Method for preparing component-adjustable two-dimensional h-BNC hybrid thin film

A hybrid and thin-film technology, applied in the field of material science, can solve problems such as expensive, unstable precursors, and difficult to control growth parameters, and achieve the effects of avoiding instability, good film uniformity, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

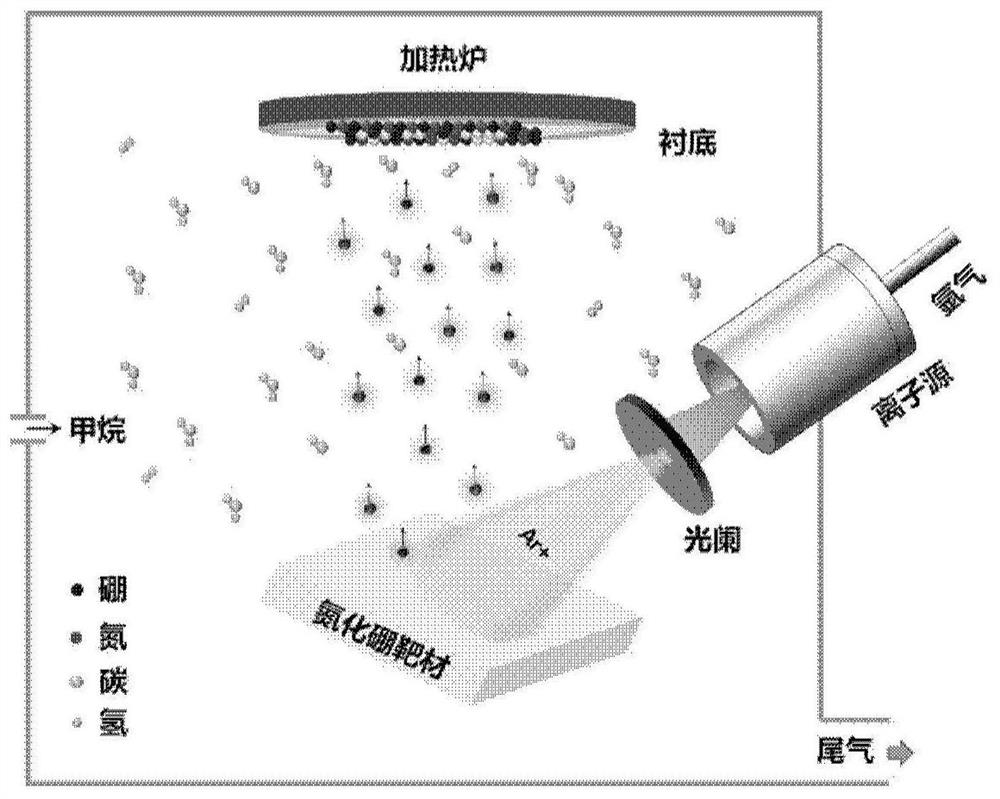

[0031] The present invention is based on the ion beam assisted deposition method, adopts argon ion beam sputtering and sintering, the boron nitride target produces B and N sources, and a certain amount of methane is passed through during the growth process to provide a carbon source to grow two-dimensional h-BNC heterogeneous At the same time, the composition of the h-BNC thin film can be adjusted by adjusting the flow rate of methane and the ion beam current density, so as to prepare a high-quality two-dimensional h-BNC hybrid thin film.

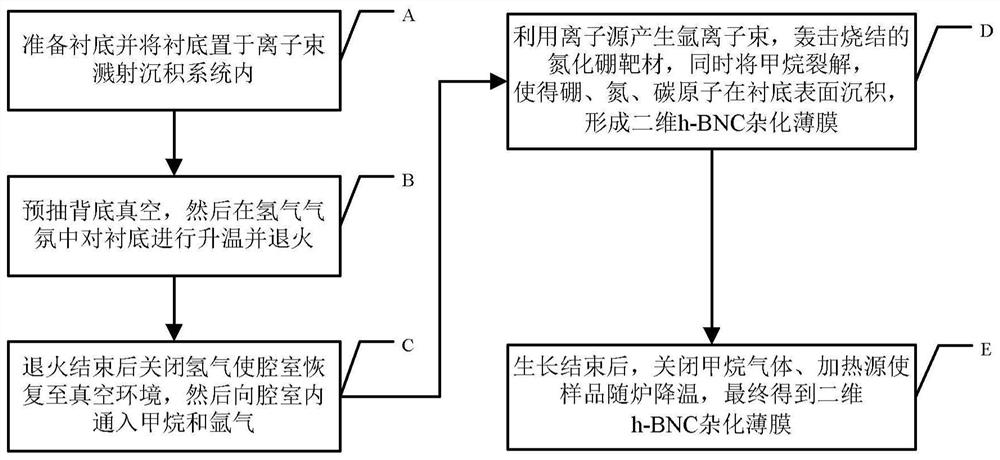

[0032] figure 1 A flow chart of a method for preparing a composition-tunable two-dimensional h-BNC hybrid film provided by the present invention is shown. Such as figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com