Hydrogen production reactor device with gas replacement and efficient methane cracking carrier

A hydrogen production reactor and gas replacement technology, applied in the fields of hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high cost of use, increase of equipment investment cost, etc., reduce equipment investment cost, avoid inhibition, and improve The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

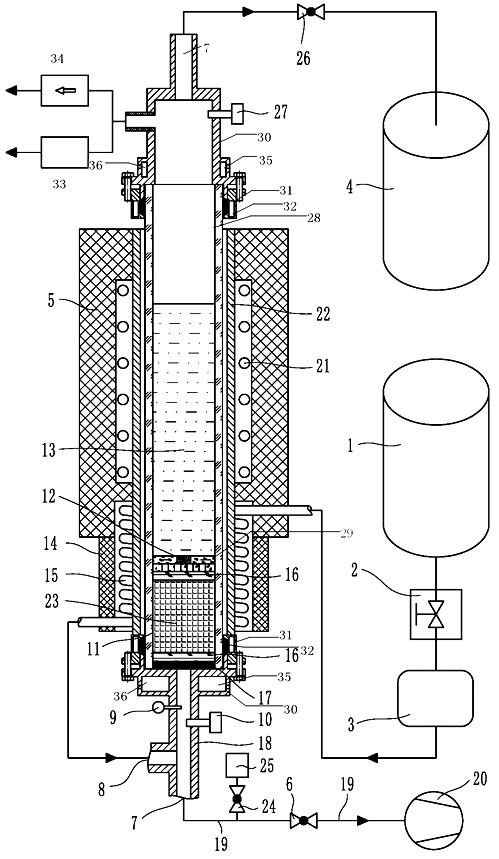

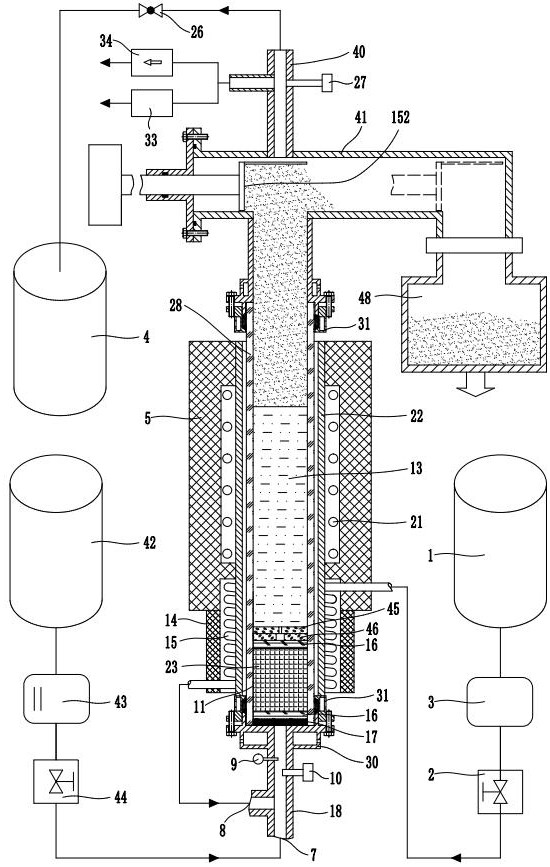

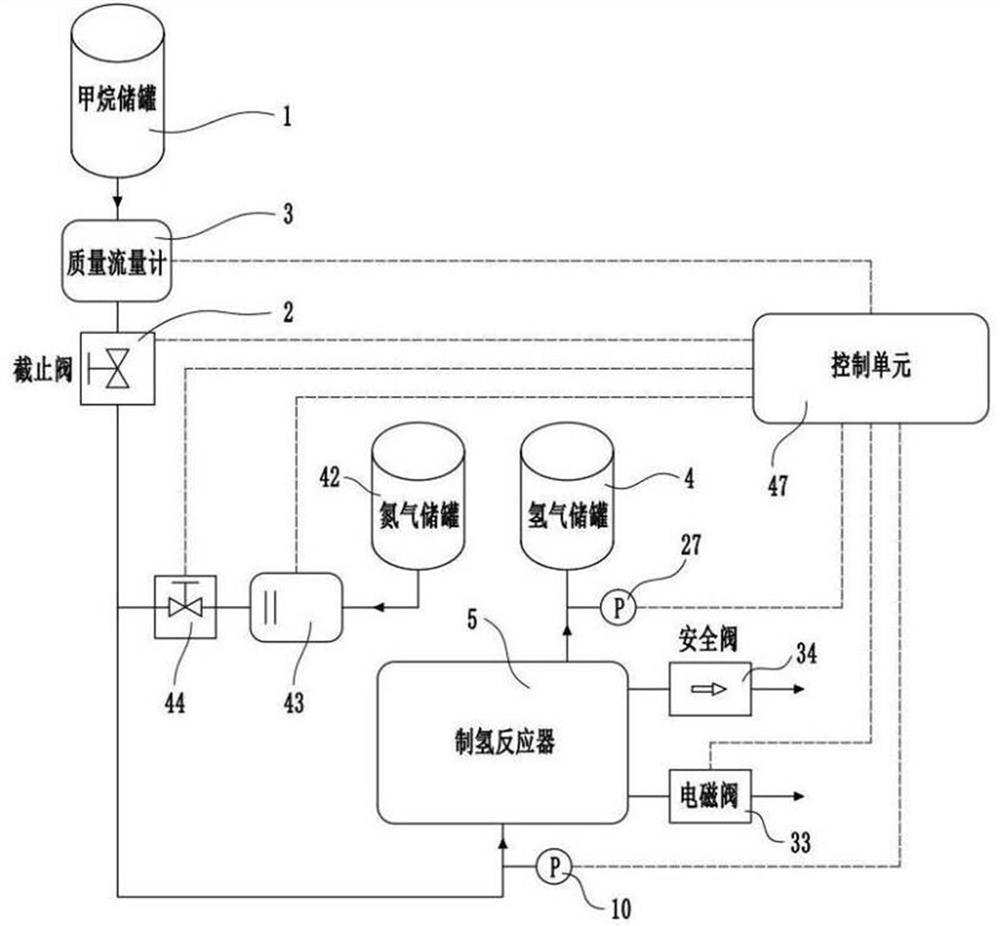

[0018] figure 2 , 3 , 4, the hydrogen production reactor device with gas replacement and high-efficiency methane cracking carrier, including protection tube 22 (protection quartz tube), quartz tube 28 (as a reaction zone), diffuser 45, support plate 46, electric heater 21. Insulation layer 14 (insulation cotton), displacement gas storage tank 42, methane storage tank 1, hydrogen storage tank 4, spiral pipe 15 (the spiral pipe 15 adopts 316L stainless steel pipe with an outer diameter of 6 mm and a wall thickness of 1 mm, and the spiral pipe 15 The inner diameter is consistent with the size of the protective tube 22, the pitch of the spiral tube 15 is 9mm, and the number of turns is 9), the flow meter 3, the connecting seat B31, the carbon discharge mechanism 41, the connecting seat A30, the control circuit board 47, and the catalyst 23; The outer side of the quartz tube 28 is installed in the protective tube 22; there are six electric heaters 21, and the six electric heaters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com