Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Phenoplasts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenoplasts plastics based on phenolic resins. Aside from the resins (novolacs or resols) themselves, which function as a binder, the principal component of phenoplasts is the filler. The choice of filler dictates the type of phenoplast obtained. Thus, powder fillers yield phenoplast molding powders, and fiber fillers yield fiber-filled (glass, asbestos ...

Method for preparing thermosetting plastic with coal gangue modified phenolic resin

The invention provides a method for preparing thermosetting plastic with coal gangue modified phenolic resin, comprising the following steps: (1) breaking coal gangue raw material into powder; (2) carrying out surface treatment to the coal gangue powder by a coupling agent; (3) mixing and heat bodying the coal gangue powder performed with surface treatment, phenolic resin, wood flour and nitrile rubber; (4) cooling and breaking the heat bodying material to obtain phenolic moulding; and (5) solidifying and shaping the phenolic moulding with a curing agent. The method of the invention takes the coal gangue to serve as a filler to carry out modified treatment to the phenolic resin, obtains the purpose of lowering phenolic plastic cost, improves various mechanical properties and mechanical capacities of phenolic plastics and opens a new path for comprehensively utilizing the coal gangue.

Owner:BAOSHAN IRON & STEEL CO LTD

Abandoned thermosetting plastic modified asphalt and modified asphalt mixture

The invention discloses an abandoned thermosetting plastic modified asphalt and a modified asphalt mixture. The modified asphalt mixture is prepared by adding abandoned thermosetting plastic to asphalt; the particle sizes of the abandoned thermosetting plastic are smaller than or equal to 0.15mm; the abandoned thermosetting plastic is one or more of abandoned phenolic plastic, amino plastic, urea formaldehyde, melamine, epoxy resin, furan resin, unsaturated polyester resin and silicon resin. By adopting the characteristics that the abandoned thermosetting plastic has certain compatibility with the asphalt, the abandoned thermosetting plastic is processed into granules of which the sizes are close to the particle sizes of mineral powder and fine aggregates, so that partial mineral powder, fine aggregates and asphalt can be replaced with the abandoned thermosetting plastic; the wastes are fully reutilized; the environment pollution is reduced; the resources and the costs are reduced; the properties such as high temperature and strength of the asphalt and the asphalt mixture are improved.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR +1

Flower arrangement mud special for cherry flower and production process thereof

InactiveCN106045673AIncrease the number of reusablePromote degradationFloral handlingAlkali orthophosphate fertiliserIonEthylene-vinyl acetate

The invention discloses flower arrangement mud special for cherry flower and a production process thereof. The flower arrangement mud comprises the following components according to parts by weight: 50-80 parts of phenolic plastic, 40-60 parts of clay powder, 15-30 parts of urea, 10-20 parts of ammonium dihydrogen phosphate, 15-25 parts of EVA (ethylene vinyl acetate), 10-15 parts of a water absorber, 10-20 parts of a degrading agent, 1-3 parts of silicone oil and deionized water. The invention has the advantages that elasticity of the flower arrangement mud is optimized through synergy of the components so that the reusable times of the flower arrangement mud can be greatly increased, up to higher than 10; in addition, in the production process of the flower arrangement mud, annealing treatment also plays a key role for the life of the flower arrangement mud; moreover, the flower arrangement mud has good degrading capacity, meets the concept of sustainable development, and has a promising market application prospect.

Owner:江苏春联农业科技发展有限公司

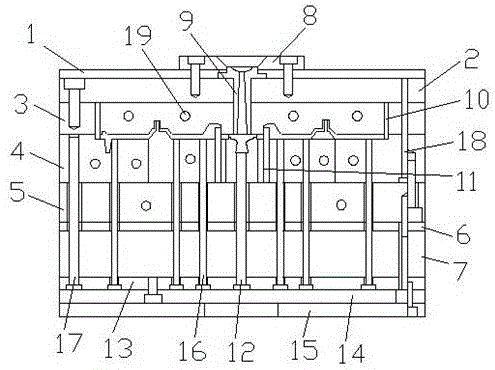

Thermal overload relay base injection mold

The invention discloses a thermal overload relay base injection mold. The thermal overload relay base injection mold comprises a fixed mold thermal insulation plate, a fixed mold bottom plate, a fixed mold plate, a movable mold plate, a movable mold bottom plate, a movable mold thermal insulation plate and a mold leg strip which are sequentially arranged from top to bottom. The fixed mold bottom plate is fixedly connected with the fixed mold plate. A positioning ring is arranged in the middle of the fixed mold thermal insulation plate and is fixedly connected with the fixed mold thermal insulation plate. A sprue bush is arranged in the positioning ring. First forming inserts are arranged at the two ends of the fixed mold plate. A second forming insert is arranged below the sprue bush. The thermal overload relay base injection mold is made of thermoset phenolic plastic through injection molding, the forming temperature is high, manufactured products are good in quality and high in machining accuracy, and mold opening is stable and reliable.

Owner:WUXI YICHEN MOLD TECH

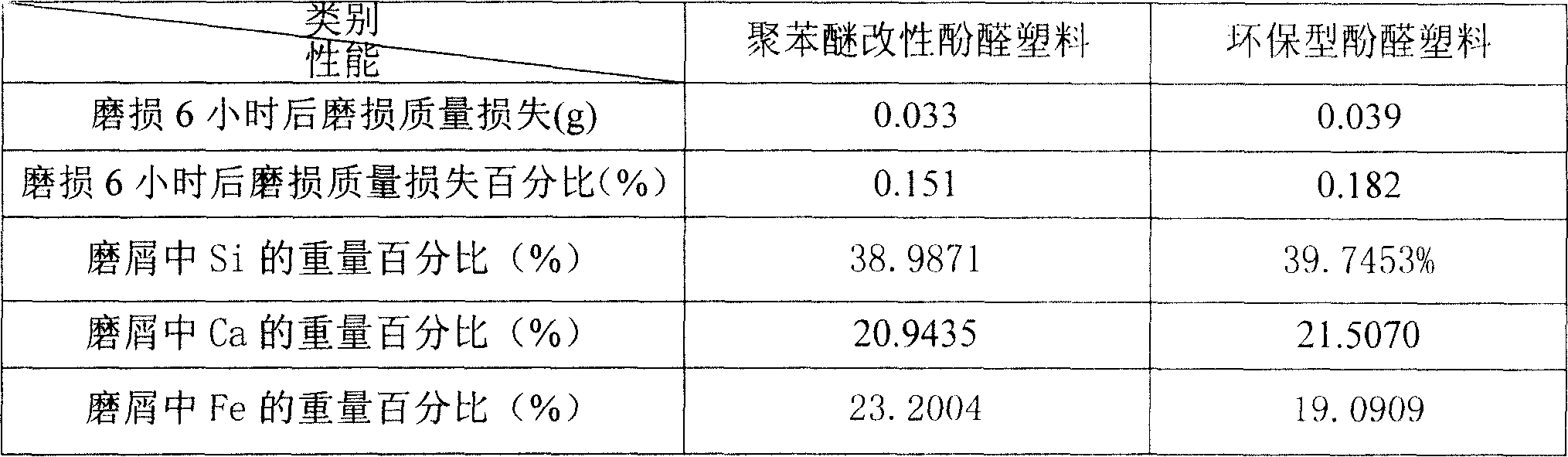

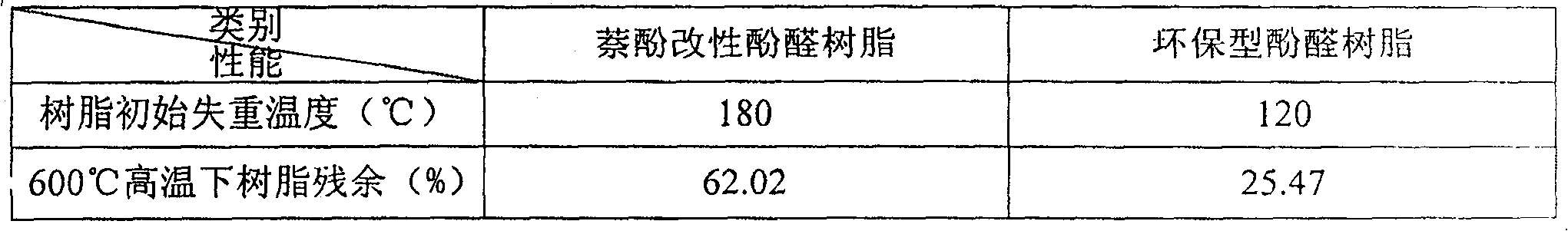

Polyphenylether modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The ratio of the components : Phenol 100, solid paraform 40 - 45, polyphenylene oxide ether10- 15, modifier X 10-15, fiberglass 55 - 60, polysulfone 10 - 20, while sodium pentachlorophenate 2 -5, solvents 94 -100. Through the stir conditions adding modifier X into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Novel chip packaging body and packaging method thereof

PendingCN111081672ASimple and flexible production processHigh hardnessSemiconductor/solid-state device detailsSolid-state devicesEngineeringPhenoplasts

The invention provides a novel chip packaging body and a packaging method thereof. The novel chip packaging body comprises a base plate, insertion pins and a cap; the base plate comprises a substrate,through holes, a well bottom, golden fingers and a base step; and the through holes are divided into inner-layer through holes and outer-layer through holes. The production process of the novel chippackaging body is simple and flexible, is compatible with existing wire bonding environments, and can be used for rapidly preparing a sample at low cost in an engineering stage. The substrate of the novel chip packaging body is made of specific phenolic plastic, so that the substrate has the characteristics of high hardness, high temperature resistance, wear resistance, corrosion resistance, insulation and the like, and is electrically connected with a chip through combining pins. According to the packaging method of the novel chip packaging body, the cap can be directly and manually added, sothat external force-induced damage is avoided; the design of the method meets FA related requirements in the engineering stage; peripheral devices are conveniently added; and electric damage can be directly observed for failure analysis.

Owner:BEIJING TONGFANG MICROELECTRONICS

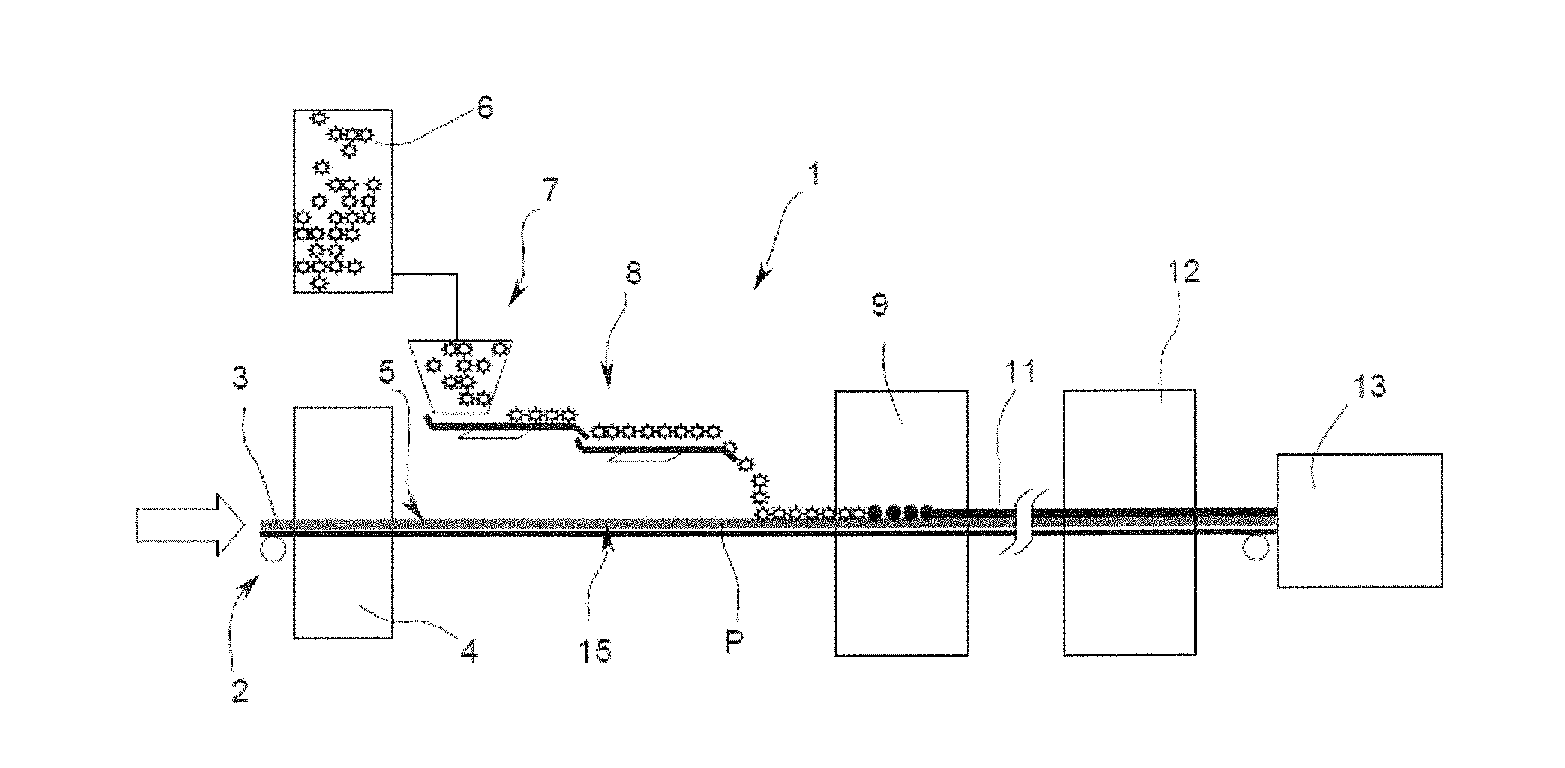

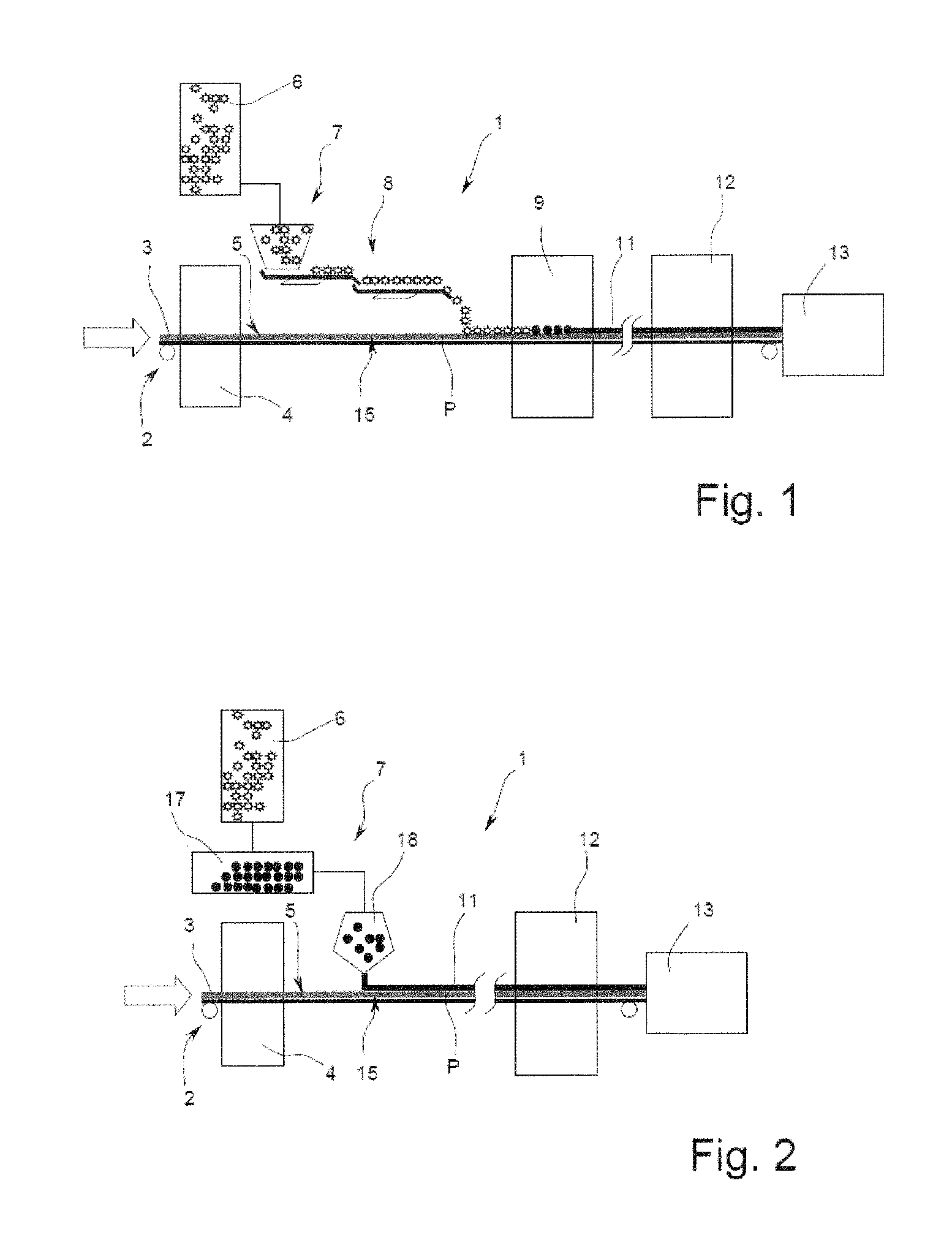

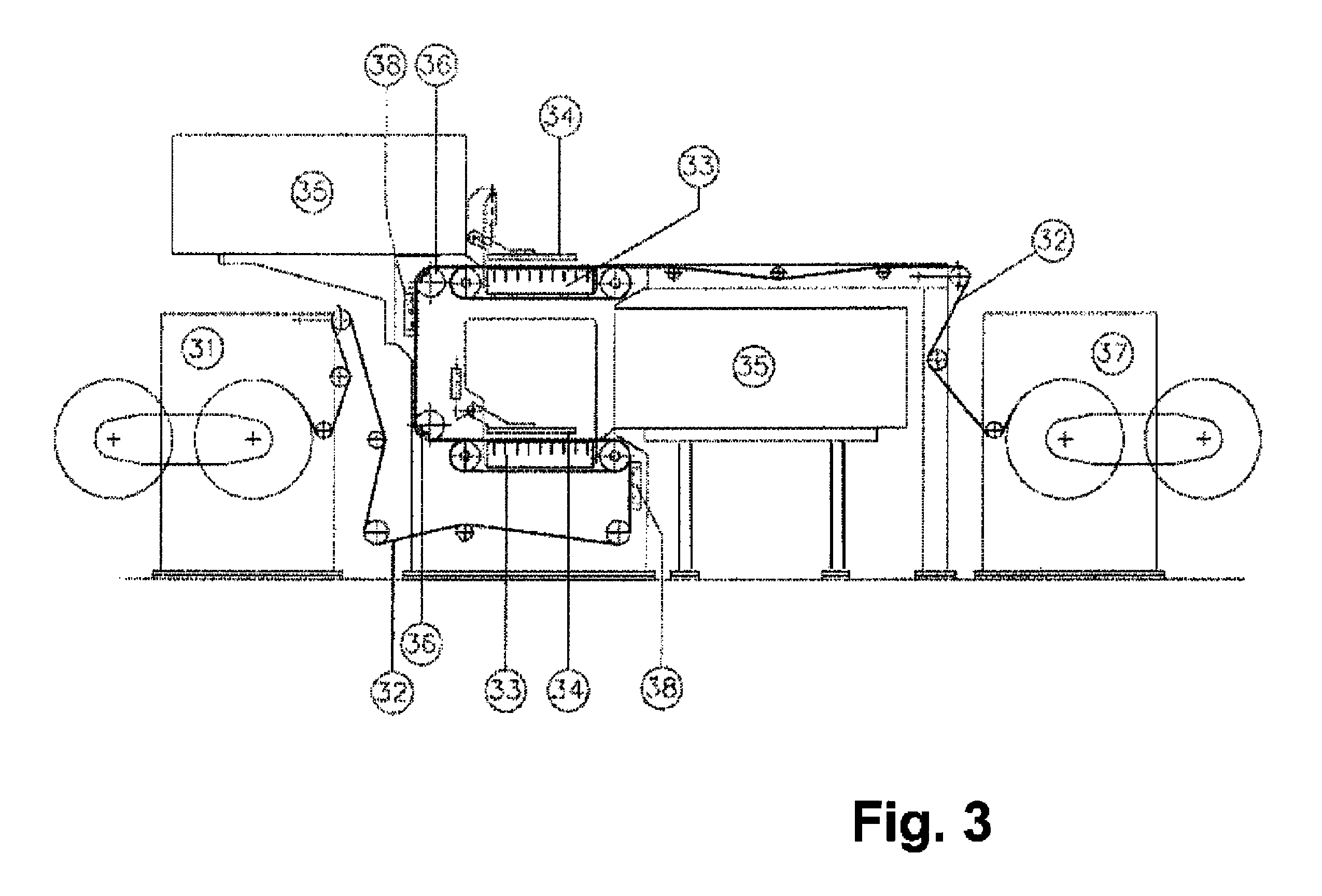

Process and apparatus for manufacturing decorative papers and/or panels for flooring or surfacing of furniture, walls, etc

ActiveUS8445060B2Avoid whiteningQuality improvementSpecial ornamental structuresPretreated surfacesEngineeringFilter paper

A process for manufacturing decorative papers and / or panels for flooring or surfacing of furniture, wall, finish foils, filter papers or kraft papers for low and high pressure use etc., in which a substantially dry solid composition is prepared in powder form, having a polymer component containing aminopiasts (amino resins) and / or phenoplasts (phenolic resins) and / or mixtures in powder form, used as such and / or mixed with additives; the composition is then applied dry on a support in powder form and is heated after being deposited onto the support to melt the composition and form a coating polymer layer onto the support; the composition may instead be heated first to be molten before and then applied in a fluid form onto the support.

Owner:SURFACE TECH

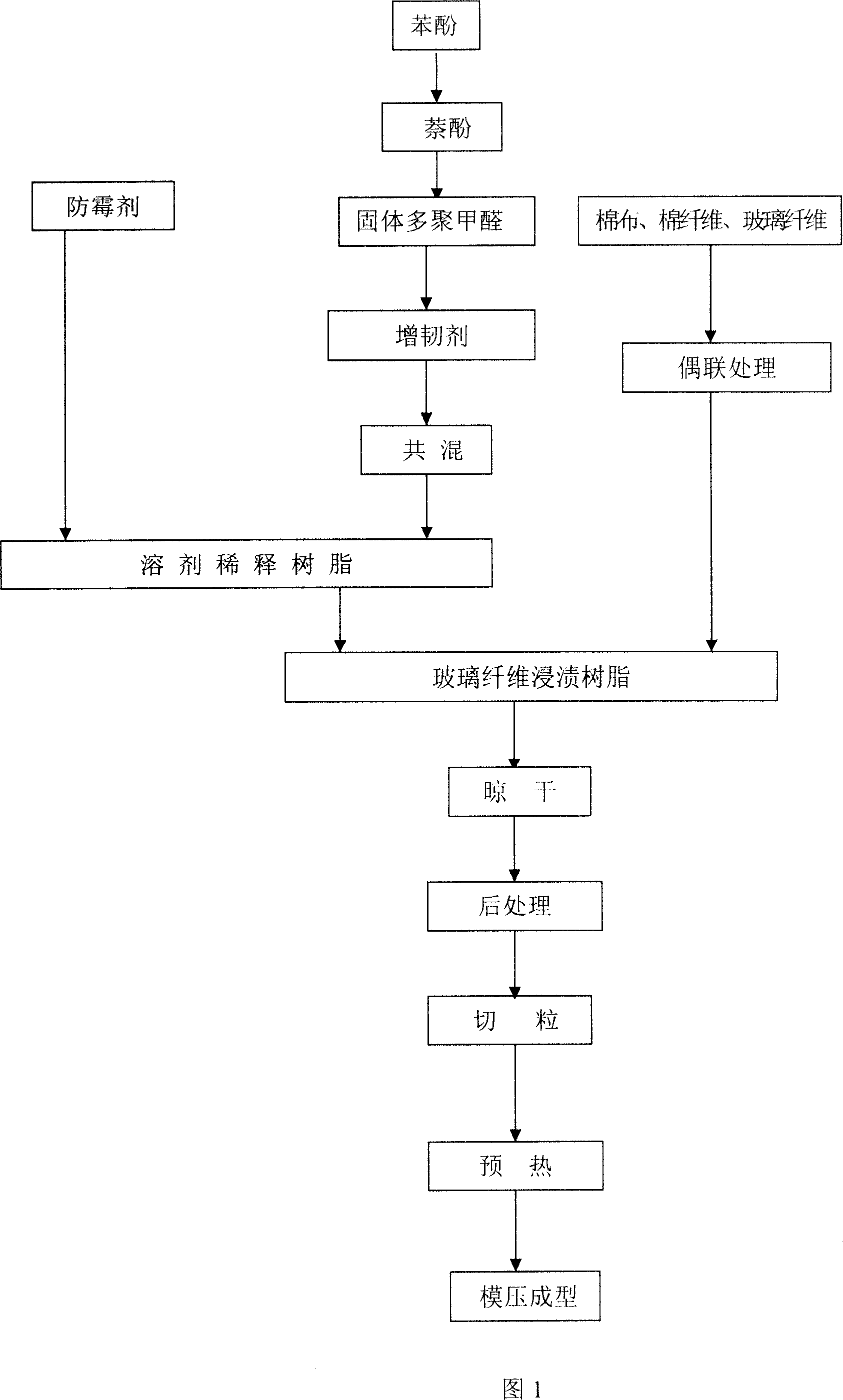

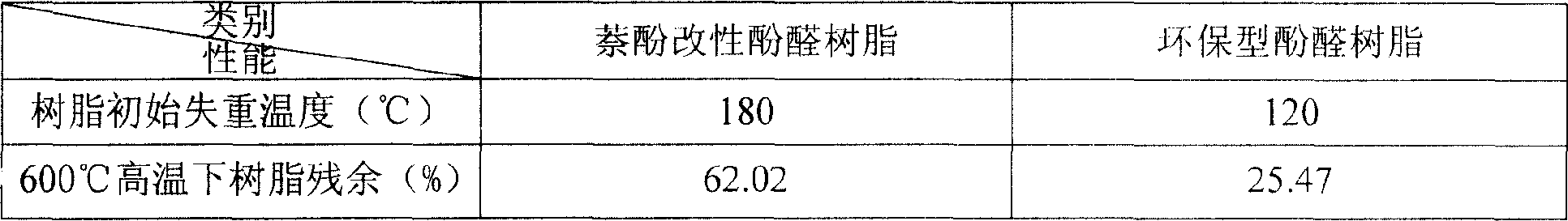

Naphthol-modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The technical characteristics lie on the ratio of the components: 100 phenol, solid paraform 40 - 45, naphthol 10 - 15 and fiberglass 55 -60, polysulfone 10- 20, sodium pentachlorophenate 2 - 5, solvents 94 -100. Through the stir conditions adding naphthol into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Chemical composition and process

The invention concerns an aqueous slurry comprising thermally expandable microspheres comprising a thermoplastic polymer shell and a propellant entrapped therein, said slurry further comprising an at least partially water soluble polymer selected from the group consisting of gums, celluloses, chitins, chitosans, glycans, galactans, pectins, mannans, dextrins, polyacrylic acid, esters and amides and co-polymers thereof, polymethacrylic acid, esters and amides and co-polymers thereof, rubber latexes, poly(vinyl chloride) and copolymers, poly(vinyl esters) and co-polymers, poly(vinyl alcohol), polyamines, polyetyleneimine, polyethylene / polypropylene oxides, polyurethane, and aminoplast and phenoplast precondensates and polyamidoamine epichlorohydrin resins. The invention further concerns a process for its preparations, use thereof for the production of paper or non-woven, and a process for the production of paper or non-woven.

Owner:AKZO NOBEL NV

Method for electroplating copper for phenolic plastic

InactiveCN104630856AEasy to operateLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention discloses a method for electroplating copper for phenolic plastic, and belongs to the field of electroplating processes. The method is characterized by comprising the following steps: soaking and cleaning work-pieces by using a 1% washing powder solution; drying the work-pieces by using a spin-drying or medium temperature baking method; performing dust removal on the surfaces of the work-pieces by using strong wind; determining the types of conductive metallic paint; preparing the conductive metallic paint by using brass powder, silver-plated copper powder, sub-nano grade copper powder, aluminum slurry and zinc powder; determining the proportion of each component of the conductive metallic paint, namely preparing the conductive metallic paint by using polyester resin, solvents, the sub-nano grade copper powder and an auxiliary agent, and determining the mass percents of the polyester resin, the solvents, the sub-nano grade copper powder and the functional auxiliary agent; and preparing a copper-plating layer by using an acidic copper plating method, and performing chemical copper plating. By adopting the method disclosed by the invention, the surface of the phenolic plastic can be directly electroplated, and the current situations that the phenolic plastic cannot be electroplated directly or in large scale and serious pollution can be caused by electroplating sewage at present can be changed; and the method disclosed by the invention is simple to operate and easy to popularize.

Owner:雷瑜

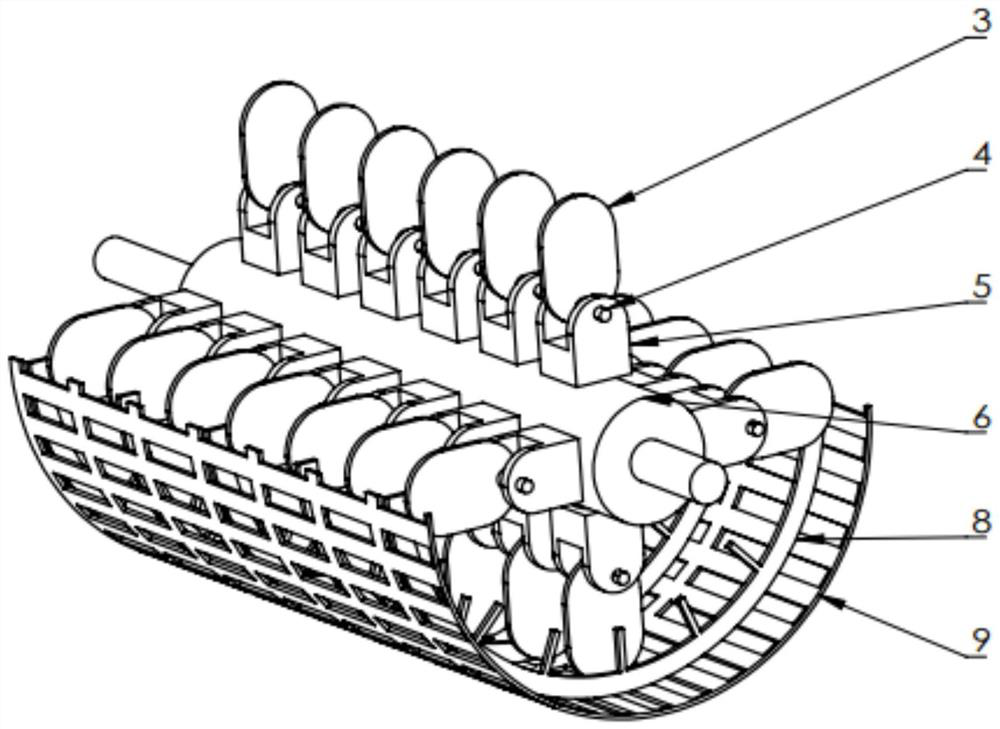

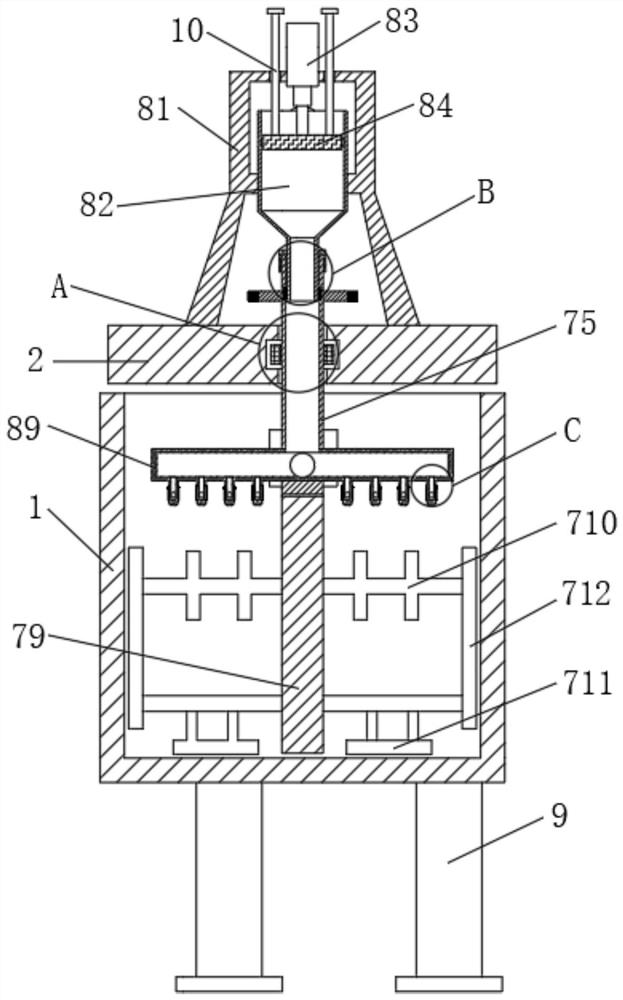

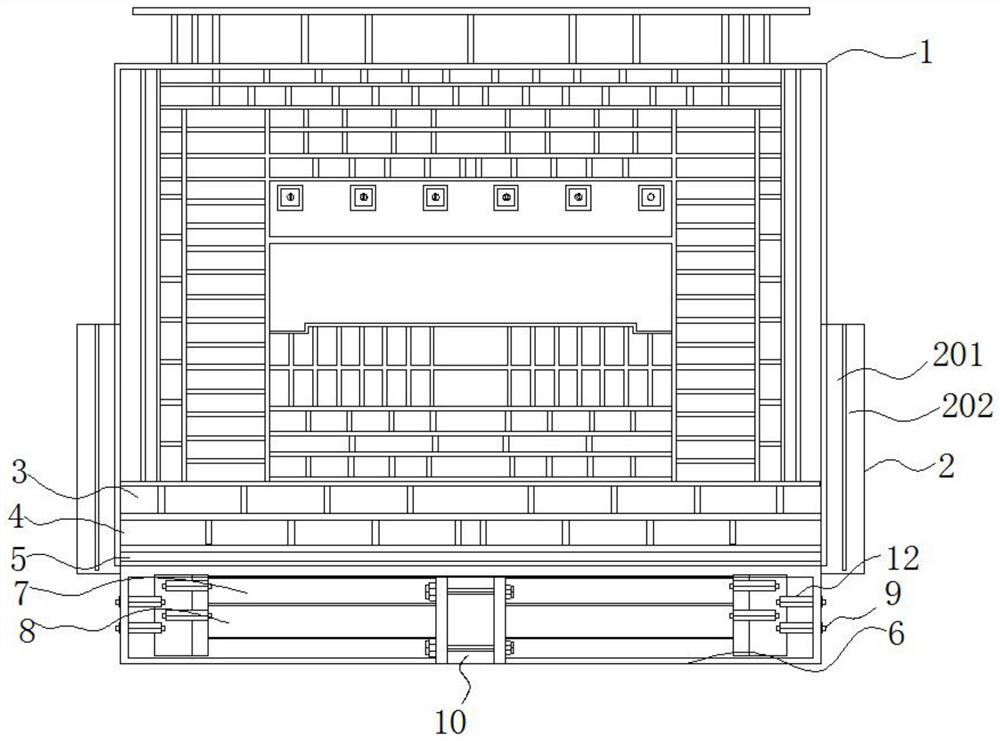

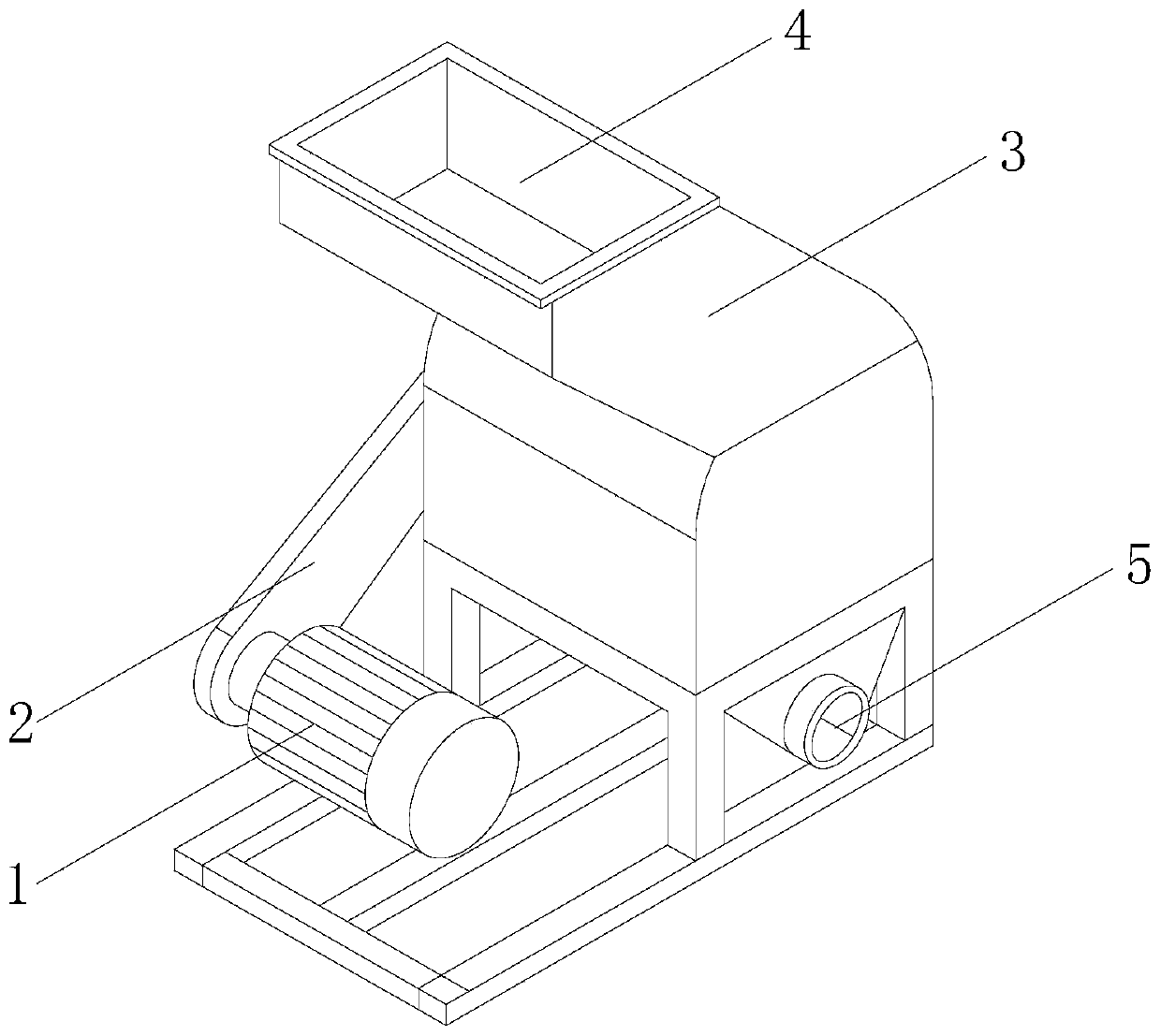

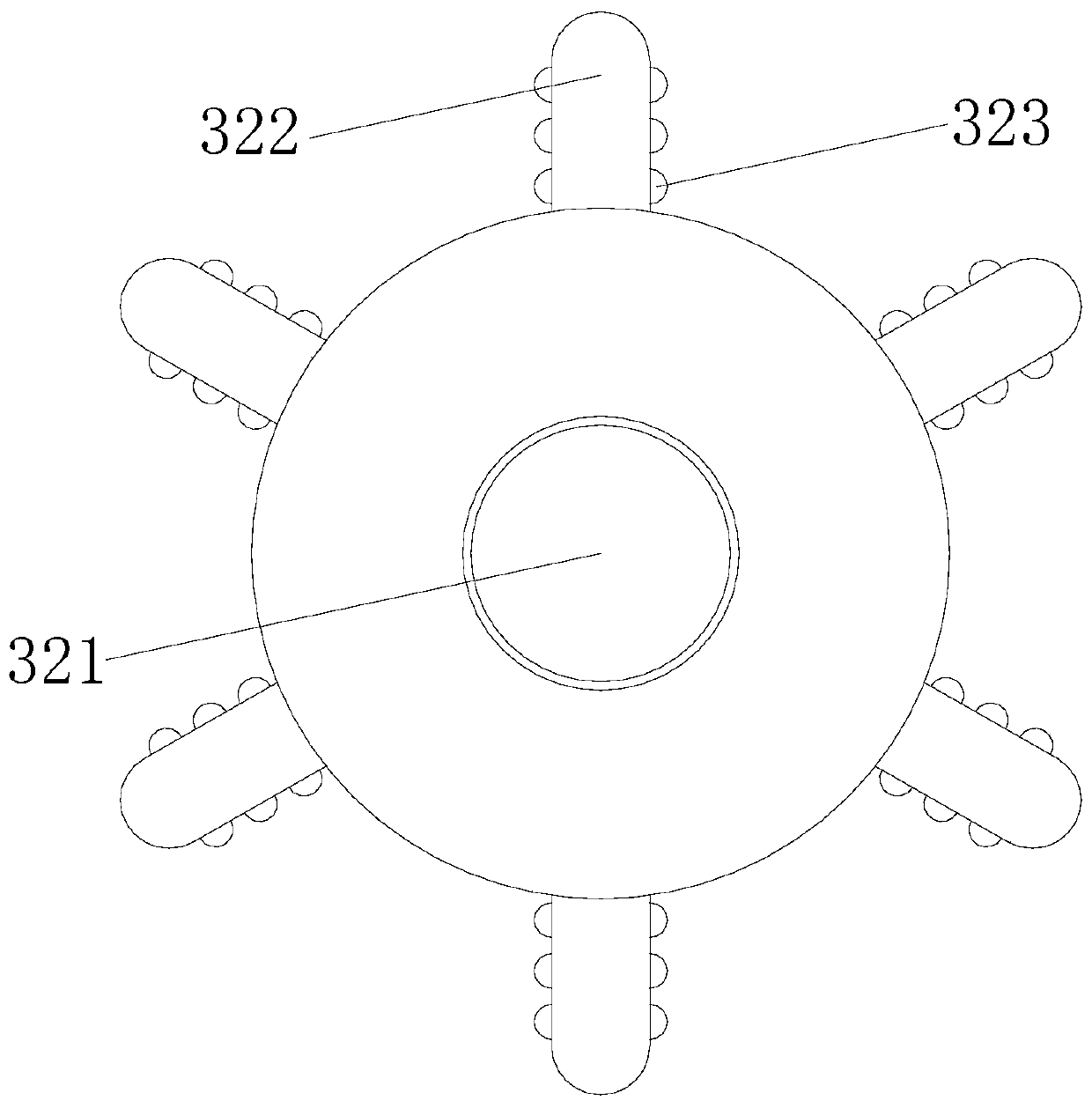

Special phenolic plastic crushing equipment based on mechanochemical method and crushing method

ActiveCN112774813ATissue crispEasy to crushPlastic recyclingGrain treatmentsElectric machineryEngineering

The invention discloses special phenolic plastic crushing equipment based on a mechanochemical method and a crushing method. The equipment comprises a supporting frame, a primary crushing device, a secondary crushing device, a third-stage crushing device and an automatic adjusting device, wherein the primary crushing device comprises a crushing box, a first motor, a first transmission rod, a plurality of cutter rests, a plurality of blades, a plurality of fixed cutters, a screen and a guide hopper, the secondary crushing device comprises a first roller, a second roller, a second transmission rod and a bevel gear set, and the third-stage crushing device comprises a second motor, a conical blade group and a plurality of strain sensors, and the conical blade group comprises a conical inner cutter and a conical outer cutter. According to the special phenolic plastic crushing equipment, the material is rapidly crushed, the crushing efficiency and the crushing effect are greatly improved, cross-linked chemical bonds of phenolic plastic can be broken, the molecular weight of the phenolic plastic can be reduced, cross-linked chemical bonds with weak bond energy can be broken without breaking a main chain of a polymer, the phenolic plastic has certain plasticity and chemical activity again, and regeneration of a new mixed material is facilitated.

Owner:INTELLIGENT MFG INST OF HFUT +1

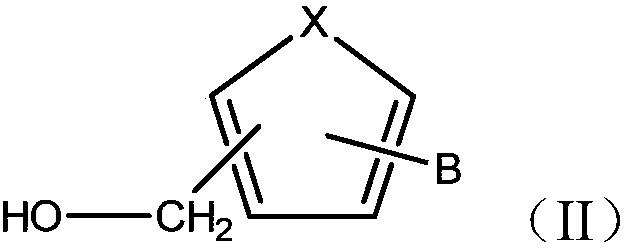

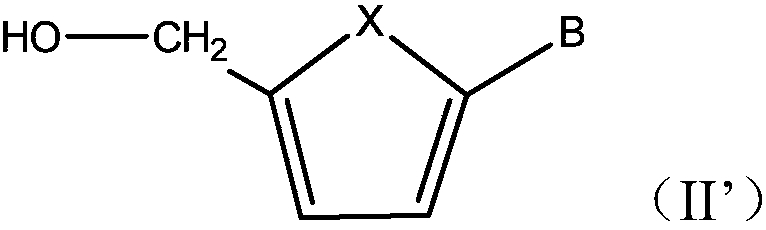

Aqueous adhesive composition comprising thermosetting resin

PendingCN109312039AEasy to understandFibre treatmentAdhesive processes with surface pretreatmentPolymer scienceOrtho position

The invention relates to an aqueous adhesive composition comprising a thermosetting resin including: at least one aromatic compound bearing at least two functions, one of said functions being a hydroxymethyl function, the other being an aldehyde function or a hydroxymethyl function, the aromatic compound comprising at least one aromatic ring; and at least one aromatic polyphenol comprising at least one aromatic ring bearing at least two hydroxyl functions in the meta position relative to one another, the two ortho-positions of at least one of the hydroxyl functions being non-substituted. Suchan adhesive composition can be used, in particular, to assemble wooden elements, and is an advantageous alternative to the use of a formaldehyde-based phenolic plastic glue.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

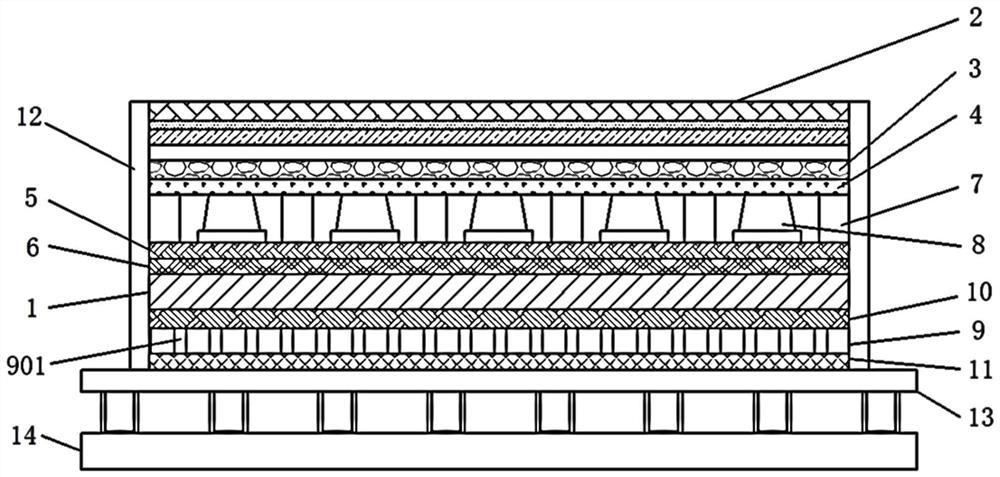

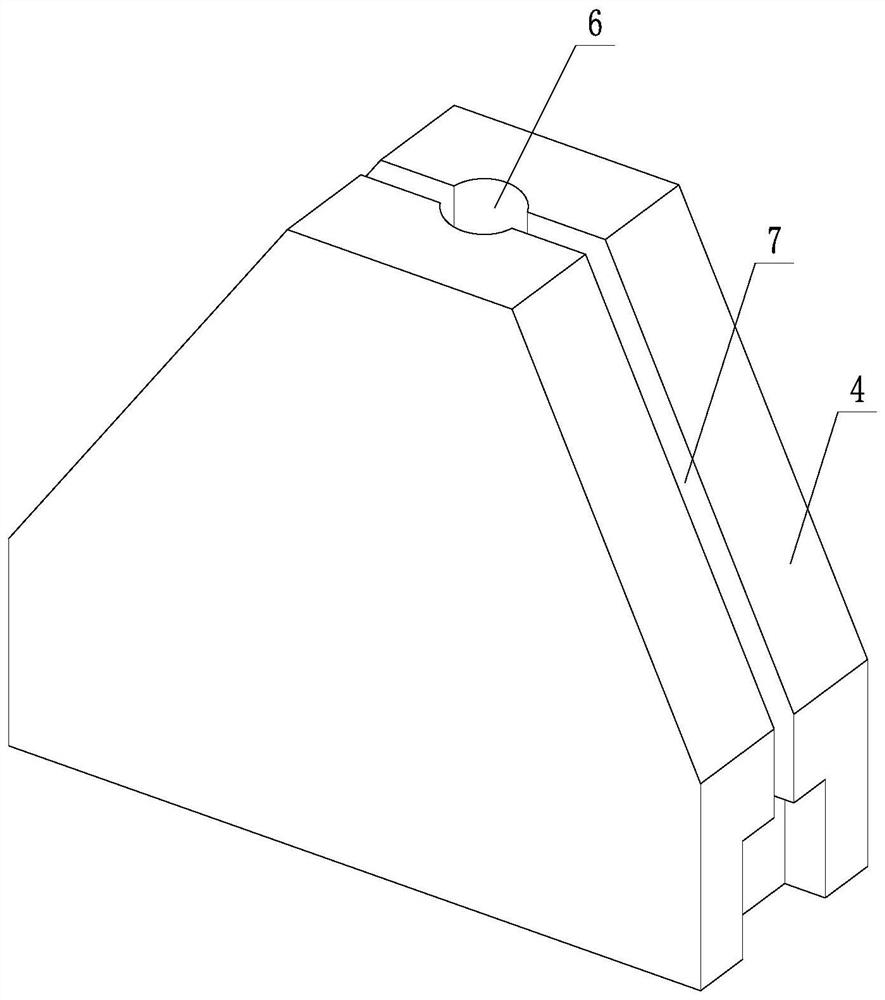

Prefabricated lightweight aggregate composite insulation board for building decoration construction

ActiveCN114412110AAvoid breakingImprove toughnessCovering/liningsSynthetic resin layered productsArchitectural engineeringStructural engineering

The prefabricated lightweight aggregate composite insulation board comprises an insulation base plate, a phenolic plastic foaming plate is arranged on the surface of the bottom of the insulation base plate, an anti-deformation mechanism is arranged on the surface of the top of the insulation base plate, and an inner supporting mechanism is arranged on the surface of the top of the anti-deformation mechanism. An installation space is provided for the composite insulation board through the insulation base board, and an insulation function is provided for the composite insulation board through the phenolic plastic foaming board. In the using process of the composite insulation board, shock absorption generated by external impact is counteracted through the anti-deformation mechanism, the external impact is buffered through the inner supporting mechanism, and therefore the composite insulation board is prevented from being broken, and the toughness and the deformation capacity of the whole composite insulation board are enhanced.

Owner:SHENZHEN BUILDING DECORATION GRP

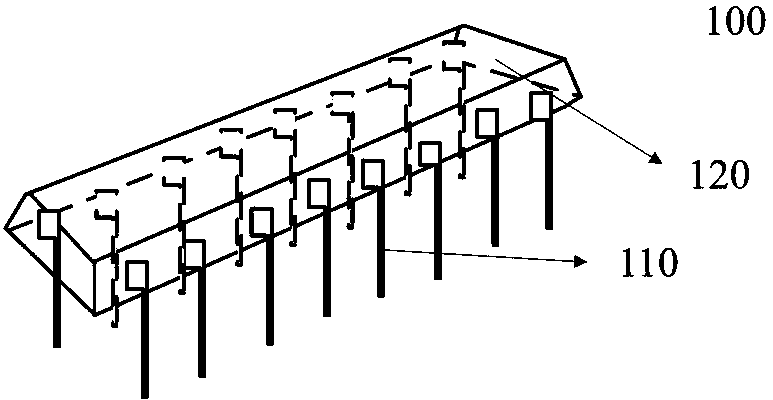

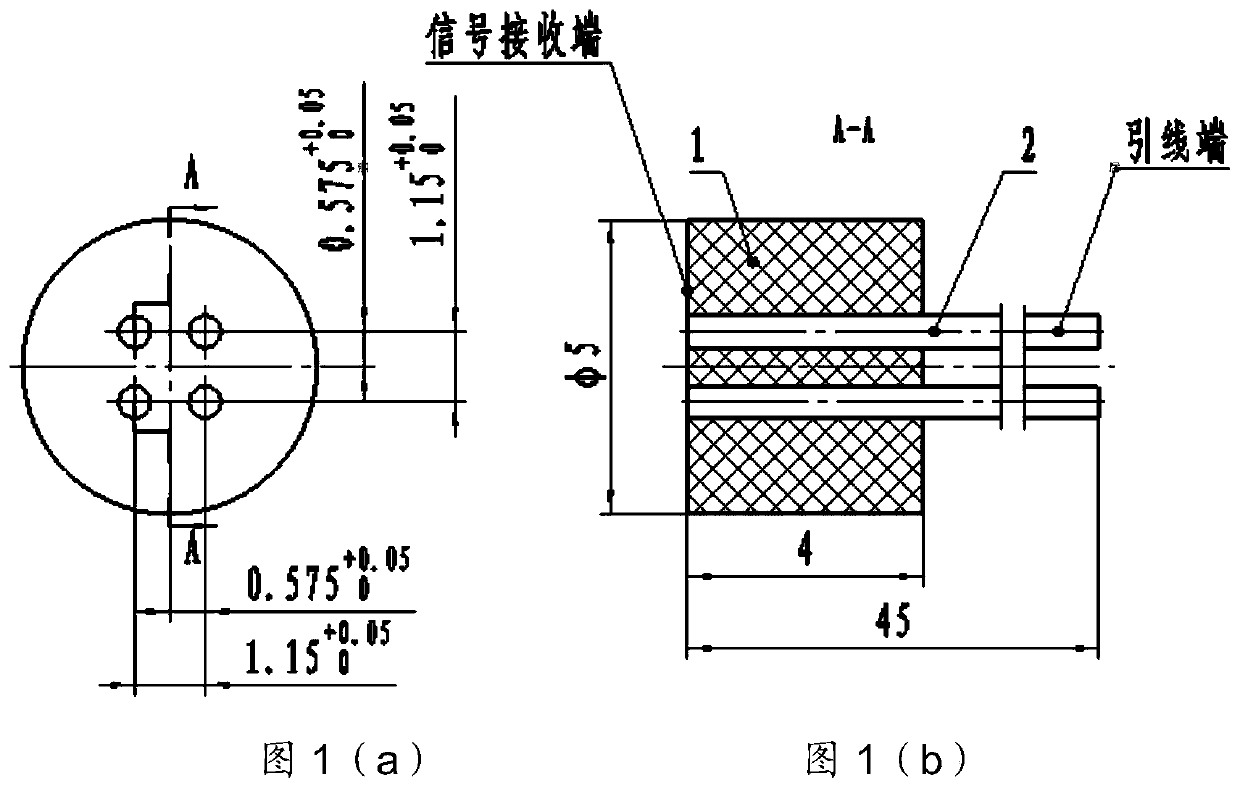

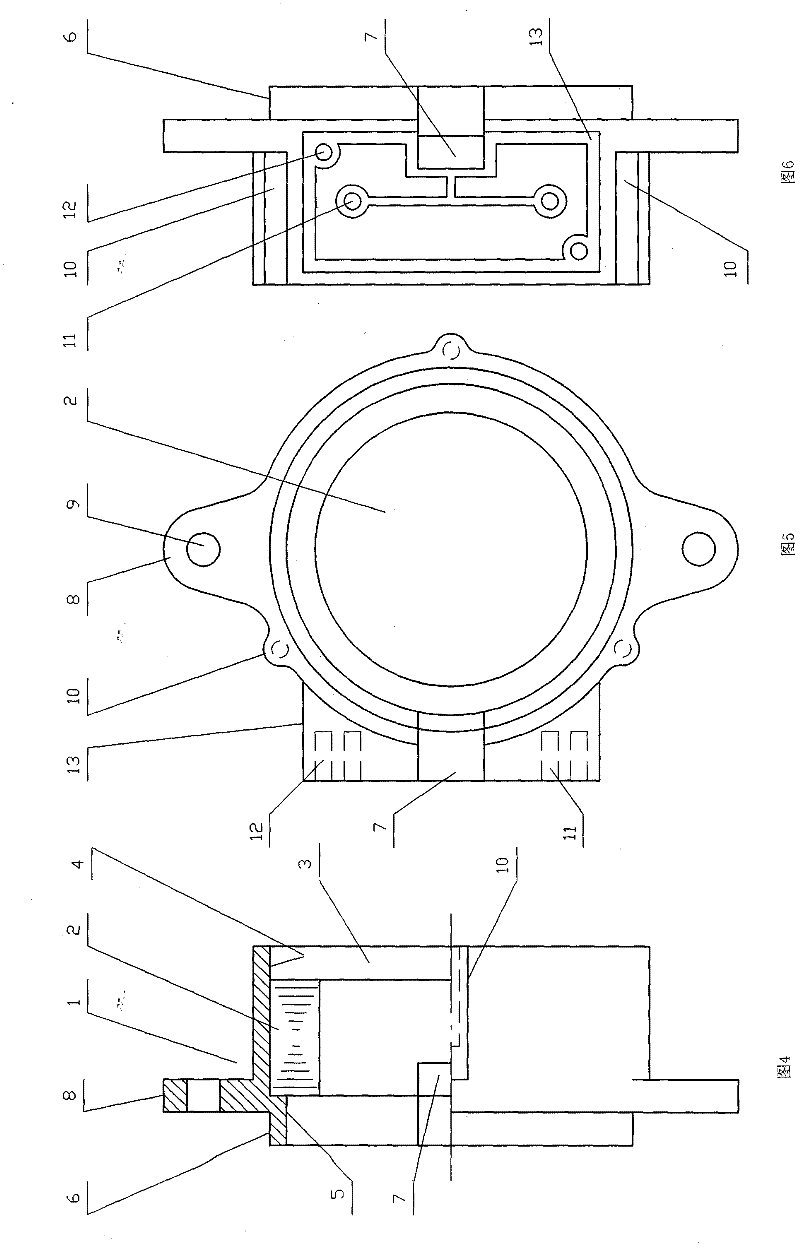

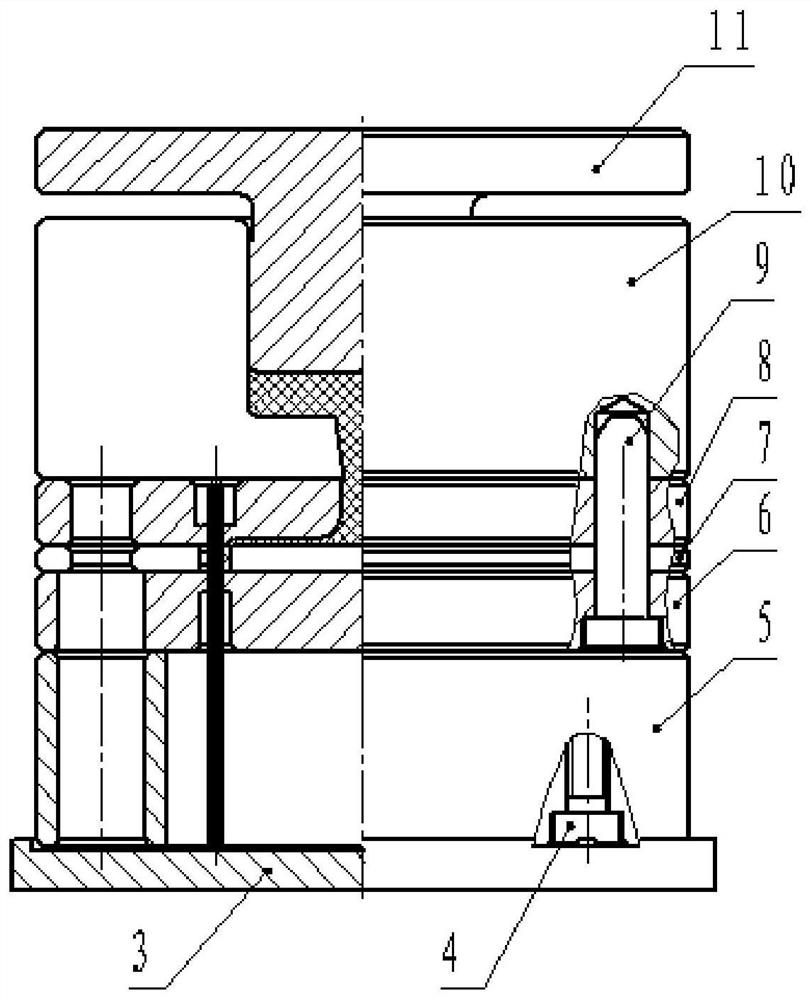

Ionization signal receiver, preparation tool and method and initiating explosive device test system

ActiveCN110768685AFor long-term storageMeet the needs of high synchronization testingDomestic articlesTransmissionStructural engineeringPhenoplasts

The invention relates to an ionization signal receiver, a preparation tool, a preparation method and an initiating explosive device test system. The ionization signal receiver comprises phenolic plastic and 2N enameled wires pressed and injected on the phenolic plastic, wherein N is greater than or equal to 1, every two varnished wires form a group, the distances between the two varnished wires ineach group are consistent, one end of each varnished wire is wrapped in phenolic plastic, the end face is flush with the end face of the phenolic plastic, ionization signals generated when the linearinitiating explosive device works are received, and the other end of each varnished wire extends out of the phenolic plastic to be output as a pole needle; and the enameled wires in each group are mutually backed up. The preparation tool and the preparation method ensure that the distance between the two enameled wires in the same group of the ionization signal receiver is 1.15 cm-1. 20cm, and finally improve the test precision of the working time synchronism of the multi-path linear initiating explosive device.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

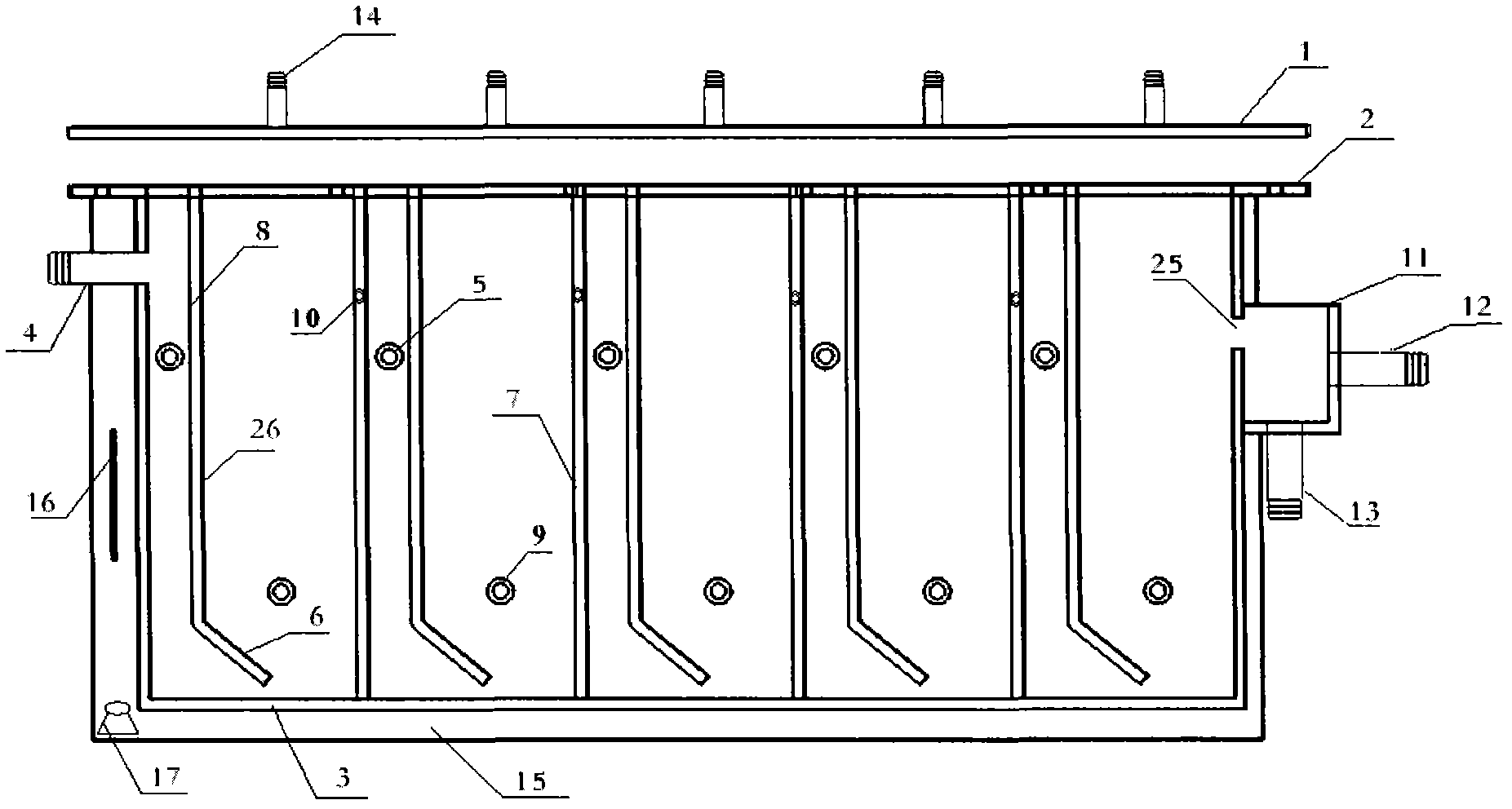

Apparatus and method for microbial treatment of high-concentration ammonia-nitrogen wastewater

ActiveCN103159321AImprove processing efficiencyAvoid churnTreatment with anaerobic digestion processesWater bathsHigh concentration

The invention discloses an apparatus and a method for microbial treatment of high-concentration ammonia-nitrogen wastewater. The apparatus is composed of a reactor main body, a temperature controller, a pump, etc. The reactor main body is a cuboid structure and prepared by transparent synthetic glass or phenoplasts. The reactor main body is divided into 3-6 same compartments, and each compartment is divided into two regions of different sizes and is filled with zeolite, maifan stone and other natural minerals. One end of the reactor is provided with a liquid inlet while the other end is provided with a liquid outlet and a water collecting groove which is provided with two outlets: a water outlet and a backflow port. The reactor main body is nested in a water bath. A to-be-processed liquid is introduced into the reactor main body through a water pump, separated and degraded by microorganism, and then introduced into the water collecting groove through a drain outlet, wherein supernatant in the water collecting groove enters a liquid collecting barrel through the water outlet, and a sinking liquid flows back to the reactor main body through a reflux pump. A degradation process of the high-concentration ammonia-nitrogen wastewater can be realized under a temperature of 30-40 DEG C, a reflux ratio of 2-5 : 1 and a pH of 7.0-8.5.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

ABS composite material, application and preparation method thereof

ActiveCN111138801AGuaranteed mechanical propertiesImprove bending abilityAdditive manufacturing apparatusPlastic recyclingCarbide siliconPolymer science

The invention relates to an ABS composite material, and application and a preparation method thereof, belonging to the technical field of macromolecules. The ABS composite material comprises the following raw material components in percentage by weight: 53.5%-89.6% of regenerated ABS, 0.1%-1% of a chain extender, 5%-15% of regenerated phenolic plastic, 2%-15% of silicon carbide, 2%-15% of aluminumoxide, 0.1%-0.3% of a coupling agent, 0.1%-0.5% of an antioxidant and 0-4% of other assistants. The ABS composite material provided by the invention has excellent mechanical properties and excellentshrinkage and warping resistance, and can be used for 3D printing.

Owner:宁波坚锋新材料有限公司

Insulating weather-resistant high-precision electronic connecting wire

InactiveCN113066607AFast agingLow heat resistanceInsulated cablesInsulated conductorsElectrical conductorWeather resistance

The invention provides an insulating weather-resistant high-precision electronic connecting wire, and relates to the technical field of electronic wires. The insulating weather-resistant high-precision electronic connecting wire comprises a conductor, an insulating layer, a filling layer and a protective layer which are arranged from inside to outside, and is characterized in that the insulating layer comprises a first insulating layer and a second insulating layer, and the inner side of the second insulating layer is provided with a frosted surface; the protective layer is prepared from the following raw materials in parts by mass: 40-60 parts of polyethylene, 15-18 parts of silicate compound particles, 12-19 parts of silicone oil, 8-11 parts of boron nitride powder, 0.6-0.9 part of dimethylaminobenzene, 0.2-0.6 part of an anti-aging agent and 2-4 parts of a vulcanizing agent. The first insulating layer and the second insulating layer are arranged, the silicone oil and the boron nitride powder are added into the protective layer, and the phenolic plastic powder and the vinyl carboxylate are added into the filling layer, so that the heat dissipation effect of the filling layer and the protective layer is improved, and the effect of prolonging the service life of the electronic connecting wire is achieved.

Owner:重庆涪昇电子科技有限公司

Phenolic plastic foam and production process thereof

The invention discloses a phenolic plastic foam. The phenolic plastic foam is prepared from 600 Kg of phenol, 375 Kg of solid formaldehyde, 8 Kg of an alkali, 25 Kg of water, 5 Kg of formic acid and 25 Kg of urea. A production process of the phenolic plastic foam comprises the following steps: preparing phenolic resin glue, firstly pumping dissolved phenol into a reaction kettle, sequentially pumping paraformaldehyde and a dissolved alkali, starting to heat the solution from about 50 DEG C to 55 DEG C for 20 min, continuing to heat the solution to 65-70 DEG C for 1.5 h, and then starting heat preservation at 72-82 DEG C. The pH value of the phenolic plastic foam is superior to that of similar products at home and abroad, most of the similar products at present have the pH value of 2-3 and can be neutral only after being neutralized by ammonia water and ammonia gas, produced phenolic plastic foam changes the PH value of existing phenolic resin, the water storage capacity and the production efficiency are improved, bad gas is discharged, the pH value reaches 5-6, plant root burning is avoided, the forming speed is high, and the phenolic plastic foam can be used for fresh-keeping and seedling raising of fresh cut flowers.

Owner:肖海风

Copper electroplating method for phenolic plastic

InactiveCN107904637AEasy to operateLiquid/solution decomposition chemical coatingElectrically-conductive paintsCopper platingSilver plate

The invention relates to a method for electroplating copper on phenolic plastics, which belongs to the field of electroplating technology. It is characterized in that it includes: soaking and cleaning the workpiece with 1% washing powder solution; drying the workpiece by drying or baking at medium temperature; dedusting the surface of the workpiece by strong wind; determining the type of conductive metal paint; using brass powder, silver-plated copper powder, sub-nanometer copper powder, aluminum paste and zinc powder to obtain conductive metal paint; determine the distribution ratio of each component of conductive metal paint: prepare conductive metal paint with polyester resin, solvent, sub-nanometer copper powder and additives, determine The mass fraction of polyester resin, solvent, sub-nanometer copper powder, and functional additives; the copper plating layer is prepared by acid copper plating method, and electroless copper plating. The surface of the phenolic plastic can be directly electroplated, which can change the current situation that the phenolic plastic cannot be directly electroplated, cannot be electroplated on a large scale, and is seriously polluted by electroplating sewage. The method of the invention is simple to operate and easy to popularize.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

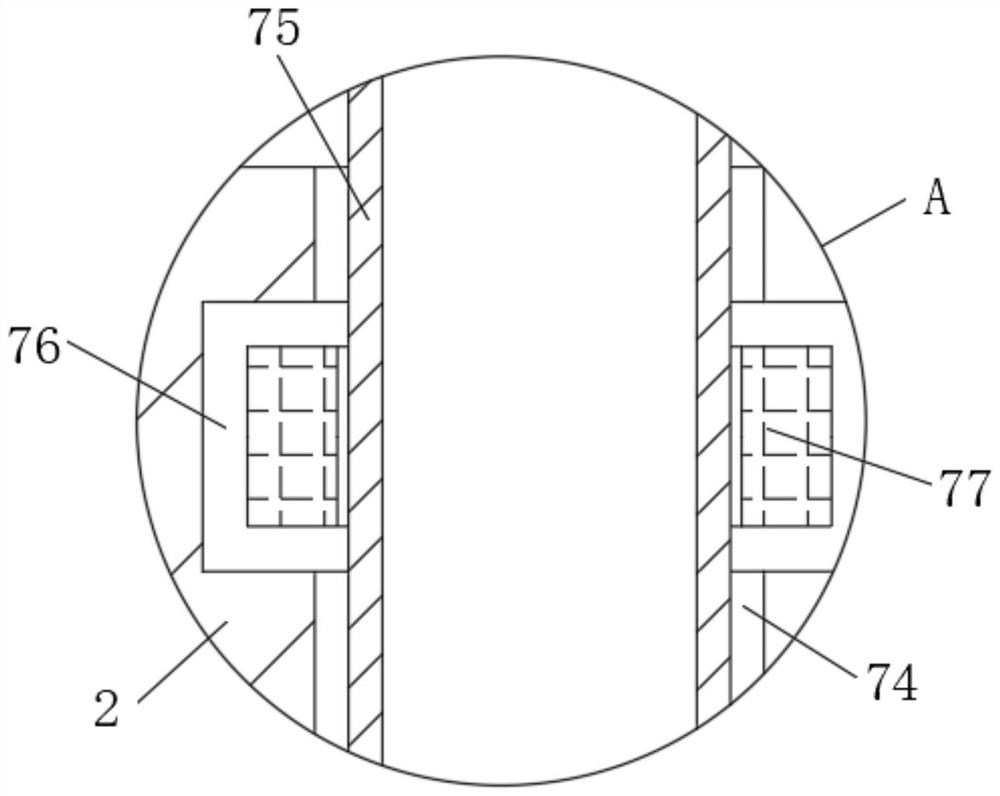

Shell of speed-measuring generator

InactiveCN102403817AReduce processing stepsImprove ergonomicsSupports/enclosures/casingsEngineeringPhenoplasts

This invention discloses a shell (1) of a speed-measuring generator, wherein the shell (1) is cylinder-shaped in general; the interior of the shell (1) is provide with a cavity body (3) portion capable of containing a stator (2); the left end of the cavity body (3) is provided with a bump part (5) portion capable of limiting the stator (2); the outer surface of the left end of the shell (1) is a circular joint (6); the right side of the joint (6) is provided with a protruding part (8) which is extended outwardly along a radial direction; holes (9) are arranged closely the edge of the protruding part; an outgoing line outlet (7) is formed on the left end of the shell (1), wherein a stator winding lead is extended out of the outgoing line outlet (7); the wall of one side of the outgoing line outlet (7) on the shell (1) is also provided with a line connection board box (13); the shell (1) disclosed by this invention is characterize in that the shell (1) is made of phenolic aldehyde plastic in an integrated-plastic method; the stator (2) can be pressed into the right end of the cavity body (3) and is retained in the cavity body (3); compared with the prior art, metal processing procedures of the shell and the stator can be saved; the consumption material of the shell is little; and the shell (1) disclosed by this invention has benefit technology effects of saving energy, reducing consumption and increasing working efficiency.

Owner:钱华

Energy-saving type mesh belt quenching furnace

PendingCN113481355AReduce thermal bridgingAvoid damageFurnace typesHeat treatment furnacesInsulation layerThermal bridge

The invention relates to an energy-saving type mesh belt quenching furnace which comprises a main body, heat preservation mechanisms and a steel channel base. The heat preservation mechanisms are arranged at the two ends of the exterior of the main body, and the steel channel base is installed at the bottom of the main body. Each heat preservation mechanism comprises a first furnace shell heat preservation layer. The first furnace shell heat preservation layers are arranged on the two sides of the bottom of the main body. The energy-saving type mesh belt quenching furnace has the beneficial effects that through the design of the steel channel base, phenolic plastic blocks with comprehensive excellent strength and heat insulation capacity are selected to be made into connecting blocks to replace a steel channel to serve as furnace bottom supporting rods, phenolic plastic is installed in the middle of the steel channel, the phenolic plastic and the steel channel are connected through bolts, the heat bridge phenomenon that furnace bottom heat energy is transmitted through the steel channel is reduced, in order to facilitate equipment manufacturing and installation, the steel channel base is designed to be of a double-supporting structure, namely, the steel channel base comprises phenolic plastic block supporting rods and steel channel supporting rods, and 6-8 steel channel supporting rods are evenly arranged on the steel channel base and connected with the base through bolts.

Owner:LENGSHUIJIANG TIANBAO IND

Waterproof antistatic wood floor of computer room

InactiveCN109025156AImprove insulation performanceImprove bearing capacityFlooring insulationsWaxAgricultural engineering

The invention discloses a waterproof antistatic wood floor of a computer room. The wood floor comprises a lower wood plate layer (4). A phenoplasts cellular column layer (3) is arranged on the lower wood plate layer (4). Cooperation protrusions (5) or cooperation grooves (6) are arranged in four edges of the phenoplasts cellular column layer (3). An upper wood plate layer (2) is arranged on the phenoplasts cellular column layer (3). The upper wood plate layer (2) is coated with a biological wax film layer (1). The wood floor is advantaged by quite good waterproof performance, quite good shock-proof performance and quite long service lifetime.

Owner:湖州春阁家居科技有限公司

Naphthol-modified phenolic resin, and its preparing method

This invention involves a naphthol modified phenolic resin and its preparation. The technical characteristics lie on the ratio of the components: 100 phenol, solid paraform 40 - 45, naphthol 10 - 15 and fiberglass 55 -60, polysulfone 10- 20, sodium pentachlorophenate 2 - 5, solvents 94 -100. Through the stir conditions adding naphthol into phenol, adding certain proportion of the solid paraform and polysulfone. In reactor adding solvents, resin diluted, and joined the sodium pentachlorophenate; fiberglass couple treated then uniform impregnation, after drying, postbaking, processing pelletizing and molding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Novel bimetallic wear-resistant pipe and manufacturing method thereof

InactiveCN114086088AImprove corrosion resistanceGood molding effectFireproof paintsAdditive manufacturing apparatusNiobiumManganese

The invention belongs to the technical field of metal casting, and particularly relates to a novel bimetallic wear-resistant pipe which comprises a lining pipe, an outer-layer pipe and a reinforcing coating. The lining pipe comprises the following raw materials in percentage by mass: less than or equal to 0.02% of carbon, 0.1-0.3% of nitrogen, 1.7-1.9% of manganese, 18-20% of chromium, 10-13% of nickel, 0.2-0.4% of silicon, 1.4-1.8% of aluminum, 0.8-2.3% of tantalum, 0.5-1.4% of niobium, 1.5-3.2% of hafnium, 0.1-0.3% of cobalt, 1-3% of tungsten, 1-3% of molybdenum, 0.3-0.6% of tellurium, 3-5% of nodular cast iron, 3-5% of gray cast iron, 3-5% of epoxy plastic, and 4-6% of phenolic plastic. The lining pipe and the outer-layer pipe are both made of stainless steel materials, so that the corrosion resistance, the formability, the compatibility and the obdurability in a wide temperature range of the bimetallic wear-resistant pipe are enhanced; and cast materials such as nodular cast iron, gray cast iron, epoxy plastic and phenolic plastic are added on the original basis, so that tensile strength of the bimetallic wear-resistant pipe is enhanced.

Owner:江苏鑫都管业有限公司

Ionization signal receiver, preparation tooling, method and pyrotechnic device test system

ActiveCN110768685BFor long-term storageMeet the needs of high synchronization testingDomestic articlesTransmissionStructural engineeringPhenoplasts

The invention relates to an ionization signal receiver, a preparation tool, a method and a pyrotechnic device testing system. The ionization signal receiver includes phenolic plastic and 2N enameled wires injected on the phenolic plastic, N is greater than or equal to 1, and every two enameled wires form a group , the distance between the two enameled wires in each group is the same, one end is wrapped in the phenolic plastic and the end face is flush with the phenolic plastic end face, to receive the ionization signal generated when the linear pyrotechnic device is working, and the other end extends out of the phenolic plastic as a pole needle output ; The enameled wires between each group are backups for each other. The preparation tooling and the preparation method ensure that the distance between two enameled wires of the same group of ionization signal receivers is 1.15 cm to 1.20 cm, and finally improve the test accuracy of the working time synchronization of the multi-line linear pyrotechnic device.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Method for producing coke through co-coking coal and waste/used phenolic plastics

ActiveCN105316016AAct as a buffer carrierReduce melting shrinkageProductsReagentsAcrylonitrileEnvironmental engineering

The invention relates to a method for producing coke through co-coking coal and waste / used phenolic plastics. The method for producing the coke through co-coking the coal and the waste / used phenolic plastics is characterized by comprising the following steps: (1) carrying out mixing and cooking on butadiene-acrylonitrile rubber and the waste / used phenolic plastics; (2) crushing treated plastics; (3) blending and crushing the treated plastics and matching coal; and (4) carrying out coking test on coal blend. According to the method for producing the coke through co-coking the coal and the waste / used phenolic plastics, disclosed by the invention, an effective method is provided for utilizing the waste / used phenolic plastics by co-charring butadiene-acrylonitrile rubber, the waste / used phenolic plastics and coking coal, the environmental pollution caused by the waste / used phenolic plastics is reduced, and meanwhile, part of replacing raw materials are provided for the shortage of coking coal resources, so that the method has very good economic and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

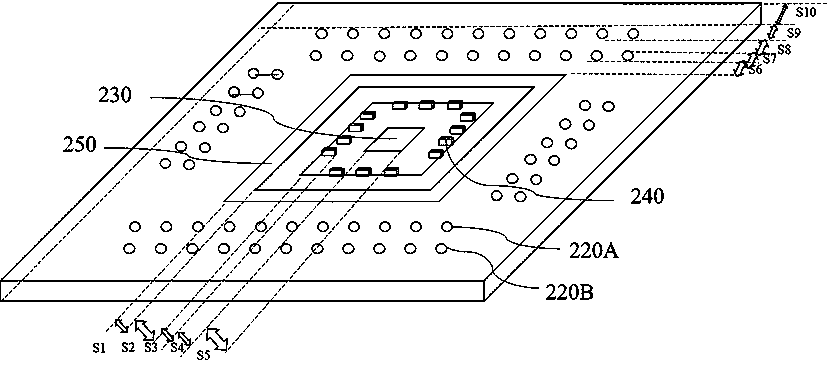

A multifunctional replaceable blasting electrode for plasma blasting experiment system

InactiveCN109855492BEasy to carry outFirmly connectedSecuring/insulating coupling contact membersCoupling contact membersEngineeringStructural engineering

A multifunctional replaceable blasting electrode for plasma blasting experiment system, including replaceable electrode assembly and base assembly; replaceable electrode assembly includes polyethylene insulating rod and copper rod electrode, and the surface of the insulating rod is provided with two electrode installation recesses Groove, the copper rod electrodes are located in the groove and distributed symmetrically; the base assembly includes a phenolic plastic substrate and copper conductive parts, the top of the substrate is provided with an electrode assembly jack, and the waist of the substrate is provided with two conductive parts installation grooves, which can replace electrodes The component is plugged and matched with the electrode component socket; one end of the electrode wire of the copper conductive part is located in the electrode component socket and is plugged with the copper rod electrode, and the other end is firmly connected with the disc joint, and the transfer screw is fixed on the disc. On the shaped joint, the adapter nut is set on the adapter screw; the installation groove of the conductive part is equipped with an insulating cover. The invention has the characteristics of small size, simple preparation process and high reutilization rate, can simulate both columnar medicine pack and spherical medicine pack, and has lower production cost.

Owner:NORTHEASTERN UNIV LIAONING

A method for producing coke by co-coking coal and waste phenolic plastics

ActiveCN105316016BAct as a buffer carrierReduce melting shrinkageProductsReagentsNitrile rubberAcrylonitrile

The invention relates to a method for producing coke through co-coking coal and waste / used phenolic plastics. The method for producing the coke through co-coking the coal and the waste / used phenolic plastics is characterized by comprising the following steps: (1) carrying out mixing and cooking on butadiene-acrylonitrile rubber and the waste / used phenolic plastics; (2) crushing treated plastics; (3) blending and crushing the treated plastics and matching coal; and (4) carrying out coking test on coal blend. According to the method for producing the coke through co-coking the coal and the waste / used phenolic plastics, disclosed by the invention, an effective method is provided for utilizing the waste / used phenolic plastics by co-charring butadiene-acrylonitrile rubber, the waste / used phenolic plastics and coking coal, the environmental pollution caused by the waste / used phenolic plastics is reduced, and meanwhile, part of replacing raw materials are provided for the shortage of coking coal resources, so that the method has very good economic and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

Pulverizer for plastic production

InactiveCN111438845AEfficient removalAvoid squeezingPlastic recyclingGrain treatmentsHeater RodPhenoplasts

The invention discloses a pulverizer for plastic production. The pulverizer structurally comprises a motor, a dustproof cover, a pulverizer body, a feeding port and a discharging port, wherein the output end of the motor is mounted in the dustproof cover; the upper end of the dustproof cover is mounted outside the pulverizer body; the feeding port is fixedly formed in the upper end of the pulverizer body and communicates with the pulverizer body; and in the process that a phenolic plastic shell is in contact with shifting plates, the moisture of phenolic resin in phenolic plastic is primarilydried through heating rods, then, the moisture in the phenolic resin is absorbed by silica gel in a storage box in the rotating process of rotating rollers, and the moisture in the phenolic plastic iseffectively removed. According to the pulverizer for plastic production, a rotating shaft rod rotates to drive movable cutters to rotate for cutting, the phenolic plastic shell is preliminarily pulverized, and a buffer distance is formed between hammer bodies and the cylinder wall through springs arranged between swing rods and the hammer bodies, so that the hammer bodies are prevented from excessively extruding fine phenolic plastic, and the phenolic plastic is prevented from being dissolved in the pulverizing process.

Owner:陈倩倩

A blocked isocyanate composition

This invention generally provides blocked isocyanate compositions and more specially blocked isocyanate compositions useful in aminoplastic resins, phenoplastic resins or latex resins for composite wood products, wherein the blocked isocyanate composition is obtained by adding alkylene carbonate to a blocked isocyanate (A), wherein the blocked isocyanate (A) is obtained by reacting a secondary amine (a1) with a reaction product (a2) of a polyfunctional isocyanate and a monofunctional hydroxyl containing compound, wherein the monofunctional hydroxyl containing compound is a polyethylene oxide polymer with terminal hydroxyl group, polyoxyethylene-polyoxypropylene monols or a mixture thereof, wherein the portion of blocked isocyanate (A) by weight percentage of the blocked isocyanate composition is between 50 and 90, preferably between 60 and 80. The compositions are stable at room temperature when mixed with active hydrogen containing compounds. The composition has low visicosity and after de-block has the potential to reduce free formaldehyde levels in formaldehyde containing resins.

Owner:HUNTSMAN INT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com