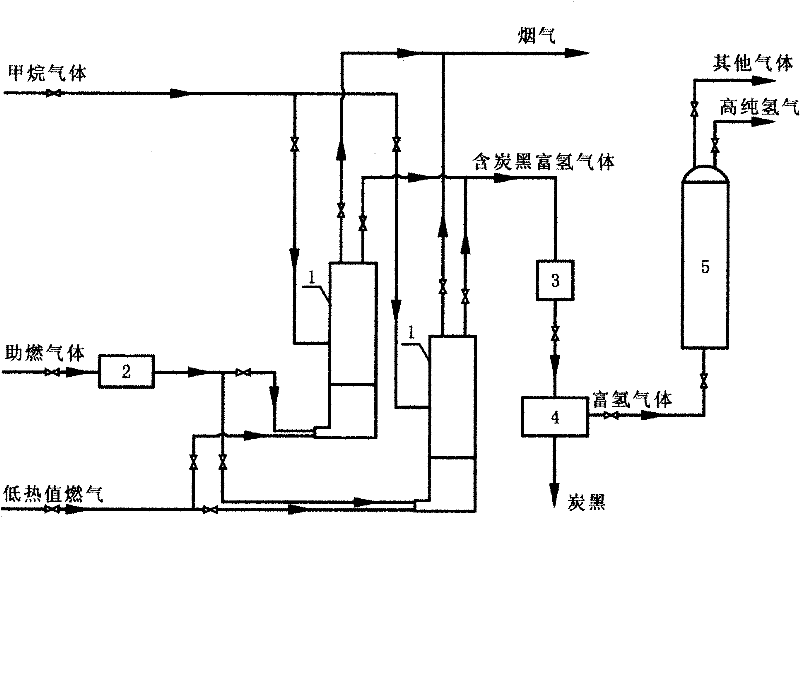

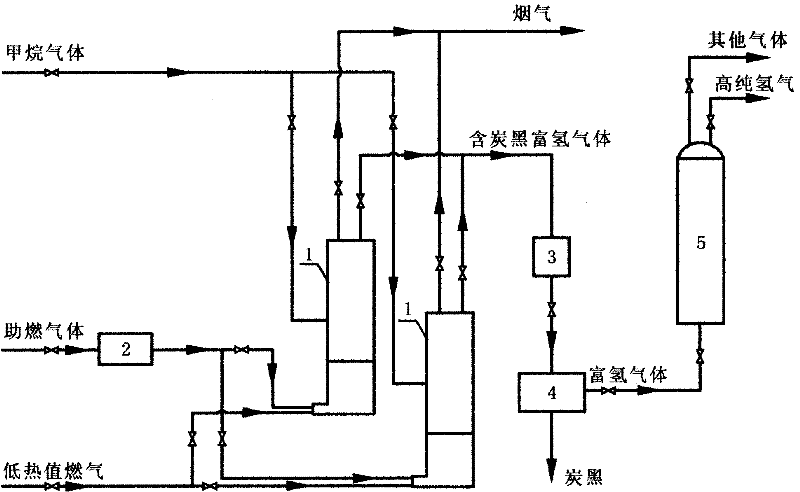

Method for coproduction of carbon black and high-purity hydrogen by high-temperature pyrolysis of methane

A high-temperature cracking and methane gas technology, which is applied in the fields of chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of long production cycle, high energy consumption, incomplete reaction, etc., and achieve less greenhouse gas emissions, simple process, and high reaction efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The oxygen-enriched gas with an oxygen content of 25% is regulated by the pressure regulating device 2, and has a calorific value of 1300kcal / Nm 3 The gas is passed into the combustion section of cracking reaction furnace 1 at a volume ratio of 1:4, and burned for about 10 minutes, so that the temperature of cracking reactor 1 reaches 1400°C, stops feeding gas and combustion-supporting gas, and removes residual gas from combustion; contains 80 methane % of the methane gas is passed into the preheated cracking reactor 1 reaction zone to undergo a cracking reaction to generate hydrogen-rich gas containing carbon black, and stop feeding the methane gas after about 10 minutes; two cracking reactors 1 work alternately for continuous production; The hydrogen-rich gas containing carbon black enters the cooling device 3 of the oil cooling method, and after being cooled by heat exchange, it is sent to the carbon black collection device 4 to separate the carbon black, and the carb...

Embodiment 2

[0032] The oxygen-enriched gas with an oxygen content of 35% is regulated by the pressure regulating device 2, and has a calorific value of 1400kcal / Nm 3 The gas is passed into the combustion section of cracking reactor 1 at a volume ratio of 1:3, and burned for about 10 minutes to make the temperature of cracking reactor 1 reach 1450°C, stop feeding gas and combustion-supporting gas, and get rid of combustion residual gas; % of the methane gas is passed into the preheated cracking reactor 1 reaction zone to undergo a cracking reaction to generate hydrogen-rich gas containing carbon black; after about 10 minutes, stop feeding the methane gas; two cracking reactors 1 work alternately for continuous production; The hydrogen-rich gas containing carbon black enters the cooling device 3 of the water cooling method, and after being cooled by heat exchange, it is sent to the carbon black collection device 4 to separate the carbon black, which is packaged as a finished product after gr...

Embodiment 3

[0035]The oxygen-enriched gas with an oxygen content of 30% is regulated by the pressure regulating device 2, and has a calorific value of 1500kcal / Nm 3 The fuel gas is passed into the combustion section of the cracking reactor 1 at a volume ratio of 1:3, and burned for about 10 minutes to make the temperature of the cracking reactor 1 reach 1500°C, stop feeding the fuel gas and combustion-supporting gas, and get rid of combustion residual gas; % of the methane gas is passed into the preheated cracking reactor 1 reaction zone to undergo a cracking reaction to generate carbon black-containing hydrogen-rich gas, and stop feeding the methane gas after about 10 minutes; two cracking reactors 1 work alternately for continuous production; The hydrogen-rich gas containing carbon black enters the cooling device 3 of the air cooling method, and after being cooled by heat exchange, it is sent to the carbon black collection device 4 to separate the carbon black, and the carbon black is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com