Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "ZINC LAURATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

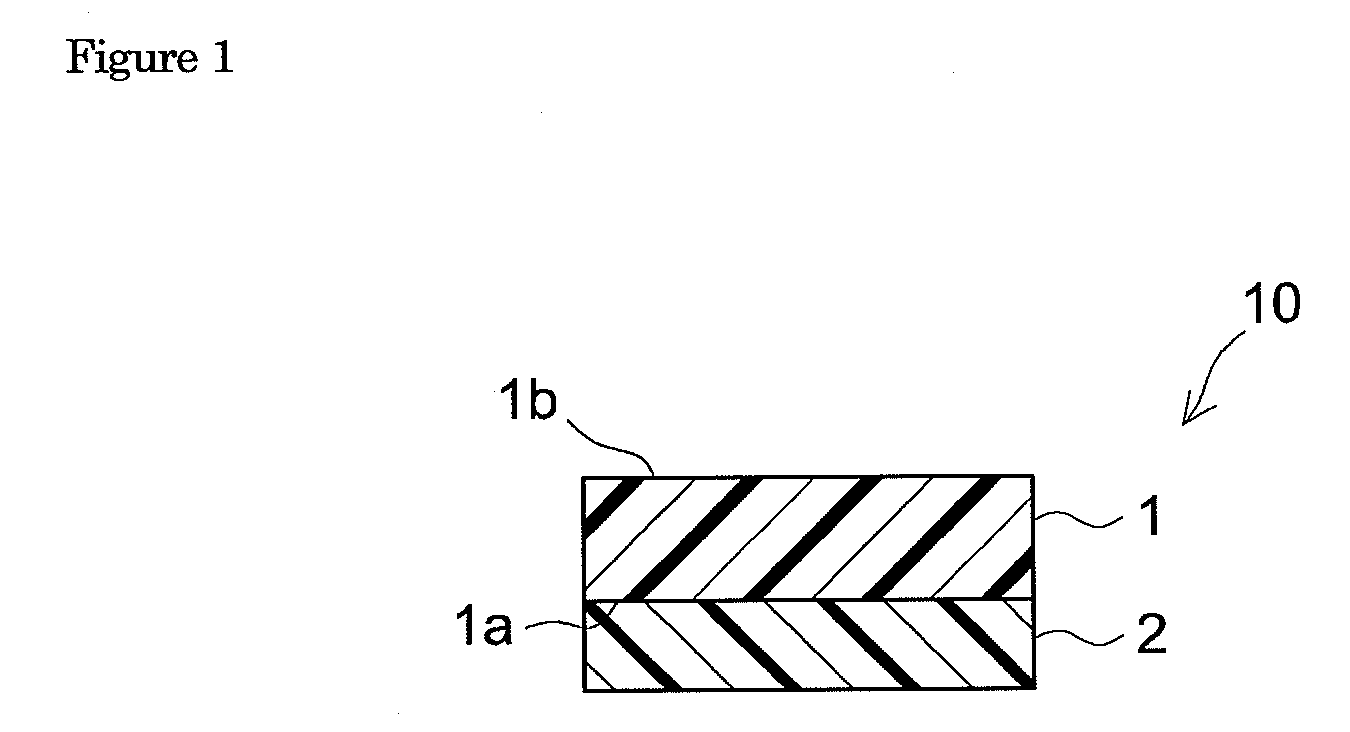

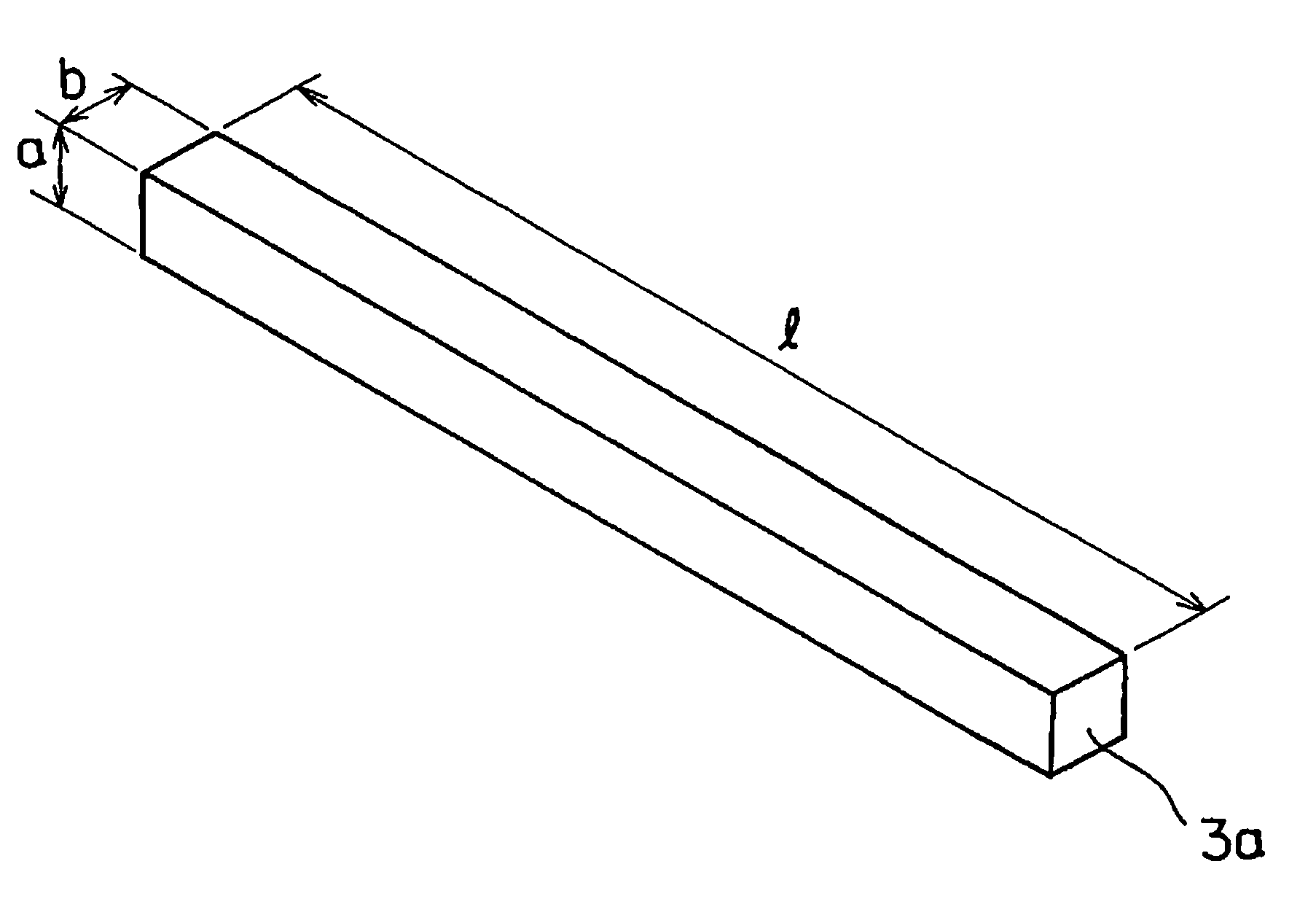

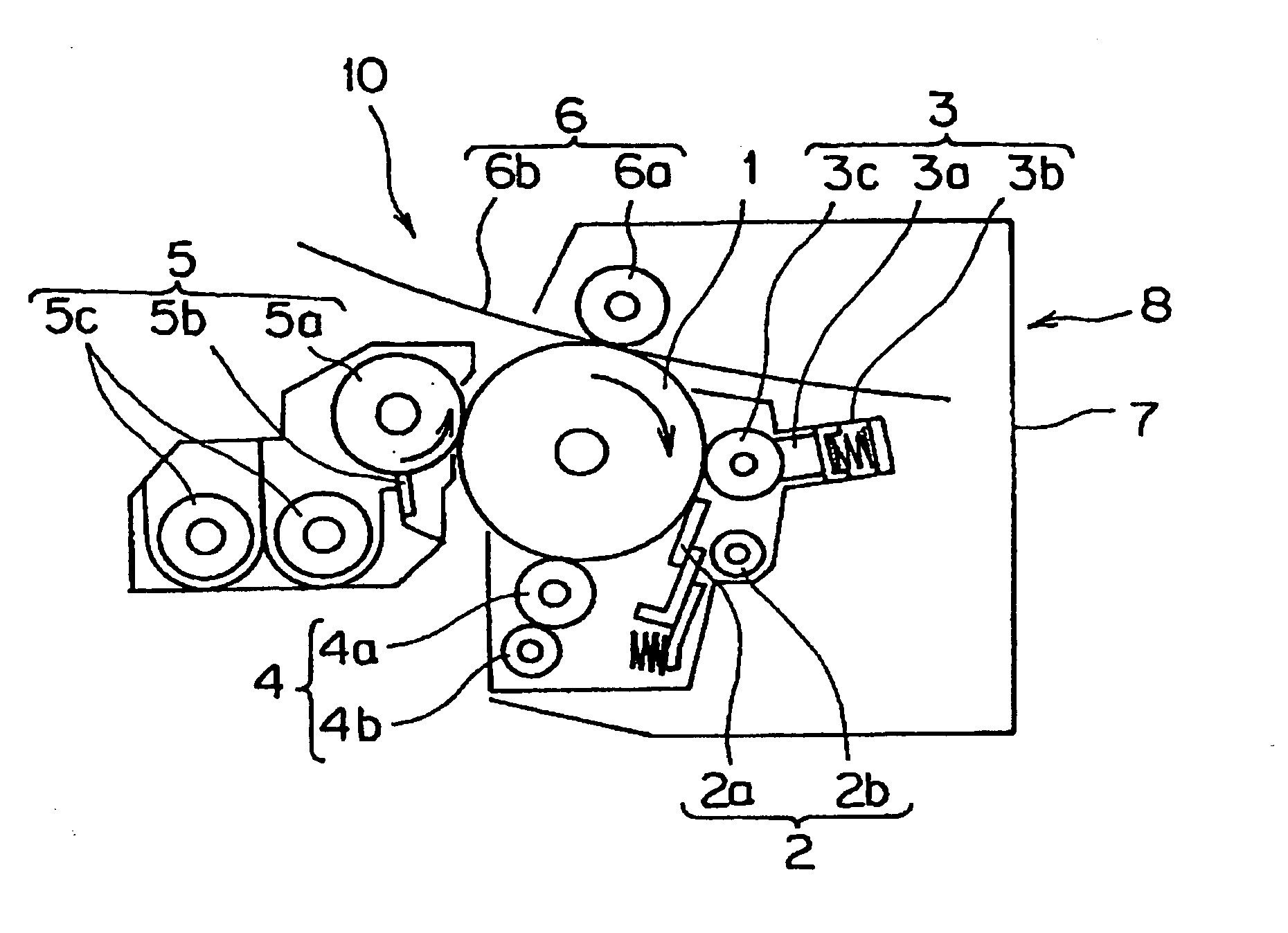

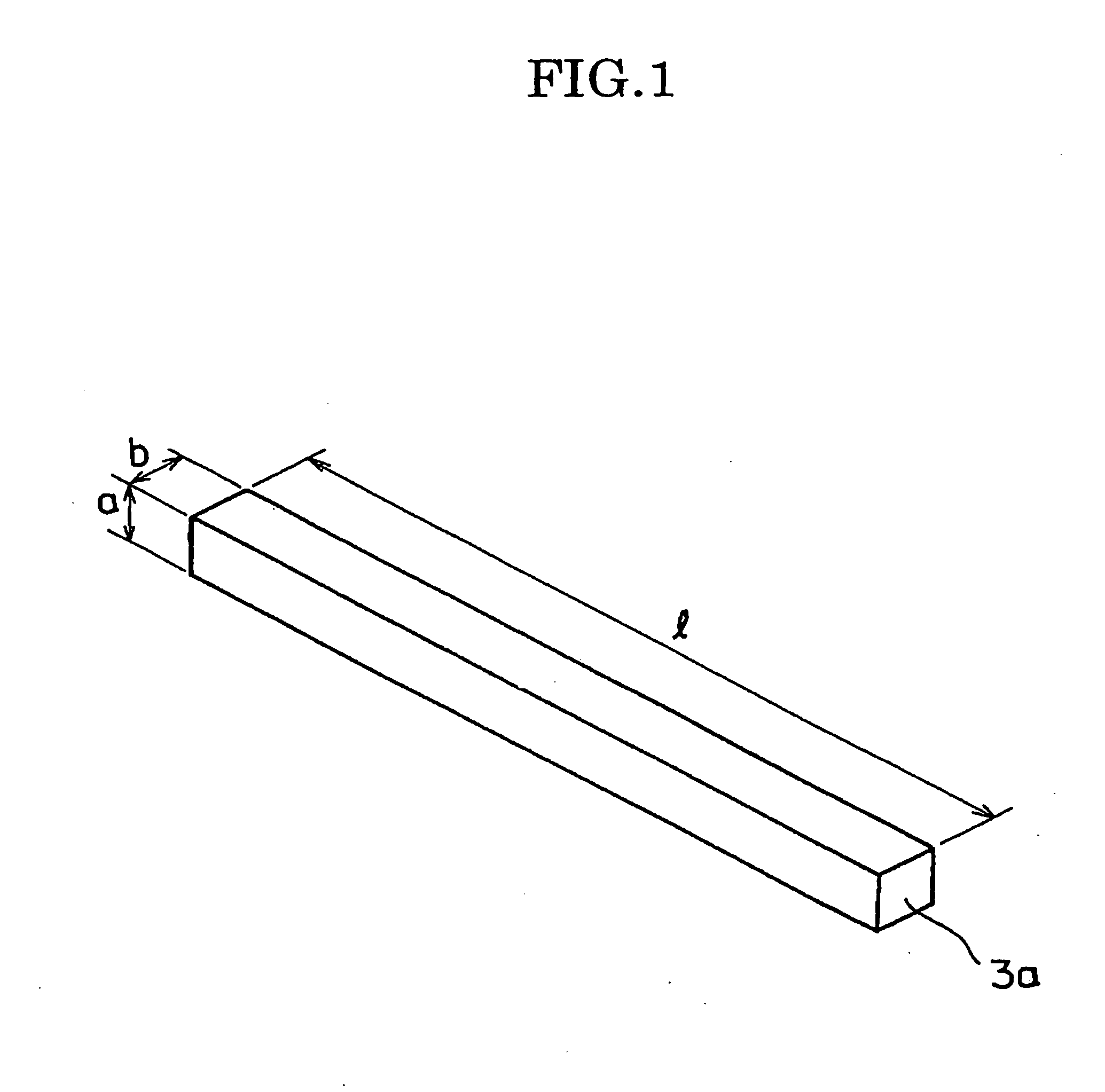

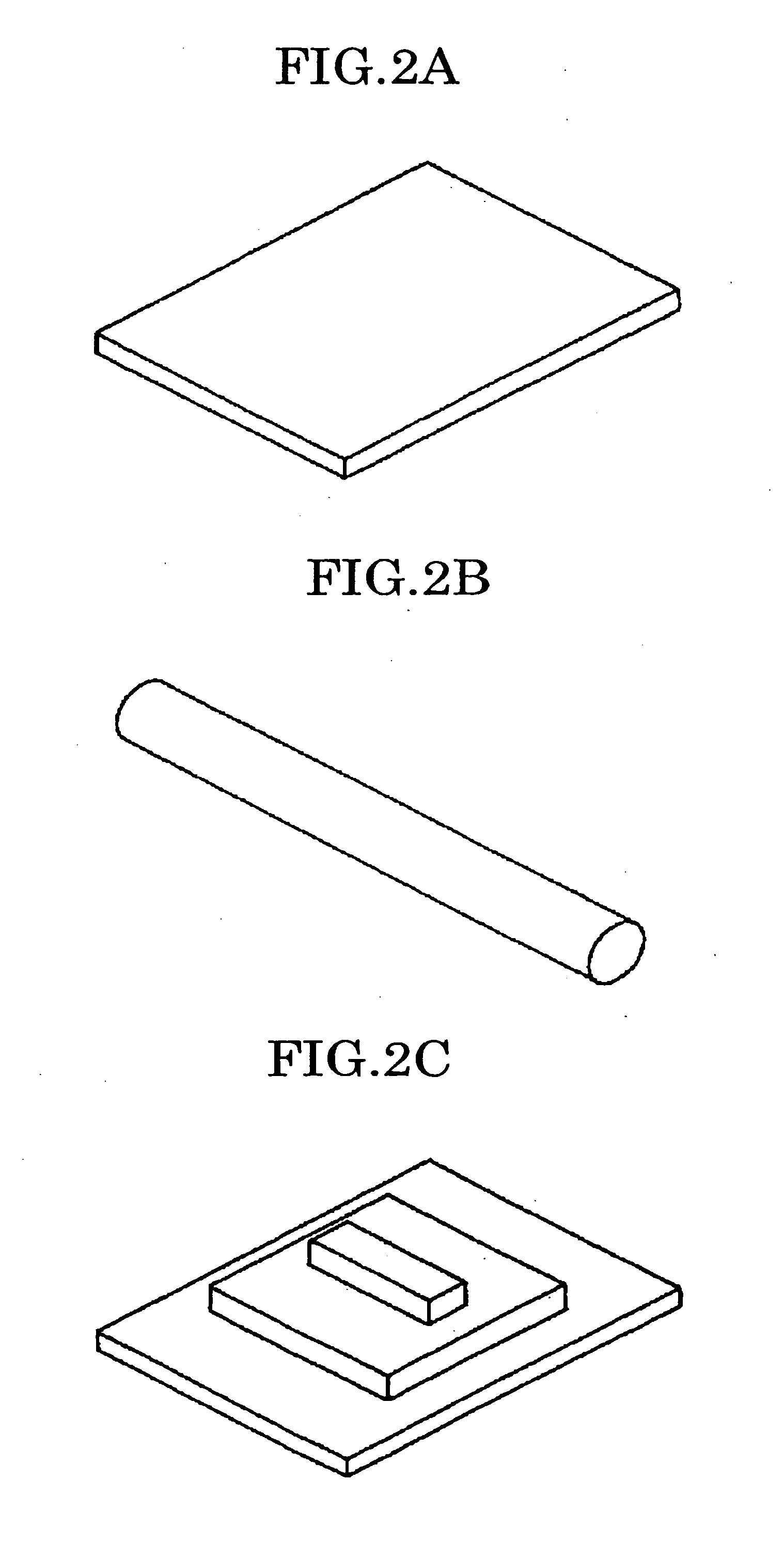

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

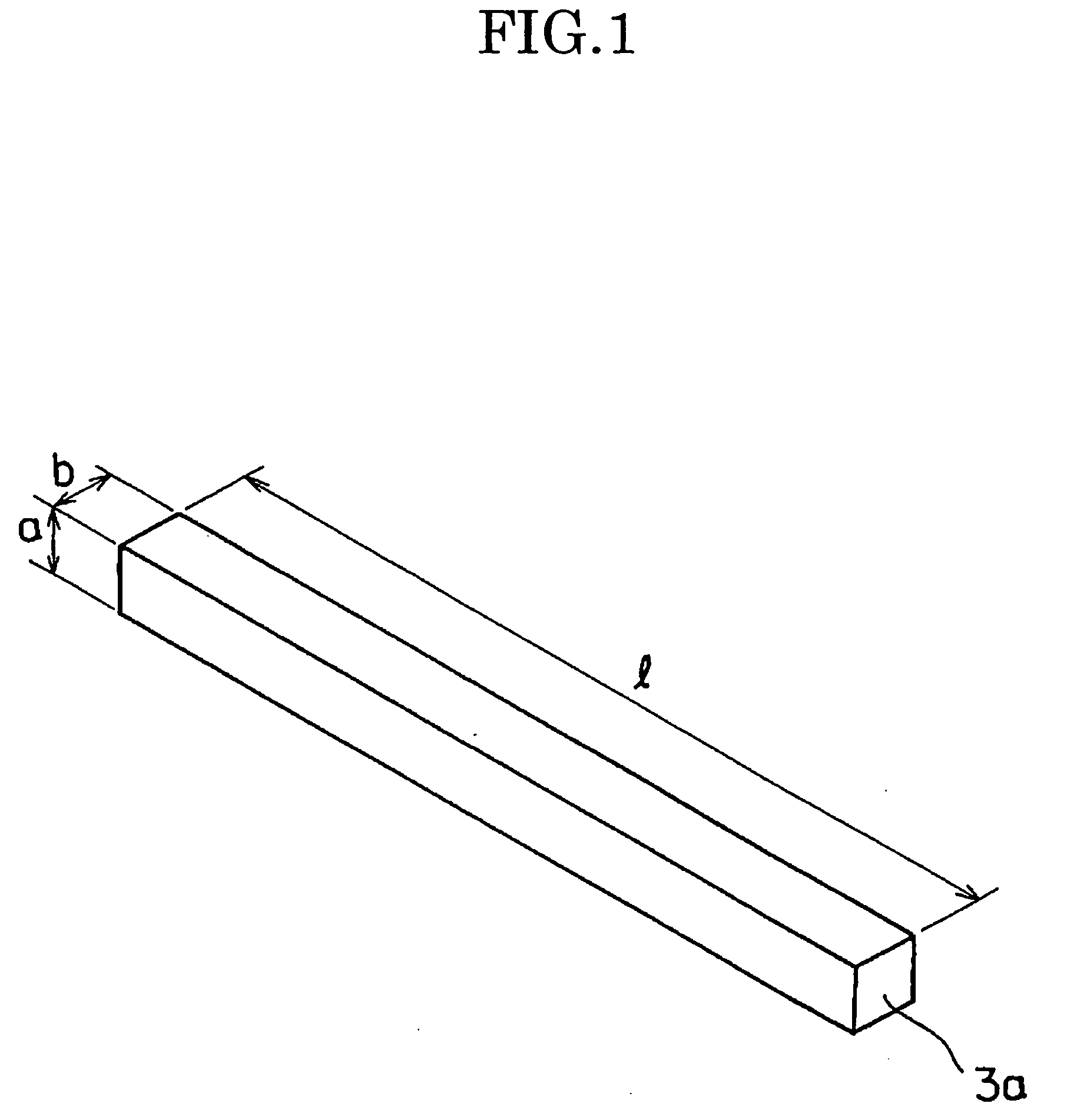

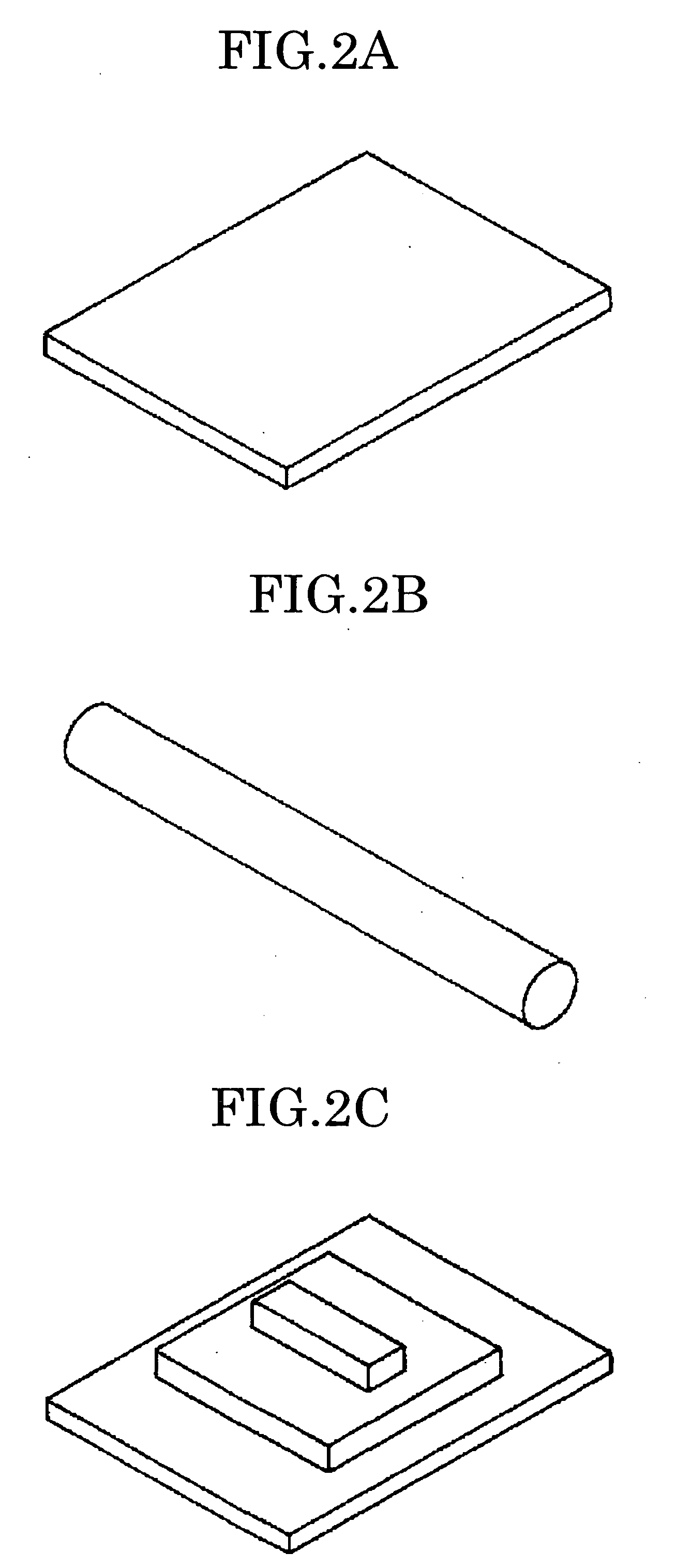

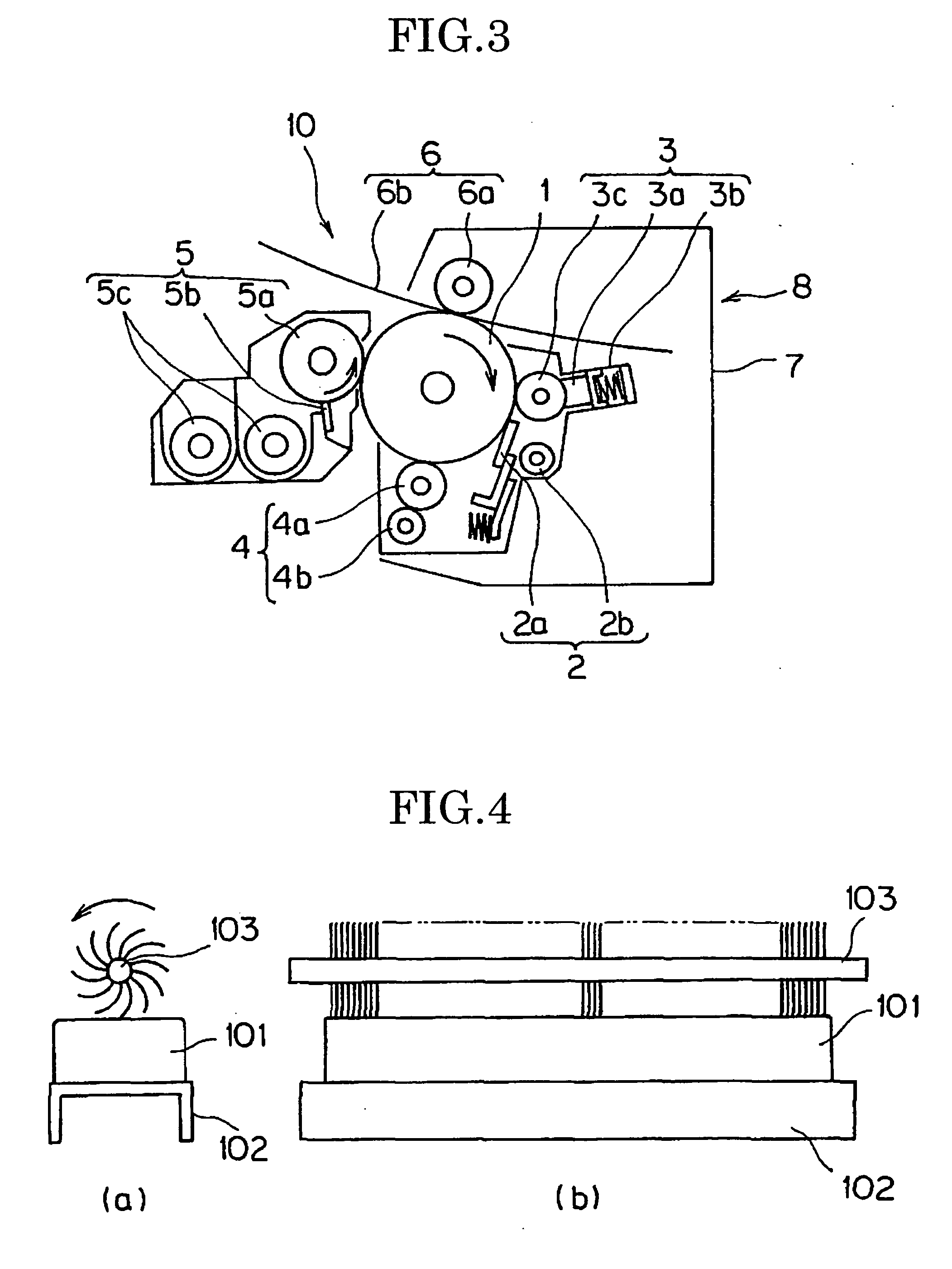

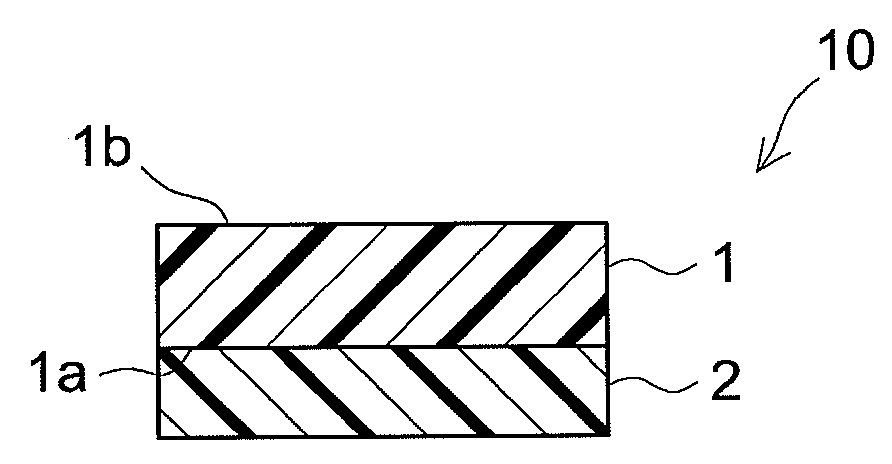

ActiveUS20070123435A1Low costFew cracking and cuttingFibre treatmentSynthetic resin layered productsCarbon numberAluminum Stearate

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:RICOH KK

PVC (Poly Vinyl Chloride) foaming simulated wood floor

The invention provides a PVC (Poly Vinyl Chloride) foaming simulated wood floor comprising the following raw materials in parts by weight: 100-150 parts of PVC powder, 100-150 parts of straw powder, 20-35 parts of light calcium carbonate, 0.5-1.0 part of a foaming agent, 2.0-5.0 parts of a foaming modifier, 0.5-1.0 part of a lubricating agent, and 5.0-5.5 parts of a stabilizer, wherein the foaming agent is an ACH (acetylcholine) composite foaming agent; the foaming modifier is an acrylic polymer; the lubricating agent is calcium stearate or oxidized polyethlene wax; and the stabilizer is zinc laurate or zinc stearate or epoxidized soybean oil. The PVC foaming simulated wood floor provided by the invention has the advantages of strong solid wood appearance, light weight, water proofing, good abrasion resistance and wide application prospect.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Pressure-sensitive adhesive sheet

InactiveUS20090252958A1Highly accessibleDiscoloration of the PVC filmSynthetic resin layered productsAntimony organic compoundsAlkaline earth metalStearate

Provided is a PSA sheet comprising a PVC film (support) provided with PSA layer formed of an aqueous dispersion-type PSA composition, which exhibits a smooth unwinding motion. The PVC film can be obtained by molding a PVC composition comprising PVC and a metal soap. The metal soap comprises an alkali earth metal soap and zinc soap. At least part of the alkali earth metal soap is a stearate and at least part of the zinc soap is zinc laurate.

Owner:NITTO DENKO CORP

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

ActiveUS7691791B2Low costFew cracking and cuttingFibre treatmentSynthetic resin layered productsCarbon numberALUMINUM STEARATES

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:RICOH KK

Sheathing material of resistant high temperature high flame retardant silicone rubber cable

InactiveCN106349705AGood mechanical propertiesGood compatibilityRubber insulatorsInsulated cablesPolymer scienceCarvacryl acetate

The invention discloses a sheathing material of resistant high temperature high flame retardant silicone rubber cable, the raw material including: silicone rubber, ethylene propylene diene monomer, fluororubber, butadiene rubber, ethylene, acrylate rubber, ethylene, ethylene vinyl-acetate copolymer, zinc oxide, stearic acid, Di-2,4-dichlorobenzoyl peroxide, triene propyl cyanuric acid ester, di-isopropyl peroxydicarbonate, aluminum hydroxide, sellaite, red phosphorus, silane coupling agent, modified graphene oxide, zinc stannate, zinc laurate, magnesium stearate, diethylene glycol px fatty acid, di-iso-decylphthalate, accelerant, antiager, silane modified cellulose, ammonium polyphosphate. The sheathing material of resistant high temperature high flame retardant silicone rubber cable has the advantages that high in strength and excellent in heat-resisting and flame retardation, and could meet with the usage requirements in many areas with good comprehensive properties and long service life.

Owner:ANHUI LAND GRP

Silanes cross-linked polyethylene insulated cable material and method for making same

The invention relates to a silane crosslinked polyethylene insulated cable material, which is formed by mixing 100 weight portions of materials A and 2 to 3 weight portions of materials B, wherein, the materials A are mixed by ethenyl trimethoxy silane, tetra (beta-(3, 5-di-tertiary butyl 4-hydroxy benzene)monoprop) pentaerythritol ester, diisopropylbenzene peroxide, low density polyethylene and polyethylene, and the materials B are mixed by low density polyethylene, dibutyl zinc laurate and tetra (beta-(3, 5-di-tertiary butyl 4-hydroxy benzene)monoprop) pentaerythritol ester. The cable material is crosslinked in the air to reach the stated service performance rather than immersed in mild water and crosslinked after the production is finished; and the production period is short and the energy consumption is low.

Owner:YUANCHENG CABLE CO LTD

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

InactiveUS20100150627A1Low costFew cracking and cuttingElectrography/magnetographyBase-materialsCarbon numberPolymer science

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:USAMI JOE

Compound rare-earth calcium zinc heat stabilizer as well as preparation method and use method thereof

ActiveCN103865196AGood compatibilityEasy to processOrganic compound preparationCarboxylic compound preparationRare earthThiodipropionic acid

The invention discloses a compound rare-earth calcium zinc heat stabilizer which comprises a main stabilizer and an auxiliary stabilizer, wherein the main stabilizer comprises the following components: 3,7-dimethyl-2,6-octadienoic acid rare earth, calcium stearate and zinc laurate; the auxiliary stabilizer comprises the following components: dibenzoyl methane, triphenyl phosphite, distearyl thiodipropionate, dihendecyl phthalate and epoxy soybean oil. The invention further provides a preparation method and a use method of the composite rare-earth calcium zinc heat stabilizer. The preparation method comprises the following steps: oxidizing citral in litsea cubeba oil to obtain 3,7-dimethyl-2,6-octadienoic acid, and reacting with rare earth chloride to prepare the 3,7-dimethyl-2,6-octadienoic acid rare earth; compounding the 3,7-dimethyl-2,6-octadienoic acid rare earth, calcium stearate and zinc laurate to generate a good synergistic effect so as to obtain the compound rare-earth calcium zinc heat stabilizer with excellent performance.

Owner:江西宏远化工有限公司

Zinc humic acid long-acting compound fertilizer and preparation method thereof

InactiveCN108558583AIncrease profitAdd functional featuresAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateChelated zinc

The invention discloses a zinc humic acid long-acting compound fertilizer and a preparation method thereof. The fertilizer is prepared from, by weight, 185-198 parts of urea, 380-398 parts of monoammonium phosphate, 255-275 parts of potassium chloride, 70-85 parts of potassium sulfate, 0-45 parts of ammonia sulfate, 10-20 parts of zinc laurate, 10-18 parts of potassium humate, 0.5-1.5 parts of stabilizer and 20-60 parts of filling agent. By adding synergistic additives such as zinc laurate and the like, the degrading and releasing speed of the urea in soil is relieved, the migration capabilityof phosphate is improved, the untoward effect between phosphate radical and calcium, magnesium and ferrum is reduced, the rapidly available phosphorus content in the soil is increased, the utilization rate of nitrogen and phosphate is improved, the fertility of the soil is improved, the activity of urease in the soil is inhibited by a urease inhibitor, the utilization rate of the nitrogen is improved, the fertilizer has chelated zinc, complexation between the soil and the chelated zinc is conducted to improve the stability of microelement fertilizer and the utilization rate of the fertilizer,functional characteristics of the fertilizer can be improved, the nutrient absorbing of crops is improved, and the stress resistance of the crops is enhanced.

Owner:ANHUI ZHONGYUAN FERTILIZER CO LTD

Calcium-zinc stabilizer for PVC, and preparation method thereof

The invention relates to a calcium-zinc stabilizer for PVC, and a preparation method thereof. The calcium-zinc stabilizer is prepared from, by mass, 5-7 parts of calcium stearate, 14-16 parts of zincstearate, 15-16 parts of zeolite, 5.5-6.5 parts of zinc laurate, 5-6 parts of a lubricant, 3.5-5 parts of beta-diketone, 1.5-2.5 parts of an antioxidant, 3-4 parts of 1,3-dimethyl-6-aminouracil, 3-4 parts of an ultraviolet light absorber and 4-5 parts of lanthanum maleamate. The 1,3-dimethyl-6-aminouracil is used for replacing unstable chlorine atoms in the PVC, so the stability of PVC is improved, and the color change phenomenon of PVC is reduced; and the lanthanum maleamate is used to solve problem of zinc burning of PVC containing the calcium-zinc stabilizer in the using process, so the good effect of inhibiting zinc burning is achieved.

Owner:惠州市兴邦新材料科技有限公司

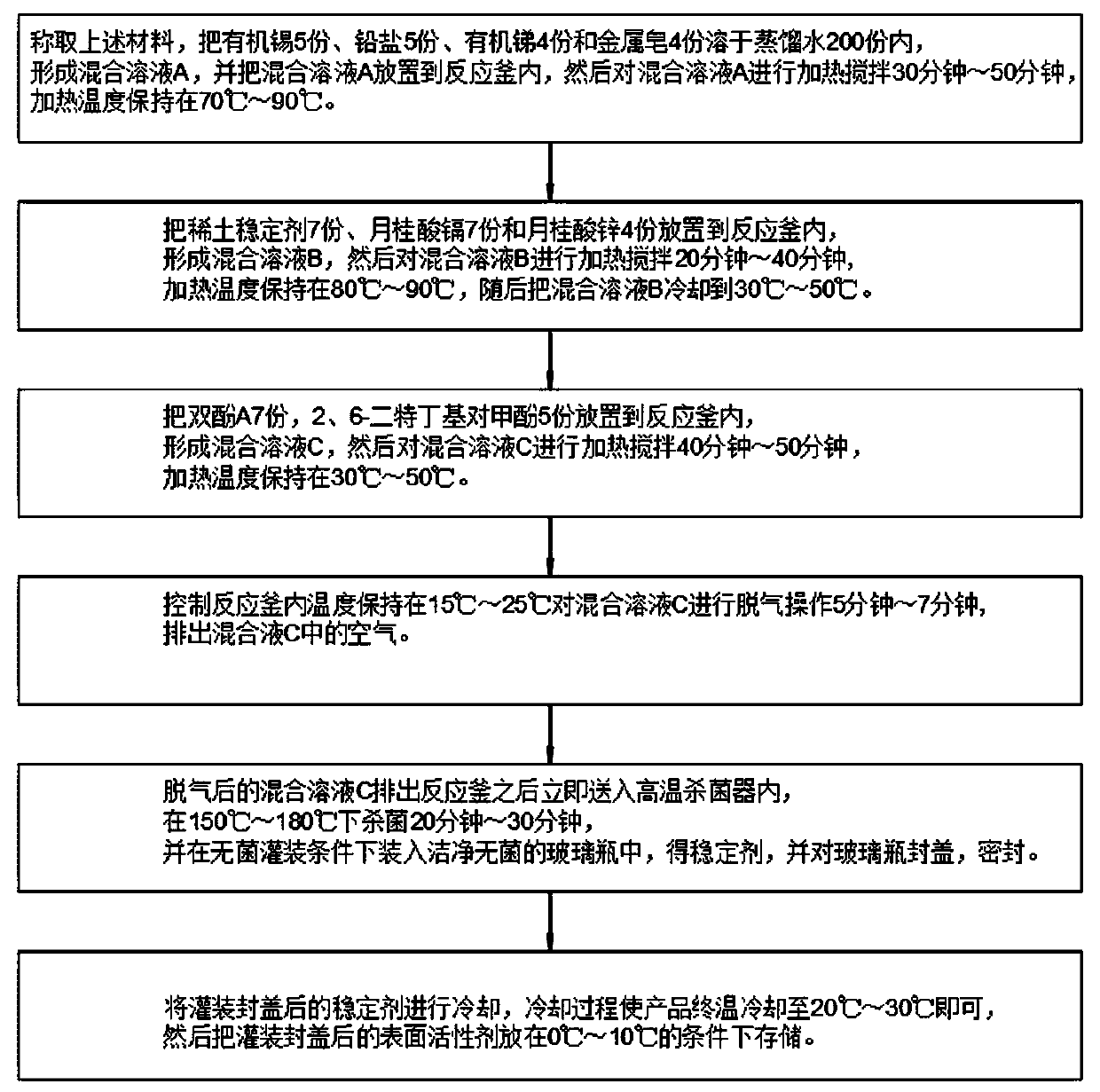

Stabilizer and preparation method thereof

InactiveCN109679694AExtended shelf lifeLow costHydrocarbon oils treatmentRare-earth elementLead salt

The invention belongs to the technical field of petroleum processing, in particular to a stabilizer. The stabilizer comprises the following materials in parts by weight: 4-6 parts of organic tin, 4-6parts of lead salt, 3-5 parts of organic antimony, 3-5 parts of metal soap, 6-8 parts of a rare earth stabilizer, 6-8 parts of cadmium laurate, 3-5 parts of zinc laurate, 6-8 parts of bisphenol A, 4-6parts of 2,6-di-tert-butyl-p-cresol and 100-300 parts of distilled water. After adoption of a ratio, the stabilizer can be avoided from deactivation under direct sunlight by being put into a brown glass bottle, so that the shelf life of the stabilizer is prolonged; the rear earth stabilizer is added into the stabilizer, and the composite rear earth stabilizer is synthesized from carboxylate or fatty acid salt of a rare earth element as a main component and contains a proper amount of rare earth metal component; the stabilizer not only can replace lead cadmium salt-type and organic tin-type toxic stabilizers and the like, but also has very good heat stability, light stability, transparency and coloring power.

Owner:濮阳市万良石油科技发展有限公司

Practical environmental fully-degradable material and method for preparing same

InactiveCN106965512AImprove waterproof performanceImprove flame retardant performanceAgricultural articlesSynthetic resin layered productsPlastic mulchButylated hydroxytoluene

The invention relates to a practical environmental fully-degradable material which comprises first-layer films and second-layer films. The first-layer films comprise polyethylene, polylactic acid, lanthanum oxide, europium chloride, yttrium nitrate, zinc laurate, 2, 6-butylated hydroxytoluene, diatomaceous earth, humic acid and polyacrylate; the second-layer films comprise polybutylene succinate, polylactic acid, polyethylene, tourmaline powder, boric acid, yttrium nitrate, 2, 4, 6-tri-tert-butylphenol and nanometer titanium dioxide. The practical environmental fully-degradable material has the advantages that the practical environmental fully-degradable material is excellent in waterproof performance, flame retardance and mechanical properties such as tensile strength and breakage elongation; excellent effects of regulating temperatures, preserving soil moisture, increasing the emergence rates of crops and the like can be realized by the practical environmental fully-degradable material when the practical environmental fully-degradable material is used as a mulching film; the practical environmental fully-degradable material is easy to degrade, particularly, various portions can simultaneously reach degradation endpoints when the practical environmental fully-degradable material is used as the mulching film, and accordingly the shortcoming of different degradation speeds of various portions of the traditional commercially available mulching films in application procedures can be overcome.

Owner:济南三才塑业有限责任公司

Modified sepiolite used for a polyethylene corrugated pipe material and a preparing method of the modified sepiolite

Modified sepiolite used for a polyethylene corrugated pipe material and a preparing method of the modified sepiolite are disclosed. The modified sepiolite is prepared from following raw materials by weight: 85-105 parts of sepiolite, 10-15 parts of nanometer zirconium dioxide, 18-26 parts of shell powder, 4-7 parts of perfluoro alkyl ethyl acrylate, 2-5 parts of tallow fatty acid, 9-16 parts of glucose pentaacetate, 10-15 parts of gum dammar, 6-12 parts of shellac, 5-10 parts of walnut shell powder, 4-8 parts of ozokerite, 1-2 parts of distearyl dimethyl ammonium chloride, 40-50 parts of polybutylene terephthalate, 25-35 parts of an ethylene-ethenol copolymer, 10-15 parts of polybrominated diphenyl ethers, 5-10 parts of calcium hypophosphite, 2-3 parts of zinc laurate and 5-7 parts of auxiliary agents. The modified sepiolite and the method can significantly improve the dispersing property of the sepiolite in a polyethylene base material, intensifying adhesion of sepiolite-polyethylene interfaces, effective overcome problems that are hard dispersion, easy layering, much dust, and the like of the sepiolite at present, and improve mechanical strength, wear resistance, fatigue resistance, elasticity, machinability, and other properties of the polyethylene material.

Owner:HEFEI HEAN MACHINERY MFG

Plastic-steel doors and windows

InactiveCN107177126AImprove impact resistanceImprove flame retardant performanceCoatingsSodium bicarbonateFiber

The invention provides plastic-steel doors and windows. The plastic-steel doors and windows are prepared from the following components of 75 to 100 parts of polyvinyl chloride resin, 15 to 25 parts of active calcium carbonate, 3 to 10 parts of plant fiber, 5 to 10 parts of flame-retardant agent, 5 to 7 parts of methacrylate-butadiene-styrene copolymer, 20 to 30 parts of water, 3 to 5 parts of nanometer barium sulfate, 5 to 7 parts of MBS (methyl methacrylate) emulsion, 2 to 3 parts of methyl (3,5-di-tert butyl-4-hydroxyphenyl)propionate, 3 to 4 parts of 2-butyne-1,4-diol, 6 to 9 parts of nanometer calcium carbonate, 2 to 3 parts of zinc laurate, 11 to 14 parts of shell powder, 1 to 2 parts of dioctyl adipate, 2 to 4 parts of lubricant, 1 to 2 parts of azodicarbonamide, 1 to 2 parts of sodium bicarbonate, 0.5 to 1 part of sodium bicarbonate, 5 to 15 parts of chlorinated polyethylene, 0 to 10 parts of acrylate anti-impact modifier, 3 to 5 parts of stabilizer and 0 to 1 part of plasticizer. The plastic-steel doors and windows have the advantages that the strength, toughness and anti-aging property are enhanced, the support is convenient, the application range is broad, the size adaptability is strong, the deformation is avoided, and the waterproof property and anti-corrosive property are greatly improved.

Owner:合肥市旺友门窗有限公司

Environment-friendly plastic and forming method thereof

The invention discloses an environmentally friendly plastic, which comprises the following raw materials in parts by weight: 10-20 parts of natural latex, 10-40 parts of polyethylene resin, 10-20 parts of polypropylene resin, 15-25 parts of calcium carbonate, and 10-18 parts of starch 5-15 parts of talcum powder, 12-18 parts of biodegradation agent, 8-15 parts of zinc laurate soap, 5-15 parts of di-sec-octyl phthalate, 5-15 parts of chlorinated paraffin, 4 parts of lubricant ‑12 servings. The environmentally friendly plastic proposed by the invention is non-toxic and odorless, will not cause air and environmental pollution, has good plasticity, can produce various plastic products suitable for production or daily life, has strong practicability, and the added biodegradant improves The degradability of the plastic improves its environmental protection. The production process of the invention is simple, the raw materials are easy to obtain, and the cost is low.

Owner:德阳市米雅乐食品厂

Halogen-free flame retardant sheath material for optical fibers

The invention discloses a halogen-free flame retardant sheath material for optical fibers. The material is prepared from, by weight, 50-55 parts of low-density polyethylene, 13-15 parts of EVA resin, 9-12 parts of nylon 6, 14-16 parts of magnesium hydrate, 0.6-0.8 part of dispersing agent NNO, 1.3-2 parts of titanate coupling agents 102, 5-8 parts of organic silicon, 3-5 parts of organic montmorillonite, 2-4 parts of vinyl acetate, 3-4 parts of loess powder, 2-3 parts of aluminum borate, 4-5 parts of hydrogenated jojoba oil, 3-4 parts of zinc laurate and a proper amount of deionized water. The halogen-free flame retardant sheath material has the excellent flame retardant environment-friendly function, and is resistant to heat, good in heat insulation performance, high in corrosion resistance, wide in raw material source, simple in preparation technology and worthy of popularization.

Owner:安徽电信器材贸易工业有限责任公司

Low-temperature-brittleness-resistant mine pipe and preparation method thereof

InactiveCN106700340AGood compatibilityImprove dispersion stabilityMicrocrystalline waxPolyvinyl chloride

The invention discloses a low-temperature-brittleness-resistant mine pipe and a preparation method thereof. The low-temperature-brittleness-resistant mine pipe is prepared from the following raw materials in parts by weight: 49-62 parts of polyvinyl chloride, 11-17 parts of butyl acetoxystearate, 10-15 parts of triethylene glycol di-2-ethylhexoate (triglycol dioctate), 1-2 parts of zinc laurate, 1-2 parts of barium laurate, 5-7 parts of microcrystalline wax, 14-19 parts of tetrahydrofurfuryl oleate, 18-26 parts of pearlife, 5-10 parts of pentaerythritol monooleate and 17-24 parts of diopside powder. Three cold-resistant plasticizers, i.e., the butyl acetoxystearate, the triethylene glycol di-2-ethylhexoate (triglycol dioctate) and the tetrahydrofurfuryl oleate are added and are matched with filler such as the pearlife and the diopside powder for use, so that not only are the cold tolerance and weather resistance of a material improved, but the mechanical strength of the material is also improved. The polyvinyl chloride (PVC) pipe prepared by the method is high in mechanical strength, good in weather resistance and excellent in cold tolerance; compared with PVC pipes in the prior art, the PVC pipe provided by the invention has greatly improved low temperature brittleness and has minimum working temperature reaching to -50 DEG C.

Owner:宋志勇

PVC pipe toughened and modified by acrylate and preparing method thereof

The invention discloses a PVC pipe toughened and modified by acrylate. The PVC pipe is characterized by being prepared from, by weight, polyvinyl chloride resin, butyl titanate, hydrochloric acid solution of 8-10%, absolute ethyl alcohol, a coupling agent KH-570, (2- ethylhexyl) acrylate, chloroethylene, methylcellulose, dioctyl sulfo substituted succinate, lauroyl peroxide, polyethylene, calcium stearate, zinc laurate, polyethylene wax, 1,3-dimethyl-6-aminouracil, octadecyl dihydroxy ethyl methyl ammonium bromide, polyethylene glycol and an appropriate amount of deionized water. The prepared PVC pipe has the advantages of being high in strength, tenacity and impact resistance and has high market competitiveness as the product component is low in price.

Owner:ANHUI LANTONG TECH CO LTD

High-speed low-noise bearing grease and preparation method thereof

InactiveCN104194893AImprove carrying capacityAdaptableLubricant compositionLow noiseHydroxystearic Acid

The invention discloses a high-speed low-noise bearing grease and a preparation method thereof. The bearing grease comprises the following components in percentage by weight: 25-30% of paraffin oil, 20-30% of naphthenic oil, 30-40% of alkyl diphenyl ether, 3-4% of 12-hydroxystearic acid, 2-3.5% of zinc laurate, 1-1.5% of molybdenum disulfide, 2-3% of zinc phosphorodithioate, 0.5-1% of octylbutyl diphenylamine and 1-2.5% of benzotriazole fatty acid ammonium salt. The bearing grease has the advantages of high carrying capacity, favorable antifriction property and favorable noise reduction property, and can effectively adapt to the occasions with high requirements for high speed and low noise. The preparation method comprises the following steps: a. heating and stirring base oil in a reaction kettle; b. adding a thickener into the reaction kettle, and heating and stirring; c. adding additives into the reaction kettle, and cooling and stirring; and d. when the temperature drops to 40 DEG C, packaging. The preparation method can effectively prepare the high-quality high-speed low-noise bearing grease.

Owner:WUXI FEITIAN GREASE

Straw reinforcement plate and preparation process thereof

The invention discloses a straw reinforcement plate and a preparation process thereof. The plate is prepared from the following raw materials in parts by weight: 120-150 parts of straw, 20-30 parts ofa binder, 18-25 parts of urea-formaldehyde resin glue, 10-18 parts of a waterproofing agent, 8-15 parts of polypropylene plastic, 6-12 parts of carbon powder, 8-13 parts of titanium dioxide, 10-18 parts of cement powder, 8-12 parts of quartz sand, 10-16 parts of zinc laurate, 8-14 parts of sodium acrylate and 6-12 parts of a curing agent. The straw reinforcement plate is prepared from the rural straw as a main material by adding the binder, the urea-formaldehyde resin glue, the curing agent and the like; the prepared reinforcement plate has higher strength and can replace solid wood to be widely used in the fields of household decoration, furniture manufacturing, handicraft manufacturing and the like, and higher economic benefits are produced; the rural waste straw is fully used, the natural environment is protected, and huge manpower and material resources are saved for straw processing.

Owner:安徽上元家居材料股份有限公司

Pressure-sensitive adhesive sheet

InactiveUS8298663B2Highly accessibleDiscoloration of the PVC filmSynthetic resin layered productsAntimony organic compoundsAlkaline earth metalShell molding

Provided is a PSA sheet comprising a PVC film (support) provided with PSA layer formed of an aqueous dispersion-type PSA composition, which exhibits a smooth unwinding motion. The PVC film can be obtained by molding a PVC composition comprising PVC and a metal soap. The metal soap comprises an alkali earth metal soap and zinc soap. At least part of the alkali earth metal soap is a stearate and at least part of the zinc soap is zinc laurate.

Owner:NITTO DENKO CORP

Modified plastic granules for accelerator pedal of automobile

The invention discloses modified plastic granules for an accelerator pedal of an automobile and relates to the technical field of plastic parts of automobiles. The modified plastic granules are prepared from raw materials in parts by weight as follows: 100-110 parts of polypropylene, 50-60 parts of diethyl maleate, 10-15 parts of nano-carbon fiber, 15-20 parts of microcrystal ceramic powder, 12-16 parts of modified straw powder, 10-15 parts of gypsum powder, 10-15 parts of palm oil, 10-15 parts of soy protein concentrate, 7-12 parts of glycerol monolaurate, 6-10 parts of pentaerythritol, 6-10 parts of epoxy acetyl methyl linoleate, 5-8 parts of ascorbic acid palmitate, 5-8 parts of a styrene-butadiene-styrene block copolymer, 4-6 parts of zinc laurate soap, 3-5 parts of sulfur, 2-4 parts of dodecyl dimethyl betaine and 60-70 parts of ethanol. The modified plastic granules have good machining forming performance, an accelerator pedal sheath, made from the modified plastic granules, of the automobile have excellent abrasive resistance, water resistance and anti-aging performance and can effectively protect the accelerator pedal, the braking performance is improved due to the friction force between the accelerator pedal and a sole, and the driving safety is guaranteed.

Owner:JIESHOU DONGWEI PLASTIC IND CO LTD

Antibacterial PVC (polyvinyl chloride) floor

An antibacterial PVC (polyvinyl chloride) floor is made from, by weight, 8 to 11 parts of antimony oxide, 3 to 5 parts of styrene, 2 to 5 parts of nucleating agent, 3.2 to 6.8 parts of oxidized polyethlene wax, 1.5 to 3 parts of zinc laurate, 10 to 14 parts of wood fiber powder, 45 to 55 parts of PVC resin, 5 to 9 parts of triphenyl phosphite, 4.3 to 8 parts of dibutyl phthalate, 6 to 10 parts of lightweight calcium carbonate, 8 to 10 parts of dioctyl phthalate, 9 to 15 parts of kaolin, 8 to 14 parts of titanium dioxide, 2 to 5 parts of antioxidant, and 8 to 10.5 parts of straw. The antibacterial PVC floor has good antibacterial effect, has improved wear resistance and impact resistance and well meets the application needs.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

Antistatic treatment of eco-friendly cold firework chemical and preparation method thereof

PendingCN111056886ANothing producedAchieve preparationNitrated pentaerythritol explosive compositionsNon-explosive/non-thermic compositionsCelluloseCyclohexanone

The invention relates to an eco-friendly antistatic smokeless sulfur-free cold firework chemical, and belongs to the field of environment-friendly pyrotechnic compositions. The cold firework chemicalcomprises the components: nano aluminum powder, modified pentaerythritol tetranitrate, nitrobamboo cellulose, cyclohexanone peroxide, propylene glycol stearate, dimethyl diphenyl urea, magnesium stearate, dibutyl phthalate, zinc laurate soap and shellac. The nano aluminum powder and the modified pentaerythritol tetranitrate powder are used as main components, so that safety and reliability are realized, and the combustion temperature is low; the components do not contain chlorine elements and sulfur elements, cyclohexanone peroxide is introduced, sufficient combustion is guaranteed, no toxic or harmful smoke is generated, and preparation of the smokeless and sulfur-free cold firework chemical can be truly achieved.

Owner:江西吉润花炮新材料科技有限公司

Method for preparing organometallic composite material

The present invention provides a method for preparing organometallic composite material, comprising: providing PVC resin, activated calcium carbonate, plant fiber, calcium stearate, barium sulfate, paraffin, sodium bicarbonate, zinc laurate, nanometre titanium dioxide, organometallic salt, shell powder, carbon nanotube, talcum powder and stabilizer; mixing and heating; subject to first cooling after extrusion and second cooling under vacuum; towing to obtain the organometallic composite material, wherein the organometallic salt is a benzoic acid metal salt mixture. The present method can significantly reduce the processing temperature of PVC composite by 20 to 50° C., and also increase the toughness and strength of the material so as to alleviate the exudation of the composite material as in the conventional technologies and extend the lifespan of the composite material.

Owner:CHANGZHOU UNIV

A kind of rare earth calcium-zinc composite heat stabilizer and its preparation and use method

ActiveCN103865196BGood compatibilityEasy to processOrganic compound preparationCarboxylic compound preparationPhosphorous acidPropanoic acid

The invention discloses a compound rare-earth calcium zinc heat stabilizer which comprises a main stabilizer and an auxiliary stabilizer, wherein the main stabilizer comprises the following components: 3,7-dimethyl-2,6-octadienoic acid rare earth, calcium stearate and zinc laurate; the auxiliary stabilizer comprises the following components: dibenzoyl methane, triphenyl phosphite, distearyl thiodipropionate, dihendecyl phthalate and epoxy soybean oil. The invention further provides a preparation method and a use method of the composite rare-earth calcium zinc heat stabilizer. The preparation method comprises the following steps: oxidizing citral in litsea cubeba oil to obtain 3,7-dimethyl-2,6-octadienoic acid, and reacting with rare earth chloride to prepare the 3,7-dimethyl-2,6-octadienoic acid rare earth; compounding the 3,7-dimethyl-2,6-octadienoic acid rare earth, calcium stearate and zinc laurate to generate a good synergistic effect so as to obtain the compound rare-earth calcium zinc heat stabilizer with excellent performance.

Owner:江西宏远化工有限公司

A kind of environment-friendly one-component polyurethane waterproof coating and preparation method thereof

ActiveCN112552811BImprove adhesionNo pinholesFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The present invention relates to the technical field of polyurethane waterproof coatings, in particular to an environment-friendly one-component polyurethane waterproof coating. The raw materials for its preparation include the following components calculated in parts by weight: 35-55 parts of polyether polyol, 15-55 parts of polyisocyanate monomer 25 parts, plasticizer 25-30 parts, filler 30-39 parts, polyadipate-1,4-butylene glycol ester 2-4 parts, zinc laurate 2-4 parts, catalyst 0.05-0.1 parts, disinfectant 0.1-0.3 parts of foaming agent, 0.05-0.2 parts of stabilizer, 0.1-0.3 parts of latent curing agent and 0.1-0.3 parts of 3,3'-dihexyl oxygen-containing carbocyanine iodide salt, the environmentally friendly one-component polyurethane proposed by the present invention The waterproof coating is prepared from environmentally friendly components. Its layer has strong adhesion, dense coating, no pinholes, no air bubbles, and a small water vapor permeability coefficient. It can be waterproof and used as an air barrier layer. Construction, the construction speed is fast, and the construction period can be shortened.

Owner:北京宇阳泽丽防水材料有限责任公司

Flame-retarding weather-resisting resin material for producing plastic-steel doors and windows

The invention relates to the technical field of resin materials and in particular relates to a flame-retarding weather-resisting resin material for producing plastic-steel doors and windows. The resinmaterial is prepared from the following raw materials: PVC (Polyvinyl Chloride) resin, CPE (Chlorinated Polyethylene) resin, modified chlorinated polypropylene, a reinforcing agent, nano titanium dioxide, a coupling agent, carbon fibers, a composite flame retardant, dodecanethiol dibutyl tin, tert-butyl hydroperoxide, zinc laurate and an ultraviolet absorbent, wherein the coupling agent is a monoalkyl titanate coupling agent; the composite flame retardant contains a mixture of two or more of nano aluminum sulfate, antimony trioxide, magnesium hydroxide and nano silicon dioxide; the ultraviolet absorbent is selected from an ultraviolet absorbent UV-9, an ultraviolet absorbent UVP-327 or a light stabilizer 744. Compared with a common PVC type sectional material, the resin material has higher structure strength and better weather resistance; the high-temperature resistance and flame-retarding performance of the material are also enhanced.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Special liquid calcium-zinc stabilizer of PVC (Polyvinyl Chloride) gloves and preparation method of stabilizer

The invention discloses a special liquid calcium-zinc stabilizer of PVC (Polyvinyl Chloride) gloves. The liquid calcium-zinc stabilizer comprises the following raw materials in parts by weight: 100 parts of calcium laurate, 10-50 parts of zinc laurate, 5-10 parts of nano-montmorillonite, 5-10 parts of nano-silica, 5-10 parts of polyethylene wax, 2-10 parts of carbon nano tube modified polyphosphazene-polyether sulfone segmented copolymer, 5-9 parts of tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]pentaerythritol ester, 5-8 parts of an ultraviolet light absorber UV-9, 5-10 parts ofdiethylene glycol monobutyl ether, 1-10 parts of beta-diketone and 1-5 parts of sulfonated polyphosphazene modified nanometer titania. The special liquid calcium-zinc stabilizer of PVC gloves disclosed by the invention is excellent in weather resistance and unlikely to discolor, so that the service life of the PVC gloves can be prolonged, and the mechanical strength and heat resistance of the PVCgloves can be greatly improved. The liquid calcium-zinc stabilizer has the characteristic of environmental friendliness.

Owner:常熟市法艾新材料科技有限公司

Application of zinc oxide to preparation of zinc laurate

InactiveCN106810438AAdequate responseEliminate bromine smellOrganic compound preparationCarboxylic acid salt preparationTalc / Zinc OxideChloride

The invention provides application of zinc oxide to preparation of zinc laurate. Through the application of zinc oxide to preparation of zinc laurate, sodium hydroxide and zinc chloride applied to the original reaction of zinc laurate are changed into zinc oxide; the productivity of reaction is greatly improved; meanwhile, the reaction of the lauric acid is more complete, so that the bromine smell of the lauric acid is eliminated.

Owner:冯炳滔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com