Ionization signal receiver, preparation tooling, method and pyrotechnic device test system

A signal receiver and tooling technology, applied in the transmission system, using the measurement of the change of electric quantity/magnetic quantity proportional to the time change, electrical components, etc., can solve the problems affecting the accuracy of the synchronism test of the linear pyrotechnic device , to achieve the effect of reducing preparation time, improving accuracy and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

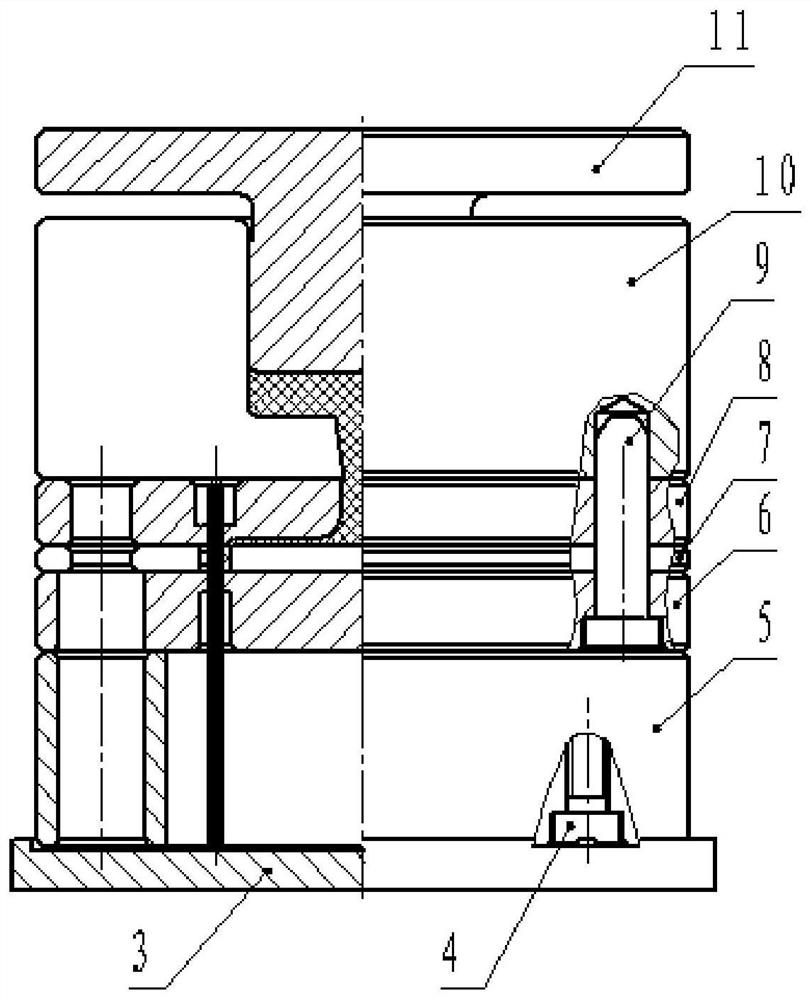

[0042] The present invention will be further elaborated below in conjunction with embodiment.

[0043]As shown in Fig. 1 (a) and Fig. 1 (b), a nanosecond-level ionization signal receiver for testing the working time of a multi-route linear pyrotechnic device of the present invention includes a phenolic plastic 1 and a pressure injection on the phenolic plastic 1 2N enameled wires 2, N is greater than or equal to 1, every two enameled wires 2 form a group, the distance between the two enameled wires 2 in each group is the same, 1.15cm to 1.20cm, one end is covered in phenolic plastic 1 and the end surface is connected with phenolic plastic The end face of 1 is flush, and receives the ionization signal generated when the linear pyrotechnic device is working, and the other end protrudes out of the phenolic plastic 1 as a pole pin output; the enameled wires 2 between each group are mutually backed up.

[0044] In order to ensure the test accuracy, the position accuracy of the 2N e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com