Coupling process method and system for methane cracking and alkaline earth metal carbide preparation

A technology of alkaline earth metal and process method, which is applied in the field of coupling process method and system of methane cracking and preparation of alkaline earth metal carbide, which can solve the problem of carbon deposition and deactivation of catalyst, and achieve continuous and stable effect of catalyst carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

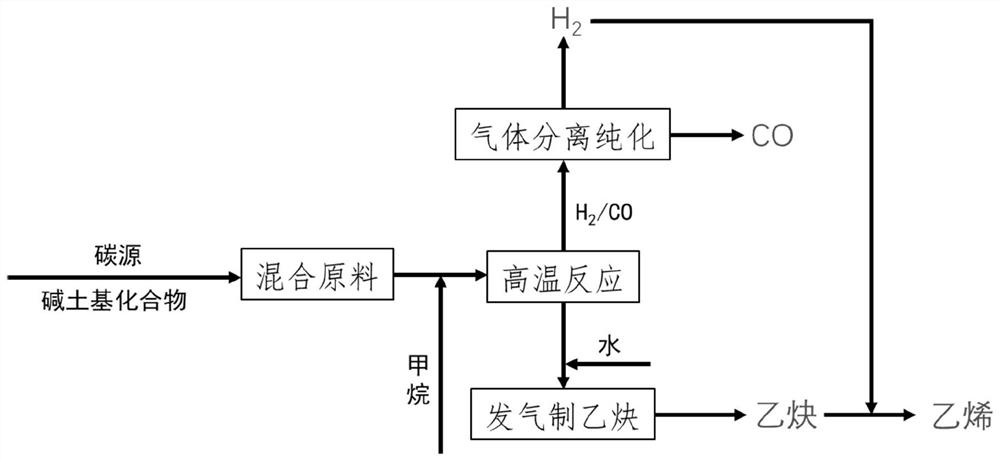

[0025] Example 1: Coupling of methane cracking and calcium carbide synthesis

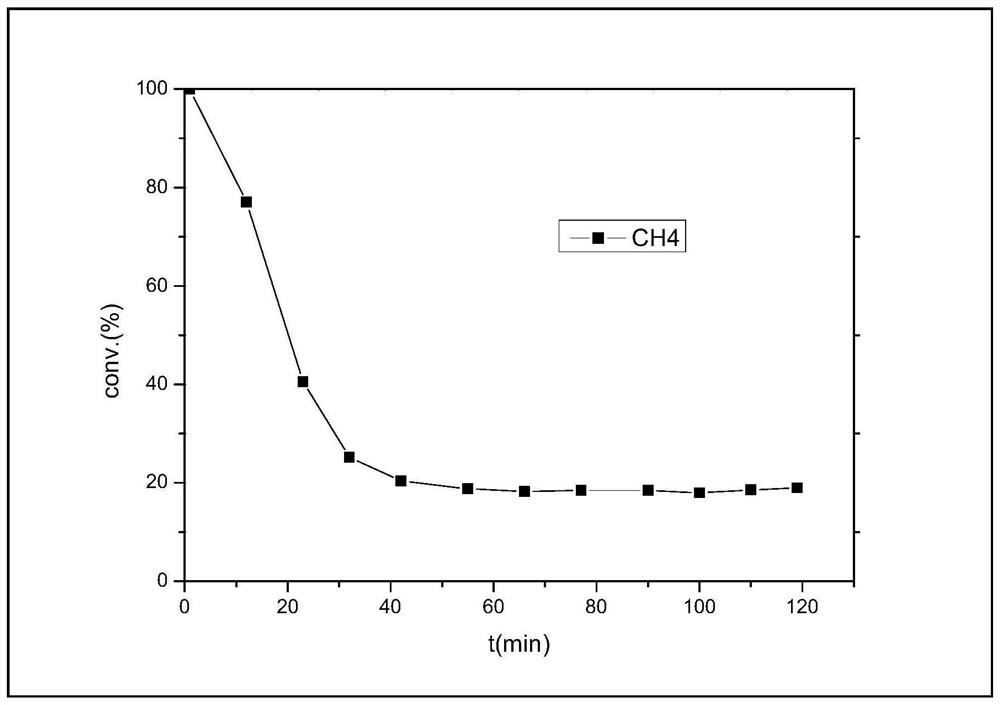

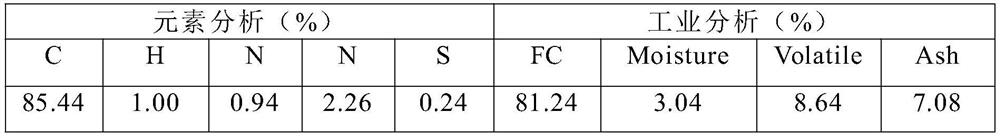

[0026] The particle size is 60-80 mesh metallurgical coke (the composition analysis of metallurgical coke is shown in Table 1) and calcite (the mass content of calcium carbonate is greater than 98.0%) according to the carbon-calcium molar ratio of 3.3:1 to be mixed, and used as calcium carbide raw material after granulation and molding. The reaction is carried out in a continuous microwave calcium carbide furnace. The reaction temperature of calcium carbide is 1750-1800°C and the residence time of the material is 1.5 hours. Methane gas is passed into the material bed according to the molar flow ratio of methane and calcium carbonate as 1:1. The reacted high-temperature furnace gas is sent to the separation and purification process after heat exchange to obtain hydrogen and carbon monoxide gas. The solid-phase calcium carbide product is cooled to room temperature and sent to an acetylene generator t...

Embodiment 2

[0029] Example 2: Coupling of methane cracking and barium carbide synthesis

[0030] The particle size is 60-80 mesh blue carbon (the composition analysis is shown in Table 2) and the barium carbonate is mixed and granulated according to the carbon-barium molar ratio of 3.7:1, and then sent to the high-temperature electrothermal reaction furnace of 1450 ° C to synthesize barium carbide, and the retention of the material The time is 1 hour. Methane gas is passed into the material bed according to the molar flow ratio of methane and barium carbonate of 0.6:1. The furnace gas of the reaction furnace is separated and purified by heat exchange and sent to obtain hydrogen and carbon monoxide. The barium carbide product is isolated from air and cooled to room temperature, and then sent to an acetylene generator to generate gas to obtain acetylene. After analysis, the content of barium carbide in the solid product was 79%, and methane could not be detected in the furnace gas. Compa...

Embodiment 3

[0033] Example 3: Coupling of methane cracking and calcium carbide synthesis

[0034] The particle size is 60-80 mesh metallurgical coke (see Table 1 for composition analysis) and calcium oxide are mixed and granulated according to the carbon-barium molar ratio of 2.8:1, and then sent to a high-temperature calcium carbide furnace at 1750-2050 ° C to synthesize calcium carbide. The reaction time is 4 hours. Methane gas is passed into the material bed according to the molar ratio of methane and calcium oxide of 0.3:1. The furnace gas generated during the reaction is separated and purified by heat exchange to obtain hydrogen and carbon monoxide. The calcium carbide product is cooled to room temperature and sent to an acetylene generator to generate gas to produce acetylene. The content of calcium carbide in the solid product was analyzed to be 76%, and methane could not be detected in the furnace gas. Compared with Comparative Example 1, the methane cracking reaction was compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com