Method for producing high-quality epoxy compound

An epoxy compound, high-quality technology, applied in chemical recycling, organic chemistry, etc., can solve the problems of BCPDS content decline, poor catalyst activity, unstable intermediates, etc., achieve high promotion value, short reaction time, and stable reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

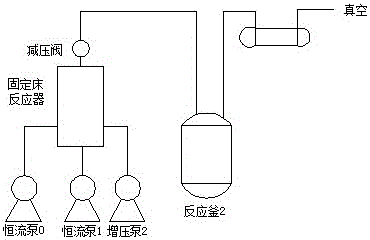

[0028] The fixed-bed reactor is filled with a 10% sodium hydroxide catalyst loaded with alumina, and the methanol with a content of 99% is first transported into the tubular fixed-bed reactor at a flow rate of 20 mL / min using a constant-flow pump 0, and then the methanol with a content of 99.5% epichlorohydrin was sent into the tubular fixed-bed reactor at a flow rate of 20mL / min using constant flow pump 1, and hydrogen sulfide with a content of 99.9% was sent into the tube at a flow rate of 24mL / min using booster pump 2. Type fixed-bed reactor, keep the reactor pressure at 0.1MPa, cool the tubular reactor to 0-10°C through a low-temperature circulation device to perform ring-opening substitution reaction to obtain compound 1; then add 10mol compound 1, 3780g methanol, 635g iodine , 50g of tetrabutylammonium bromide was added to the reactor for oxidation reaction, the temperature was kept at 25°C, and the reaction was carried out for 4h to obtain bis(3-chloro-2-hydroxypropyl)di...

Embodiment 2

[0030]The fixed-bed reactor is filled with a silica-loaded 10% sodium carbonate catalyst. First, methanol with a content of 99% is transported into the tubular fixed-bed reactor at a flow rate of 20 mL / min using a constant-flow pump 0, and then the methanol with a content of 99.5% epichlorohydrin was sent into the tubular fixed-bed reactor at a flow rate of 20mL / min using constant flow pump 1, and hydrogen sulfide with a content of 99.9% was sent into the tube at a flow rate of 24mL / min using booster pump 2. Type fixed-bed reactor, keep the reactor pressure at 0.1MPa, cool the tubular reactor to 0-10°C through a low-temperature circulation device to perform ring-opening substitution reaction to obtain compound 1; then add 10mol compound 1, 3780g methanol, 635g iodine , 63g of tetrabutylammonium bromide was added to the reaction kettle for oxidation reaction, and the temperature was kept at 30°C for 3 hours to obtain bis(3-chloro-2-hydroxypropyl) disulfide crude product); after ...

Embodiment 3

[0032] The fixed-bed reactor is filled with dipotassium hydrogen phosphate catalyst loaded with 10% alumina, and methanol with a content of 99% is first transported into the tubular fixed-bed reactor at a flow rate of 20 mL / min using a constant flow pump 0, and then the content is 99.5% epichlorohydrin is sent into the tubular fixed-bed reactor at a flow rate of 20mL / min using constant flow pump 1, and hydrogen sulfide with a content of 99.9% is sent into the reactor at a flow rate of 24mL / min using booster pump 2 Tubular fixed-bed reactor, keeping the reactor pressure at 0.11MPa, cooling the tubular fixed-bed reactor to 0-10°C through a low-temperature circulation device to perform ring-opening substitution reaction to obtain compound 1, and then add 10mol compound 1, 3780g methanol , 635g iodine and 37.8g tetrabutylammonium bromide were added to the reaction kettle for oxidation reaction, keeping the temperature at 20°C, and reacting for 5h to obtain bis(3-chloro-2-hydroxypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com