Stabilizer and preparation method thereof

A technology of stabilizer and rare earth stabilizer, which is applied in the petroleum industry and the treatment of hydrocarbon oil, etc., can solve the problems of reducing the service life of the stabilizer, deactivating the activity of the stabilizer, and the economic loss of the user, so as to improve the shelf life and good thermal stability Sex, avoid the effect of direct sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

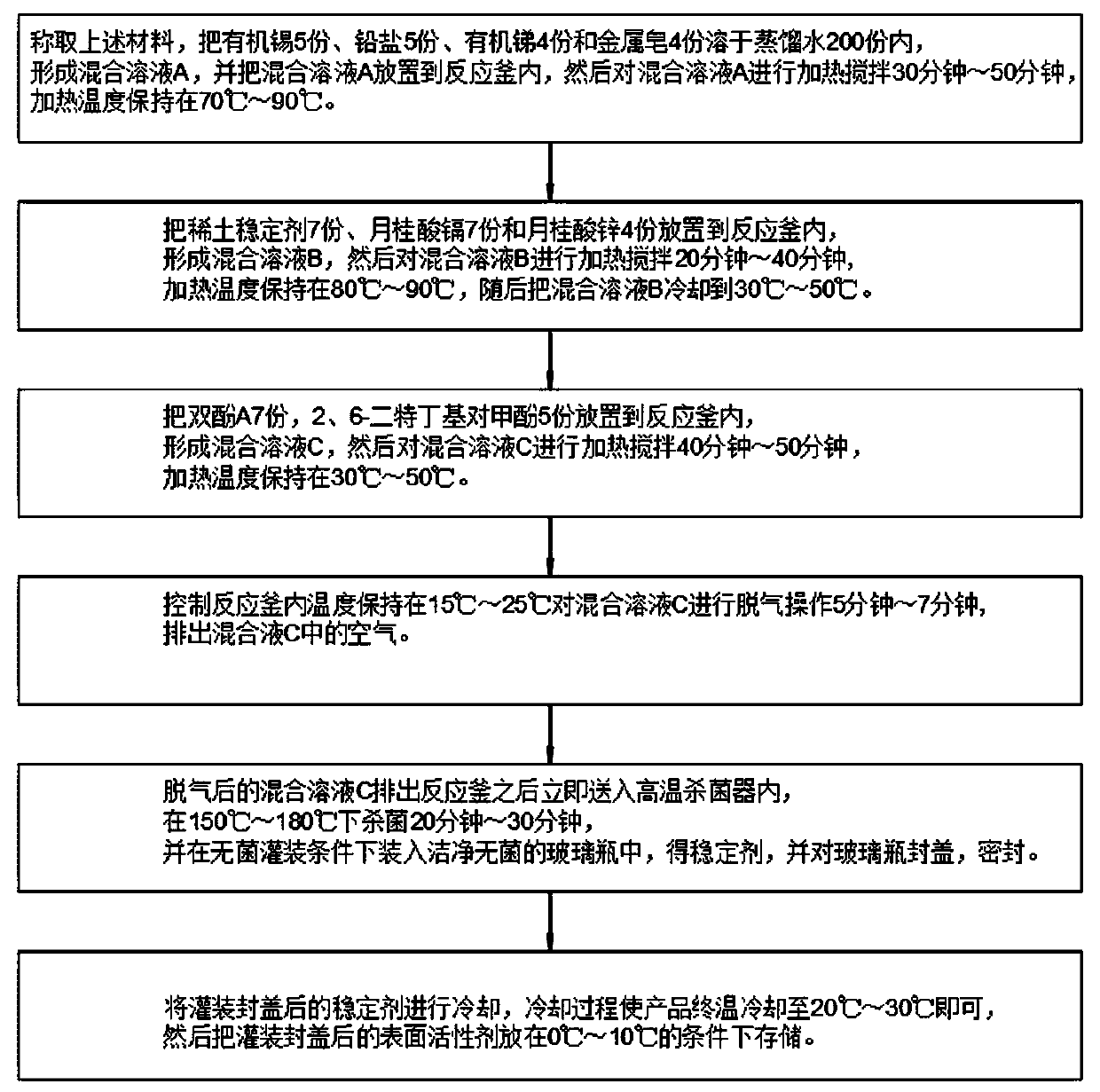

Method used

Image

Examples

Embodiment 1

[0023] A stabilizer, which is composed of the following materials according to the proportion: 4 parts of organic tin, 4 parts of lead salt, 3 parts of organic antimony, 3 parts of metal soap, 6 parts of rare earth stabilizer, 6 parts of cadmium laurate, zinc laurate 3 parts, 6 parts of bisphenol A, 4 parts of 2,6-di-tert-butyl-p-cresol, 100 parts of distilled water.

[0024] A preparation method comprising steps as follows:

[0025] S1: Weigh the above materials, dissolve 4 parts of organic tin, 4 parts of lead salt, 3 parts of organic antimony and 3 parts of metal soap in 100 parts of distilled water to form a mixed solution A, and put the mixed solution A into the reaction kettle, Then the mixed solution A was heated and stirred for 30 minutes, and the heating temperature was kept at 70°C;

[0026] S2: Put 6 parts of rare earth stabilizer, 6 parts of cadmium laurate and 3 parts of zinc laurate into the reaction kettle to form a mixed solution B, then heat and stir the mixe...

Embodiment 2

[0034] A stabilizer, which is composed of the following materials according to the proportion: 5 parts of organic tin, 5 parts of lead salt, 4 parts of organic antimony, 4 parts of metal soap, 7 parts of rare earth stabilizer, 7 parts of cadmium laurate, zinc laurate 4 parts, 7 parts of bisphenol A, 5 parts of 2,6-di-tert-butyl-p-cresol, 200 parts of distilled water.

[0035] A preparation method comprising steps as follows:

[0036] S1: Weigh the above materials, dissolve 5 parts of organic tin, 5 parts of lead salt, 4 parts of organic antimony and 4 parts of metal soap in 200 parts of distilled water to form a mixed solution A, and put the mixed solution A into the reaction kettle, Then the mixed solution A was heated and stirred for 40 minutes, and the heating temperature was kept at 80°C;

[0037] S2: Put 7 parts of rare earth stabilizer, 7 parts of cadmium laurate and 4 parts of zinc laurate into the reaction kettle to form a mixed solution B, then heat and stir the mixe...

Embodiment 3

[0045] A stabilizer, which is composed of the following materials according to the proportion: 6 parts of organic tin, 6 parts of lead salt, 5 parts of organic antimony, 5 parts of metal soap, 8 parts of rare earth stabilizer, 8 parts of cadmium laurate, zinc laurate 5 parts, 8 parts of bisphenol A, 6 parts of 2,6-di-tert-butyl-p-cresol, 300 parts of distilled water.

[0046] A preparation method comprising steps as follows:

[0047] S1: Weigh the above materials, dissolve 6 parts of organic tin, 6 parts of lead salt, 5 parts of organic antimony and 5 parts of metal soap in 300 parts of distilled water to form a mixed solution A, and put the mixed solution A into the reaction kettle, Then the mixed solution A was heated and stirred for 50 minutes, and the heating temperature was kept at 90°C;

[0048] S2: Put 8 parts of rare earth stabilizer, 8 parts of cadmium laurate and 5 parts of zinc laurate into the reaction kettle to form a mixed solution B, then heat and stir the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com