Preparation method of lithium phosphide-based composite material and application of lithium phosphide-based composite material as lithium supplement material

A technology of composite materials and lithium phosphide, which is applied in the field of lithium-ion batteries, can solve problems such as unfavorable contact between lithium phosphide and conductive agent, difficulty in obtaining pure lithium phosphide materials, and poor electronic conductivity of lithium phosphide. Effects of improving chemical stability, shortening crystallization time, improving electronic conductivity and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a lithium phosphide-based lithium supplement material, comprising the following steps:

[0028] S1, dissolve a certain mass of lithium hydroxide in deionized water, the mass fraction of lithium hydroxide is 20%, put the lithium hydroxide solution into a microwave reaction furnace, evaporate the water with a power of 500W, and precipitate lithium hydroxide, then put The precipitated lithium hydroxide is placed in the heating and discharging integrated equipment.

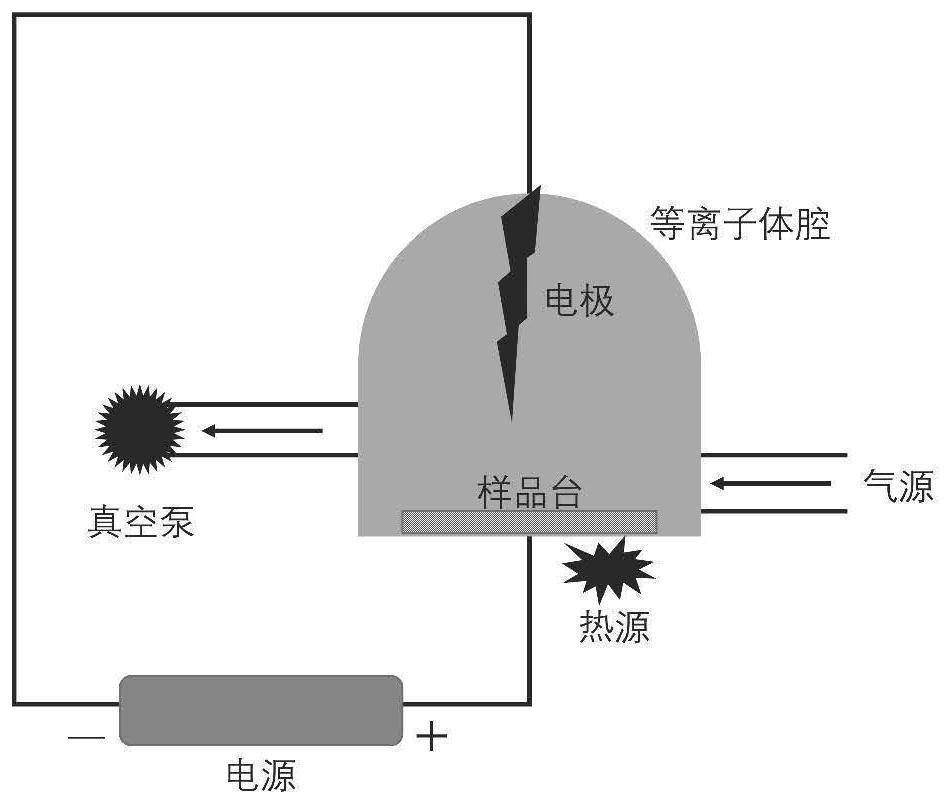

[0029] Such as figure 1 As shown, the heating and discharging integrated equipment includes a reaction chamber, a sample stage, electrodes, a gas source, a heat source, a power supply and a vacuum pump. Both the sample stage and the electrodes are arranged in the reaction chamber; the sample stage can be rotated under the drive of the power element; the electrodes are located directly above the sample stage. The two sides of the reaction chamber are respectively provided with an air inl...

Embodiment 2

[0033] A method for preparing a lithium phosphide-based lithium supplement material, comprising the following steps:

[0034] S1, dissolve a certain mass of lithium hydroxide in deionized water, the mass fraction of lithium hydroxide is 20%, put the lithium hydroxide solution into a microwave reaction furnace, evaporate the water with a power of 300W, and precipitate lithium hydroxide, then put The precipitated lithium hydroxide is placed in the heating and discharging integrated equipment. The structure of the heating and discharging integrated equipment is the same as that of Embodiment 1.

[0035] S2, put lithium hydroxide into the chamber, pass a mixed gas of argon and phosphine into the chamber, the content ratio of phosphine and argon is 2:1, the gas flow rate is 20 sccm, and the chamber maintains atmospheric pressure , the chamber was heated at 2°C / min to 500°C and kept for 2h, and then cooled naturally.

[0036] S3, using the mixed gas of argon and methane as the pla...

Embodiment 3

[0038] A method for preparing a lithium phosphide-based lithium supplement material, comprising the following steps:

[0039] S1, a certain mass of lithium hydroxide is dissolved in deionized water, the mass fraction of lithium hydroxide is 20%, the lithium hydroxide solution is put into a microwave reaction furnace, the water is evaporated with a power of 400W, and lithium hydroxide is precipitated, and then the The precipitated lithium hydroxide is placed in the heating and discharging integrated equipment. The structure of the heating and discharging integrated equipment is the same as that of Embodiment 1.

[0040] S2, put lithium hydroxide into the chamber, pass a mixed gas of argon and phosphine into the chamber, the content ratio of phosphine and argon is 3:1, the gas flow rate is 20 sccm, and the chamber maintains atmospheric pressure , the chamber was heated at 2°C / min to 600°C and kept for 2h, and the temperature was naturally lowered.

[0041] S3, using the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com