Synthesis method of SAPO-34 molecular sieve

A technology of SAPO-34, synthesis method, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate and other directions, can solve the problem of reducing the amount of template agent, not doing exploration, and not solving the problem of template agent amount, etc. The effect of reducing the amount of template agent, reducing environmental pollution, and shortening crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

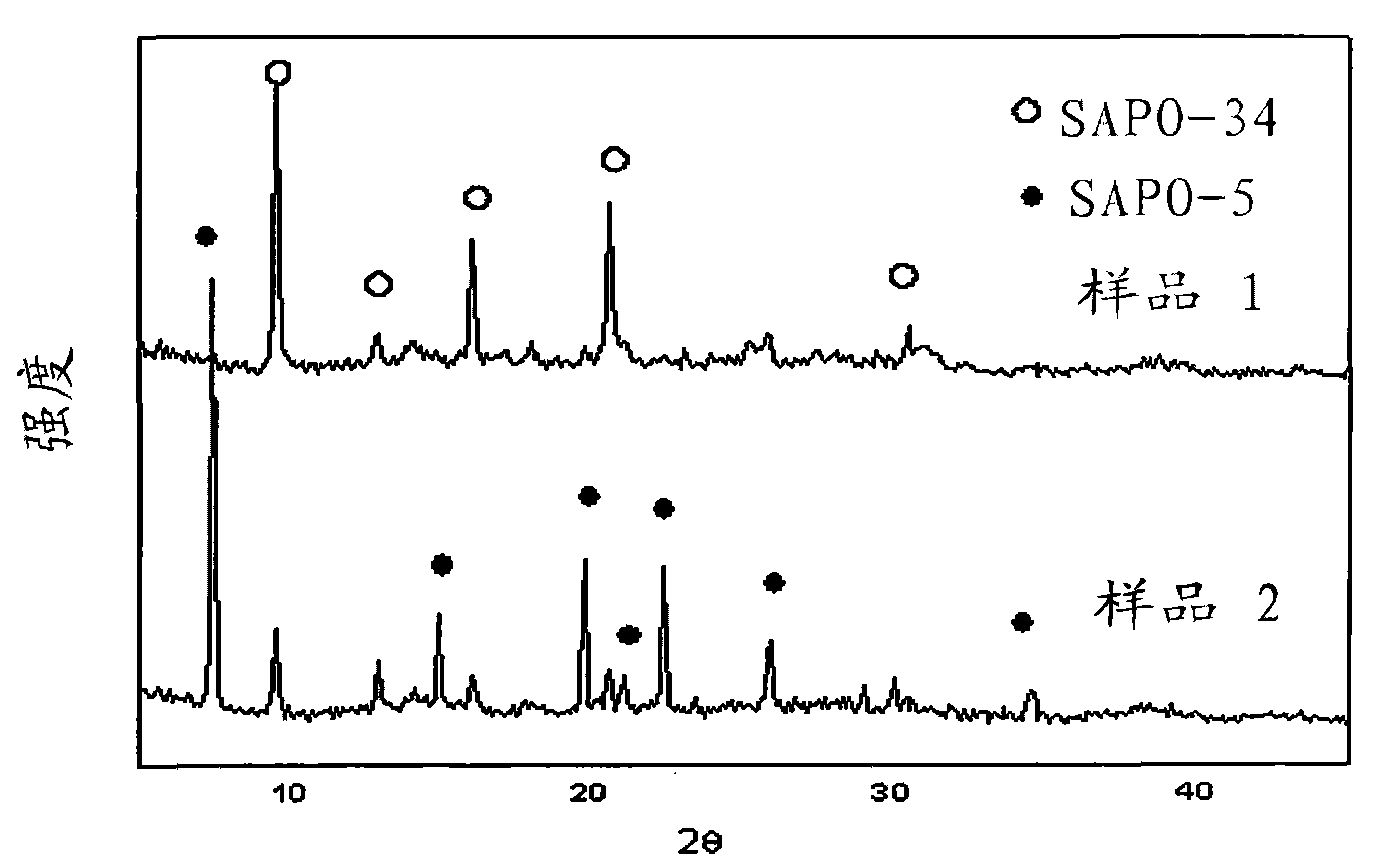

[0023] Get 14.80 grams of pseudo-boehmite and 61.87 grams of tetraethylammonium hydroxide (30% TEAOH) and mix and stir, then add 13.52 grams of silica sol (40% SiO 2 ), after stirring evenly, add 0.54 gram SAPO-34 seed crystals (calcination type SAPO-34 molecular sieve prepared by patent CN1088483) and 10.37 gram phosphoric acid (85% H 3 PO 4 ), added 12.41 grams of deionized water, fully stirred. The above-mentioned crystallization solution was packed into a pressure-resistant container lined with polytetrafluoroethylene, and crystallized at a constant temperature of 200° C. for 48 hours. The solid obtained by filtering the product was washed with water and dried at 100°C for 10 hours to obtain sample 1. The molar ratio of each component in the resulting mixed solution is: 1.4TEAOH: 1.0Al 2 o 3 : 0.5P 2 o 5 : 1.0 SiO 2 :50H 2 O, m(SAPO-34) / m(SiO 2 ) = 0.1. See the test results figure 1 .

Embodiment 2

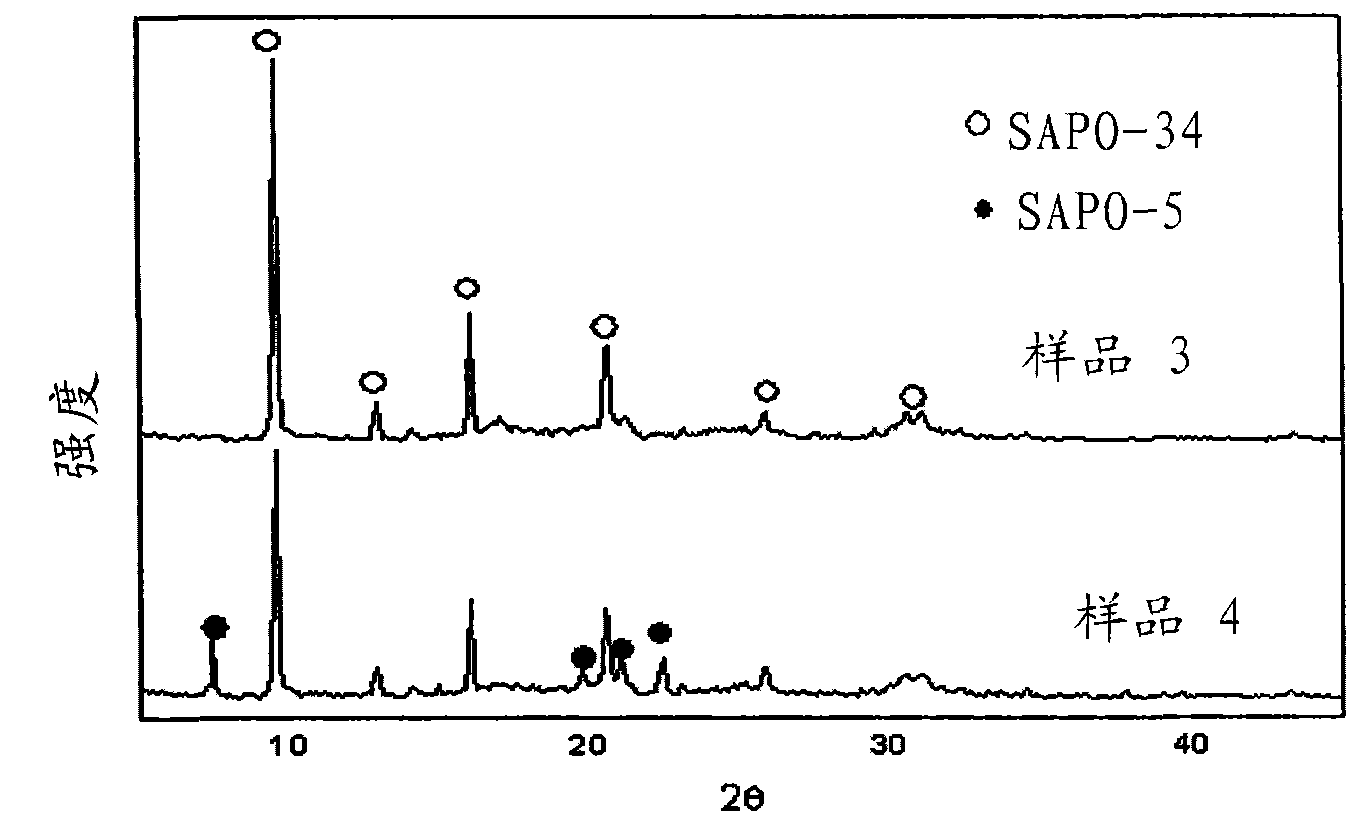

[0027] Get 13.16 grams of pseudo-boehmite and mix and stir with 20.01 grams of deionized water, then add 16.36 grams of triethylamine, add 12.02 grams of silica sol (40% SiO 2 ), 0.48 grams of SAPO-34 seed crystals (prepared by roasting type SAPO-34 molecular sieve powder prepared by patent US4440871) and 18.44 grams of phosphoric acid (85% H 3 PO4), supplemented with 37.15 g of deionized water, and fully stirred. The above-mentioned crystallization solution was packed into a pressure-resistant container lined with polytetrafluoroethylene, and crystallized at a constant temperature of 200° C. for 48 hours. The solid obtained by filtering the product was washed with water and dried at 100°C for 10 hours to obtain the synthetic sample 3. The molar ratio of each component in the resulting mixed solution is: 2.0Et 3 N: 1.0Al 2 o 3 : 1.0P 2 o 5 : 1.0 SiO 2 :50H 2 O. Test results such as figure 2 shown.

Embodiment 3

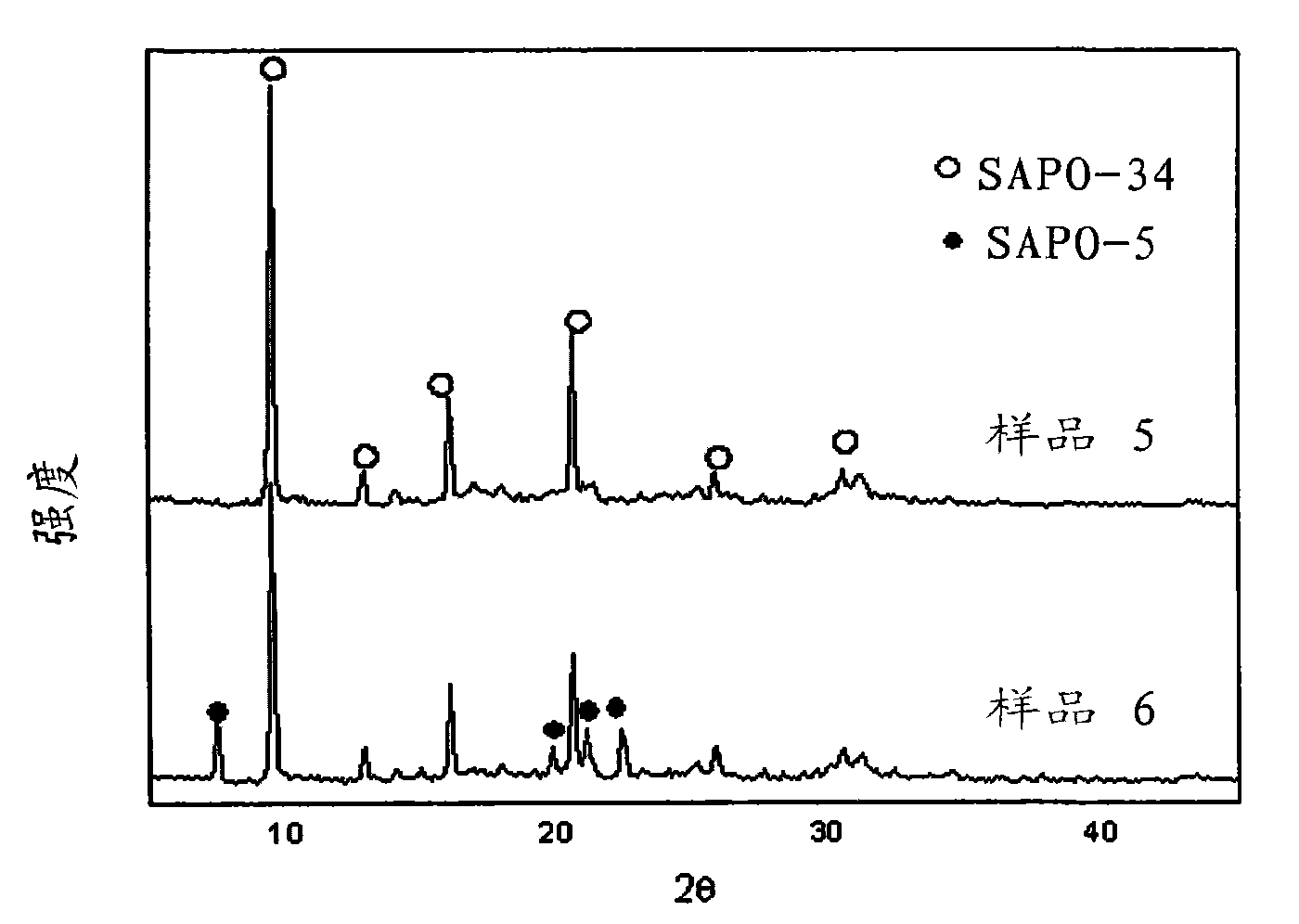

[0031] Get 13.16 grams of pseudo-boehmite and mix and stir with 18.20 grams of deionized water, then add 16.36 grams of triethylamine, add 7.21 grams of silica sol (40% SiO 2 ), 0.75 grams of SAPO-34 seed crystals (the original powder of calcined SAPO-34 molecular sieve prepared by patent CN1088483) and 18.44 grams of phosphoric acid (85% H 3PO4), supplemented with 43.13 g of deionized water, and fully stirred. The above-mentioned crystallization solution was packed into a pressure-resistant container lined with polytetrafluoroethylene, and crystallized at a constant temperature of 200° C. for 48 hours. The solid obtained by filtering the product was washed with water and dried at 100° C. for 10 hours to obtain a synthetic sample 5 . The molar ratio of each component in the resulting mixed solution is: 2.0Et 3 N: 1.0Al 2 o 3 : 1.0P 2 o 5 : 0.6SiO2 2 :50H 2 O, m(SAPO-34) / m(SiO 2 ) = 0.26. Test results such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com