Green and efficient ammonia fuel combustion system and method

A combustion system and fuel technology, which is applied to the charging system, turbine/propellant fuel delivery system, and adding non-fuel substances to fuel, etc., can solve the problems of large pollution, poor ignition, etc., and achieve the effect of reducing emissions and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

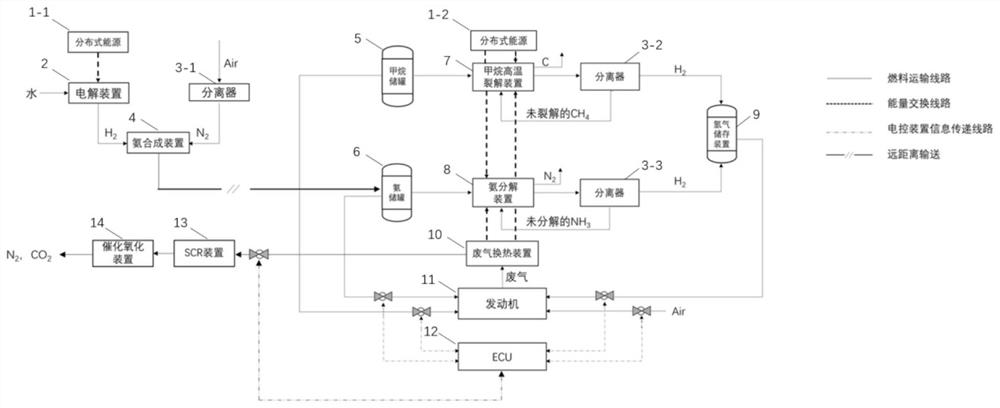

[0025] Such as figure 1 As shown, a green and efficient ammonia fuel combustion system of the present invention mainly includes two parts: ammonia utilization and waste gas recovery and treatment. The ammonia utilization part mainly includes an engine 11. The engine 11 has four inlets and an exhaust gas outlet. The four inlets are respectively connected to the methane storage tank 5, the ammonia storage tank 6, the hydrogen storage device 9 and the air, and the exhaust gas outlet is connected to the waste gas heat exchange device 10. Entrance.

[0026] Through combination, there are two fuel supply modes of the engine 11, which are respectively methane, ammonia and air and hydrogen, ammonia and air. In the two supply modes, ammonia is the main fuel, and methane or hydrogen is the combustion aid to improve combustion.

[0027] The exhaust gas heat exchange device 10 has three outlets, two of which are respectively connected to the methane pyrolysis device 7 and the ammonia dec...

Embodiment 2

[0034] This embodiment provides the ammonia production part, that is, the ammonia synthesis unit 4 that provides liquid ammonia for the ammonia storage tank 6. The ammonia synthesis unit 4 has two inlets, which are respectively connected to the outlet of the electrolysis unit 2 and the separator one 3-1. Device 2 electrolyzes water to generate oxygen and hydrogen, separator 1 3-1 separates air to obtain nitrogen, hydrogen and nitrogen are synthesized in ammonia synthesis device 4 to obtain ammonia, and are supplied to ammonia storage tank 6 through long-distance transportation, etc., in liquid form In the form of storage, the electricity required by the electrolysis device 2 is provided by the distributed energy source 1-1.

Embodiment 3

[0036] In this embodiment, automatic control is added, that is, an electronic control unit (ECU) 12 is also included, and the electronic control unit 12 is used to control the fuel entering the engine 11 and its supply amount, and to detect the composition and content of the exhaust gas. By detecting the composition and content of the exhaust gas, and then adjusting the supply amount of each fuel, the thermal efficiency of the engine 11 is at a better performance, and the emission is at a lower level.

[0037] The electronic control device 12 controls the supply of fuel and air, wherein the equivalence ratio is controlled at about 1.15, and the mixing ratio of methane or hydrogen and ammonia is 30%. Under these conditions, the system can achieve optimal operation.

[0038] Specifically, there are two fuel supply modes of the engine 11: methane / ammonia / air, hydrogen / ammonia / air. This embodiment also includes an electronic control unit (ECU) 12, which is used to control the type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com