in operation and low in cost; according to the obtained composite reinforced aluminum-based material, through construction of the three-dimensional carbon nanophases, the load transfer efficiency is improved, so that the mechanical property of the aluminum-based composite material is improved obviously; the aluminum-based material not only is high in tensile strength, but also remains higher elongation and toughness, and is high in generalizability.

Owner:FUZHOU UNIV

Preparation method of high-thermal-conductivity composite material

The invention discloses a preparation method of a high-thermal-conductivity composite material. The method comprises the following steps: adding a heat conduction material, a dispersing agent, a natural organic polymer material and polymer powder into an aqueous solution in parts by weight, and carrying out pre-dispersion treatment; after pre-dispersion treatment, transferring the mixture into anautoclave reactor for heat treatment; after heating treatment, carrying out drying treatment, adding the dried product into an organic solvent after drying, grinding, carrying out an electrostatic spinning technology to obtain micron-sized mixed heat-conducting polymer fiber yarns, and carrying out melt extrusion and granulation on the heat-conducting polymer fiber yarns by using a double-screw extruder to obtain the high-heat-conducting polymer master batch. The high-heat-conducting polymer master batch has the advantages of low addition amount of a heat-conducting filler, excellent heat-conducting property, favorable dispersity and the like, has favorable mechanical properties, obtains high heat conductivity, has favorable mechanical properties, and solves the problems of poor affinity and non-uniform dispersion between heat-conducting filler and a polymer matrix, higher heat conductivity, lower mechanical properties and the like.

Owner:中节能(唐山)环保装备有限公司 +1

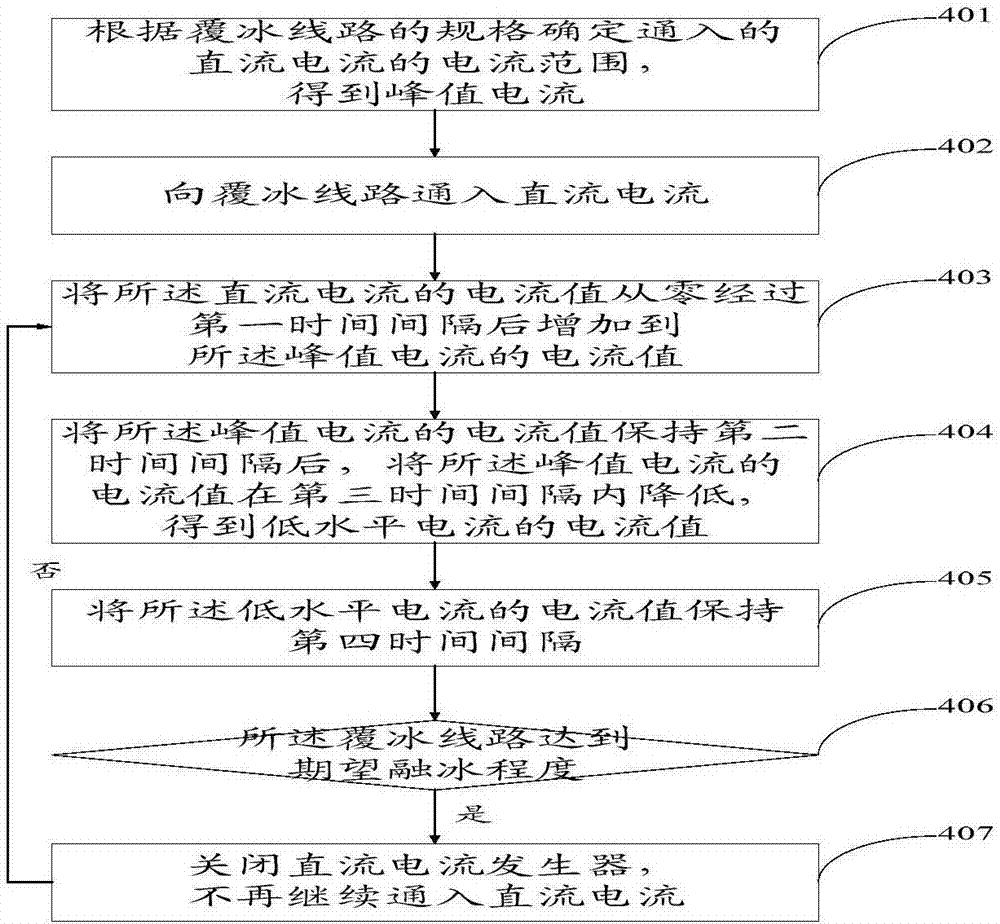

Deicing method and apparatus for connecting direct current to ice-covered circuit

ActiveCN106877265AUniform and stable temperatureUniform and stable temperature rangeOverhead installationCurrent rangeDc current

The invention discloses a deicing method and apparatus for connecting a direct current to an ice-covered circuit. The deicing method comprises the steps of determining a current range of the connected direct current according to the specification of the ice-covered circuit to obtain a peak current; connecting the direct current to the ice-covered circuit; increasing the current value of the direct current from zero to the current value of the peak current after a first time interval; maintaining the current value of the peak value for a second time interval, and then reducing the current value of the peak value in a third time interval to obtain a low-low current value; maintaining the low-low current value for a fourth time interval; judging whether the ice-covered circuit achieves an expected deicing degree or not, if not, not connecting the direct current; and if so, returning to execute the step of increasing the direct current from zero to the peak current after the first time interval. By adoption of the deicing method and apparatus disclosed by the invention, the deicing efficiency is effectively improved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

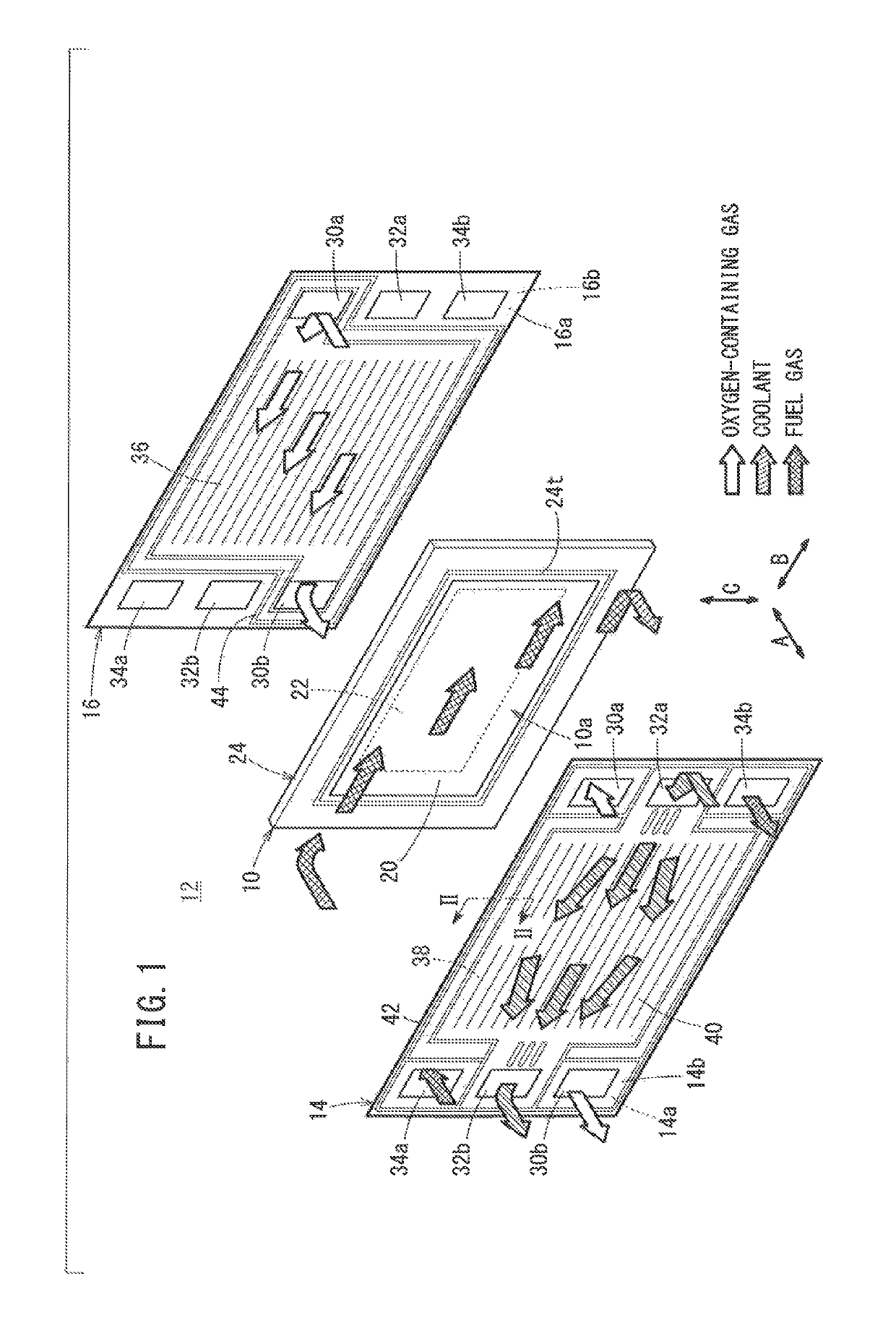

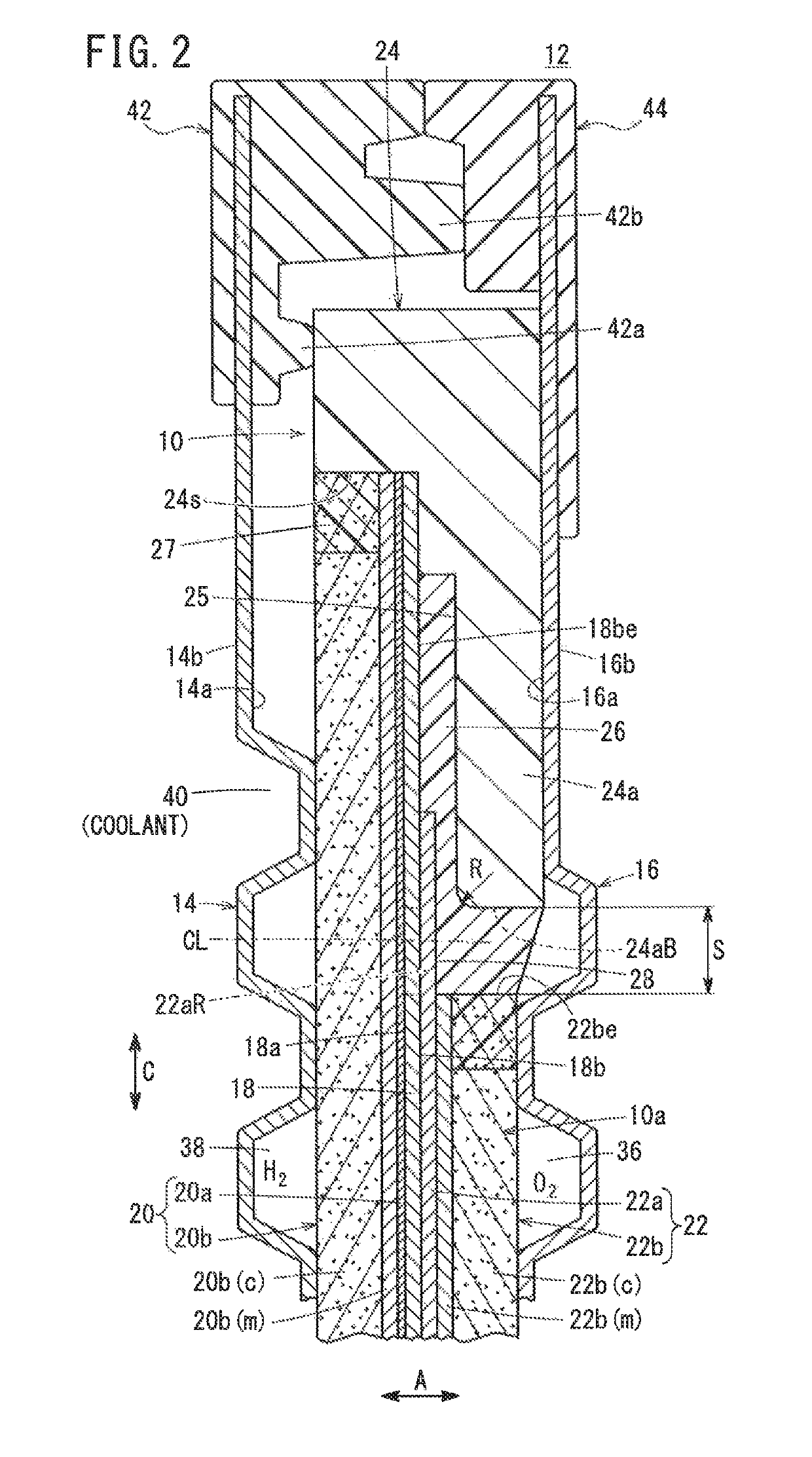

Resin frame equipped membrane electrode assembly for fuel cell

ActiveUS10381661B2Significant dimensional changeEasy to transformMotive system fuel cellsTransportation fuel cell technologyFuel cellsEngineering

Owner:HONDA MOTOR CO LTD

Heat-resistant and crack-resistant polyethylene material for water horse

The invention discloses a heat-resistant and crack-resistant polyethylene material for a water horse. The heat-resistant and crack-resistant polyethylene material comprises the following raw materialsin parts by weight: 150-200 parts of a mixed main material, 70-90 parts of a composite filler, 20-25 parts of maleic anhydride grafted polyolefin, 20-30 parts of microcapsulated red phosphorus, 15-20parts of melamine, 6-8 parts of silicone powder, 7-9 parts of epoxidized soybean oil, 5-7 parts of Si69, 1-1.5 parts of vinyltriethoxysilane, 8-1.2 parts of double 25, 0.6-0.8 part of stannous octoate, 0.5-1 part of an anti-aging agent 264 and 1-1.5 parts of UV-531. The heat-resistant and crack-resistant polyethylene material provided by the invention is good in heat resistance, high in toughnessand good in crack resistance.

Owner:芜湖盈奇塑业有限公司

High-strength and high-toughness long carbon fiber reinforced nylon composite and preparation method thereof

InactiveCN106675015APrevents precipitation and blooming problemsAvoid degradation of mechanical propertiesCarbon chainAntioxidant

The invention discloses a high-strength and high-toughness long carbon fiber reinforced nylon composite and a preparation method thereof. The nylon composite is prepared from the following raw materials in parts by weight: 40 to 80 parts of nylon 610, 20 to 30 parts of nylon 6, 20 to 60 parts of long carbon fiber, 0.5 to 1 part of lubricant and 0.1 to 1.5 parts of antioxidant. The high-strength and high-toughness long carbon fiber reinforced nylon composite provided by the invention has the advantages that firstly, long carbon chain nylon is selected as a nylon base material and has low water absorption and high toughness; secondly, the high rigidity of long carbon fiber makes up the insufficient rigidity of nylon 610 and nylon 6; thirdly, the viscosity of a nylon melt can be greatly reduced by adding the lubricant so as to improve the impregnation effect of nylon on carbon fiber; finally, 4, a toughening agent does not need to be added, so that the effect of reduction in mechanical property caused by addition of the toughening agent is avoided.

Owner:SHANGHAI PRET COMPOSITES +4

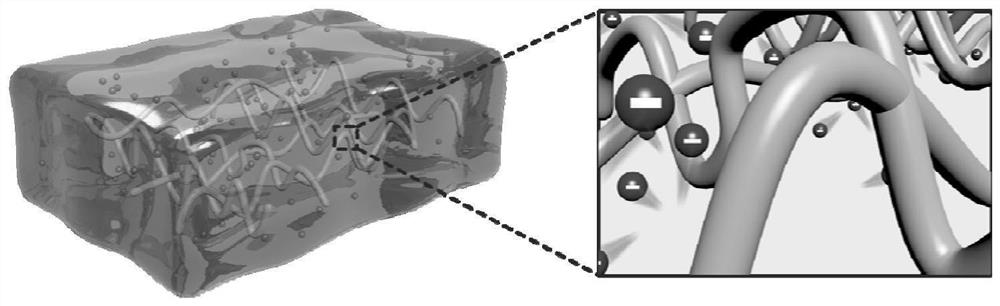

Method for preparing a conductive resin composition

ActiveCN107099077AAvoid degradation of mechanical propertiesGood electrical conductivityOlefin polymerizationMasterbatch

The present invention provides a method for preparing a conductive resin composition. According to one aspect of the present invention, a masterbatch comprising a high content of a conductive filler is prepared by mixing a conductive filler and a first olefin polymer resin. The first olefin polymer resin is mixed with the same or different kinds of the second olefin polymer resin, so that the mechanical properties of the olefin polymer resin can be prevented from being lowered and good electrical conductivity can be realized.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Anti-static wear-resistant dust collecting bag material

InactiveCN108970246AImprove hydrophilicityImprove dyeing effectElectroconductive/antistatic filament manufactureDispersed particle filtrationEpoxyAntioxidant

The invention discloses an anti-static wear-resistant dust collecting bag material, which is prepared from the following materials in parts by weight: 10-25 parts of modified phenolic resin, 10-15 parts of nitrile rubber, 70-90 parts of polyamide, 20-30 parts of PBT, 10-15 parts of PET, 0.5-1 part of polytetrafluoroethylene powder, 1-2 parts of epoxy rein, 1-2 parts of modified organic silicon resin, 10-15 parts of polydiphenyl terephthalate propane ester, 1-5 parts of graphite powder, 0.5-1 part of potassium iodide, 10-13 parts of polyethylene glycol, and 0.5-1 part of antioxidant.

Owner:ANHUI YUANYE FILTER MATERIAL

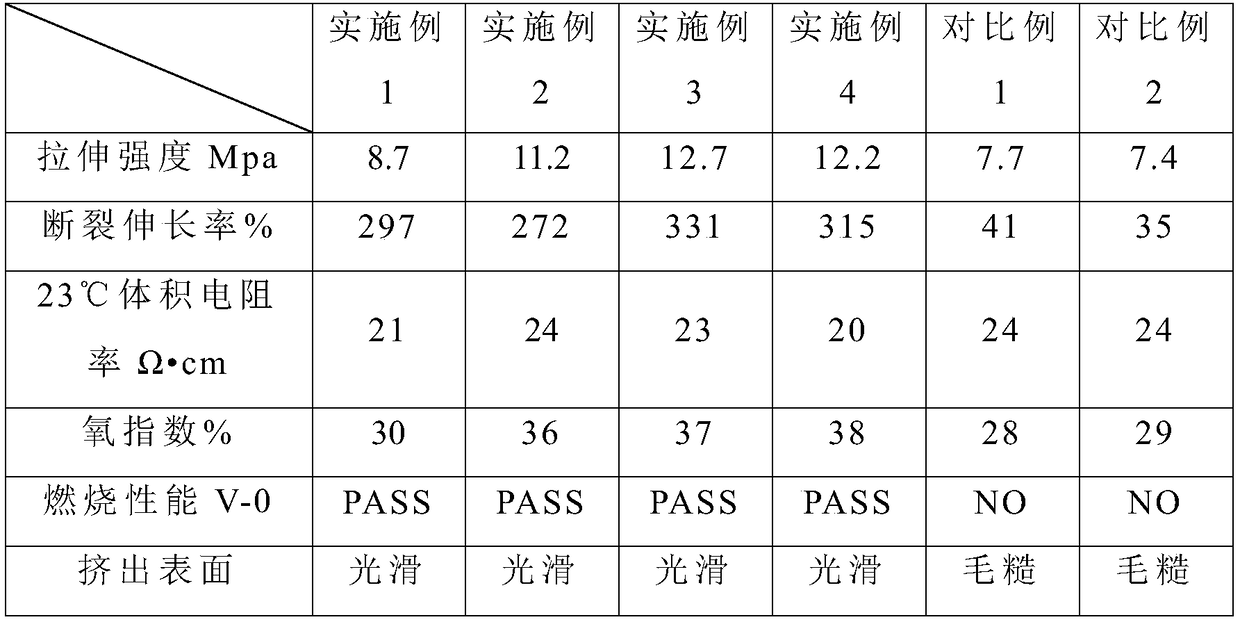

Flame-retardant semiconductive sheathing material for coal mine gas tubes, and preparation method and application thereof

The invention discloses a flame-retardant semiconductive sheathing material for coal mine gas tubes, and a preparation method and application thereof. The flame-retardant semiconductive sheathing material comprises high-density polyethylene, an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a flame retardant and conductive carbon black. The flame retardant comprises ammonium polyphosphate, melamine cyanurate, and a combination of one or more of pentaerythritol and a derivative thereof; the conductive carbon black accounts for 30% or more of the raw materials by mass. The preparation method includes 1) mixing components of resin to obtain a first mixture; 2) mixing the other remaining raw materials to obtain a second mixture; 3) respectively feeding the first mixture and the second mixture into a main feeding bucket and a lateral feeding bucket of a twin-screw extruder, and performing melting and extruding to obtain the flame-retardant semiconductive sheathing material.The invention further provides a gas exhaust tube. The gas exhaust tube comprises an exhaust tube body and a sheath covering the exhaust tube body; the sheath is made from the sheathing material. Thesheathing material has the advantage that high electrical conductivity, high flame retardance and excellent mechanical property can be maintained.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Antistatic polyamide composite material and preparation method thereof

PendingCN110511375AImprove the characteristics of easy agglomerationImprove conduction efficiencyThermal deformationPolyamide

The invention provides an antistatic polyamide composite material, which comprises the following production raw materials: 20-80 parts of aliphatic / aromatic dibasic acid, 0.2-10 parts of dibasic acidcontaining a sulfonate group, 20-80 parts of aliphatic diamine, 2-30 parts of a graphene aqueous solution, 0.1-0.4 part of an end-capping reagent, 0.01-0.06 part of a catalyst, and 30-160 parts of deionized water. The invention further provides a preparation method of the composite material. According to the present invention, the prepared antistatic polyamide composite material has advantages ofgood antistatic property, good mechanical property, excellent compatibility, good heat resistance, high thermal deformation temperature, expanded application range and reduced production cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Intrinsic conductive elastomer, preparation method thereof and flexible device

PendingCN113214431AImprove stabilityAvoid degradation of mechanical propertiesElastomerPolymer science

The invention provides an intrinsic conductive elastomer, a preparation method thereof and a flexible device. The structural formula of the intrinsic conductive elastomer is shown in the specification, R1 comprises hydrogen or methyl, R2 comprises an ester group or phenylene, R3 is-(CH2) m-or-(CH2CH2O) n-, and m and n are respectively and independently positive integers from 1 to 8; and X< + > is an imidazole cation, a pyridine cation, a pyrrole cation, a piperidine cation, a quaternary ammonium cation or a quaternary phosphonium cation, and Y <-> is any one of a chloride ion, a bromide ion, a tetrafluoroboric acid ion, a hexafluorophosphate ion or a bis (trifluoromethylsulfonyl) imide anion. The preparation method of the intrinsic conductive elastomer comprises the following steps: mixing the raw materials including the functional ionic liquid monomer, the comonomer, the cross-linking agent and the initiator, and reacting to obtain the intrinsic conductive elastomer. The raw material of the flexible device comprises the intrinsic conductive elastomer. The intrinsic conductive elastomer has the characteristics of high tensile property, high transparency and excellent stability.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN

High-bending-resistance hold hoop joint mechanically connected with precast concrete beam-column pile rods

PendingCN109989487AImprove connection quality and performanceEliminate machining deviation and assembly clearanceBuilding constructionsBulkheads/pilesThreaded fastenerPrecast concrete

The invention relates to a high-bending-resistance hold hoop joint mechanically connected with a precast concrete beam-column pile rod. The hold hoop joint comprises two reinforcing hoops which are oppositely arranged, and a plurality of reinforcing ribs are fixedly connected to the inner side of each reinforcing hoop; a positioning groove and a sealing groove are horizontally formed in the outercircle face of each reinforcing hoop at intervals, a stress ring is arranged in each positioning groove, and a sealing ring is arranged in each sealing groove. An outer hoop sleeves the outer side ofthe two reinforcing hoops, a groove corresponding to each positioning groove is formed in the inner side wall of the outer hoop, a threaded fastener penetrating through the grooves is arranged on theouter hoop, and the threaded fastener is used for fixing the outer hoop and the stress rings to the reinforcing hoops in an abutting mode together. According to the hold hoop joint, manual welding process operation is avoided, the quality is controllable, mechanical connection is reliable, the labor intensity is reduced, the anti-corrosion performance is good, the steel consumption is extremely low, and the product cost and the construction cost are greatly reduced.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

Electrode and preparation method thereof

InactiveCN110980889AHigh activityImprove stabilityWater/sewage treatment using germicide/oligodynamic-processIridiumRuthenium

The invention relates to the field of electrochemical electrode preparation, and especially relates to an electrode. The electrode comprises a matrix and an active layer, and the matrix is any one ofa titanium matrix, a copper matrix, a nickel matrix and graphite or carbon nanofibers; and the active layer is any one of a ruthenium-iridium active layer and a graphene active layer. The electrode prepared by taking any one of the titanium matrix, the copper matrix, the nickel matrix and graphite or carbon nanofibers as the matrix and taking the ruthenium-iridium active layer or the graphene active layer as tje active layer has high activity and high stability. Compared with a common electrode, the electrode has better electrocatalytic activity, and the electrocatalytic activity is shown as rising of oxygen evolution potential and lowering of chlorine evolution potential.

Owner:北京丰舜通环保科技有限公司

Crack-resistant silicone rubber cable sheath material and preparation method thereof

ActiveCN109206920BImprove cooling efficiencyImprove aging resistanceRubber insulatorsCelluloseParaffin wax

The invention proposes a crack-resistant silicone rubber cable sheath material, which includes the following raw materials: methyl vinyl silicone rubber, hydrogenated nitrile rubber, chlorinated polyethylene, vulcanizing agent, accelerator, paraffin, anti-aging agent RD, Plasticizer, lubricant, carbon black, silicon micropowder, flame retardant reinforcing agent and filler; the plasticizer is composed of dibutyl phthalate and polyether silicone oil, and the flame retardant reinforcing agent is mainly composed of It is prepared from slag, nano silicon dioxide, carboxymethyl cellulose and coupling agent. Preparation method: Put the above-mentioned raw materials into the internal mixer for internal mixing, and then transfer to the open mill for thinning and rolling, put the thinned film into the three-roller sheeting machine for rolling and cutting, and open the cooling drum Cooling water, pass the cut film through the cooling drum, and then through the isolation powder tank to make a film. The anti-crack silicone rubber cable sheath material not only has good flame retardant and environmental protection performance, but also has excellent tensile strength and crack resistance.

Owner:宁波金三湖科技有限公司

Polymer melt shear vibration extrusion molding device

The invention provides a polymer melt shear vibration extrusion molding device which comprises an extruding machine 13, an extrusion head 1 connected with the extruding machine through a flange plate, a mouth mould 12, a stock mould 14, a cooling water tank 15, a traction device 16 and a cutting device 17, and is characterized by further comprising a crank connecting rod shear vibration system 18 and a melt runner vibration chamber 2, wherein the crank connecting rod shear vibration system 18 is arranged above the extrusion head 1; the melt runner vibration chamber 2 is arranged inside the extrusion head 1; the crank connecting rod shear vibration system is composed of a crank connecting rod mechanism and a reciprocating vibration rod 3; the reciprocating vibration rod 3 is positioned in a through hole 9 formed in the extrusion head 1; the through hole 9 is communicated with the melt runner vibration chamber 2. The device provided by the invention not only can simultaneously promote polymer molecule chain orientation, shish-kebab structure generation and polymer crystalline grain refinement, and improve mechanical property of products, but also can reduce extrusion resistance and improve production efficiency.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com