Cultivation box for agricultural planting

An incubator and agricultural technology, applied in the field of incubators, can solve the problems of slow absorption rate, easy dryness or even death of grain seedlings, and excessive waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

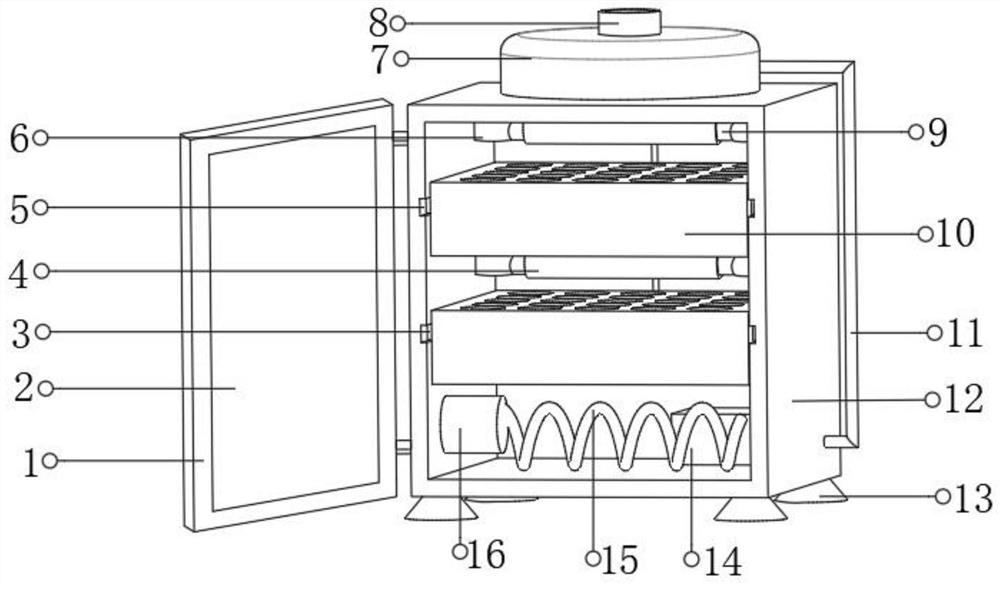

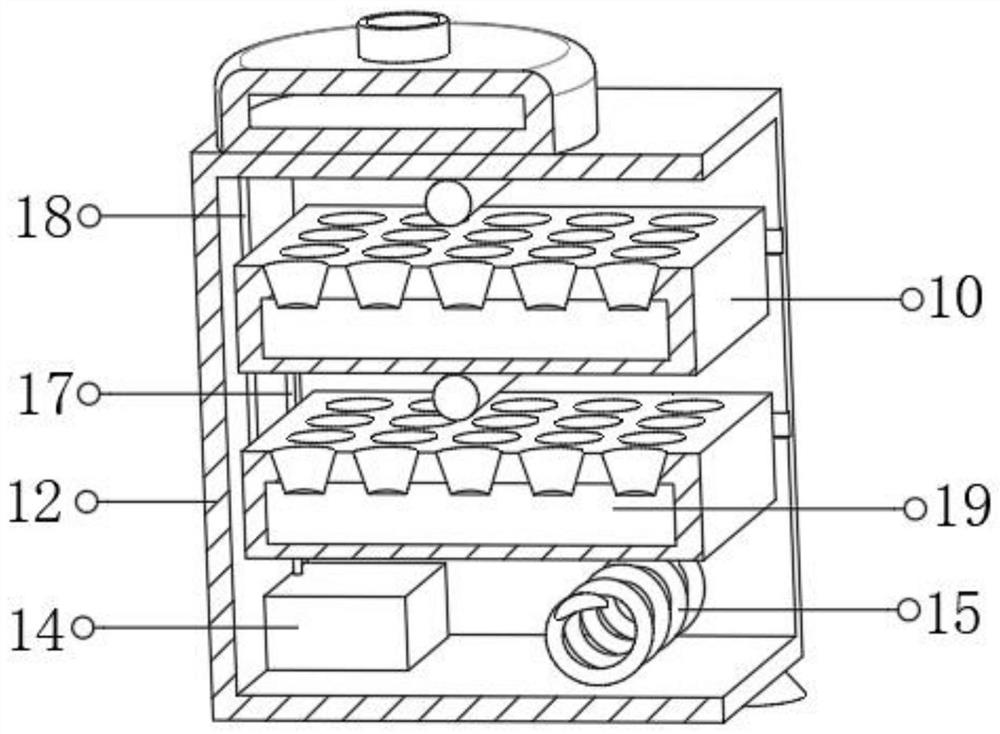

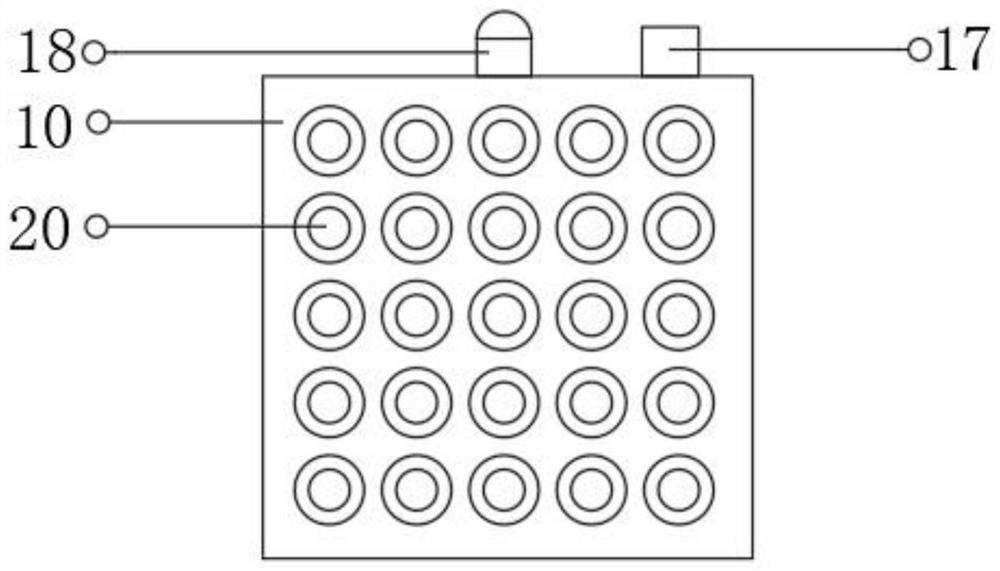

[0027] refer to Figure 1-3 , an incubator for agricultural planting, comprising an incubator body 12 and four legs 13, the four corners of the bottom outer wall of the incubator body 12 are connected with legs 13 by bolts, and both ends of the incubator body 12 opposite inner walls are provided with chute 5, and slide block 3 is slidably connected to the outer wall of one side of chute 5, is connected with cultivation plate 10 by bolt between two relative slide blocks 3, and has a plurality of cultivation holes 20 on the top outer wall of cultivation plate 10, two There is a nutrient solution tank 19 inside the cultivation plate 10, and the nutrient solution tank 19 is located directly below the cultivation hole 20, and the outer wall of the top of the incubation box body 12 is connected with the nutrient solution tank 7 by bolts, and the 7 top outer walls of the nutrient solution tank are located in the middle position Be connected with feeding pipe 8 by bolt, one end of the...

Embodiment 2

[0031] refer to Figure 4 , an incubator for agricultural planting. Compared with Embodiment 1, the inside of the U-shaped tube 11 is connected with a filter screen 21 by bolts, and the filter screen 21 extends to the outer wall of the U-shaped tube 11 side. The filter screen 21 and the The position where the outer wall of the U-shaped pipe 11 contacts is connected with a gasket 23 by bolts, and the end of the filter screen 21 extending to the outside of the U-shaped pipe 11 is connected with a pull ring 22 by bolts.

[0032] Working principle: when in use, first add a sufficient amount of nutrient solution into the nutrient solution tank 7 through the feed pipe 8, then slide the slider 3 in the chute 5, pull out the cultivation plate 10, and put the required nutrient solution into the cultivation hole 20. The seedling of cultivating, then it is sent back to incubating box body 12, this moment closes chamber door 1, watches the internal seedling growth situation by glass windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com