A method for producing light tar by catalytic co-refining of low-rank coal and methane

A methane catalysis and low-rank coal technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of energy consumption and economic cost increase, and achieve the effects of reducing hydrogen production costs, simplifying the process, and high process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

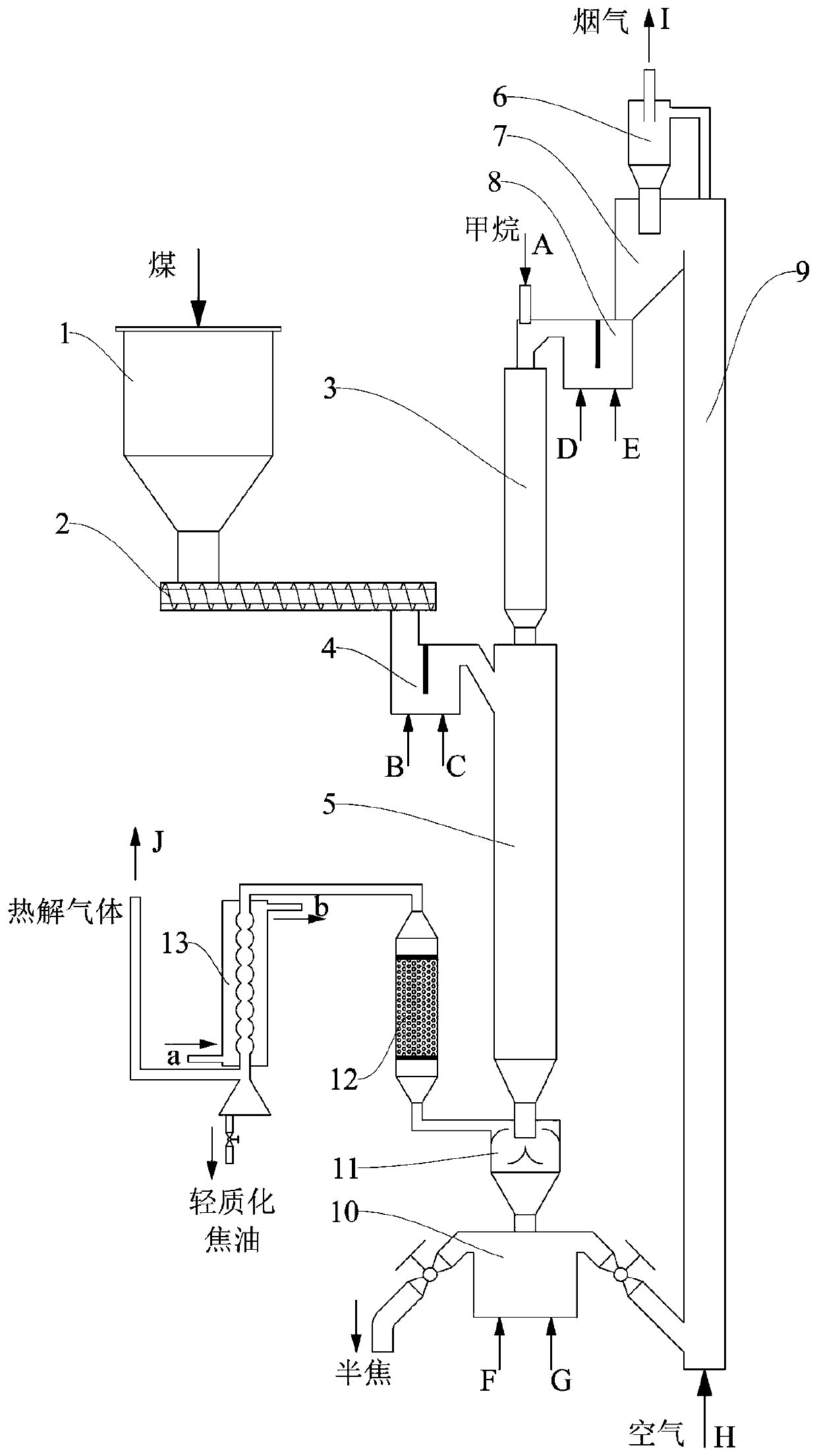

Method used

Image

Examples

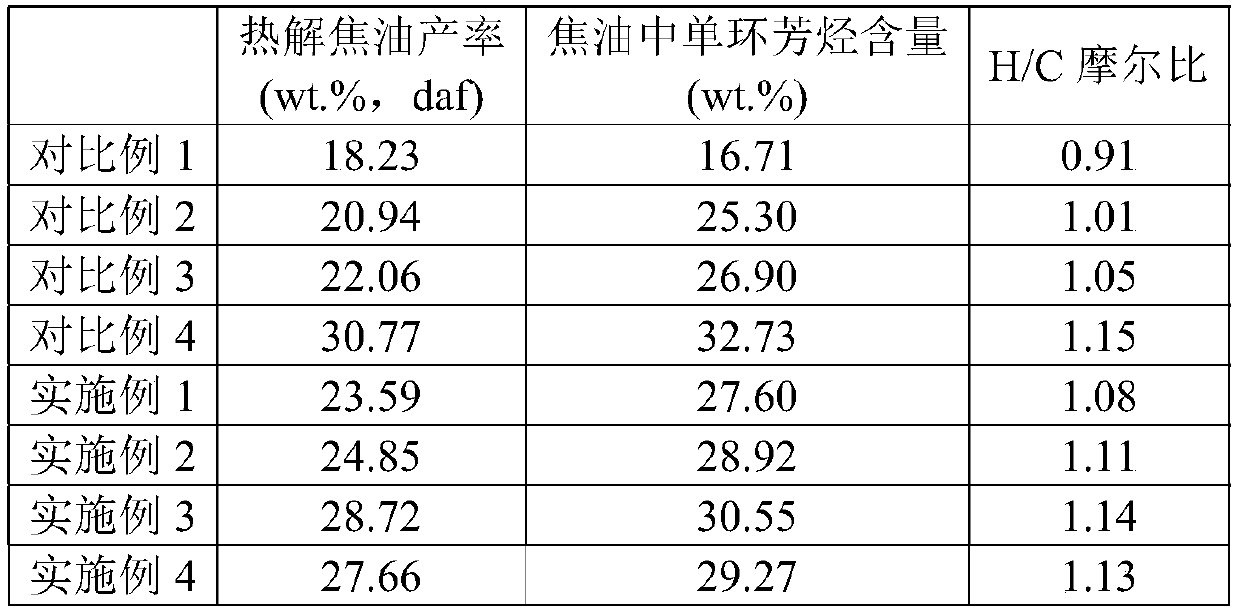

Embodiment 1

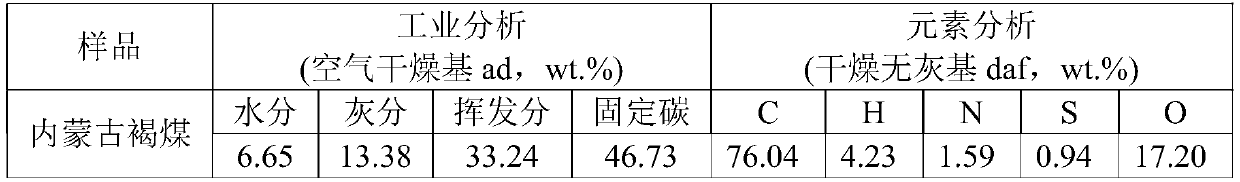

[0029]The selected coal is Inner Mongolia lignite, and its industrial analysis and elemental analysis data are shown in Table 1. The coal particle size is 40-60 mesh, the fluidization gas (gas inlet C) used by the return pneumatic valve 4 is methane, and the loosening gas (gas inlet B) is nitrogen. By adjusting the rotation speed of the screw feeder and the return pneumatic valve The gas flow rate in valve 4 is such that the feed rate of coal particles is 10g / min; methane enters from gas inlet A, and the flow rate is set at 2000mL / min; the temperature in the down-bed is set at 700°C, and the pressure is 0.1MPa; 12 in HZSM-5 (SiO 2 with Al 2 o 3 The molar ratio is 50:1) particles, the particle size is 20-40 mesh, and the temperature is set at 600°C; the temperature of the circulating cooling water passing through the tar condensation device 13 is about 5°C; a certain amount of hot semi-coke is passed through the two-way return After the pneumatic valve 10, return to the rise...

Embodiment 2

[0031] In this example, the same experimental method as in Example 1 is adopted, except that after passing through the riser reactor 9, the temperature of the high-temperature semi-coke is raised to 1000±10°C.

Embodiment 3

[0033] In this example, the same experimental method as in Example 2 is adopted, the difference is that the fixed bed 12 is filled with nickel-supported HZSM-5 (Ni / HZSM-5) as a catalyst, and its specific preparation method is comparative example 4 unanimous.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com