Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Methane decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

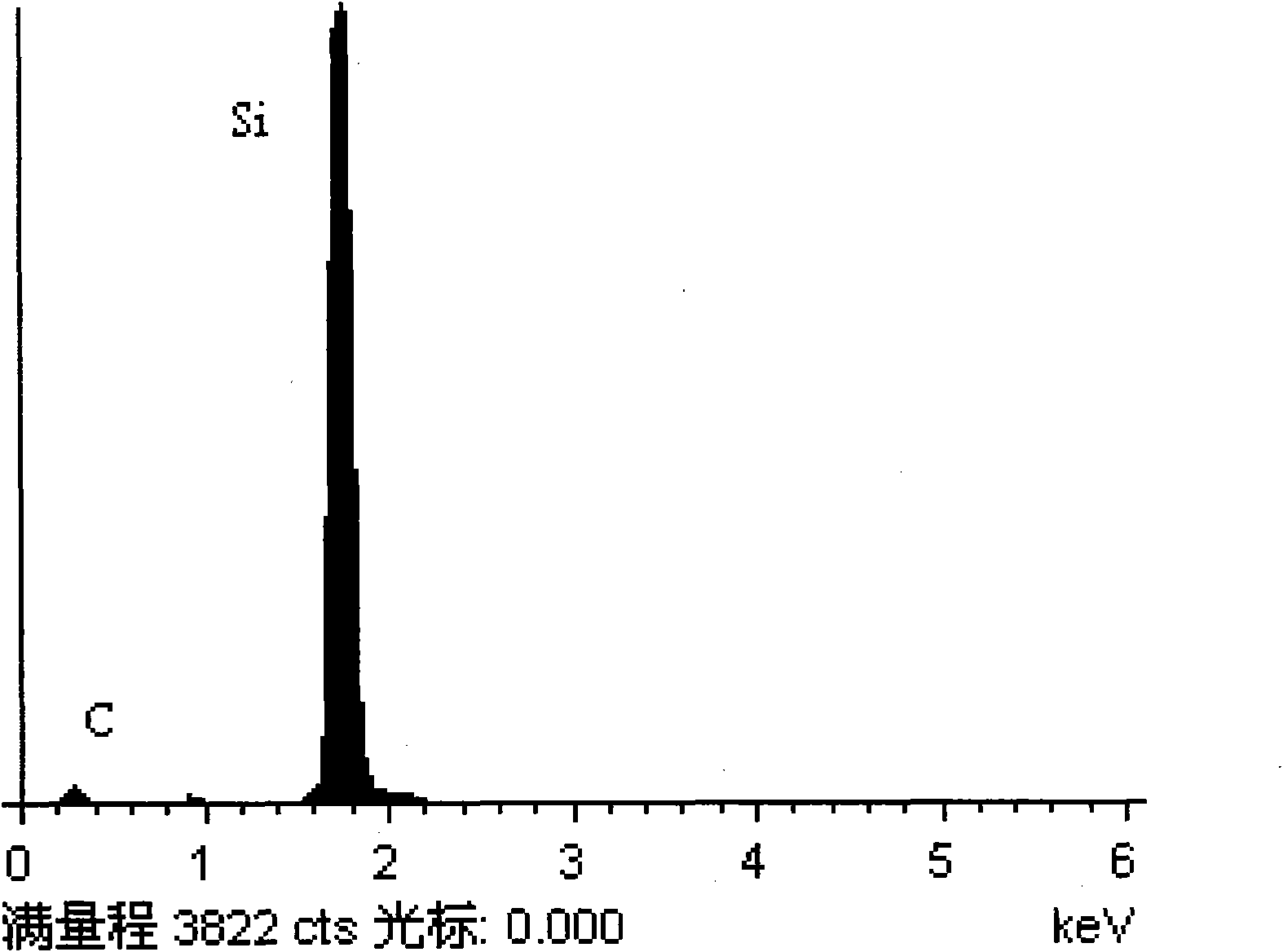

Si-base reversed extension 3C-SiC monocrystal film and preparation method thereof

InactiveCN101942696AEasy to operateAvoid difficultiesPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsSingle crystal

The invention relates to a cubic silicon carbide (3C-SiC) monocrystal film with reversed extension growth on a Si base and a preparation method thereof, belonging to the preparation field of novel Si-base wide band-gap semiconductors, wherein the cubic silicon carbide (3C-SiC) monocrystal film with reversed extension growth on the Si base is formed by diffusing carbon on the Si base to Si and reacting with the Si. The method adopts low-temperature chemical vapor deposition (LPCVD for short), comprising the following steps of: diffusing the carbon to the Si by utilizing methane decomposition at high temperature to effectively displace the Si, and forming the 3C-SiC monocrystal film with the stoichiometric ratio of 1:1 by using a reversed extension growth mechanism, wherein the thickness of the 3C-SiC monocrystal film can reach the micrometer level, the electronic Hall mobility at the room temperature reaches 1.22*10<3> cm<2> / (V.S), and the electronic Hall mobility in liquid nitrogen reaches 2.06*10<3> cm<2> / (V.S). The impurity concentration and the condition type of the 3C-SiC monocrystal film prepared in the method can be controlled through the impurity concentration and the condition type of a monocrystal silicon substrate, and the impurity concentration in the film is uniform. The preparation method can be used for obtaining the Si-base reversed extension 3C-SiC monocrystal film with low stress and high quality.

Owner:SICHUAN UNIV

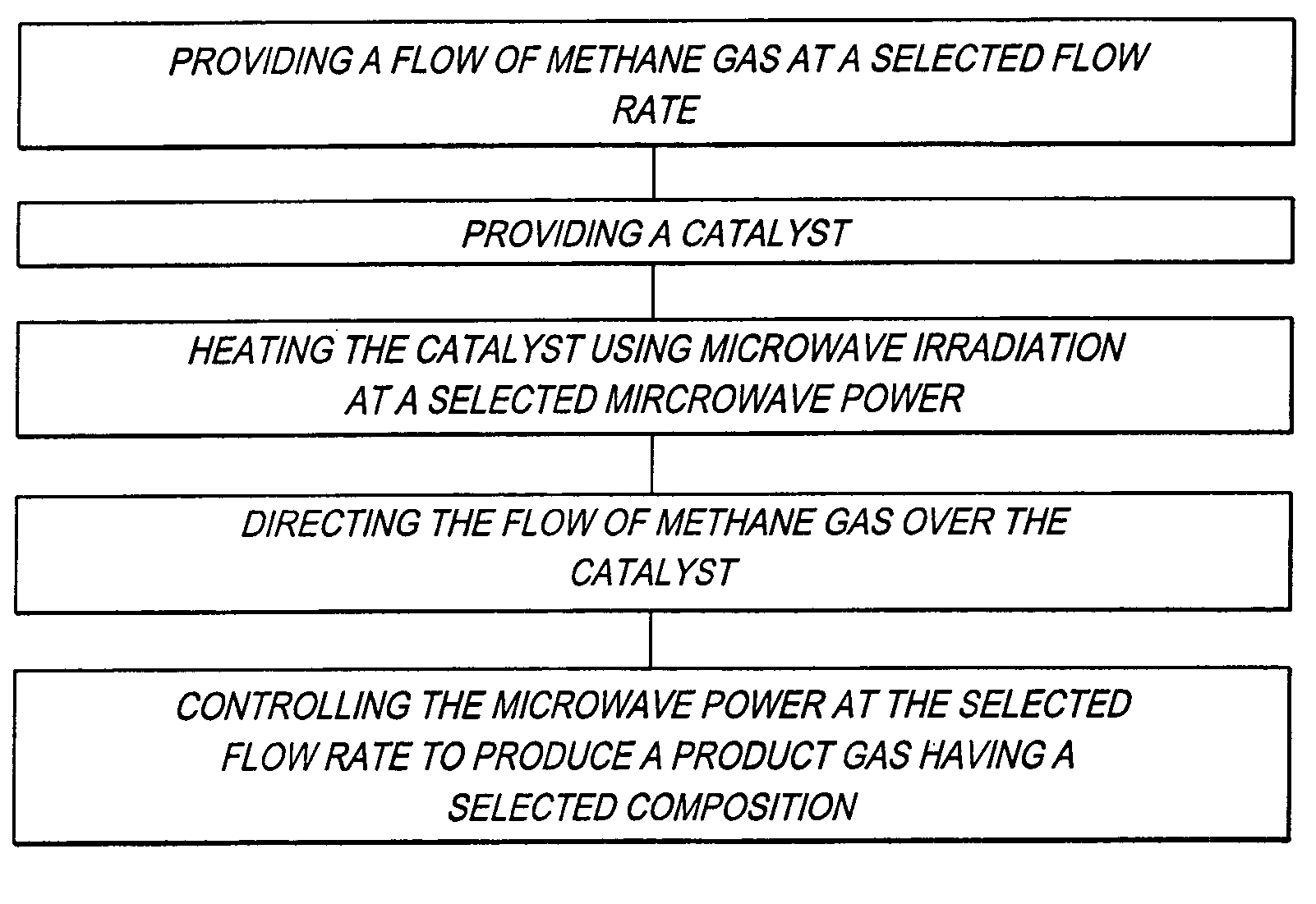

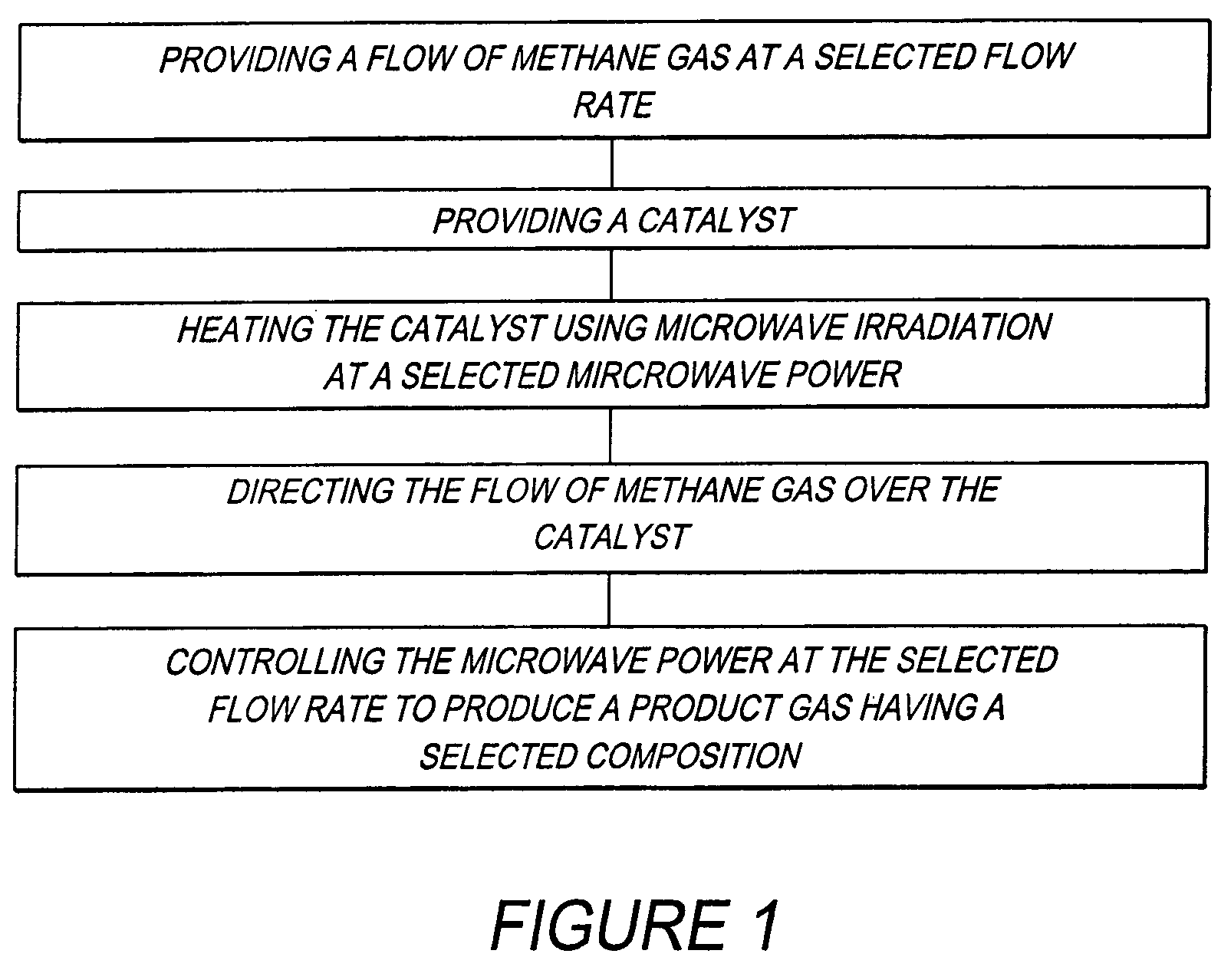

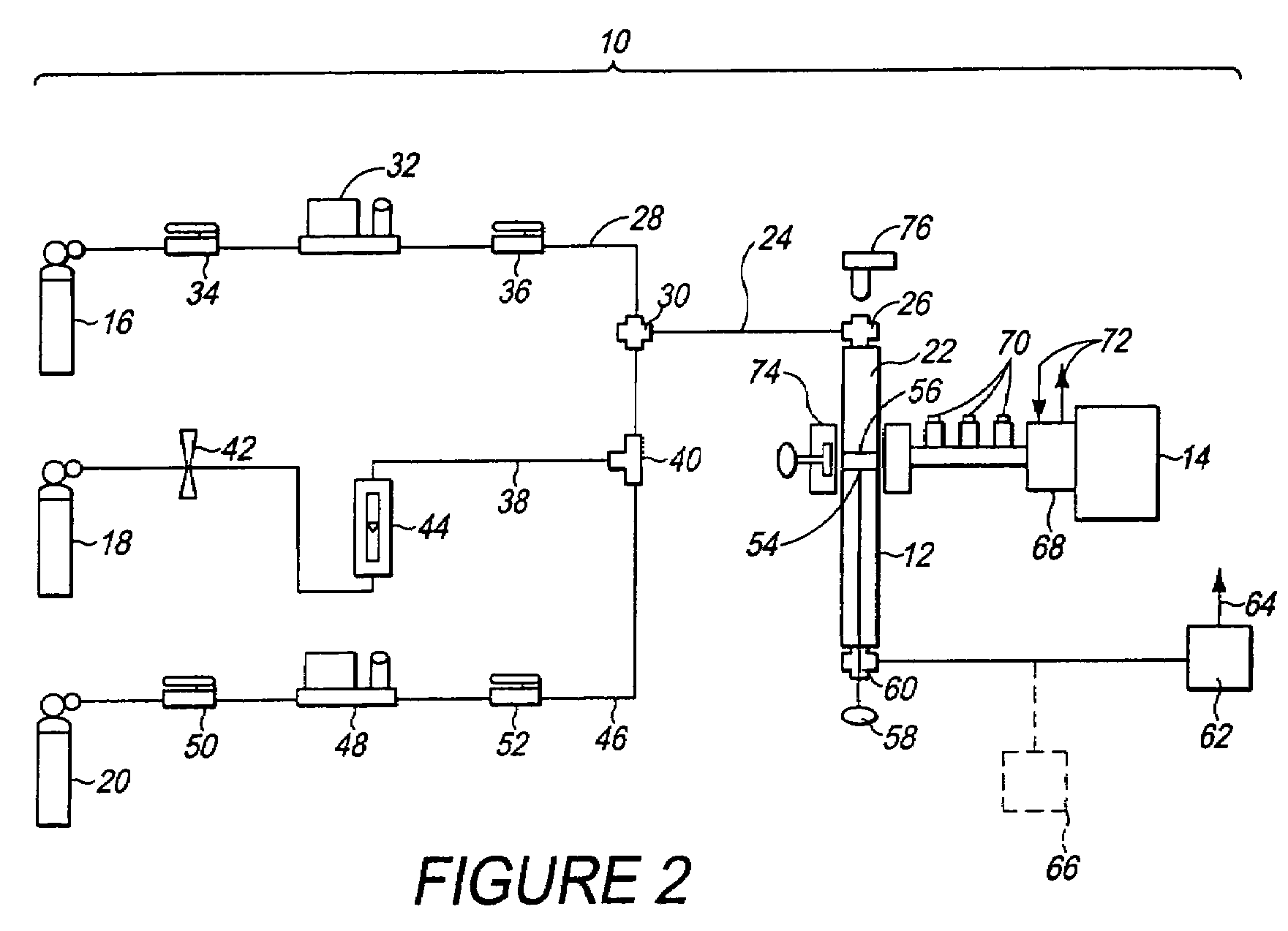

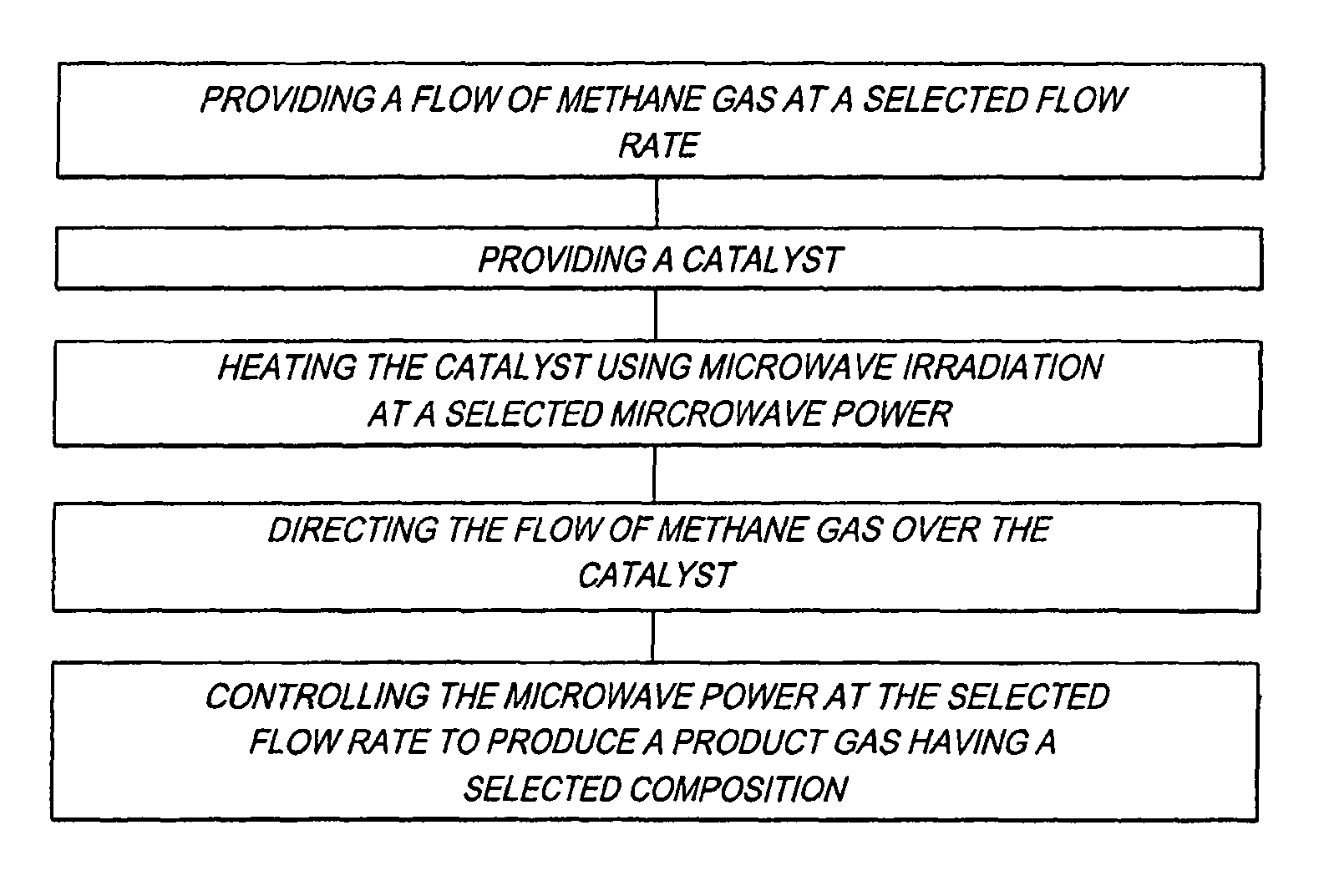

Method and system for producing a hydrogen enriched fuel using microwave assisted methane decomposition on catalyst

ActiveUS8075869B2Low costMaintenance characteristicComponent separationHydrocarbonsHydrogenMicrowave power

Owner:EDEN ENERGY

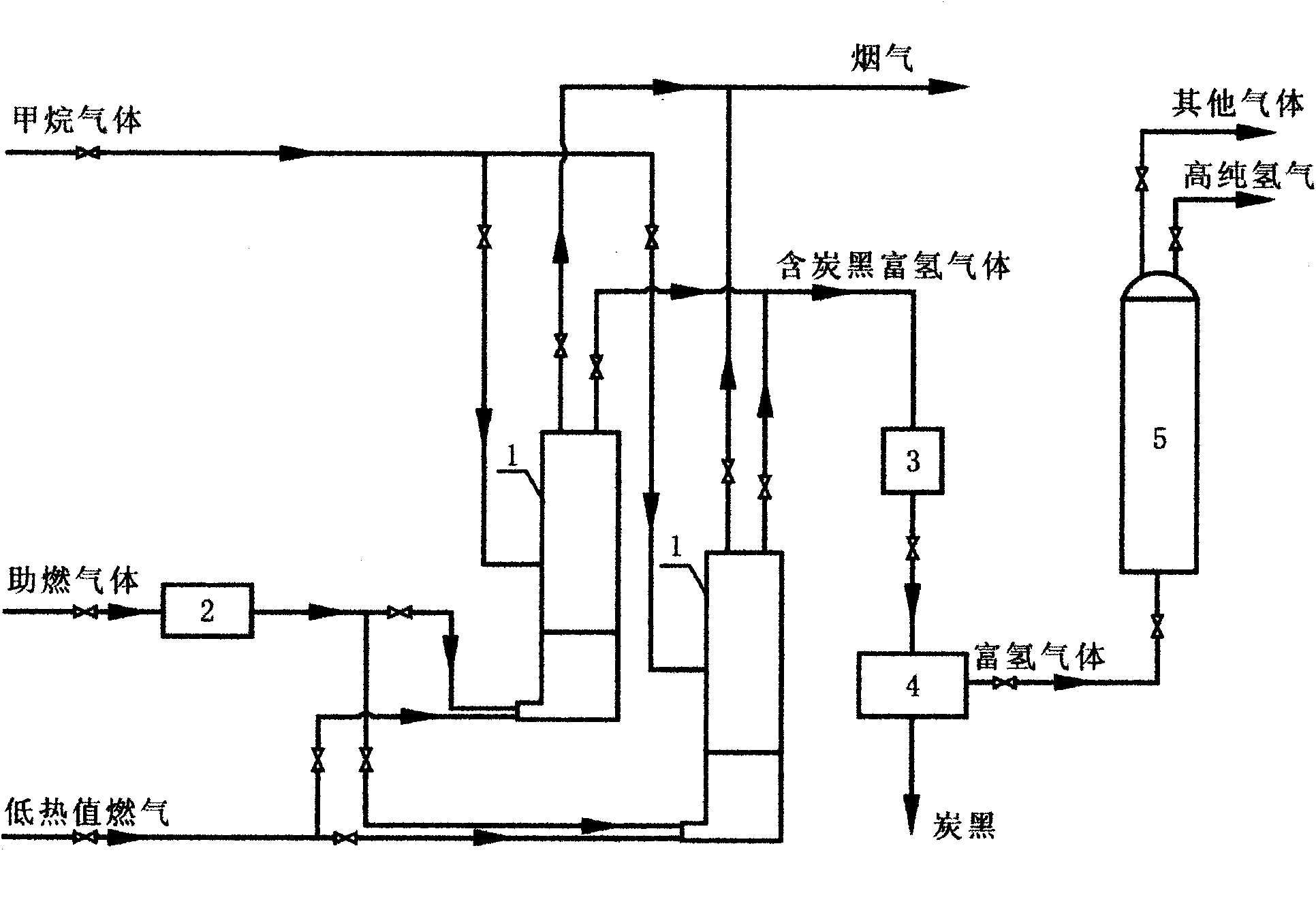

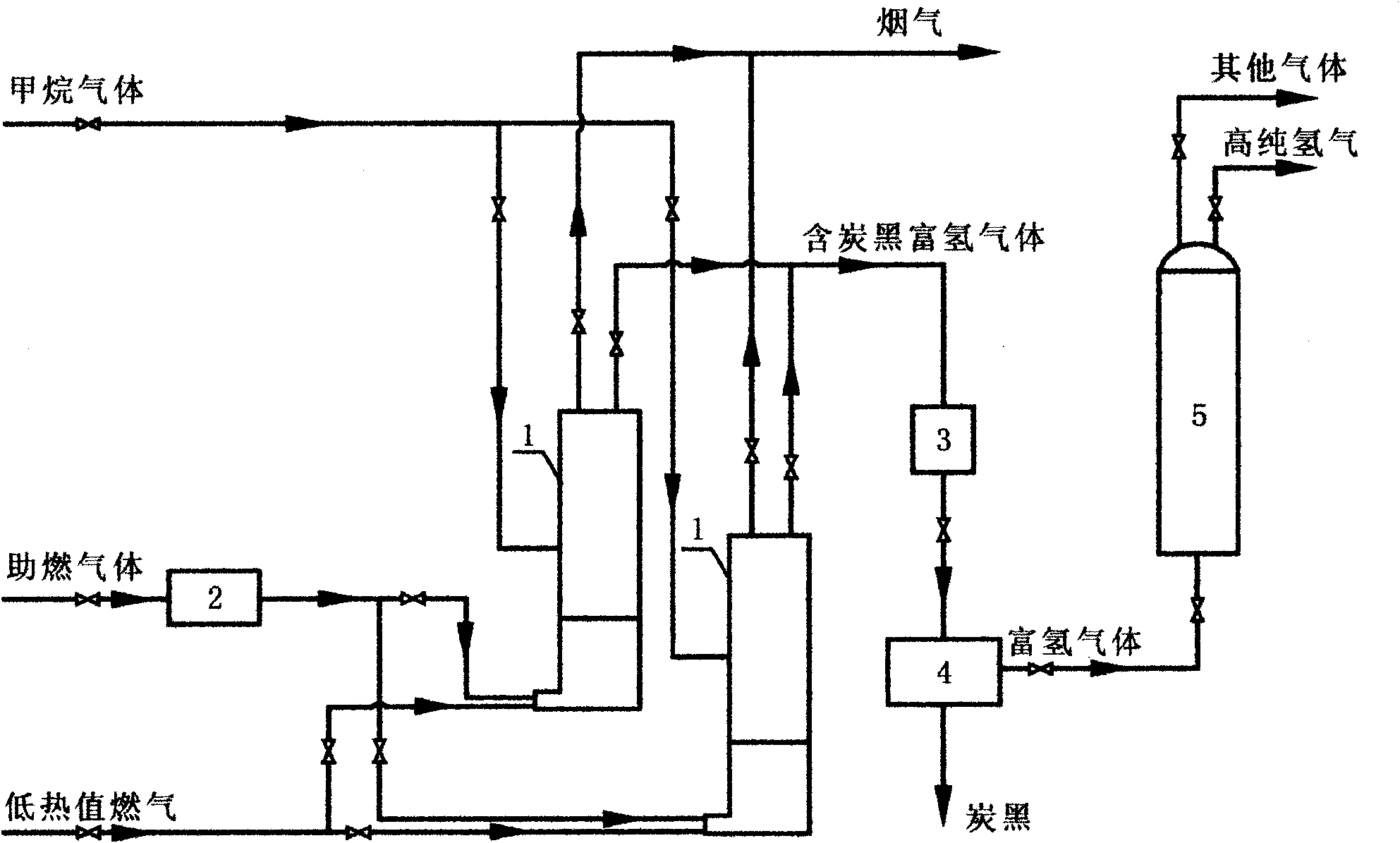

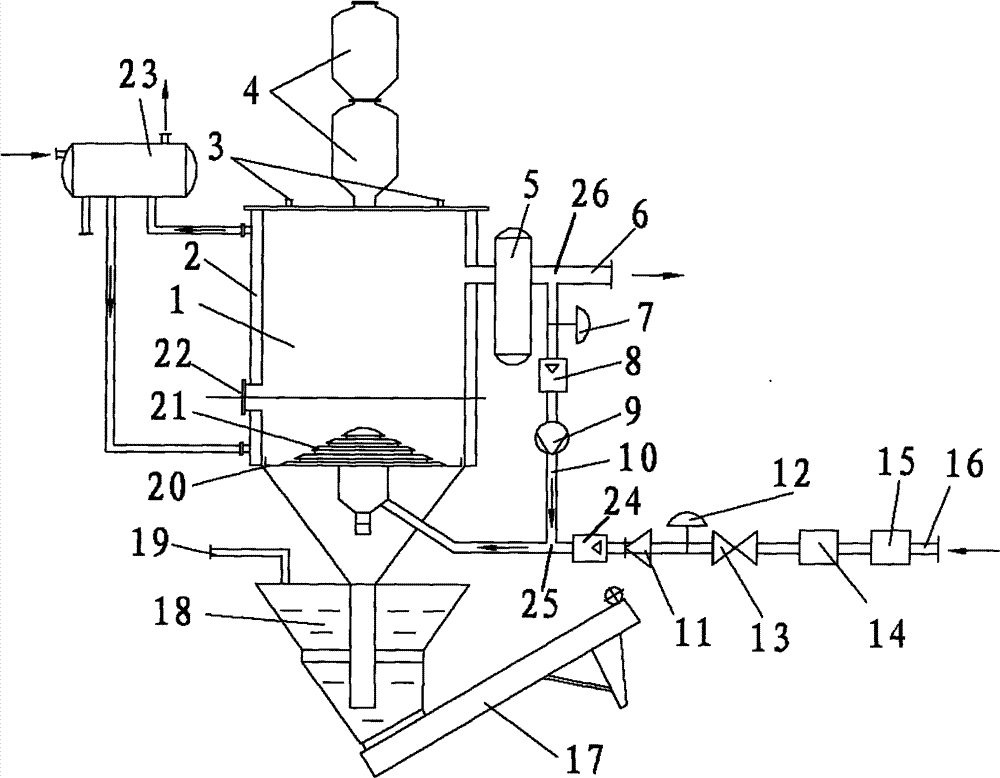

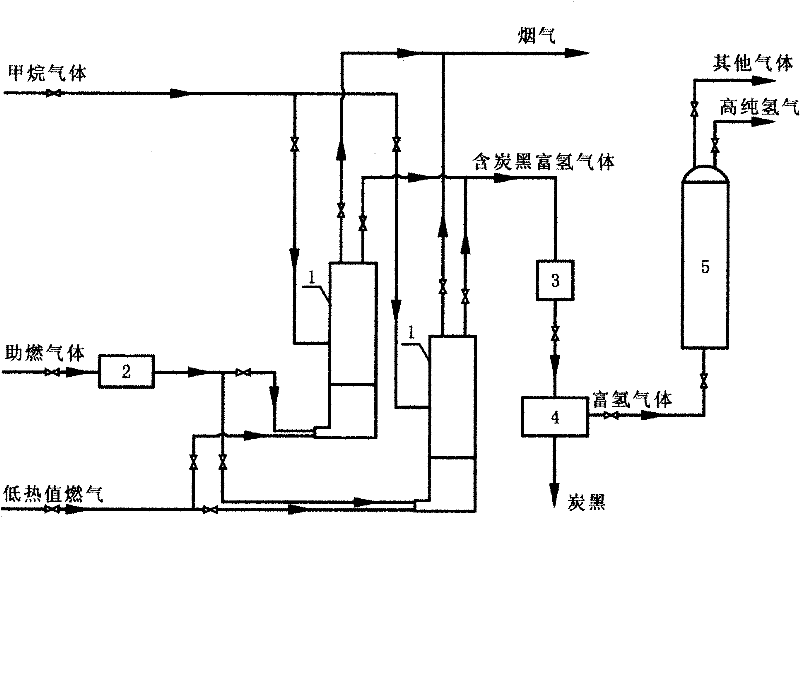

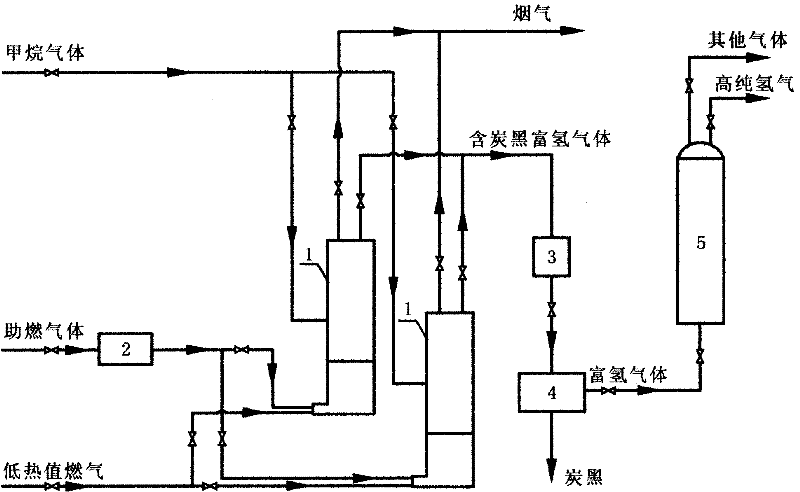

Method for coproduction of carbon black and high-purity hydrogen by high-temperature pyrolysis of methane

ActiveCN101838480AEmission reductionImprove reaction efficiencyPigmenting treatmentHydrogenHydrogenCaloric values

The invention discloses a method for coproduction of carbon black and high-purity hydrogen by high-temperature pyrolysis of methane, which comprises the following steps: taking fuel gas with low caloric value of 1300-1500kcal / Nm3 as a fuel, taking methane-containing gas as a raw material, adopting the alternate working mode of controlling the quantity of supplied oxygen used for combustion-supporting for further promoting the full combustion of the fuel gas with the low caloric value, storing heat in a reaction furnace, removing the residual gas and carrying out methane pyrolysis, and building a methane non-oxygen high-temperature pyrolysis reaction environment, and the method specifically comprises the process steps of regulating the combustion-supporting gas, storing the heat in the reaction furnace, removing the residual gas, carrying out the methane pyrolysis, collecting the carbon black, and purifying for producing the hydrogen. The process is simple, and the amplification of production capacity and the continuous high-efficient production can be realized through the multi-stage combination of the pyrolysis reaction furnaces. The method can not only fully utilize the low-caloric value fuel gas resources and realize high reaction efficiency, but also reduce the emission of greenhouse gas and realize the low-carbon clean circulatory production, and a set of production process can realize the coproduction of the high-quality carbon black and the high-purity hydrogen.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

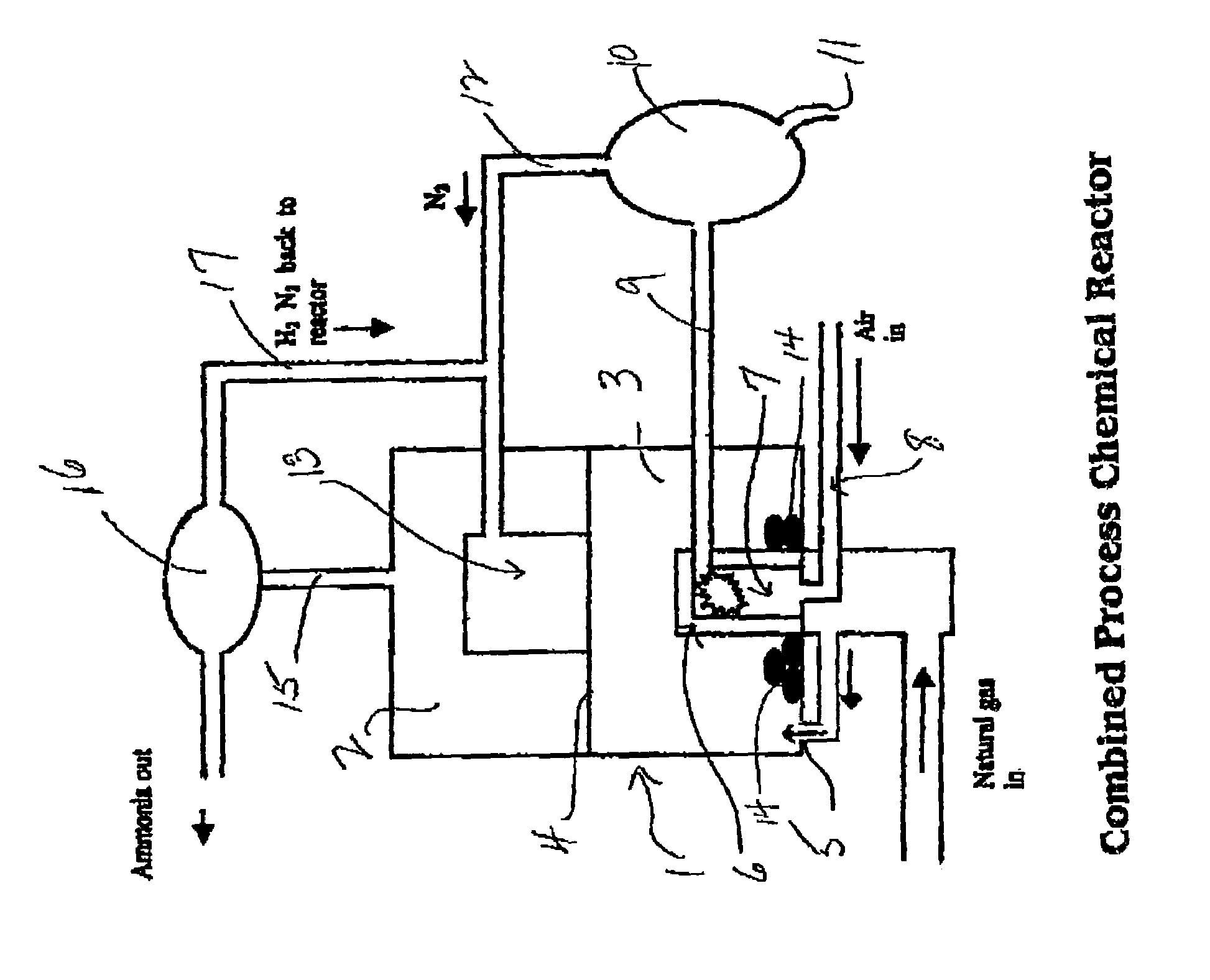

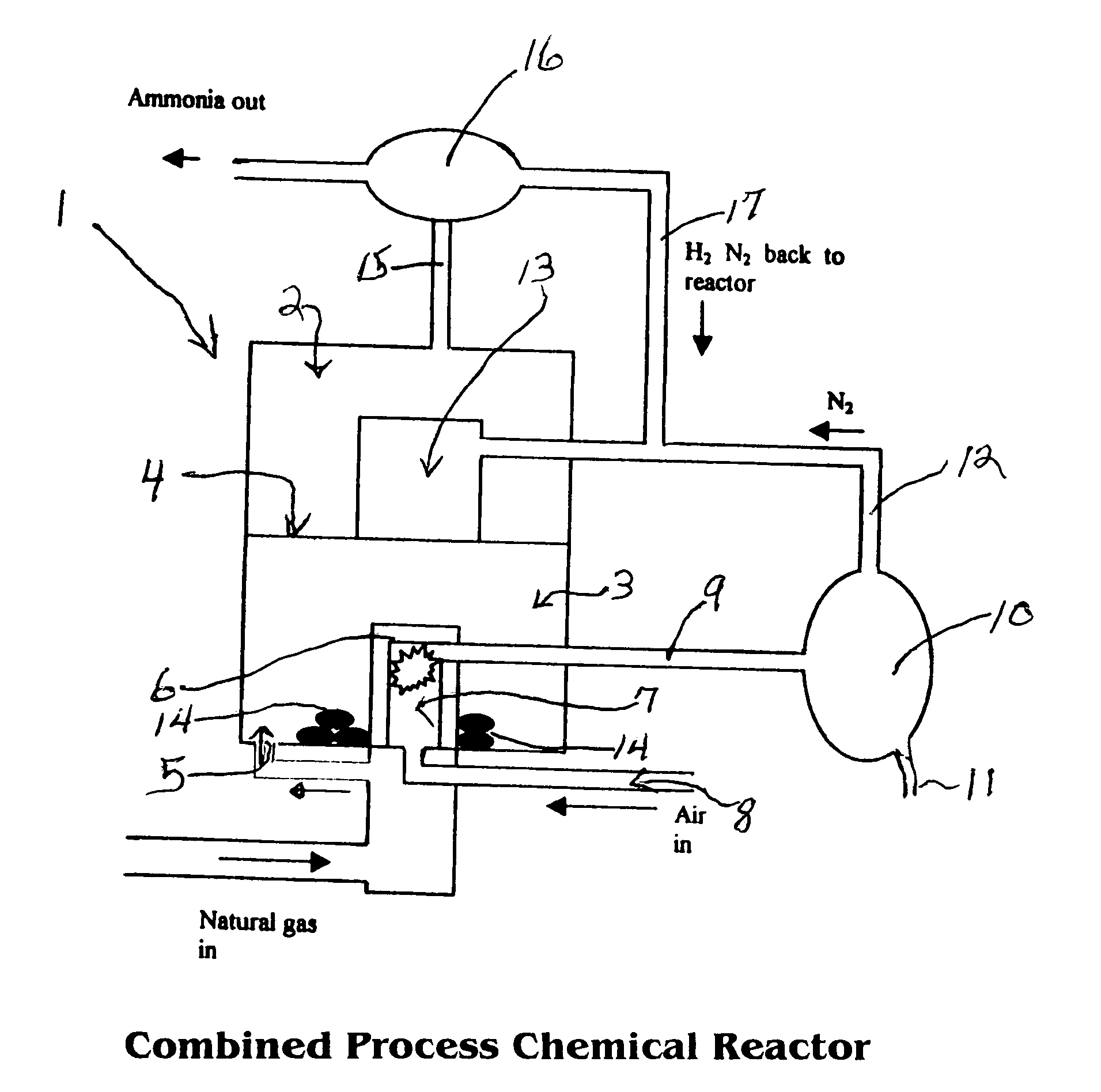

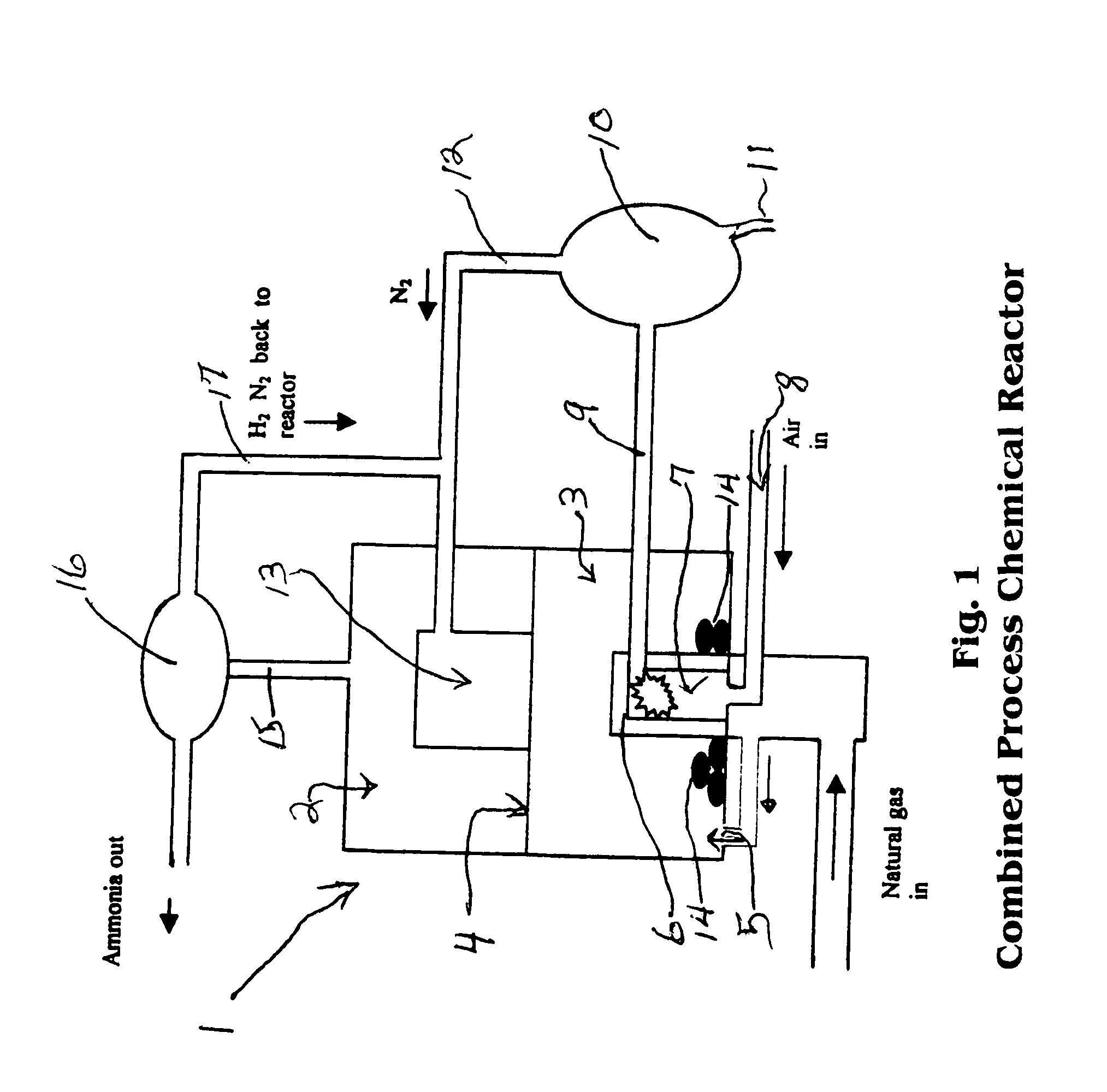

Combined methane decomposition and ammonia formation cell

InactiveUS7094384B1Reduce needImprove efficiencyHydrogen/synthetic gas productionHydrogen separation by diffusionChemical industryOxygen

An ammonia synthesis process and apparatus are provided which are energy efficient and minimize greenhouse-gas-emission during the processing of natural gas and air. In the process a stream of natural gas is divided into two streams, one of which is mixed with air and ignited to provide heat for the thermal decomposition of natural gas into hydrogen and carbon and also to provide deoxygenated nitrogen for an ammonia synthesis process. The process essentially prepares hydrogen and nitrogen on a low average temperature side of a chemical reactor and then feeds both gases to the high average temperature side of the chemical reactor where they react to form ammonia. The formation of ammonia is exothermic, whereas the thermal decomposition of methane is endothermic and the combustion of methane to remove oxygen is also exothermic; the sum of the heats absorbed and released in these reactions is positive. Catalysts, high temperatures and pressure are used to promote the rapid formation of ammonia, as is standard practice in the chemical industry. Catalysts, and high temperatures are used to promote the thermal decomposition of natural gas and combustion of oxygen that provides hydrogen and nitrogen for ammonia synthesis.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Preparation method of compact C/C composite material

The invention discloses a preparation method of a compact C / C composite material. The method includes: firstly preparing a 3D or 2.5D braided carbon fiber preform; then putting the preform into a vacuum chemical vapor deposition furnace, introducing methane and hydrogen, letting pyrolytic carbon produced by methane decomposition infiltrate the preform by chemical vapor infiltration to realize compaction of carbon fiber filaments within the preform, thus turning the preform into a C / C composite material skeleton; then infiltrating the obtained C / C composite material skeleton with a thermosetting resin solution by precursor infiltration and pyrolysis method, and conducting high temperature pyrolysis in a vacuum furnace to obtain a glass carbon matrix; and finally cycling the step (3) repeatedly, and stopping the operation when the weight gain rate of the material is lower than 1%, and finally conducting pyrolysis to obtain pyrolytic glass carbon filled among fiber bundles, thus realizing compaction of fiber bundles, and obtaining the compact C / C composite material. The material has the advantages of high density, low porosity, high specific strength, specific modulus, and good toughness, high compactness, wear resistance and long service life.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

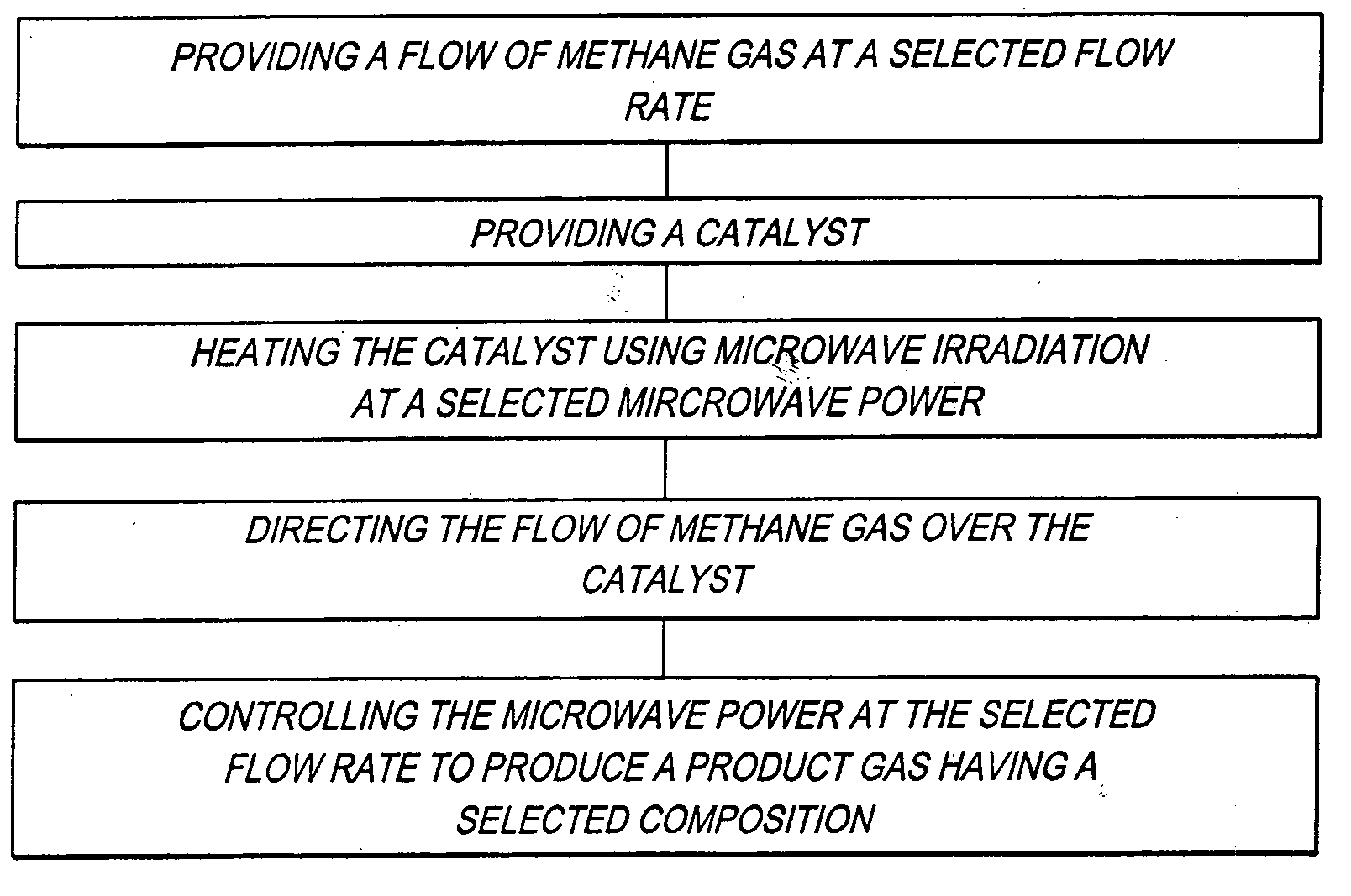

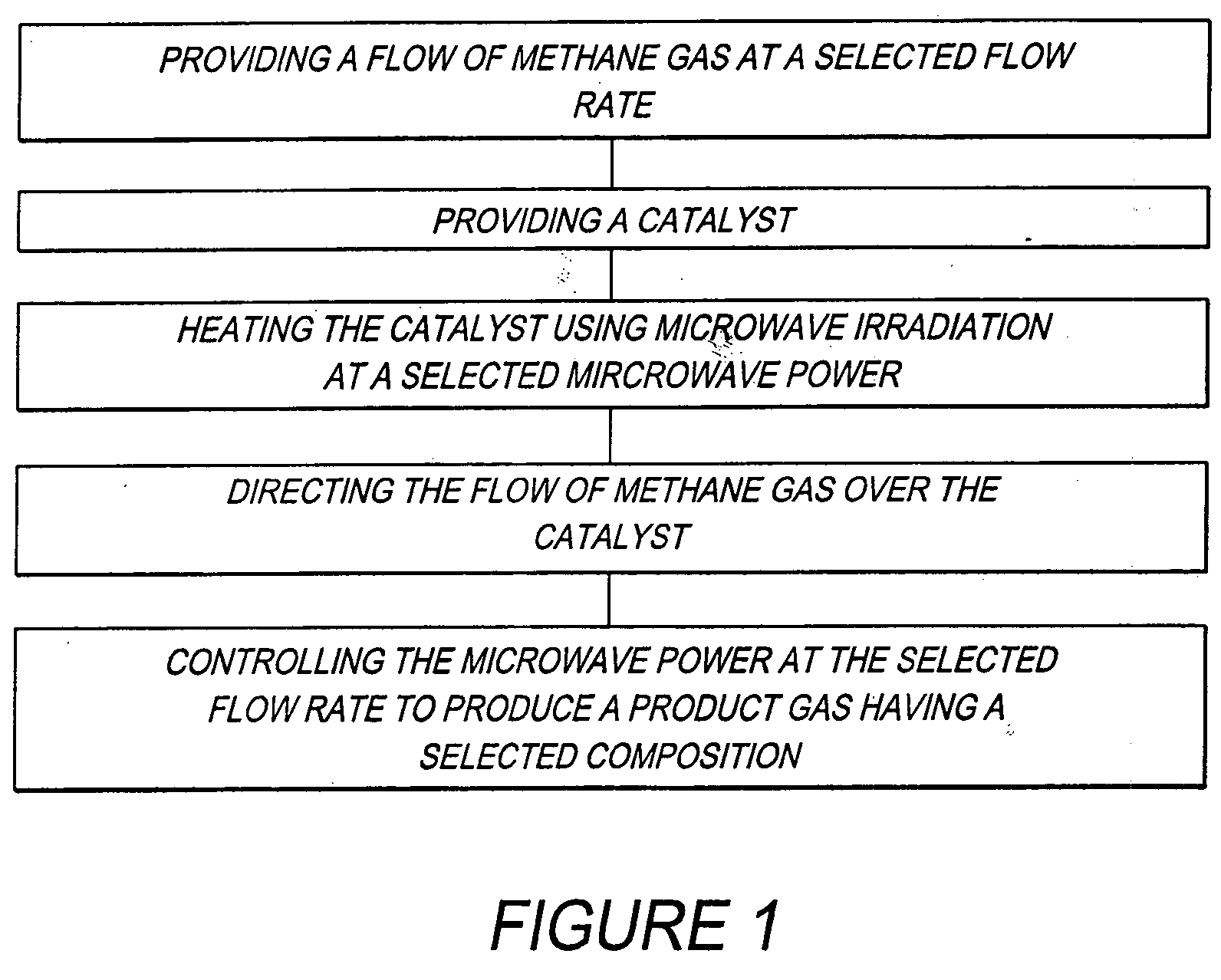

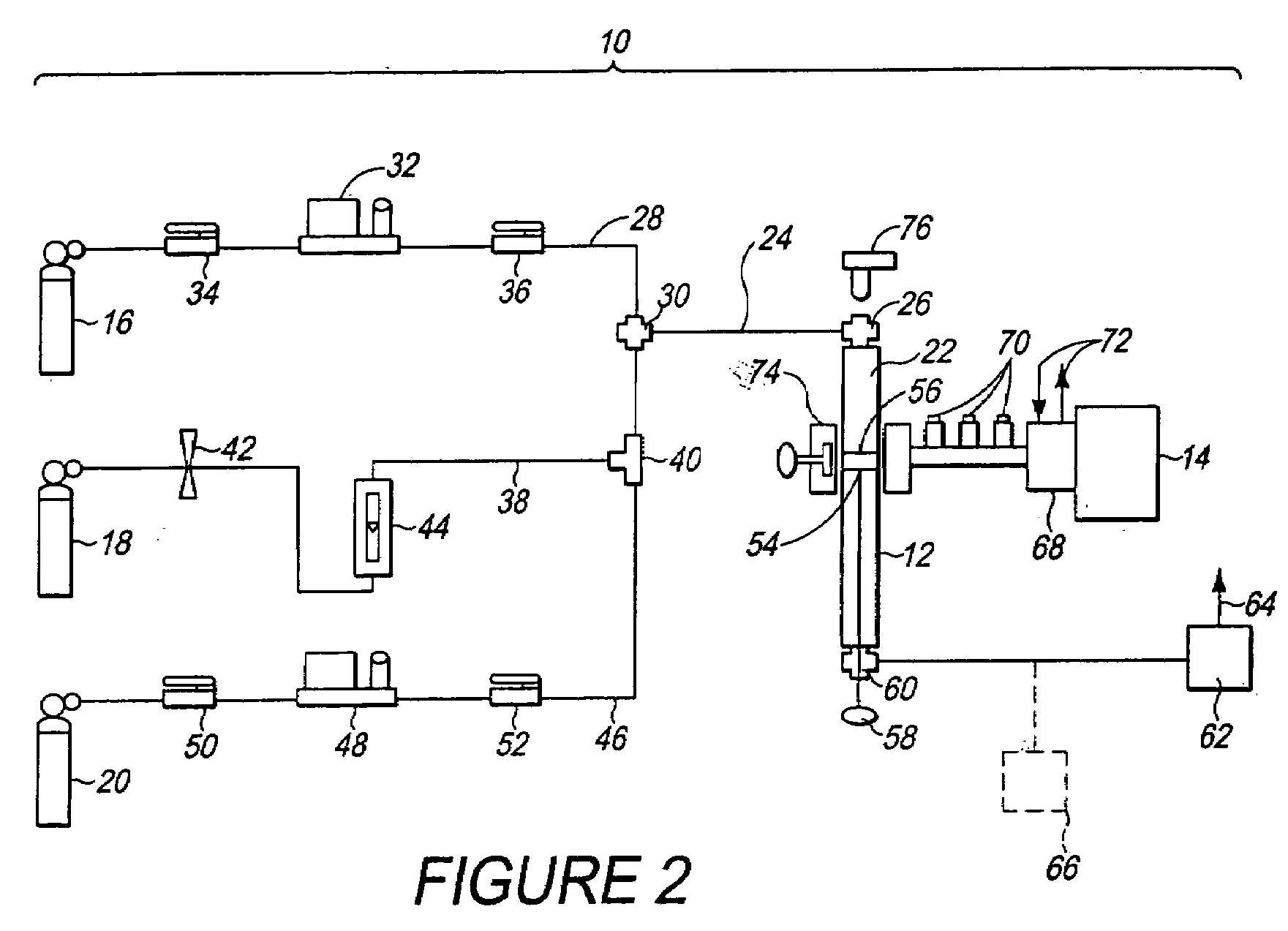

Method and system for producing a hydrogen enriched fuel using microwave assisted methane decomposition on catalyst

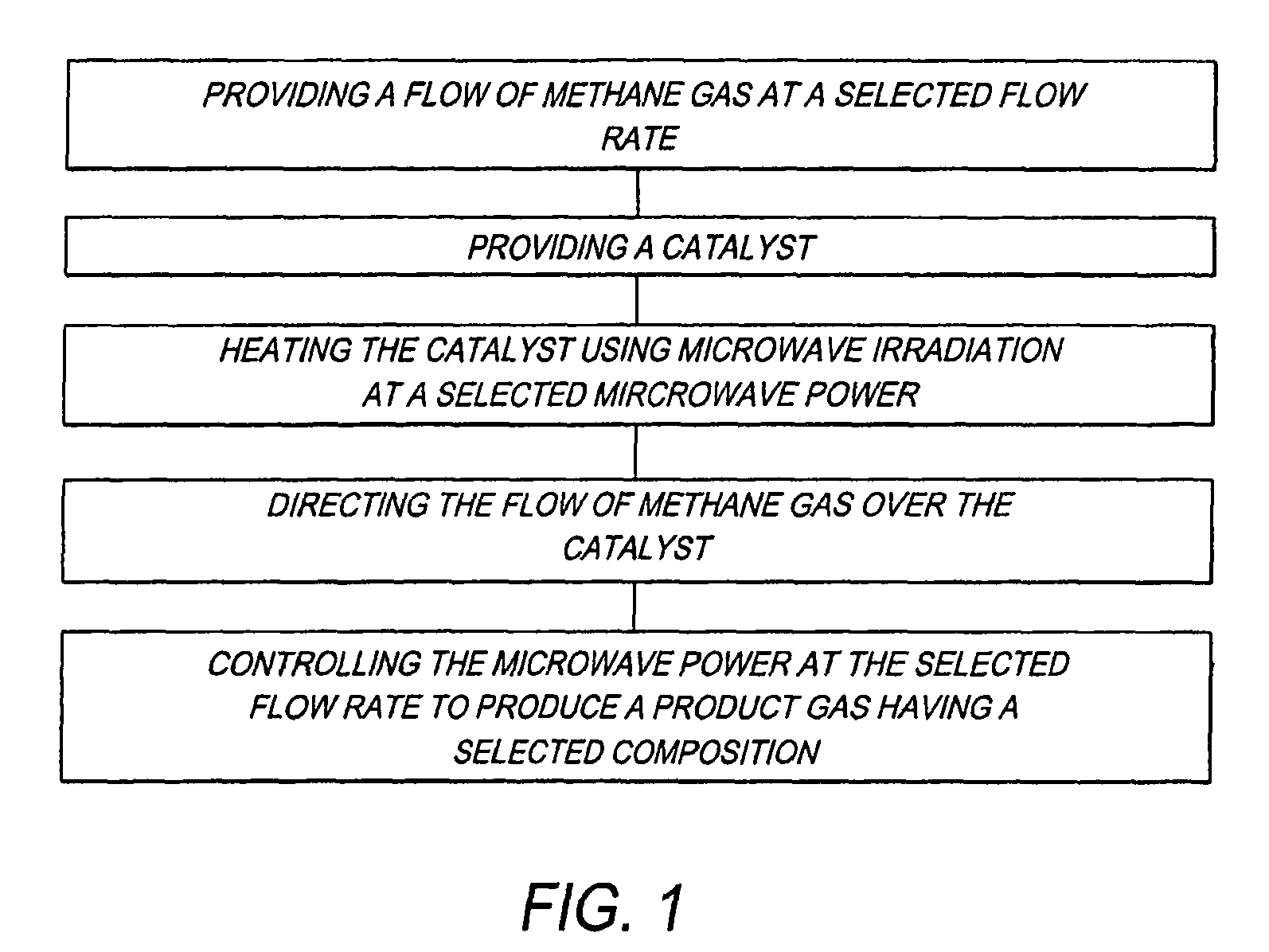

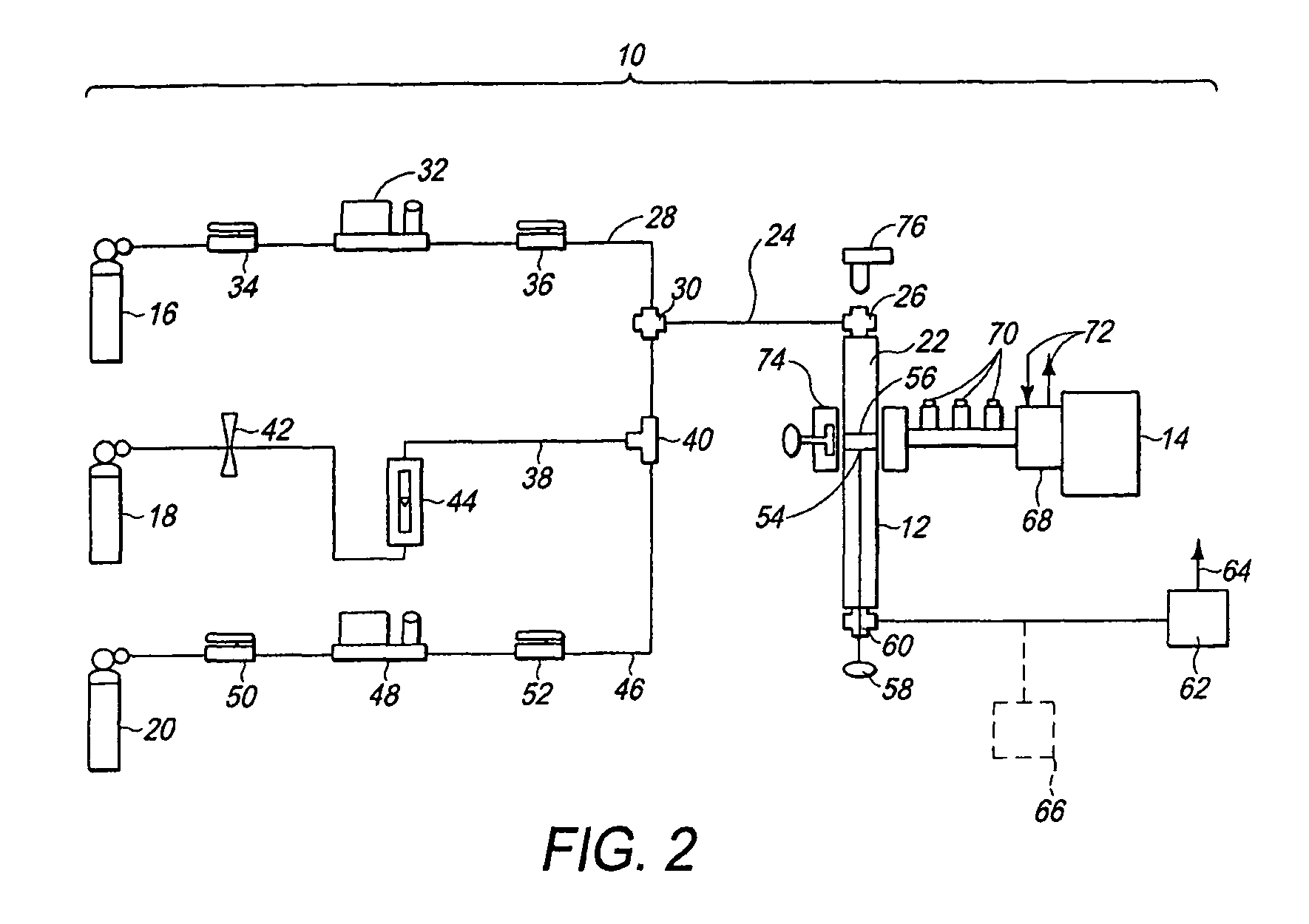

ActiveUS20080173532A1Low costMaintenance characteristicComponent separationHydrocarbonsHydrogenMicrowave power

A method for producing a hydrogen enriched fuel includes the steps of providing a flow of methane gas, and providing a catalyst. The method also includes the steps of heating the catalyst instead of the reactor walls and the methane gas using microwave irradiation at a selected microwave power, directing the flow of methane gas over the catalyst, and controlling the microwave power to produce a product gas having a selected composition. A system for producing a hydrogen enriched fuel includes a methane gas source, a reactor containing a catalyst, and a microwave power source configured to heat the catalyst.

Owner:EDEN ENERGY

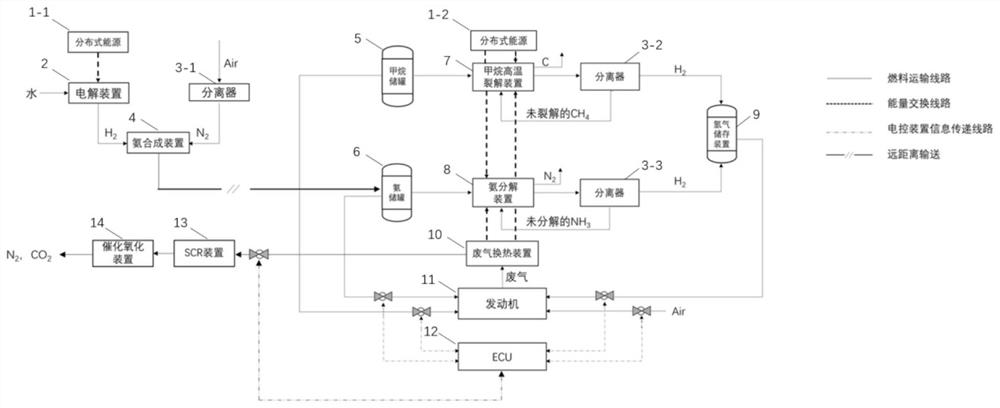

Green and efficient ammonia fuel combustion system and method

ActiveCN112648113ASolve the problem of poor ignitionEmission reductionElectrical controlInternal combustion piston enginesCombustion systemThermodynamics

A green and efficient ammonia fuel combustion system comprises an engine, the engine is provided with four inlets and a waste gas outlet, the four inlets are connected with a methane storage tank, an ammonia storage tank, a hydrogen storage device and air correspondingly, the waste gas outlet is connected with an inlet of a waste gas heat exchange device, the waste gas heat exchange device is provided with three outlets, two of the outlets are connected with a methane high-temperature cracking device and an ammonia decomposition device correspondingly to provide heat energy for the methane high-temperature cracking device and the ammonia decomposition device, an inlet of the methane cracking device is connected with the methane storage tank, an outlet of the methane cracking device is connected with a second separator, mixed gas obtained by methane cracking is separated into methane and hydrogen in the second separator, and a hydrogen outlet is connected with the hydrogen storage device. An inlet of the ammonia decomposition device is connected with the ammonia storage tank, an outlet of the ammonia decomposition device is connected with a third separator, mixed gas obtained through ammonia decomposition is separated into ammonia gas and hydrogen in the third separator, and a hydrogen outlet is connected with the hydrogen storage device. According to the green and efficient ammonia fuel combustion system, pollutant discharge can be controlled at a low level, and meanwhile the problem of poor ignitability of ammonia serving as fuel is solved.

Owner:XI AN JIAOTONG UNIV

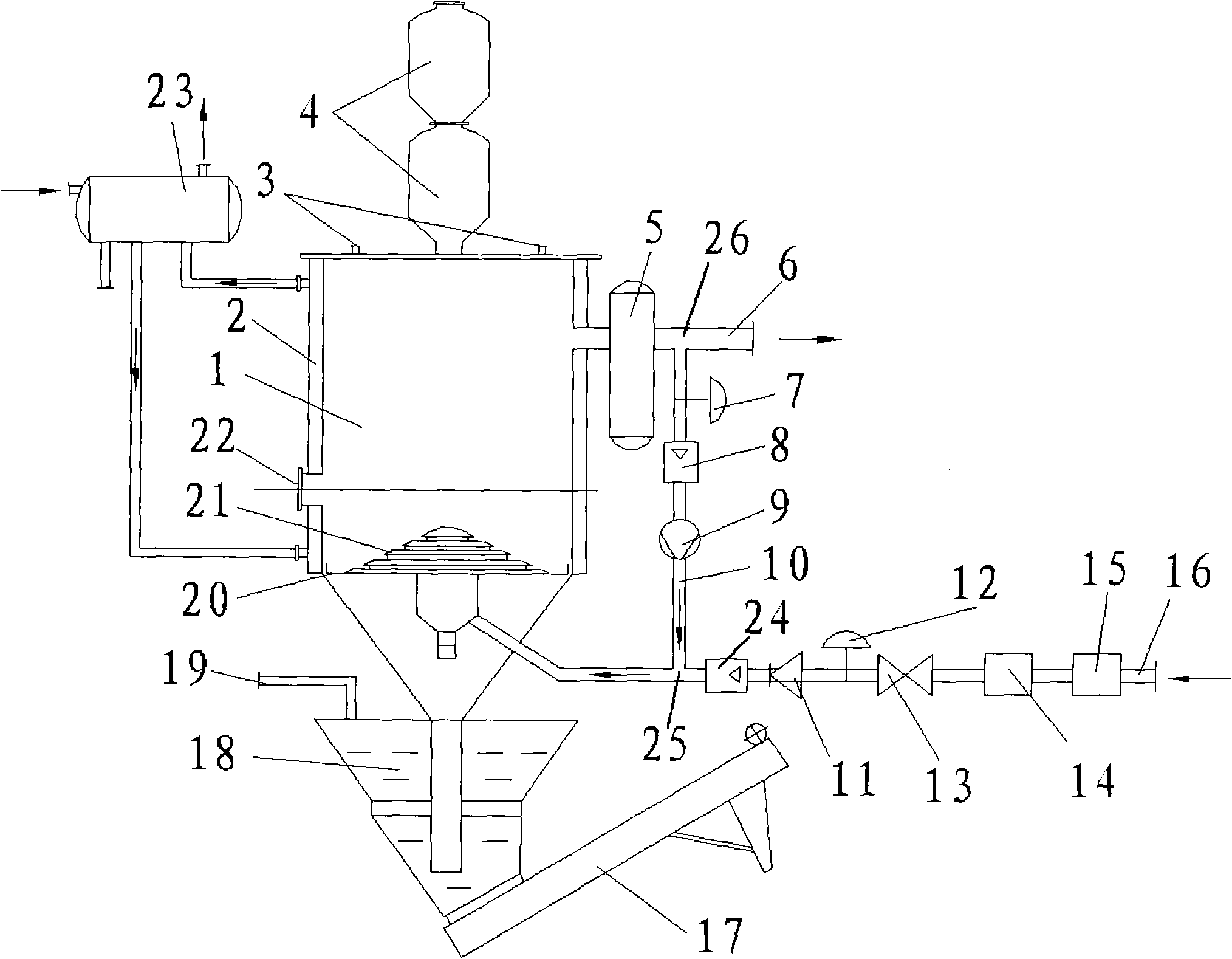

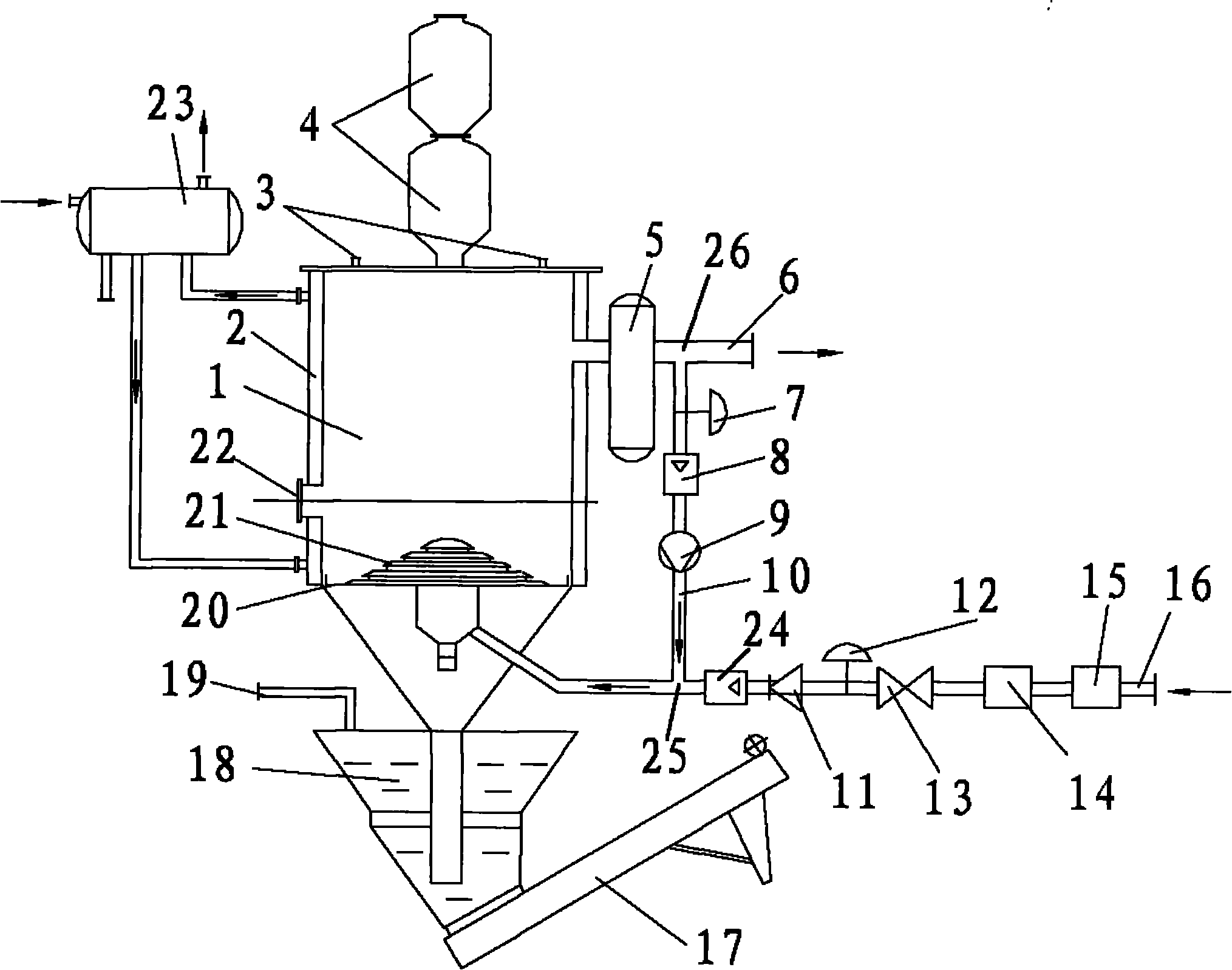

Fixed bed coal seam gas non-catalytic deoxidization method and device

ActiveCN101914402ASolving security problems in enrichmentAvoid security issuesGaseous fuelsFixed bedProcess engineering

The invention discloses a fixed bed coal seam gas non-catalytic deoxidization method and a fixed bed coal seam gas non-catalytic deoxidization device. The device comprises a fixed bed coal seam gas deoxidization device body including a furnace body (1), wherein the side wall of the furnace body (1) is provided with a water jacket (2) enclosing the side wall of the furnace body; the upper part of the water jacket (2) is connected with an air inlet of a steam pocket (23) through a pipeline; and a water inlet pipe on the lower part of the water jacket is connected with a water outlet of the steam pocket (23). The device deoxidizes the coal seam gas, can effectively control the deoxidization temperature and reduce the oxygen content in the coal seam gas to less than 0.5 percent, and maximallyreduces methane decomposition to make the methane loss less than 5 percent.

Owner:CCTEG CHINA COAL RES INST

Method for producing a hydrogen enriched fuel and carbon nanotubes using microwave assisted methane decomposition on catalyst

ActiveUS8092778B2Low costMaintenance characteristicMaterial nanotechnologyHydrogenHydrogenCarbon nanotube

Owner:UNIQUEST +2

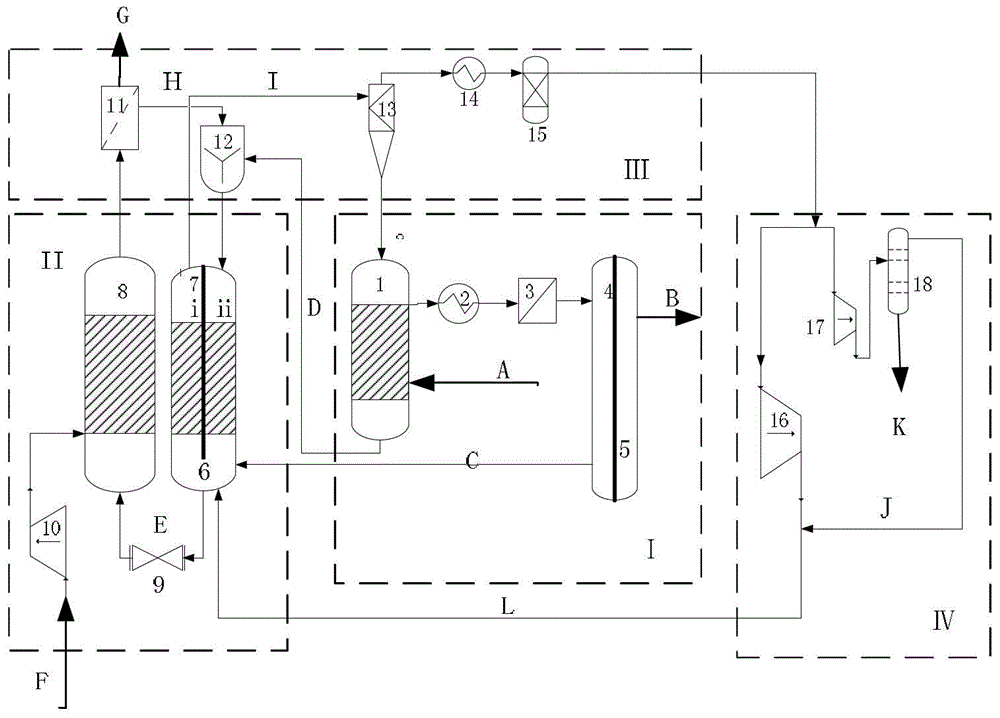

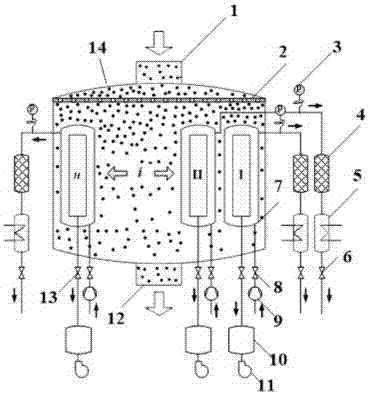

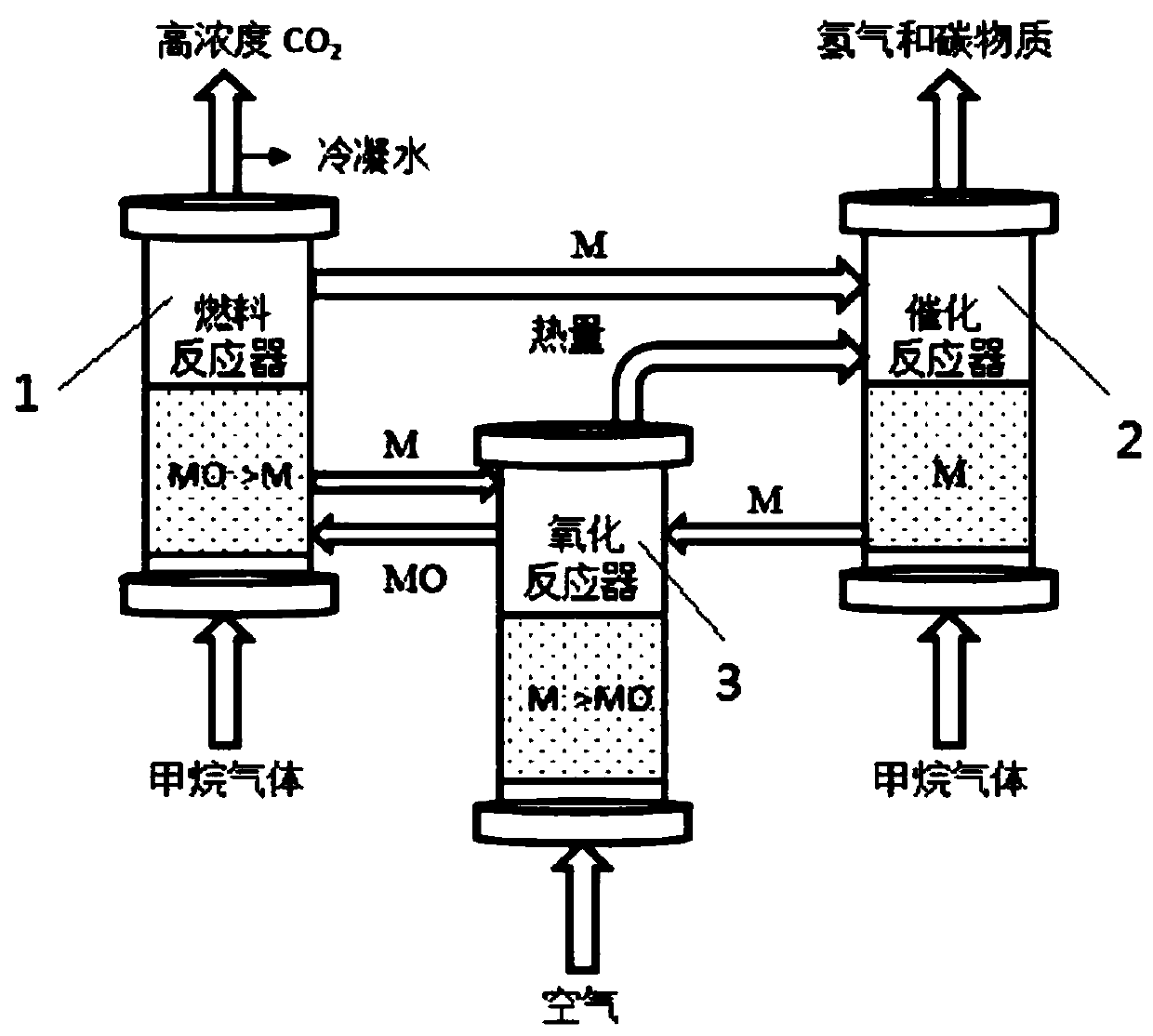

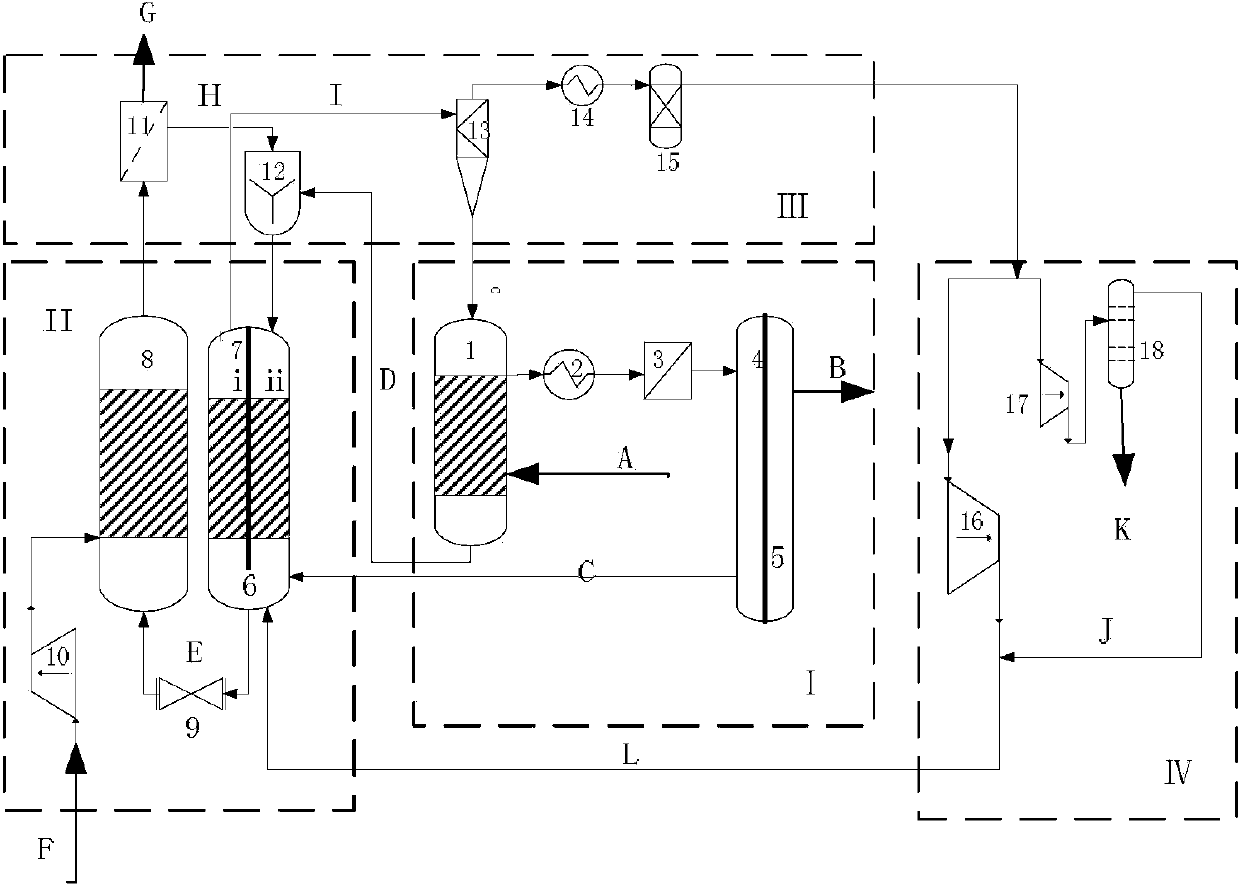

System and method for simultaneous dry-method hydrogen production from catalytic methane decomposition and carbon dioxide separation

ActiveCN103332650AEliminate carbon depositsLow costHydrogenCarbon compoundsDecompositionSolid particle

The invention provides a system and method for simultaneous dry-method hydrogen production from catalytic methane decomposition and carbon dioxide separation. The system comprises a methane decomposition system (I), a catalyst regeneration system (II), a gas solid separation system (III), and a gas circulating system (IV), wherein the methane decomposition system (I) is used for preparing and purifying hydrogen; the catalyst regeneration system (II) is used for receiving the deactivated catalyst, and the methane mixed gas, which is not completely converted, from the methane decomposition system (I), and causing the deactivated catalyst and the methane mixed gas to react with an oxide to eliminate carbon decomposition and provide the heat needed by the methane decomposition system (I); the gas solid separation system (III) is used for receiving and separating the solid particle and conveyed gas from the catalyst regeneration system (II) and the methanol decomposition system (I), and conveying the separated solid particle and conveyed gas into corresponding reactors; the gas circulating system (IV) is used for receiving the carbon dioxide gas from the gas solid separation system (III), collecting partial carbon dioxide gas, and returning partial carbon dioxide and decomposed gas into a reduction reactor (7). By adopting the system disclosed by the invention, the full-component graded conversion of the methanol is achieved.

Owner:SOUTHEAST UNIV

Combined methane decomposition and ammonia formation cell

InactiveUS6986870B1Reduce needImprove efficiencyPhysical/chemical process catalystsChemical industryChemical industryOxygen

An ammonia synthesis process and apparatus are provided which are energy efficient and minimize greenhouse-gas-emission during the processing of natural gas and air. In the process a stream of natural gas is divided into two streams, one of which is mixed with air and ignited to provide heat for the thermal decomposition of natural gas into hydrogen and carbon and also to provide deoxygenated nitrogen for an ammonia synthesis process. The process essentially prepares hydrogen and nitrogen on a low average temperature side of a chemical reactor and then feeds both gases to the high average temperature side of the chemical reactor where they react to form ammonia. The formation of ammonia is exothermic, whereas the thermal decomposition of methane is endothermic and the combustion of methane to remove oxygen is also exothermic; the sum of the heats absorbed and released in these reactions is positive. Catalysts, high temperatures and pressure are used to promote the rapid formation of ammonia, as is standard practice in the chemical industry. Catalysts, and high temperatures are used to promote the thermal decomposition of natural gas and combustion of oxygen that provides hydrogen and nitrogen for ammonia synthesis.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

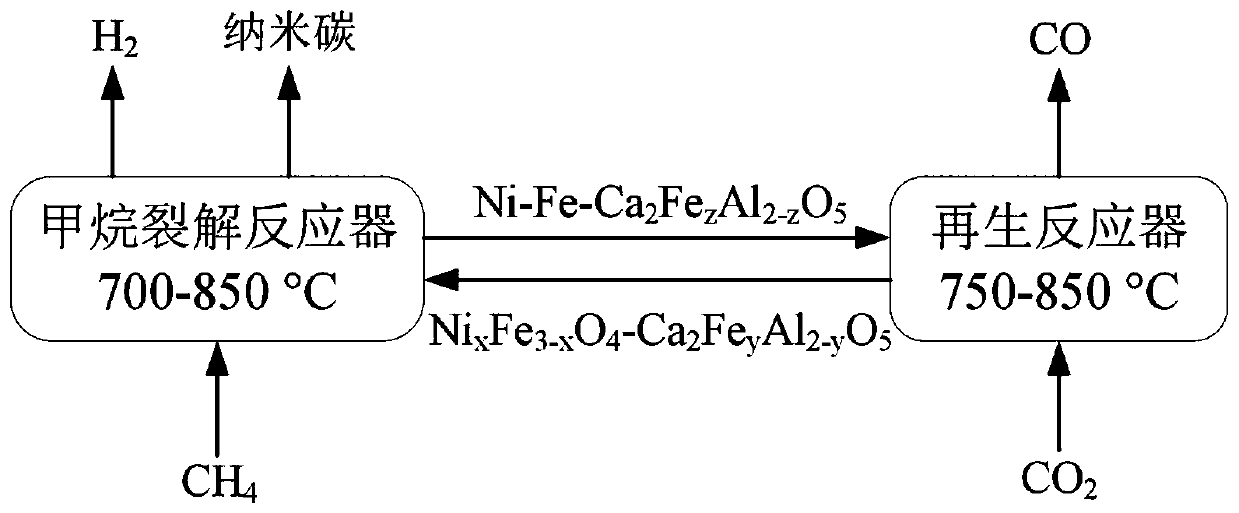

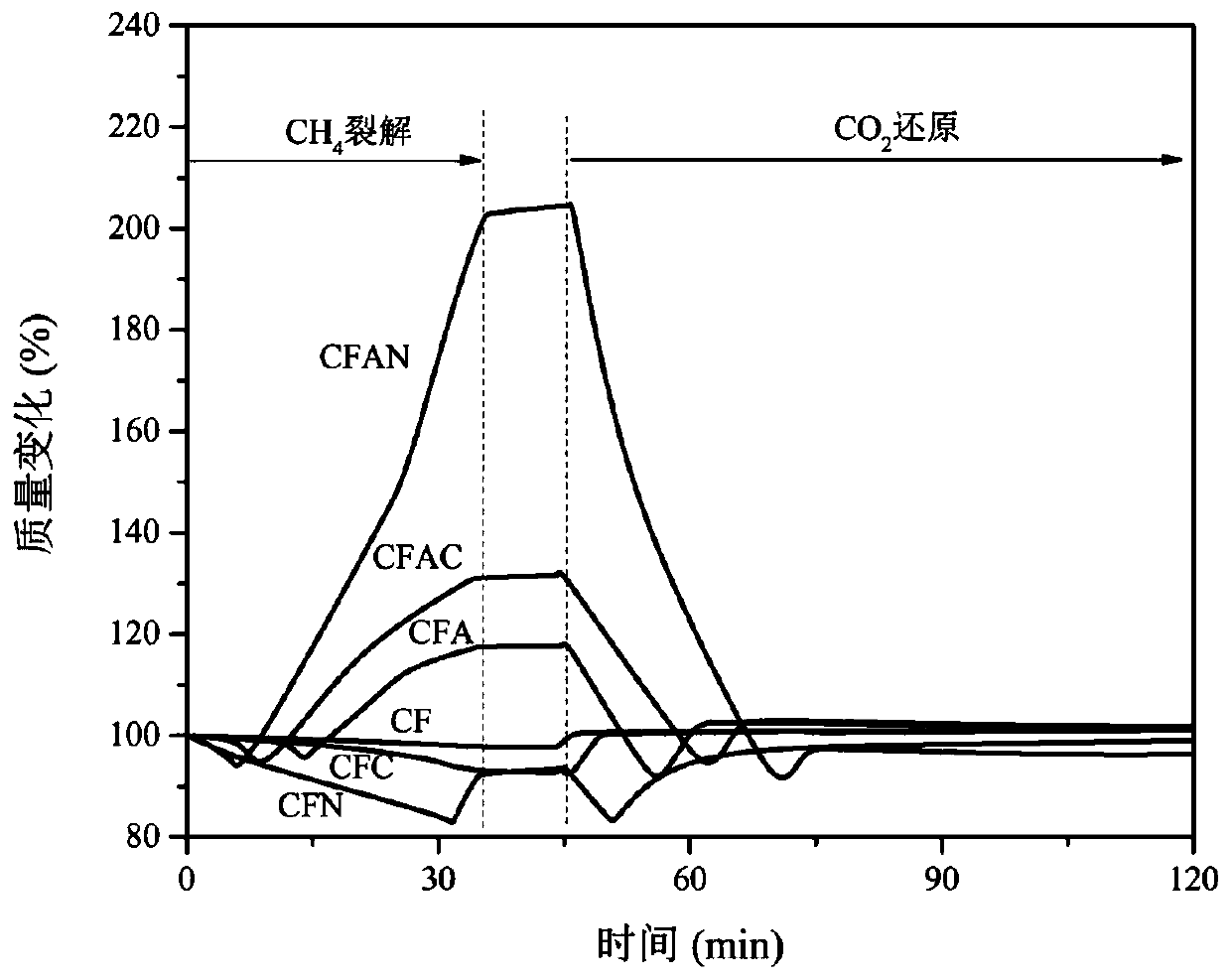

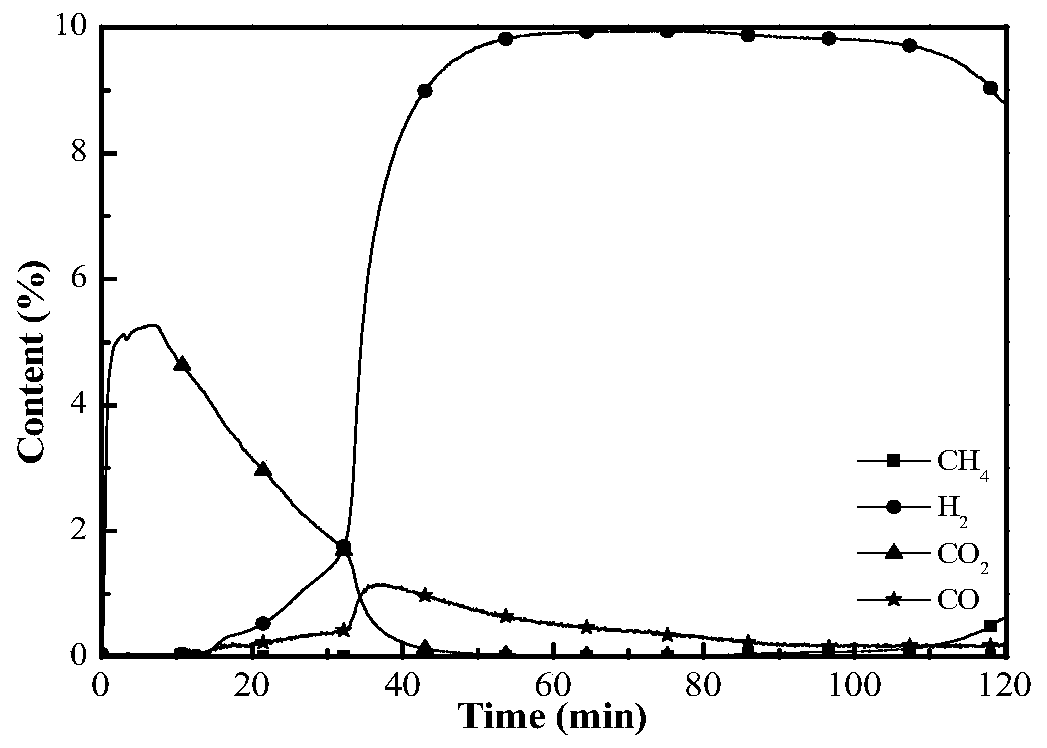

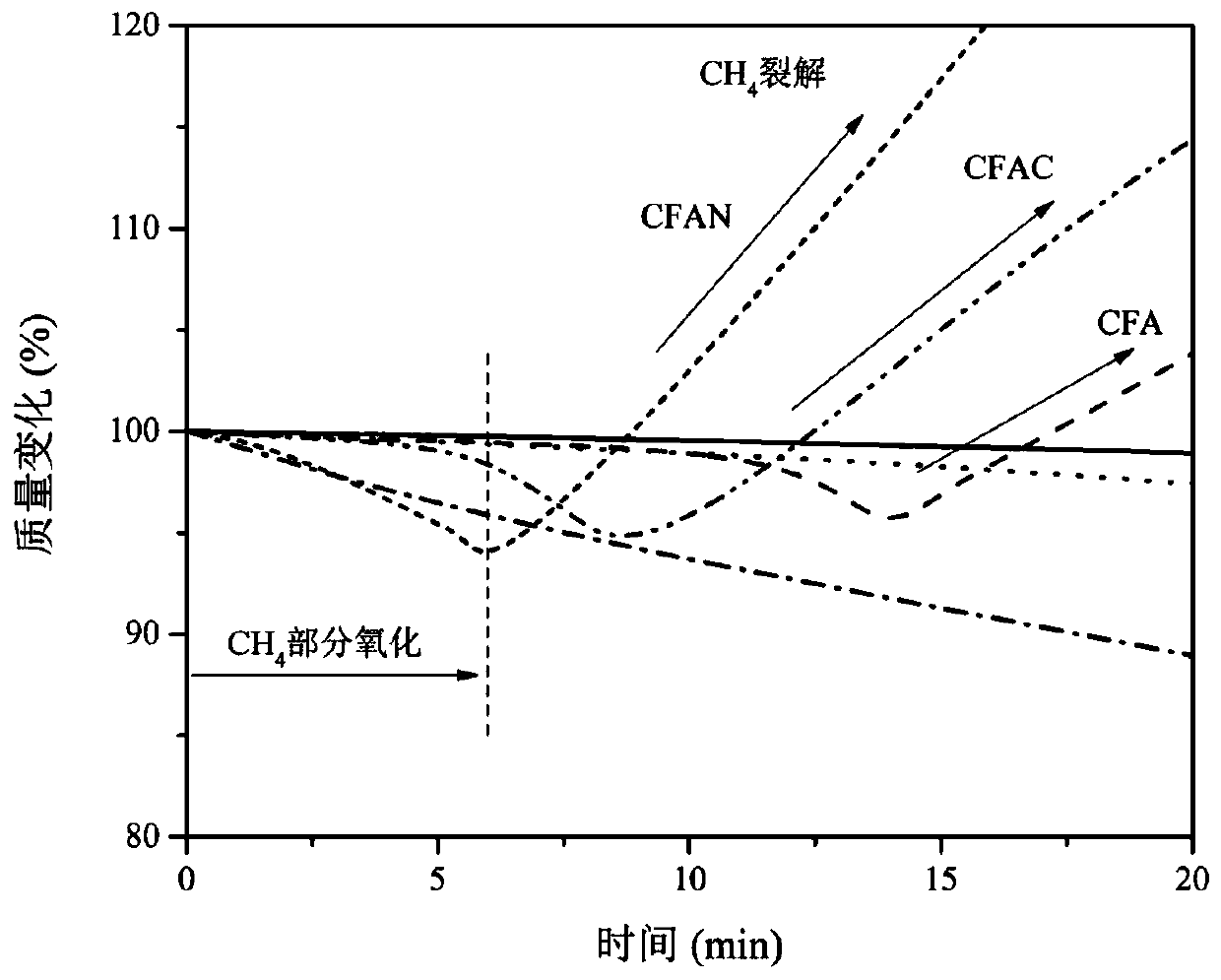

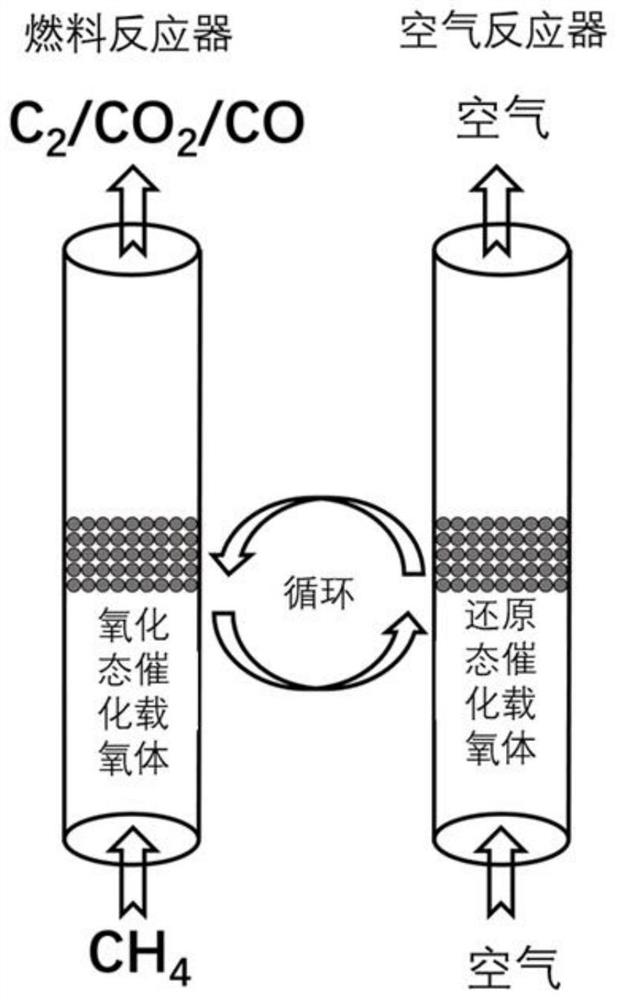

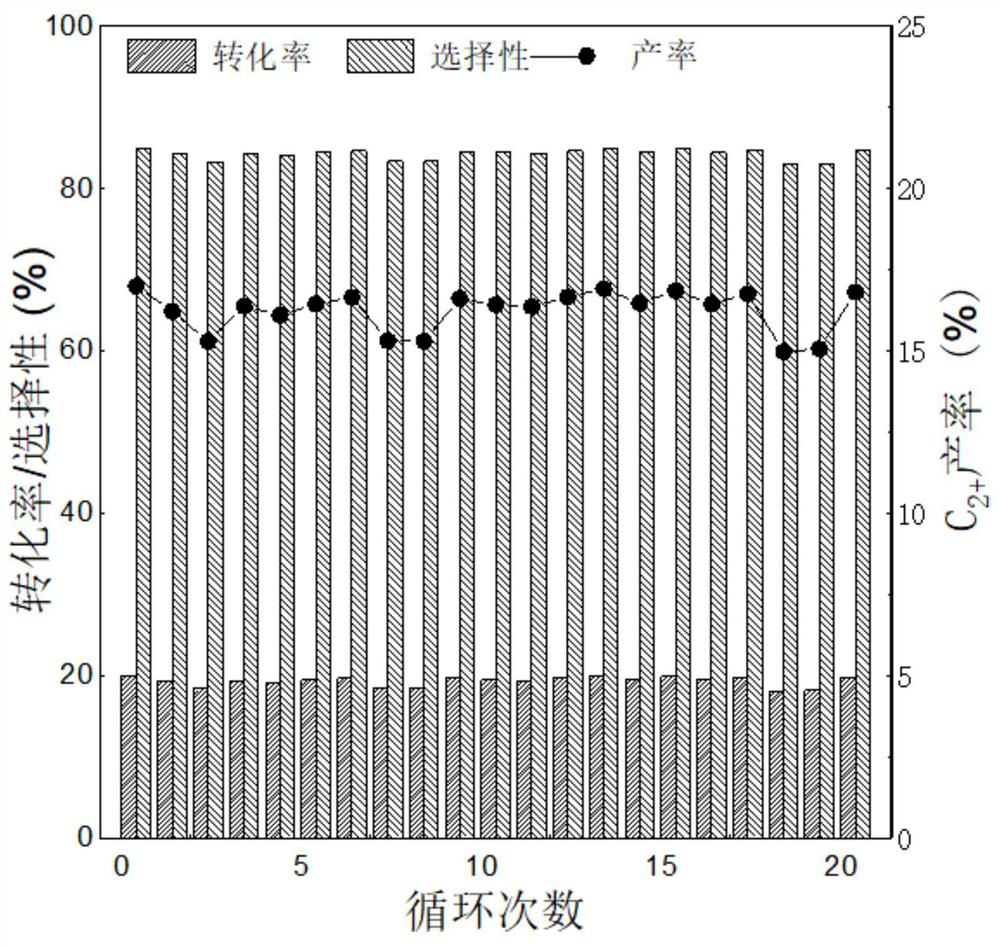

Chemical-looping circulation method for coupling of hydrogen production through methane cracking with CO2 reduction

ActiveCN110683511AGood dispersionEfficient conversionHydrogenCarbon monoxideChemical industryPtru catalyst

The invention belongs to the field of combustion chemical industry and materials, and specifically discloses a catalytic oxygen carrier which is Ni<x>Fe<3-x>O<4>-Ca<2>Fe<y>Al<2-y>O<5>. The invention further discloses a method for applying the novel catalytic oxygen carrier to catalysis of both efficient cracking of methane to produce hydrogen and CO2 reduction. The novel catalytic oxygen carrier provided by the invention can be used for respectively regulating and controlling a reaction of methane catalytic cracking for hydrogen production and a CO2 reduction reaction based on chemical-loopingcirculation. The method comprises the following specific steps: (1) a methane cracking stage: catalyzing methane cracking under the condition of composite catalysis to realize high methane conversionrate and high hydrogen selectivity and to obtain a by-product, i.e., nanocarbon; and (2) a CO2 reduction stage: in the presence of the catalyst and the nanocarbon, realizing high carbon dioxide conversion rate and high carbon monoxide selectivity and realizing the regeneration of the catalytic oxygen carrier at the same time. The method realizes continuous and efficient production of high-purityH2 and emission reduction of CO2 gas.

Owner:CENT SOUTH UNIV

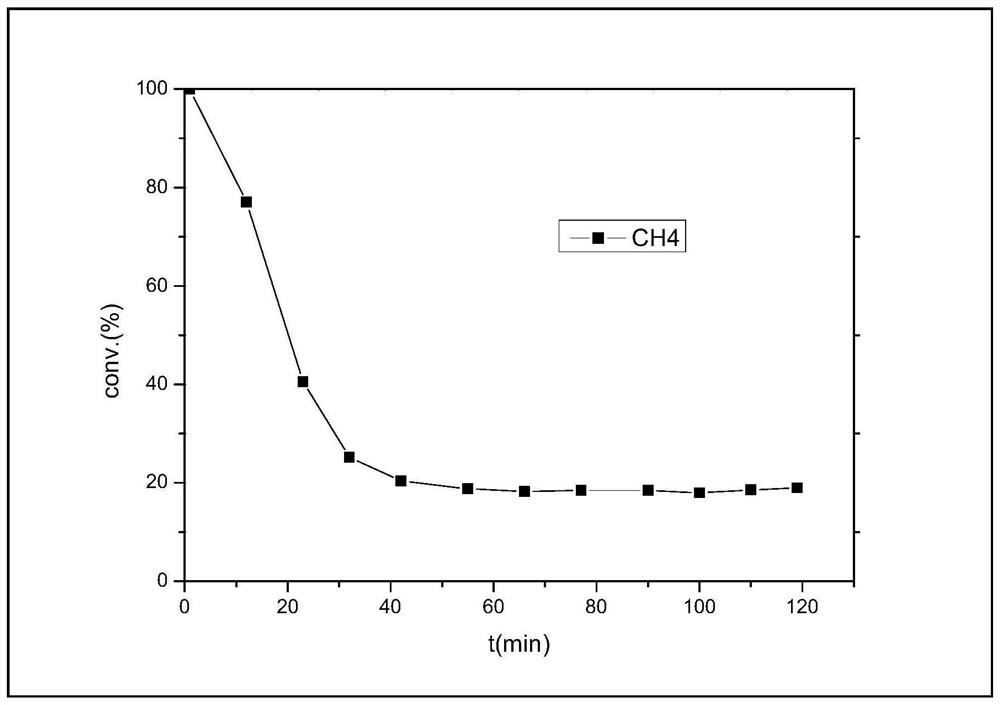

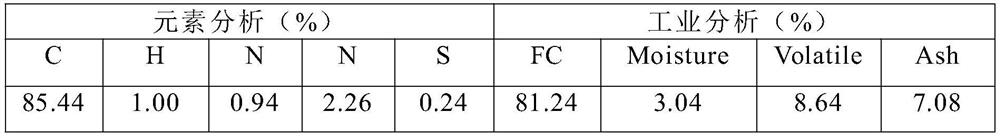

Method for producing hydrogen by catalyzing methane cracking with activated carbon as catalyst

ActiveCN111689467AImprove conversion efficiencyExtended inactivation timeHydrogenCarbon preparation/purificationActivated carbonPtru catalyst

The invention discloses a method for producing hydrogen by catalyzing methane cracking with activated carbon as a catalyst. According to the method, a gas-solid phase catalytic reaction fixed bed reactor is adopted, methane is taken as a raw material, a trace amount of hydrogen sulfide is added, activated carbon is taken as a catalyst, a reaction is carried out at the temperature of 900-950 DEG Cunder normal pressure, products hydrogen and carbon are obtained, and the concentration of hydrogen sulfide is 100 ppm-300 ppm. The trace amount of hydrogen sulfide is added into the methane raw material gas, so that the activity of the activated carbon for catalyzing methane cracking to produce hydrogen is improved, the inactivation time of the activated carbon catalyst is prolonged, and the method has important industrial application value for improving the conversion efficiency of the activated carbon for catalyzing methane cracking to produce hydrogen.

Owner:CHINA UNIV OF MINING & TECH

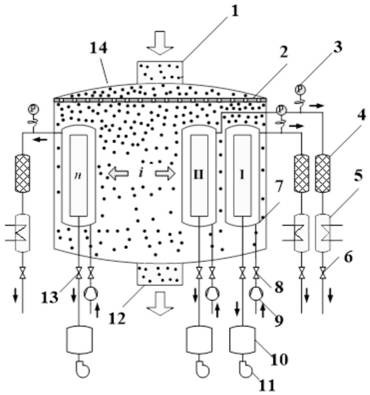

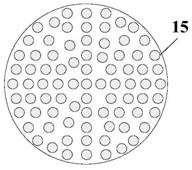

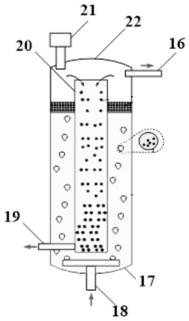

Bubbling type methane decomposition reaction device for high-temperature particle heating

ActiveCN107986231ASolve thermal stressReduce entryHydrogenHydrogen/synthetic gas productionHydrogenReactive gas

The invention discloses a bubbling type methane decomposition reaction device for high-temperature particle heating. The device is mainly applied to an ultra-high temperature condensation solar system. A plurality of special bubbling type direct methane decomposition reactor units are arranged in a main body part (a heat-carrying particle heat release tank) of the device; high-temperature heat-carrying particles downwards flow through the reactor units from the top of the heat release tank and transfer heat to heat-carrying fluid in the reactor units; methane bubbles are decomposed to producehydrogen and carbon nano-particles in the heat-carrying fluid; the carbon nano-particles and reactive gases are separated in the reactor units and extracted by an induced draft fan; and after discharged from the reactor units, the reacted mixed gases (the hydrogen and unreacted methane gas) are cooled to be fed into the next-stage reactor units to be continuously reacted or fed out of the device to enter a hydrogen separation system. According to the device disclosed by the invention, the heat-carrying fluid does not need to be fed out of the device to be heated, and safe and stable operationsof the system are ensured; and due to the modular design of the reactor units, the zoom design of the device is conveniently realized.

Owner:CHINA UNIV OF MINING & TECH

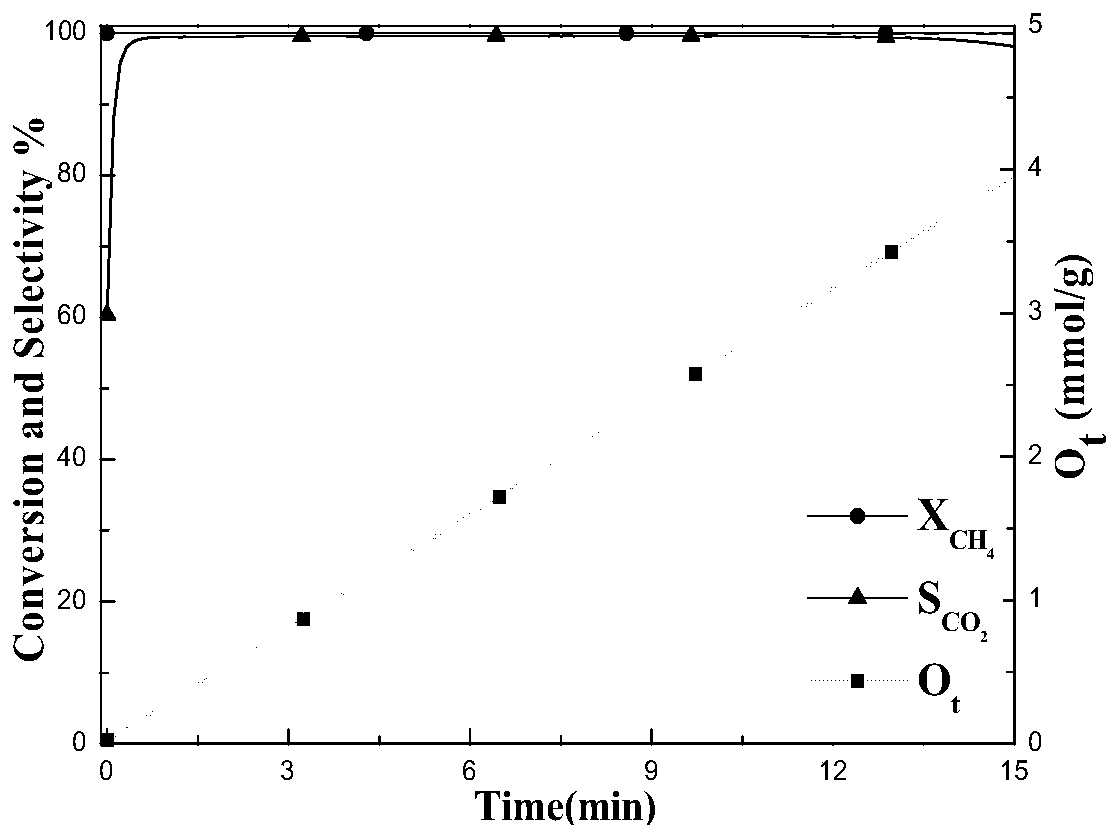

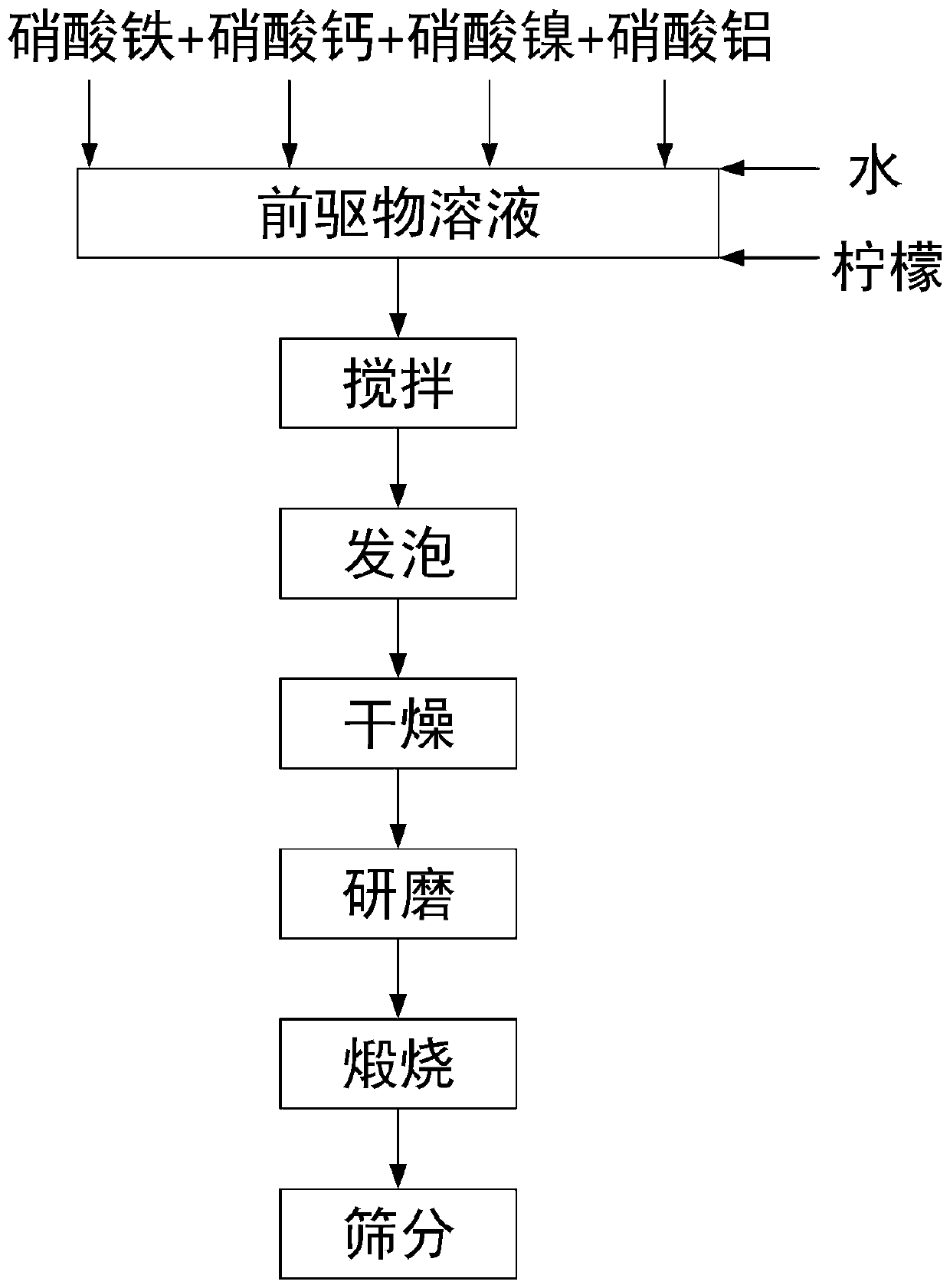

Oxygen carrier for chemical-looping combustion and cracking and preparation method and application thereof

InactiveCN111266113AImprove stabilityReduce packageHydrogenHeterogenous catalyst chemical elementsMethaneFerric nitrate nonahydrate

The invention relates to an oxygen carrier for chemical-looping combustion and cracking and a preparation method and application thereof. The general formula of the oxygen carrier is NiO-AFexAl12-xO19(A = La or Ba, 0 < x < 5), and the molar ratio range of ferronickel is 0-10. Nickel nitrate, ferric nitrate, aluminum nitrate and lanthanum nitrate / barium nitrate are used as precursors to prepare anitrate solution, then coprecipitation is carried out, suction filtration, washing, drying and roasting are carried out, and the preparation method is simple and easy to industrialize. The oxygen carrier has a CH4 conversion rate of nearly 100% and CO2 selectivity of 100% in a chemical looping combustion stage and CO2 can be captured at a low cost. Besides, the oxygen carrier obtained after the chemical-looping combustion reaction is used for methane catalytic cracking hydrogen production, the CH4 conversion rate is 100%, and high-purity H2 and nanocarbon materials can be produced; when the oxygen carrier is used for chemical-looping combustion and methane cracking, the reaction activity is high, the cycling stability is high and the economical efficiency is high.

Owner:NORTHWEST UNIV

Fixed bed coal seam gas non-catalytic deoxidization method and device

ActiveCN101914402BSolving security problems in enrichmentAvoid security issuesGaseous fuelsFixed bedEngineering

The invention discloses a fixed bed coal seam gas non-catalytic deoxidization method and a fixed bed coal seam gas non-catalytic deoxidization device. The device comprises a fixed bed coal seam gas deoxidization device body including a furnace body (1), wherein the side wall of the furnace body (1) is provided with a water jacket (2) enclosing the side wall of the furnace body; the upper part of the water jacket (2) is connected with an air inlet of a steam pocket (23) through a pipeline; and a water inlet pipe on the lower part of the water jacket is connected with a water outlet of the steam pocket (23). The device deoxidizes the coal seam gas, can effectively control the deoxidization temperature and reduce the oxygen content in the coal seam gas to less than 0.5 percent, and maximallyreduces methane decomposition to make the methane loss less than 5 percent.

Owner:CCTEG CHINA COAL RES INST

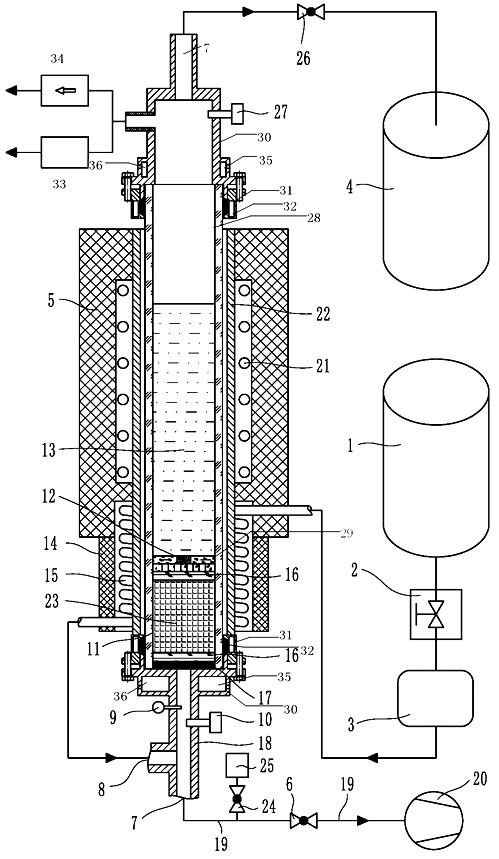

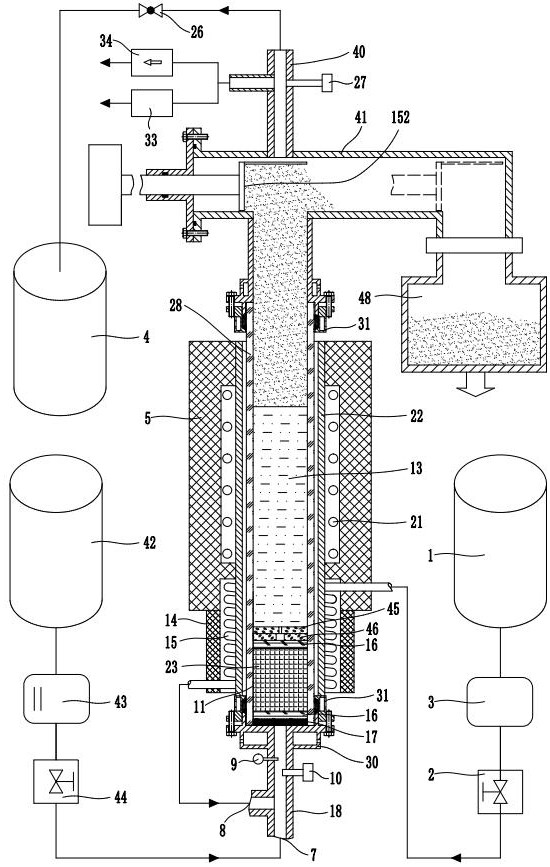

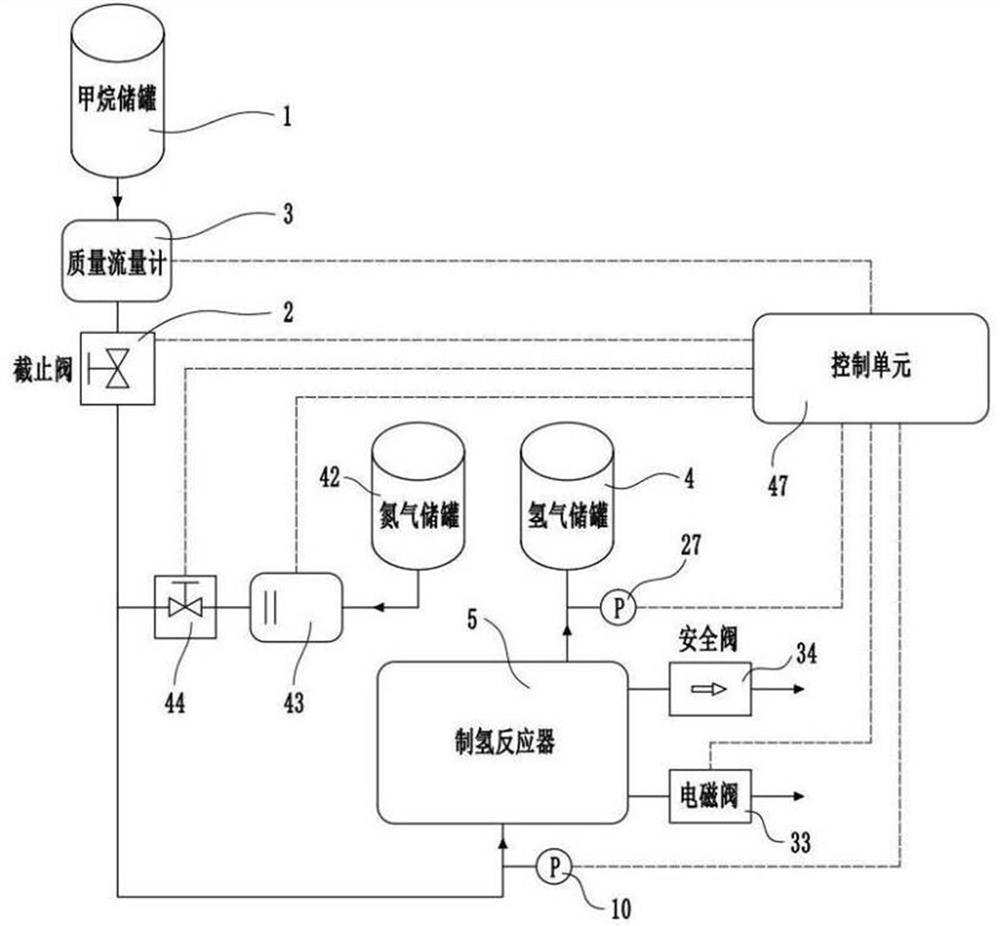

Hydrogen production reactor device with gas replacement and efficient methane cracking carrier

The invention discloses a hydrogen production reactor device with a gas replacement and efficient methane cracking carrier. The hydrogen production reactor device comprises a protection tube, a quartz tube, a diffuser, a supporting plate, an electric heater, a heat preservation layer, a nitrogen storage tank, a methane storage tank, a hydrogen storage tank, a spiral tube, a flow meter, a connecting base B, a carbon discharging mechanism, a connecting base A, a control circuit board and a catalyst which are installed together, wherein the methane cracking carrier is one of molten salt and fused salt. According to the invention, hydrogen is produced by gradually cracking methane, air in the hydrogen production reactor is replaced by gas, compared with a vacuum pump for pumping gas, the structure is simple, the equipment investment cost is reduced under the condition that the amount of carbon dioxide is reduced, the methane cracking carrier is selected as a molten alloy or a molten salt substance, and the methane cracking temperature can be reduced. Due to the catalytic activity of the methane cracking carrier, the hydrogen production rate of the cracked methane is better than that of the original liquid tin serving as a cracking carrier. The methane vent hole of the diffuser is designed to be a round hole, so that the gas inlet inhibition effect is avoided, the methane gas inlet rate is increased, and the productivity is improved.

Owner:芶富均

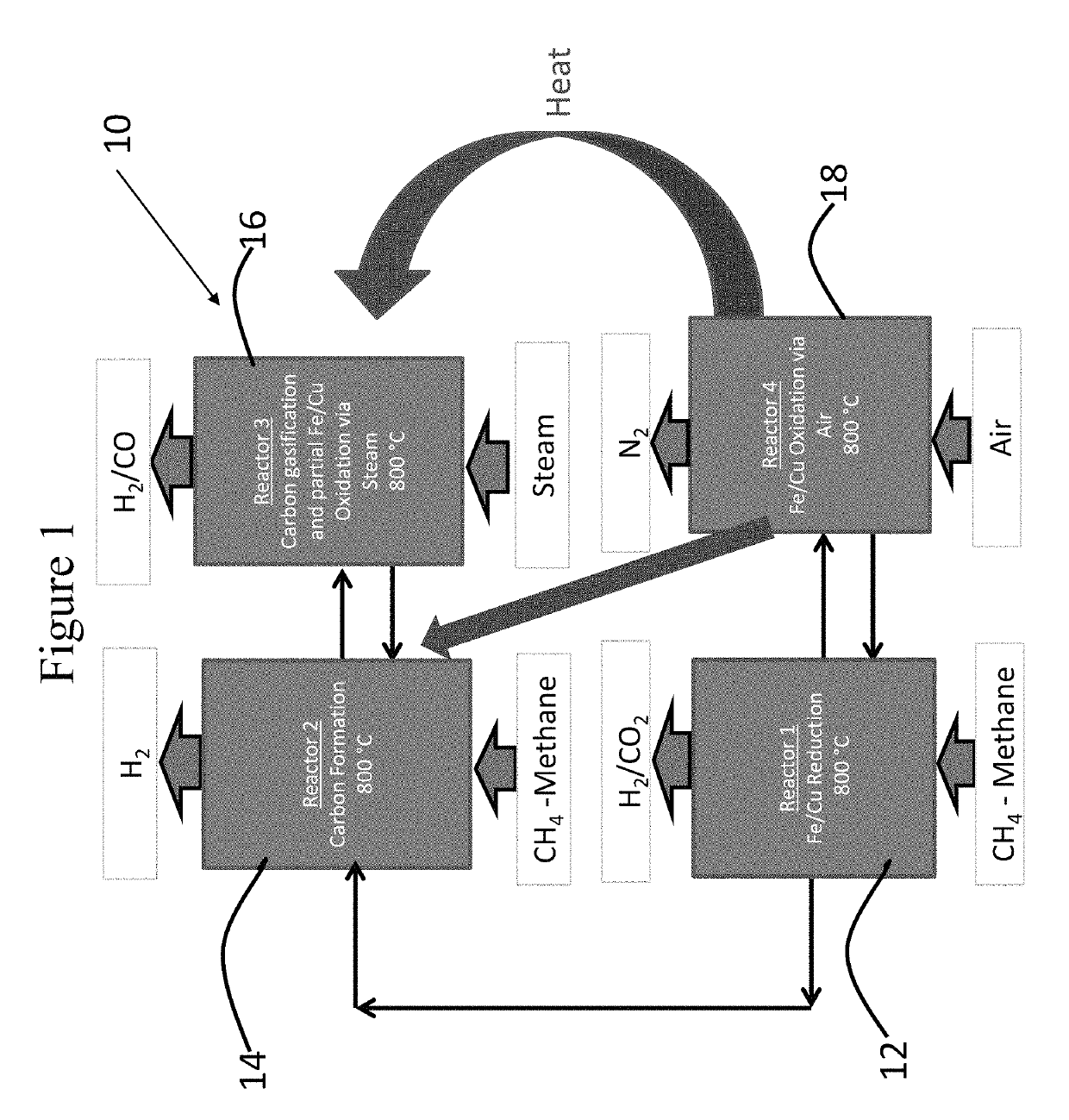

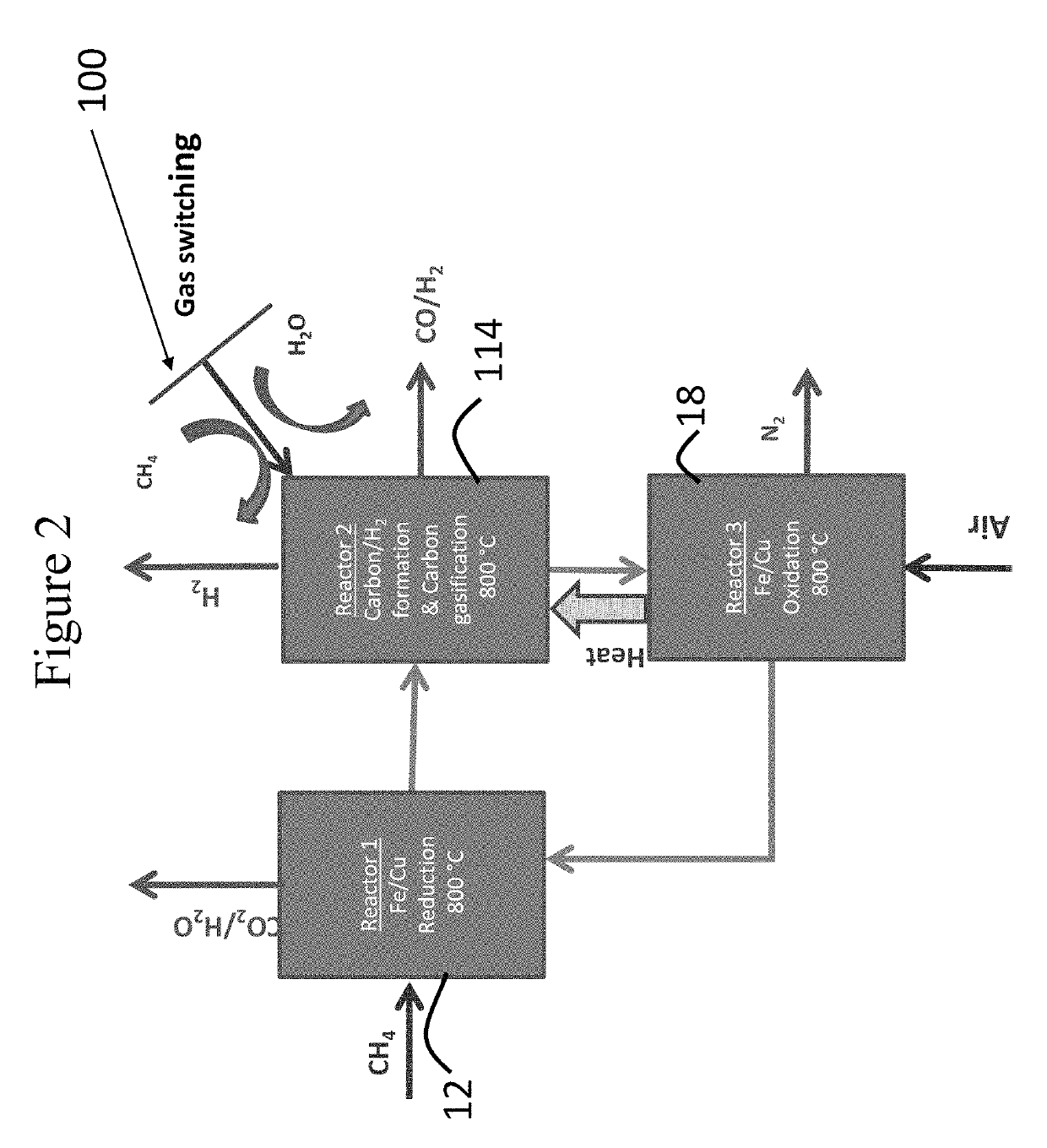

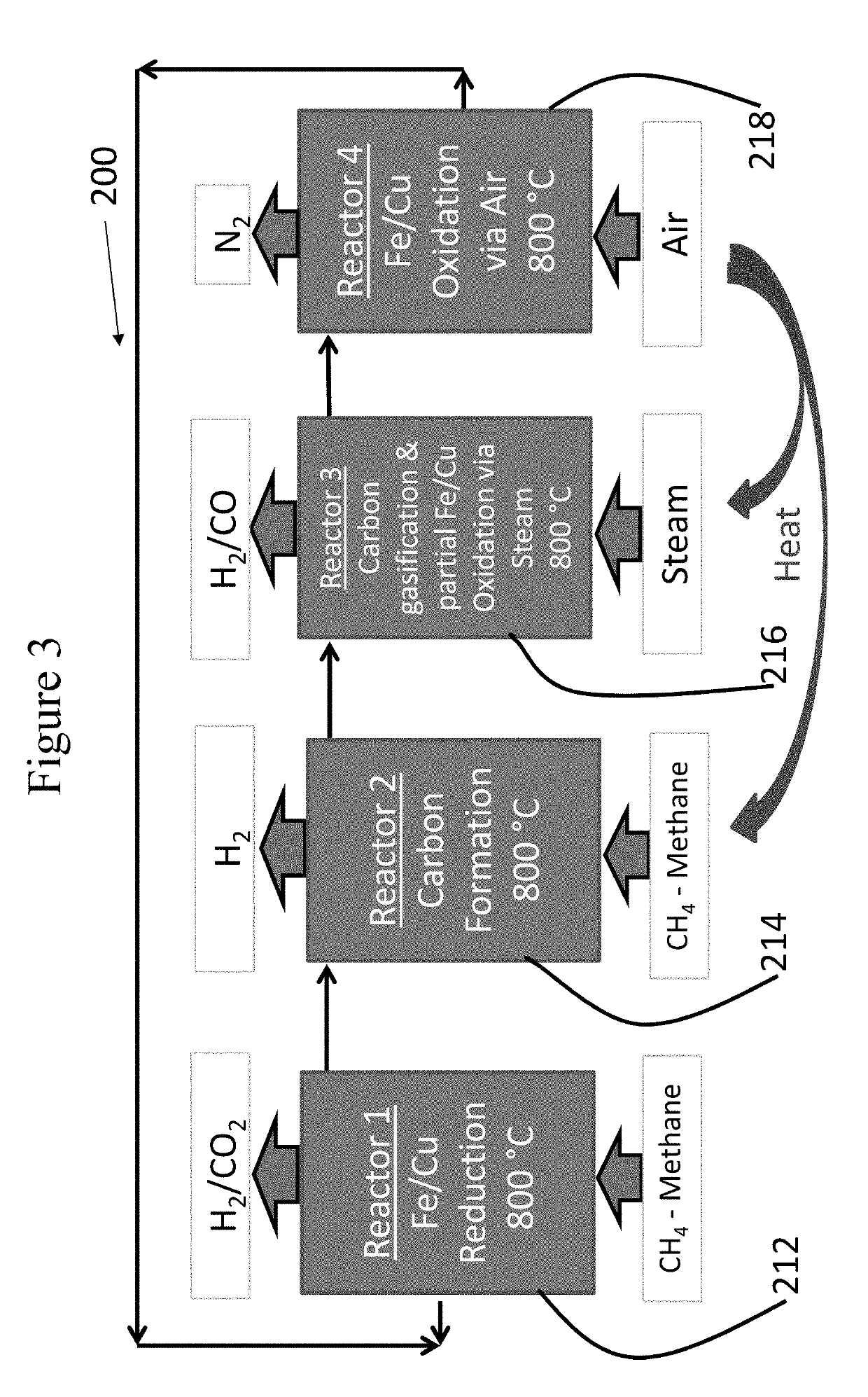

Production of pure hydrogen and synthesis gas or carbon with CUO-Fe2O3 oxygen carriers using chemical looping combustion and methane decomposition/reforming

ActiveUS10513436B1Increase productionReduced metalCatalyst activation/preparationHydrogen productionSyngasMetal catalyst

Methods, systems and apparatus relate to producing synthesis gas or carbon and hydrogen utilizing a reduced catalyst CuO—Fe2O3. The method comprises introducing CH4; reducing the CuO—Fe2O3 with the introduced CH4, yielding at least a reduced metal catalyst; oxidizing the reduced metal with O2 yielding CuO—Fe2O3; and generating heat that would be used for the hydrogen and carbon or syngas production with the reduced catalyst CuO—Fe2O3.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

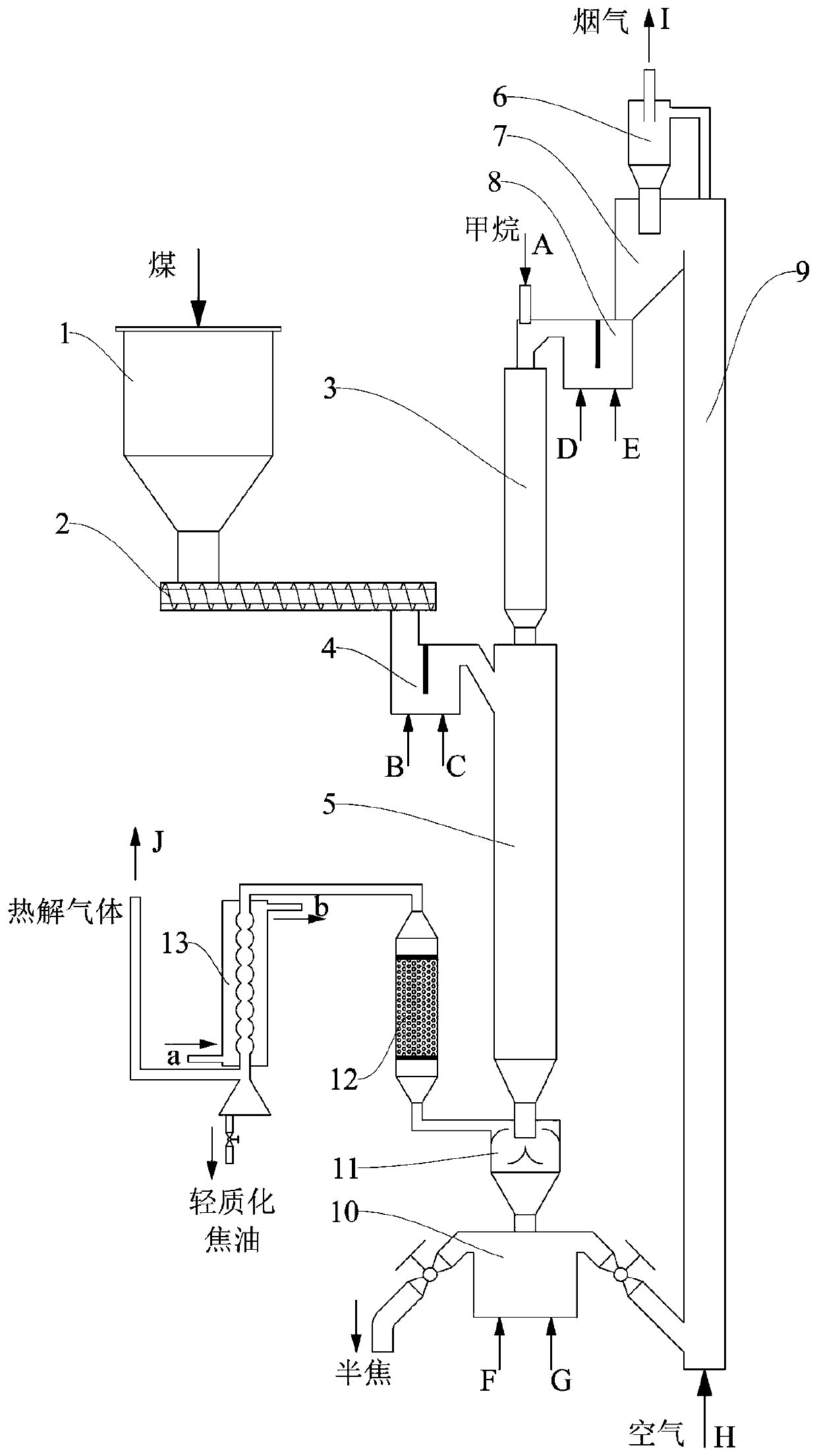

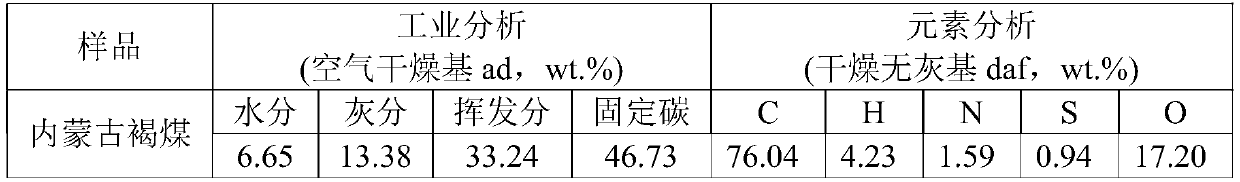

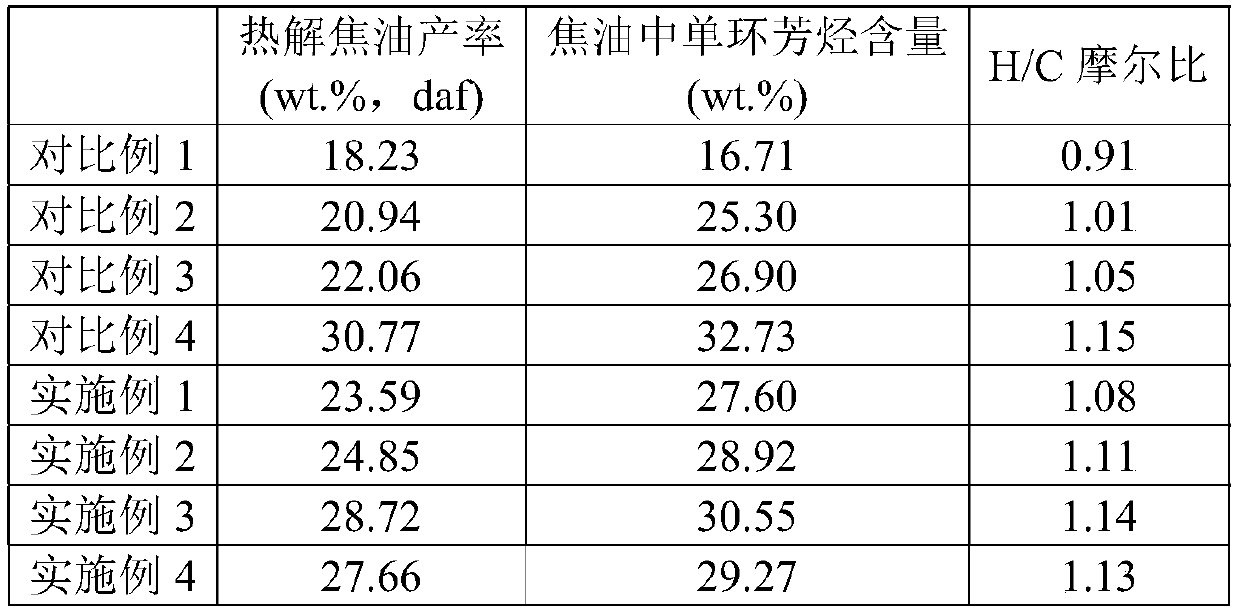

A method for producing light tar by catalytic co-refining of low-rank coal and methane

ActiveCN108219816BHigh mass and heat transfer efficiencyHigh process integrationLiquid hydrocarbon mixture productionChemical industryPtru catalyst

The invention belongs to the fields of energy and chemical industry, particularly provides a method for producing light tar by catalyzing and corefining low-rank coal and methane, and mainly solves the technical problem that the quality of pyrolytic tar of low-rank coal is increased is solved so as to increase the content of light aromatic hydrocarbon with important application values in tar. A down reactor, which is a riser coupling reactor, is adopted as a main body reaction unit, and the main body reaction unit is high in heat and mass transfer efficiency, simple in technological process, high in integration level and continuous and reliable in operation; high-temperature semicoke is taken as a catalyst, and methane is cracked into hydrogen, so that hydrogenation pyrolysis of coal is realized, the yield of tar and the content of light aromatic hydrocarbon inside tar are improved, and the cost of the catalyst and the hydrogen source is obviously reduced; moreover, the high-temperature semicoke is taken as a solid heat carrier, so that the heat efficiency of the process is greatly improved; moreover, an new approach for efficient clean utilization is developed for methane-rich rawmaterial gas such as traditional fossil energy coal and natural gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

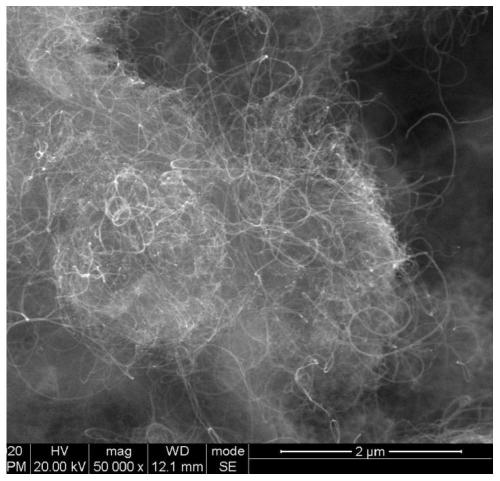

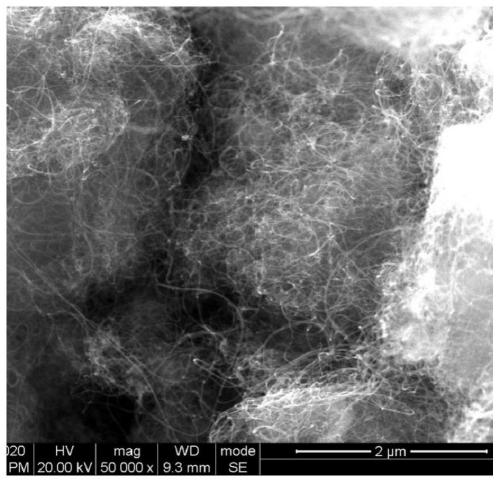

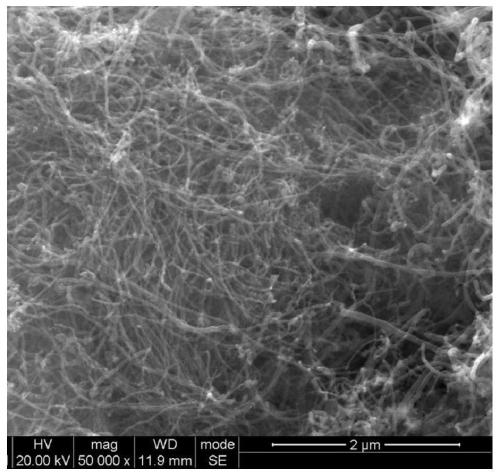

Preparation method of carbon nanotube

The invention discloses a preparation method of a carbon nanotube. The carbon nanotube is prepared by catalytically cracking a carbon source gas by using a catalyst, the carbon source gas comprises methane and polycarbon alkane, and the content of the polycarbon alkane in the carbon source gas is 5-63% of the total carbon source gas based on the number of carbon atoms. According to the preparationmethod, the addition of the polycarbon alkane in the carbon source gas can do work in the cracking reaction process so that methane cracking is promoted, the conversion rate of methane is increased,the growth rate of the carbon nanotubes can be increased, the production efficiency of the carbon nanotubes is improved and the production cost is reduced.

Owner:内蒙古骏成新能源科技有限公司

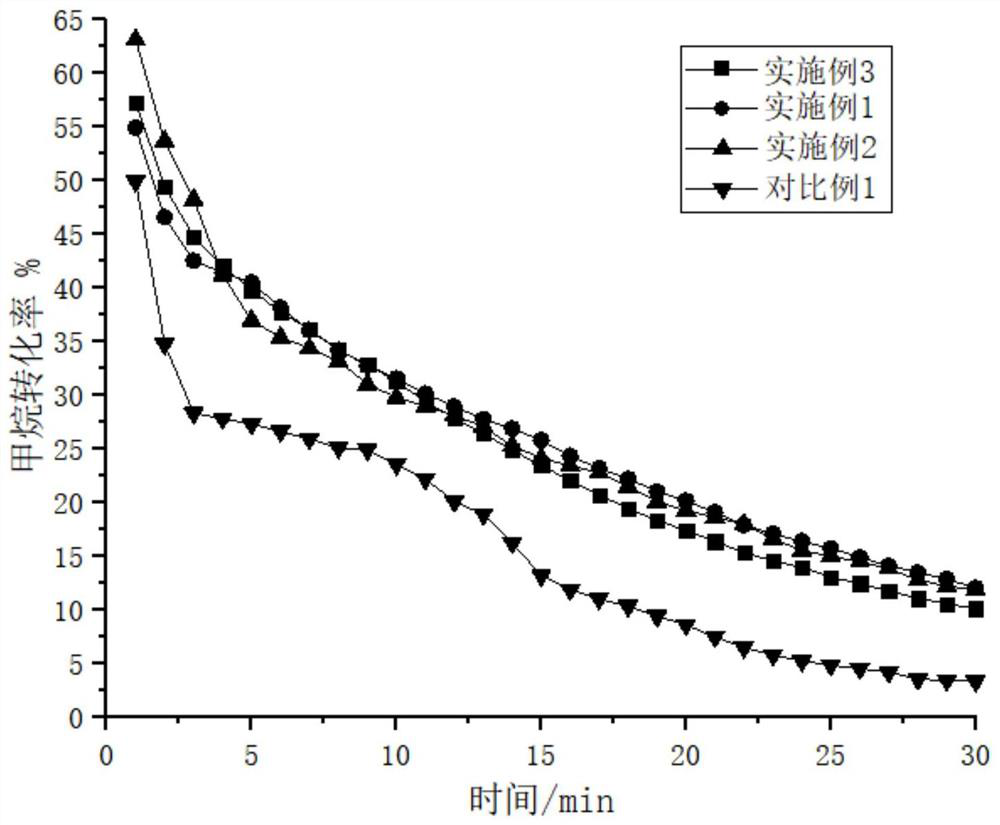

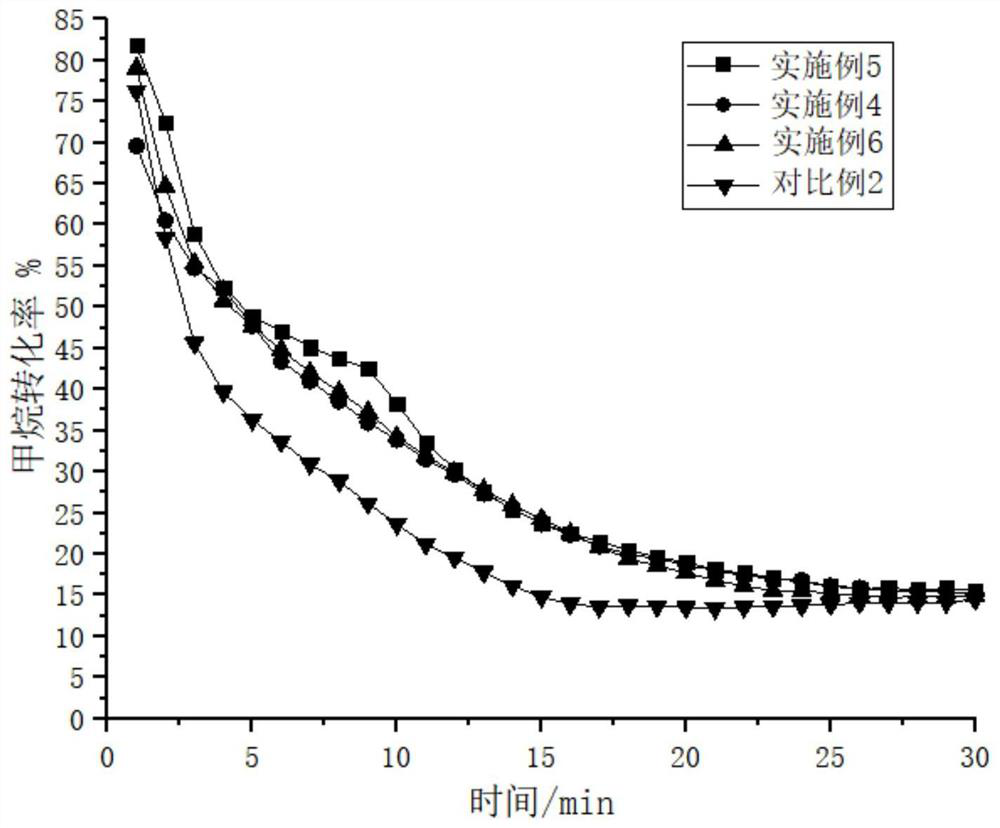

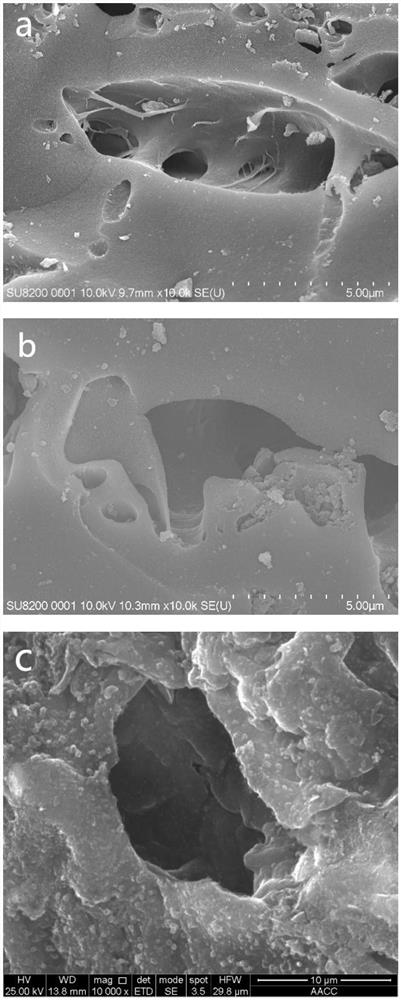

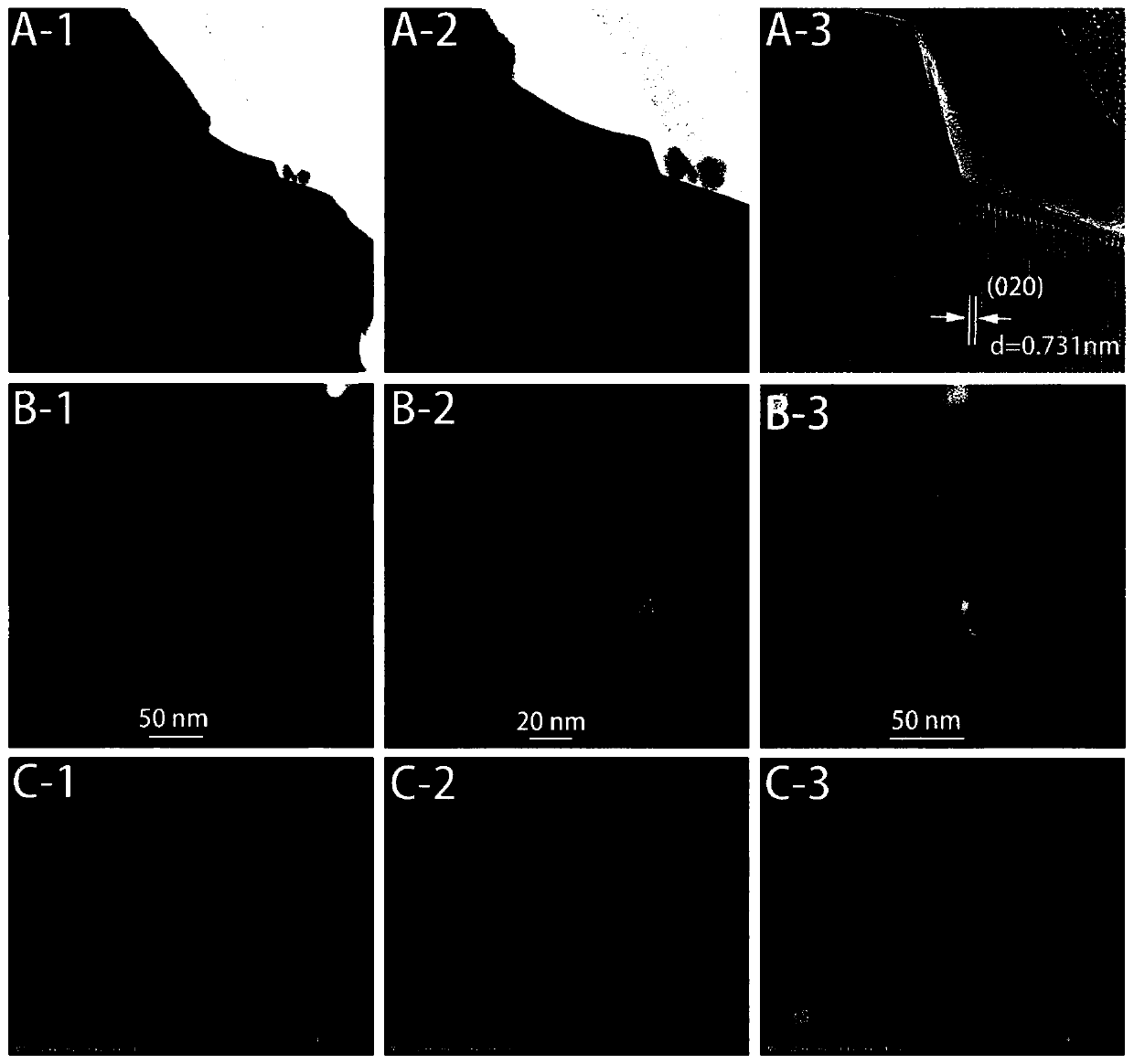

CFAN catalyst, preparation method thereof, and application of CFAN catalyst in production of hydrogen from methane

ActiveCN110721691APromote lysisRapid hydrogen productionHydrogenHeterogenous catalyst chemical elementsPtru catalystNanoparticle

The invention belongs to the fields of combustion chemical industry and materials, and particularly discloses a novel catalyst material NixFe3-xO4-Ca2FeyAl2-yO5 for catalyzing efficiently cracking methane to prepare high-purity hydrogen. NixFe3-xO4 nanoparticles are loaded through a Ca2FeyAl2-yO5 carrier, high dispersion of the NixFe3-xO4 nanoparticles is realized, the special design of the carrier realizes uniform and continuous reduction in the methane cracking process, the carrier is split, and the grain size of active groups in the catalytic process is kept, so that the sintering and agglomeration of the catalyst in the methane catalytic cracking process are effectively inhibited. The catalyst still has methane cracking catalytic activity and stability after long-time catalytic methanecracking, and can realize high methane conversion rate and continuous and efficient production of high-concentration hydrogen, and nanocarbon with a low graphitization degree can be obtained.

Owner:CENT SOUTH UNIV

System and method for simultaneous dry-method hydrogen production from catalytic methane decomposition and carbon dioxide separation

ActiveCN103332650BEliminate carbon depositsLow costHydrogenCarbon compoundsDecompositionSolid particle

The invention provides a system and method for simultaneous dry-method hydrogen production from catalytic methane decomposition and carbon dioxide separation. The system comprises a methane decomposition system (I), a catalyst regeneration system (II), a gas solid separation system (III), and a gas circulating system (IV), wherein the methane decomposition system (I) is used for preparing and purifying hydrogen; the catalyst regeneration system (II) is used for receiving the deactivated catalyst, and the methane mixed gas, which is not completely converted, from the methane decomposition system (I), and causing the deactivated catalyst and the methane mixed gas to react with an oxide to eliminate carbon decomposition and provide the heat needed by the methane decomposition system (I); the gas solid separation system (III) is used for receiving and separating the solid particle and conveyed gas from the catalyst regeneration system (II) and the methanol decomposition system (I), and conveying the separated solid particle and conveyed gas into corresponding reactors; the gas circulating system (IV) is used for receiving the carbon dioxide gas from the gas solid separation system (III), collecting partial carbon dioxide gas, and returning partial carbon dioxide and decomposed gas into a reduction reactor (7). By adopting the system disclosed by the invention, the full-component graded conversion of the methanol is achieved.

Owner:SOUTHEAST UNIV

Method for coproduction of carbon black and high-purity hydrogen by high-temperature pyrolysis of methane

ActiveCN101838480BEmission reductionImprove reaction efficiencyPigmenting treatmentHydrogenThermodynamicsOxygenate

The invention discloses a method for coproduction of carbon black and high-purity hydrogen by high-temperature pyrolysis of methane, which comprises the following steps: taking fuel gas with low caloric value of 1300-1500kcal / Nm3 as a fuel, taking methane-containing gas as a raw material, adopting the alternate working mode of controlling the quantity of supplied oxygen used for combustion-supporting for further promoting the full combustion of the fuel gas with the low caloric value, storing heat in a reaction furnace, removing the residual gas and carrying out methane pyrolysis, and building a methane non-oxygen high-temperature pyrolysis reaction environment, and the method specifically comprises the process steps of regulating the combustion-supporting gas, storing the heat in the reaction furnace, removing the residual gas, carrying out the methane pyrolysis, collecting the carbon black, and purifying for producing the hydrogen. The process is simple, and the amplification of production capacity and the continuous high-efficient production can be realized through the multi-stage combination of the pyrolysis reaction furnaces. The method can not only fully utilize the low-caloric value fuel gas resources and realize high reaction efficiency, but also reduce the emission of greenhouse gas and realize the low-carbon clean circulatory production, and a set of production process can realize the coproduction of the high-quality carbon black and the high-purity hydrogen.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

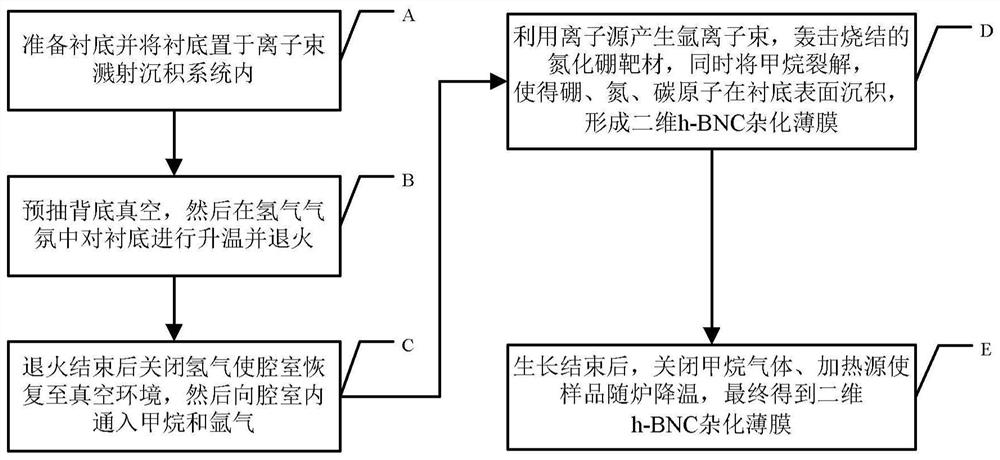

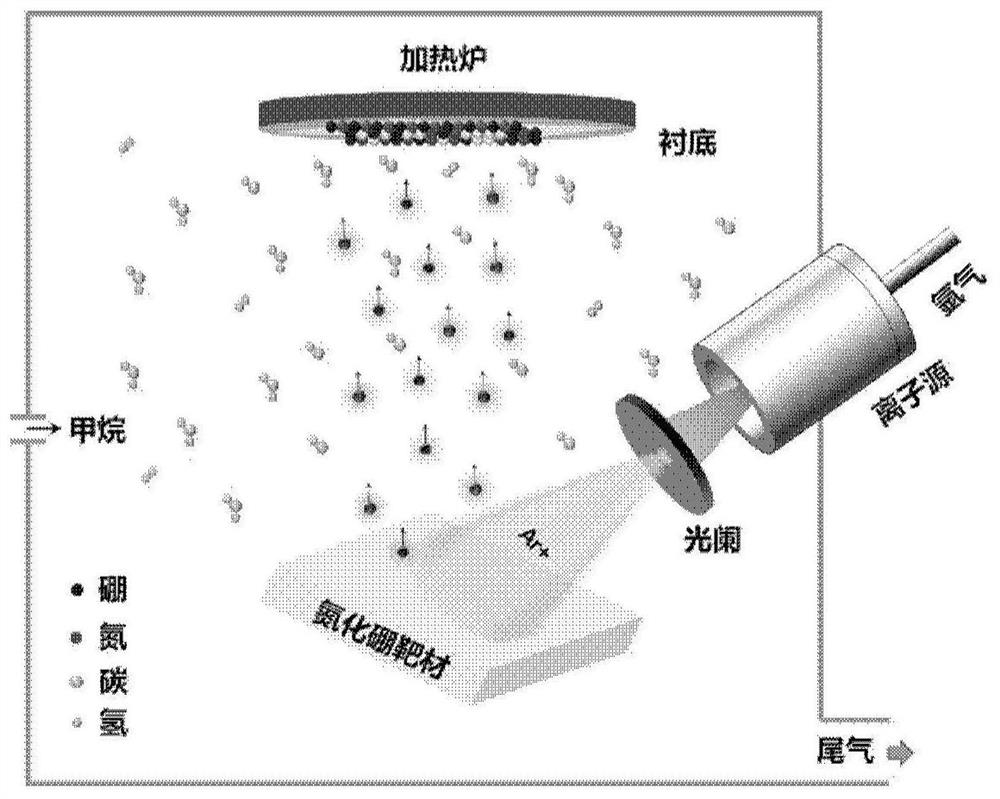

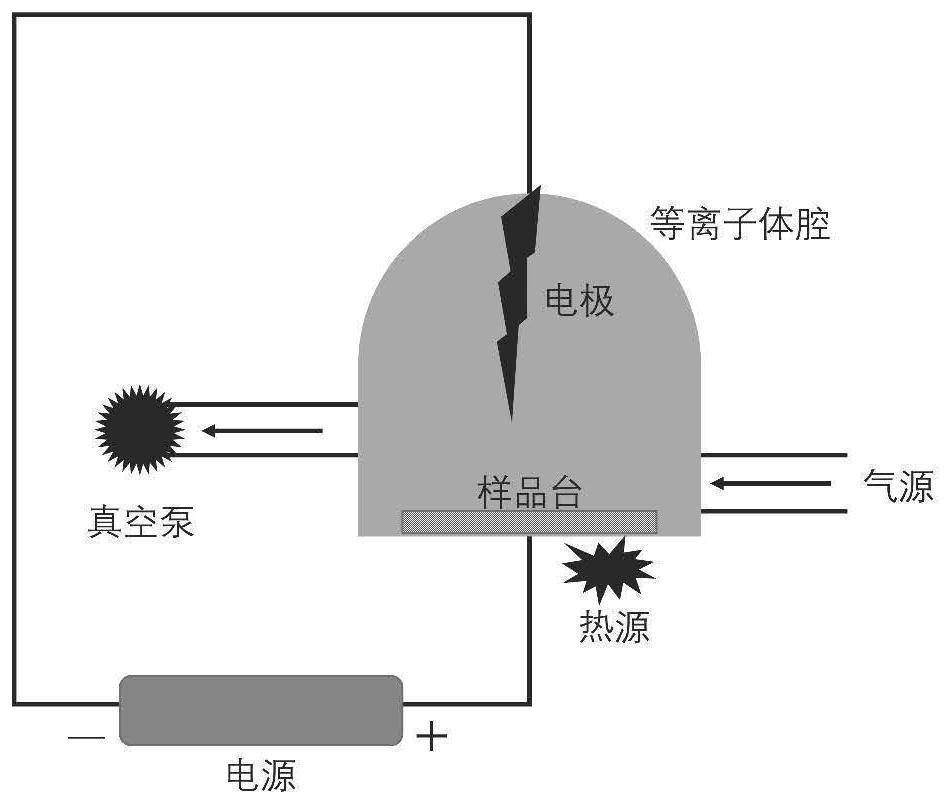

Method for preparing component-adjustable two-dimensional h-BNC hybrid thin film

InactiveCN111607775AAvoid stabilityAvoid problems such as excessive by-productsVacuum evaporation coatingSputtering coatingChemical physicsHydrogen atmosphere

The invention provides a method for preparing a component-adjustable two-dimensional h-BNC hybrid thin film. The method comprises the steps that a substrate is prepared, and the substrate is placed inan ion beam sputtering deposition system; back bottom vacuum is pre-extracted, and the substrate is warmed and annealed in the hydrogen atmosphere; after annealing is finished, hydrogen is shut off,so that a chamber restores to the vacuum environment, and then methane and argon are input into the chamber; an argon ion beam is generated through an ion source, a sintered boron nitride target material is subjected to bombardment, meanwhile, methane is decomposed, boron, nitrogen and carbon atoms are deposited on the surface of the substrate, and a two-dimensional h-BNC hybrid thin film is formed; and after growing is finished, methane gas and a heating source are shut off so that a sample can be cooled along with a furnace, and the two-dimensional h-BNC hybrid thin film is finally obtained.According to the method for preparing the two-dimensional h-BNC hybrid thin film, the problems that precursors are instable, and many by-products are generated can be effectively avoided, controllability is good, and the uniformity of the prepared thin film is good.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

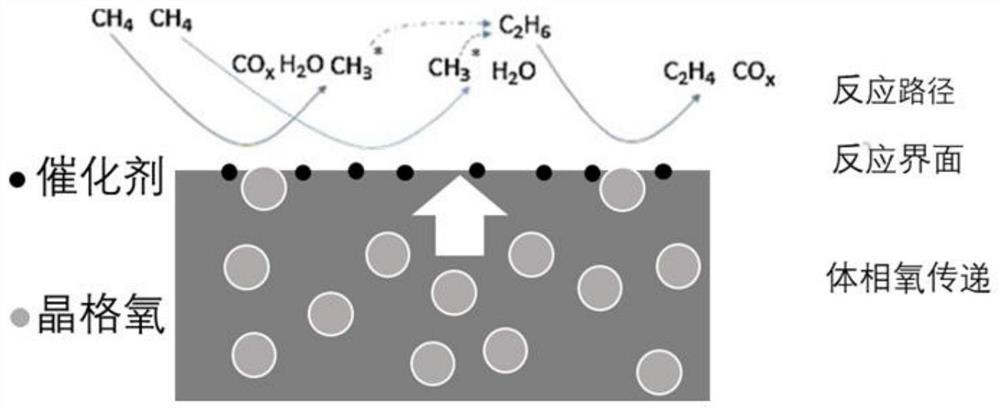

A methane oxidative coupling method based on chemical chain lattice oxygen transfer technology

ActiveCN109438159BReduce over-oxidationAvoid direct contactCatalystsHydrocarbon preparation catalystsPtru catalystLattice oxygen

The invention belongs to the technical field of methane conversion, in particular to a methane oxidative coupling method based on the chemical chain lattice oxygen transfer technology, which uses a composite material with methane catalytic cracking and selective oxygen supply functions to realize one-step efficient methane oxidative coupling The catalytic oxygen supply material is composed of a methane cracking catalyst and a selective oxygen supply material. The catalytic part provides active sites for the activated cracking of methane, and the oxygen supply material part transmits oxygen atoms through lattice oxygen to supply oxygen for the reaction. Oxidation and regeneration of free oxygen; Catalytic oxygen carrier oxidation-reduction cycle realizes the transfer of oxygen in this reaction, avoiding the direct contact between free oxygen and methane; Directional control of lattice oxygen activity weakens the excessive oxidation of methane and improves the oxidation of olefins. Selectivity and yield of olefins; at 800°C to 850°C, methane oxidative coupling has higher reactivity and selectivity.

Owner:SOUTHEAST UNIV

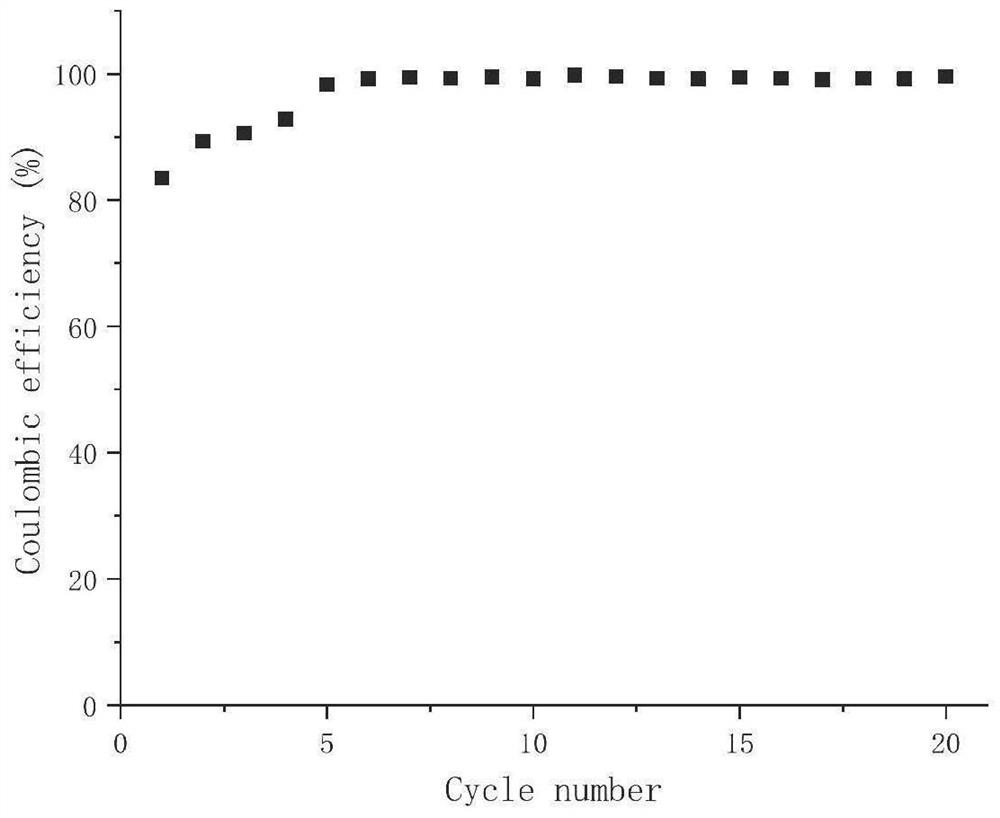

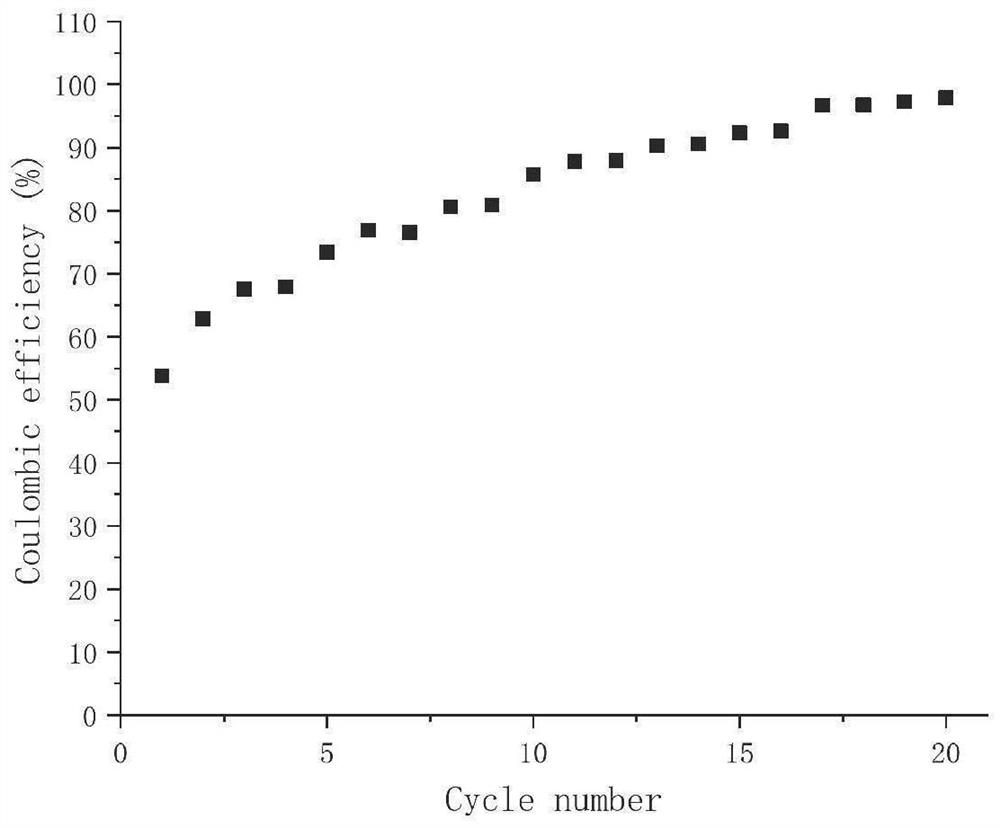

Preparation method of lithium phosphide-based composite material and application of lithium phosphide-based composite material as lithium supplement material

ActiveCN114314537AShorten crystallization timeSmall scaleCell electrodesCarbon preparation/purificationLithium hydroxideNanoparticle

The invention discloses a preparation method of a lithium phosphide-based composite material and application of the lithium phosphide-based composite material as a lithium supplement material. The preparation method comprises the following steps: 1, placing a lithium hydroxide solution in a microwave environment to evaporate water in the solution, and separating out lithium hydroxide nanoparticles; and 2, placing the lithium hydroxide nano-particles in a chamber, introducing a mixed gas of hydrogen phosphide and a protective gas, and heating to convert the lithium hydroxide nano-particles into the lithium phosphide nano-particles. And 3, taking a mixed gas of methane and a protective gas as a plasma source, performing plasma discharge in the chamber filled with the lithium phosphide nanoparticles, decomposing the methane, and forming a carbon shell on the surface of the lithium phosphide nanoparticles to obtain the lithium phosphide-based composite material. Carbon shells are formed on the surfaces of the lithium phosphide particles through methane decomposition, and the carbon shells can further enhance the electronic conductivity of the lithium phosphide particles and isolate lithium phosphide from the external environment, so that the chemical stability of lithium phosphide is improved.

Owner:HANGZHOU DIANZI UNIV

Mechanical catalysis method for preparing hydrogen and carbon through methane cracking

PendingCN114751373ALow reaction temperatureReduce consumptionHydrogenHydrogen/synthetic gas productionPtru catalystReaction energy

The invention relates to a mechanocatalysis method for preparing hydrogen and carbon through methane cracking, which is characterized in that deposited carbon on the surface of a catalyst is removed in time through mechanocatalysis, and the reaction life of the catalyst is prolonged; meanwhile, the mechanical energy can effectively activate reaction molecules, reduce the catalytic reaction energy barrier and gentle the catalytic reaction conditions; and finally, methane cracking products only comprise hydrogen and carbon, and the mechanocatalysis process of methane cracking is simple to operate and low in energy consumption.

Owner:SHANDONG UNIV

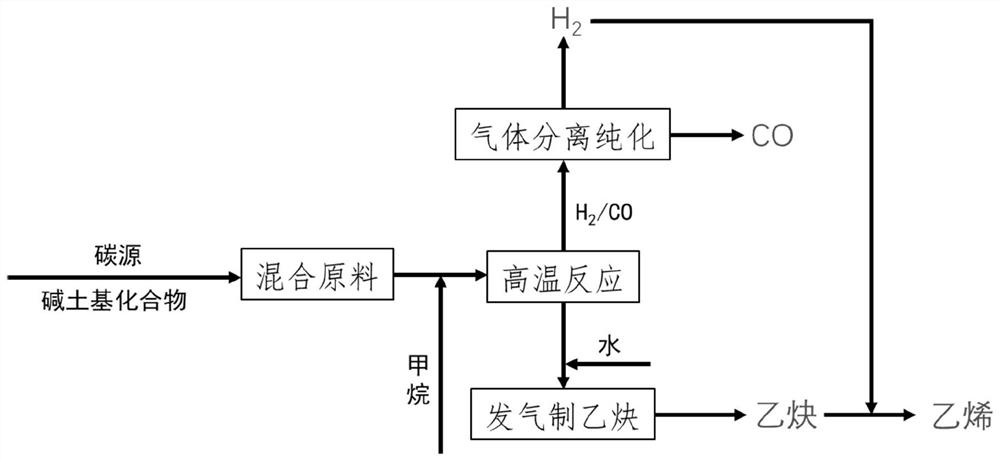

Coupling process method and system for methane cracking and alkaline earth metal carbide preparation

PendingCN114835083AFacilitate synthesis reactionSolve the problem of carbon deposition and deactivationHydrogen separationAcetylene gas generator detailsAlkaline earth metalPtru catalyst

The invention discloses a coupling process method and system for methane cracking and alkaline earth metal carbide preparation. The coupling process method comprises an alkaline earth metal carbide synthesis process and a methane cracking process. In the alkaline earth metal carbide synthesis process, an alkaline earth metal-based compound and a carbon source are put into a high-temperature reaction furnace for a high-temperature reaction, and in the methane cracking process, methane is introduced into the high-temperature reaction furnace for a cracking reaction; the methane cracking reaction and the alkaline earth metal carbide synthesis reaction are simultaneously carried out in the high-temperature reaction furnace. The alkaline-earth metal-based compound reacts with the carbon source and also serves as a catalyst to catalyze methane cracking reaction, and carbon generated by methane cracking can serve as the carbon source to react with the alkaline-earth metal-based compound to generate alkaline-earth metal carbide.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

A bubbling methane cracking reaction device heated by high temperature particles

ActiveCN107986231BWill not affect normal operationSolve thermal stressHydrogenHydrogen/synthetic gas productionThermodynamicsReactive gas

Owner:CHINA UNIV OF MINING & TECH

Method for stably catalyzing methane cracking hydrogen production by using carbon black enhanced activated carbon and application

ActiveCN113307225AReduce manufacturing costImprove economyHydrogenHydrogen/synthetic gas productionActivated carbonPtru catalyst

The invention discloses a method for stably catalyzing methane cracking hydrogen production by using carbon black enhanced activated carbon and application. According to the method, 8-16-mesh coconut shell activated carbon is adopted as a carrier to load carbon black, two carbon catalysts are combined through a series of preparation processes, and a reaction is performed at 850-1000 DEG C under normal pressure. According to the method, the conversion rate of a single activated carbon catalyst for catalyzing methane cracking hydrogen production is effectively improved, so that the activated carbon catalyst has a higher initial conversion rate and shows an inactivation delaying effect, and the method is a method for effectively improving the catalytic activity of cheap activated carbon. The method has important application value for industrial application of catalyzing methane cracking hydrogen production by the carbon catalyst and increasing the methane cracking conversion rate.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com