Naphthol-modified phenolic resin, and its preparing method

The technology of phenolic resin and naphthol is applied in the field of naphthol modified phenolic resin and its preparation, which can solve the problems that phenolic resin does not have self-lubricating effect, mechanical wear of materials, and high friction coefficient, and achieves excellent mechanical properties and improved impact resistance. performance, the effect of improving the bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

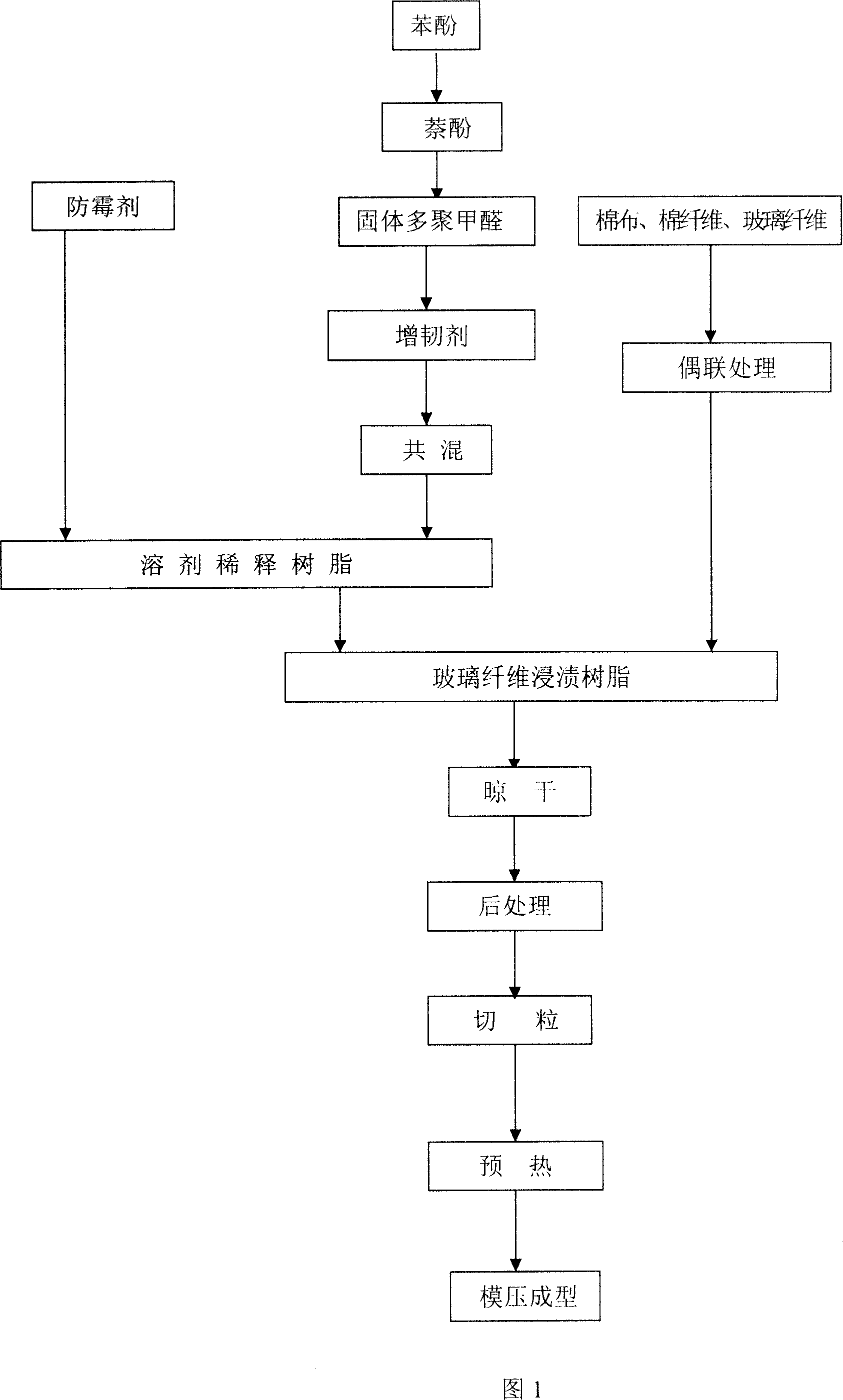

Method used

Image

Examples

Embodiment 1

[0030] a: Add 10 parts of naphthol to 100 parts of phenol under stirring condition, and make it dissolve in phenol;

[0031] b: After naphthol is fully dissolved, add 40 parts of solid paraformaldehyde under stirring conditions;

[0032] c: Add 10 parts of polysulfone under stirring condition;

[0033] d: Add 94 parts of solvent acetone in the reactor to dilute the resin, and add 2 parts of sodium pentachlorophenate;

[0034] e: Evenly impregnate 55 parts of glass fiber into the above resin after coupling treatment;

[0035] f: Dry the impregnating material so that the water and volatile matter content is 2-5%;

[0036] g: After-baking the toughened phenolic molding compound;

[0037] h: Cut the impregnating material into pellets on a pelletizer, and mold them into pieces.

Embodiment 2

[0039] a: Add 15 parts of naphthol to 100 parts of phenol under stirring condition, and make it dissolve in phenol;

[0040] b: After naphthol is fully dissolved, add 45 parts of solid paraformaldehyde under stirring conditions;

[0041] c: Add 20 parts of polysulfone under stirring condition;

[0042] d: Add 100 parts of solvent ethanol to the reactor to dilute the resin, and add 5 parts of sodium pentachlorophenate;

[0043] e: Coupling 60 parts of cotton fiber and evenly impregnating it in the above resin;

[0044] f: Dry the impregnating material so that the water and volatile matter content is 2-5%;

[0045] g: After-baking the toughened phenolic molding compound;

[0046] h: Cut the impregnating material into pellets on a pelletizer, and mold them into pieces.

Embodiment 3

[0048] a: Add 12 parts of naphthol to 100 parts of phenol under stirring condition, and make it dissolve in phenol;

[0049] b: After naphthol is fully dissolved, add 42 parts of solid paraformaldehyde under stirring conditions;

[0050] c: Add 15 parts of polysulfone under stirring condition;

[0051] d: Add 96 parts of solvent ethanol in the reactor to dilute the resin, and add 3 parts of sodium pentachlorophenate;

[0052] e: Evenly impregnate 60 parts of cotton cloth in the above resin after coupling treatment;

[0053] f: Dry the impregnating material so that the water and volatile matter content is 2-5%;

[0054] g: After-baking the toughened phenolic molding compound;

[0055] h: Cut the impregnating material into pellets on a pelletizer, and mold them into pieces.

[0056] In the above embodiments, the size of the diced impregnating material is about 15-25 mm or the orientation is 1600-1800 mm. The molding temperature is 160±5°C, the molding pressure is 20-40MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com