Shell of speed-measuring generator

A technology for tachogenerators and shells, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., which can solve the problems of increasing die-casting processes, high prices of aluminum alloy materials, and labor-intensive problems, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

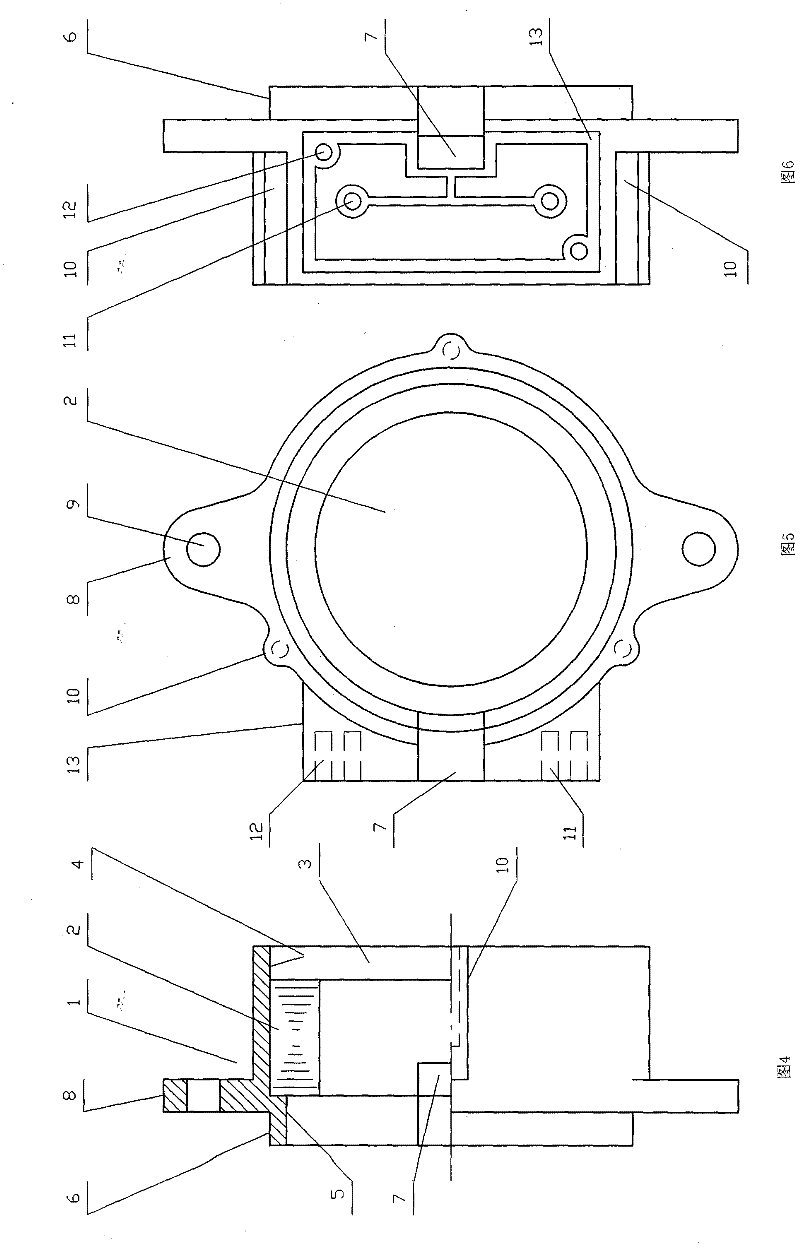

[0016] The outer surface of the left end of the housing 1 is a circular joint 6, the outer circle of the joint 6 is coaxial with the inner circle of the cavity 3; the right side of the joint 6 has a protruding part 8 protruding outward in the radial direction, close to the edge of the protruding part There is a hole 9 at the place, and the test generator is fixed at the coaxial position corresponding to the speed-measuring part with the joint 6 as the reference through connecting pieces such as bolts. The protruding part 8 can be a flange, or a plurality of semi-elliptical or trapezoidal symmetrically arranged parts to reduce material consumption. The protruding part 8 in this embodiment is two symmetrically arranged trapezoidal parts .

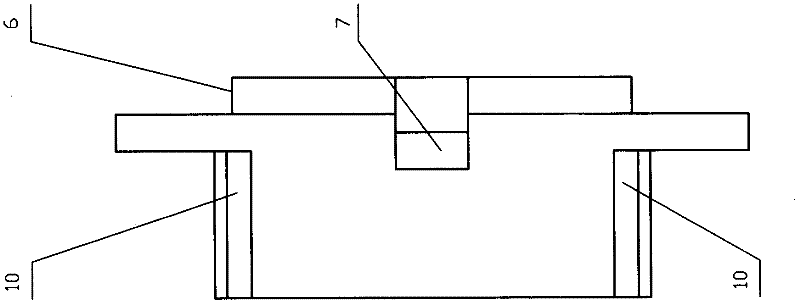

[0017] The left end of the casing 1 is provided with an outlet 7 for the lead wires of the stator winding to protrude. The shape of the outlet 7 on the surface of the casing can be U-shaped or a rectangle with one side missing.

[0018] A pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com