Special phenolic plastic crushing equipment based on mechanochemical method and crushing method

A mechanochemical method, phenolic plastic technology, applied in special equipment for plastic crushing, special equipment for crushing phenolic plastics based on mechanochemical method, based on the field of mechanical chemical method phenolic plastic crushing, can solve the problem of uncontrollable chemical properties and material forms of materials And other problems, to improve the efficiency and crushing effect, which is conducive to the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

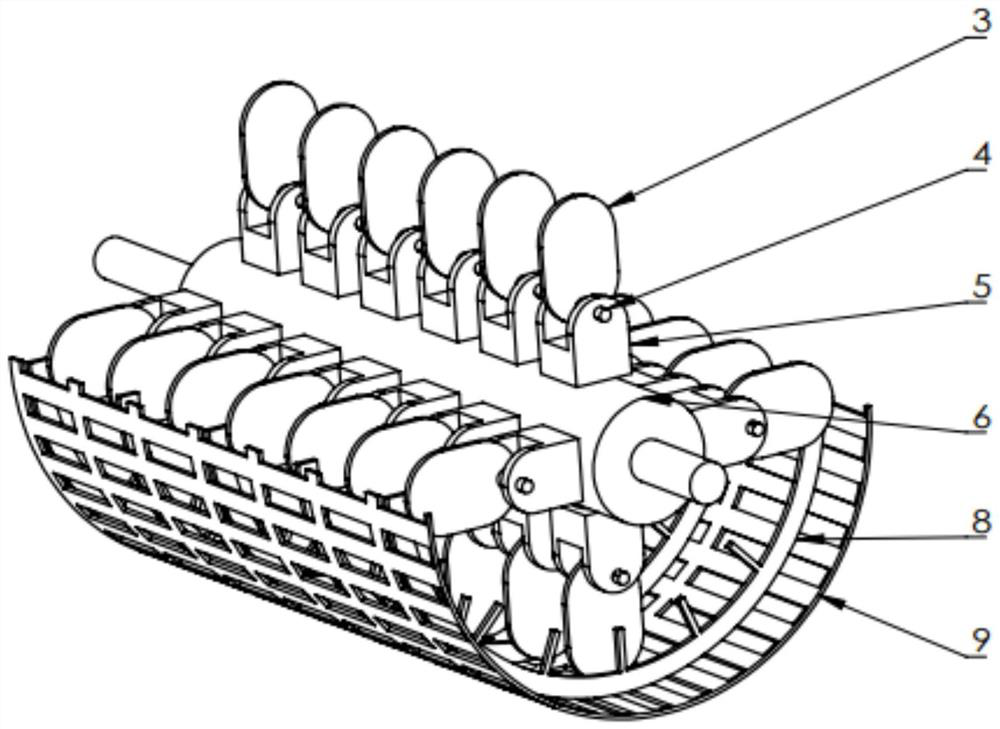

[0069] see Figure 1-8 , this embodiment provides a special equipment for pulverizing phenolic plastics based on the mechanochemical method. The special equipment is equipment for pulverizing large-sized materials into required sizes. The equipment includes a support frame 25, a primary crushing device, a secondary crushing device, a tertiary crushing device and an automatic adjustment device. These three crushing devices can crush phenolic plastics in turn, and the automatic adjustment device controls the three-stage crushing device to use appropriate mechanical stress to break its cross-linking chemical bonds to reduce its molecular weight, so that it can regain certain plasticity and chemical activity.

[0070] The support frame 25 is used to support the entire device, and it has a motor frame 22 and a mounting frame 27 . The supporting frame 25 can be directly placed on the ground, or can be installed on other equipment platforms. The support frame 25 can be made of mate...

Embodiment 2

[0086] This embodiment provides a method for pulverizing phenolic plastics based on the mechanochemical method, which is applied to the special equipment for pulverizing phenolic plastics based on the mechanochemical method in Example 1, and includes the following steps.

[0087] Detect the stress of the phenolic plastic falling from the crushing gap into the crushing cavity for transverse shearing and longitudinal extrusion. In this embodiment, the stress on the phenolic plastic can be known through a plurality of strain sensors 40 , and these strain sensors 40 are evenly distributed along the tapered outer cutter 38 to monitor the stress on the phenolic plastic in the cavity at all times.

[0088] Determine whether the stress is within a preset interval. The preset interval has a lower limit and an upper limit. This interval can be set according to actual needs, especially according to the situation of phenolic plastics and the appropriate mechanical stress required to break...

Embodiment 3

[0093] This embodiment provides a computer terminal, which includes a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, the steps of the method for pulverizing phenolic plastics based on the mechanochemical method in Embodiment 2 are realized.

[0094] When the method of Embodiment 2 is applied, it can be applied in the form of software, such as a program designed to run independently, installed on a computer terminal, and the computer terminal can be a computer, a smart phone, a control system, and other Internet of Things devices. The method in Embodiment 2 can also be designed as an embedded running program, installed on a computer terminal, such as a single-chip microcomputer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com