Fixed bed coal seam gas non-catalytic deoxidization method and device

A technology of coalbed methane and fixed bed, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of difficult reaction temperature, increased methane loss, and long residence time, so as to reduce energy consumption and production cost, and reduce methane cracking , Thorough and rapid deoxygenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

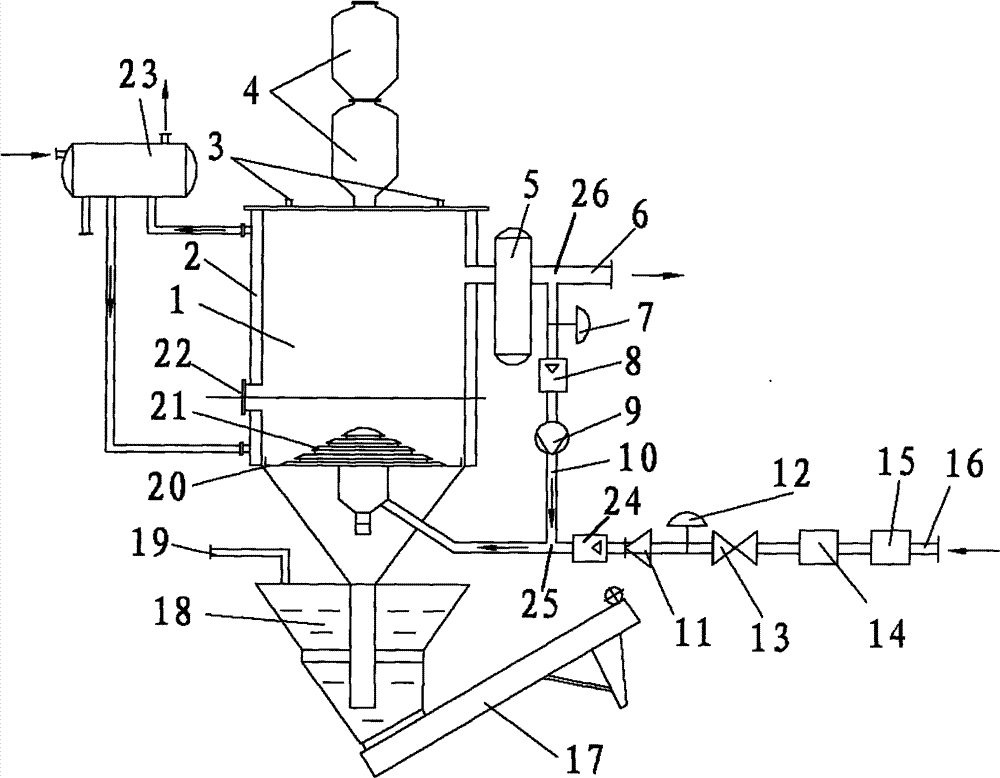

[0036] figure 1 The fixed bed coalbed methane non-catalytic deoxidation device shown includes the body of the fixed bed coalbed methane deoxidation device including the furnace body 1, wherein the side wall of the furnace body 1 is provided with a water jacket 2 surrounding the side wall of the furnace body; The top of this water jacket 2 links to each other with the air inlet of steam drum 23 by pipeline, and the steam in water jacket 2 enters steam drum 23 through this pipeline, and the water inlet pipe of the bottom of this water jacket 2 and the water outlet of steam drum 23 Connected, water enters the water jacket 2 from the steam drum 23 through this pipeline.

[0037] In this device, the body of the fixed-bed coalbed methane deoxidation device includes a furnace body 1, a grate 21 located at the bottom of the furnace body 1 and connected to the coalbed gas inlet pipe 16, and a furnace body 1 connected to the top of the fixed-bed reactor through a pipeline. The coal box...

Embodiment 2

[0042] closure figure 1 After the circulating gas pressure regulating valve 7 of the fixed-bed coalbed methane non-catalytic deoxidation device (the internal diameter of the fixed-bed reactor 1 of the device is 3m and the height is 5m), coke with a particle diameter of 25-50mm is used as the deoxygenation fuel, and the deoxidation The fuel is fed into the furnace body 1 of the fixed bed reactor through the coal box 4, the feeding amount is 300kg / h, and the flow rate is 2543Nm 3 Coal bed methane (raw material gas) at / h (air velocity is 0.1m / s) passes through the flame arrester 15 on the coal bed gas inlet pipe 16, the pressure sensor 14, the overpressure cut-off valve 13, the intake pressure regulating valve 12, and the check valve 11 and flow meter B 24, enter the furnace body 1 of the fixed-bed reactor by the grate 21, and carry out deoxidation reaction with the deoxygenated fuel. The deoxidation reaction pressure in the furnace body of the fixed-bed reactor is 5KPa. The te...

Embodiment 3

[0046] closure figure 1After the circulating gas pressure regulating valve 7 of the non-catalytic deoxidation device for fixed bed coalbed methane (the inner diameter of the body of furnace 1 of the fixed bed reactor of the device is 3m and the height is 5m), coke with a particle diameter of 25-50mm is used as the deoxygenation fuel, Add the deoxygenated fuel into the body of furnace 1 of the fixed-bed reactor through the coal box 4, the feed rate is 490kg / h, and the flow rate is 5087Nm 3 Coalbed methane (raw material gas) at / h (air velocity is 0.2m / s) passes through the flame arrester 15 on the coalbed gas inlet pipe 16, the pressure sensor 14, the overpressure cut-off valve 13, the intake pressure regulating valve 12, and the check valve 11 and flowmeter second 24, enter in the furnace body 1 of fixed-bed reactor by grate (21), carry out deoxidation reaction with deoxygenation fuel, the deoxidation reaction pressure in the furnace body of fixed-bed reactor is 6KPa, control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com